Section

7 Container securing arrangements for stowage using cell guides

7.1 General

7.1.1 Cell

guide systems may be fitted to support containers stowed in holds

or on exposed decks.

7.1.2 The

cell guides are not to form an integral part of the ship’s structure.

The guide system is generally to be so designed as to keep it free

of the main hull stresses.

7.1.3 Cell

guides are to be designed to resist loads caused by loading and unloading

of the containers, to prevent shifting of the containers and to transmit

the loads caused by motions of the ship into the main hull structure.

7.2 Arrangement and construction

7.2.1 Cell

guides are to be of robust construction and generally fabricated from

steel plate and rolled sections. They are to have sufficient vertical

extent and continuity to provide efficient support to containers.

Guide bars are to be effectively attached to the supporting structure

to prevent tripping or distortion resulting from container loading.

7.2.2 The

intersection between cell guide and cross ties is to provide adequate

torsional stability.

7.2.3 Intermediate

brackets are to be fitted to vertical cell guides at suitable intervals.

7.2.4 The

cell guides are to give a total clearance between the container and

guide bars not exceeding 25 mm in the transverse direction and 40

mm in the longitudinal direction. The deviation of the cell guide

bar from its intended line is not generally to exceed 4 mm in the

transverse direction and 5 mm in the longitudinal direction.

7.2.5 Athwartship

cross ties are to be fitted between cell guides at a spacing determined

from the loading on the guides but, generally, not more than 3,0 m

apart. Wherever possible, cross ties are to be arranged in line with

the corners of the containers as stowed and are to be supported against

fore and aft movement at a minimum of two points across the breadth

of the hold. Where, however, the maximum fore and aft deflection in

the cross tie can be shown not to exceed 20 mm, one support point

may be accepted.

7.2.7 Where,

at the sides or ends of holds, the guide rails are fitted to transverse

or longitudinal bulkheads, the bulkhead is to be locally reinforced

to resist the additional loads.

7.2.8 If

the carriage of 45 ft Euro containers complying with EU Directive

96/53 is specified to be carried in 45 ft cell guides, attention is

to be paid to the arrangement of the corner castings, see

Figure 14.7.1 45 ft euro container in cell guides. The guide bars need

to be increased in order to ensure that a minimum design overlap, a, of 20 mm is achieved, taking into account the design clearances

and tolerances defined in Pt 3, Ch 14, 7.2 Arrangement and construction 7.2.4.

Consideration is to be given to the torsional loads being applied

to the guide bars.

Figure 14.7.1 45 ft euro container in cell guides

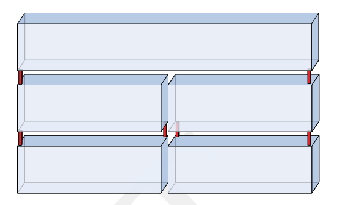

7.3 Carriage of 20 ft containers in 40 ft cell guides in holds

7.3.1 Where the cell guides are arranged for the carriage of 40 ft containers,

provision may be made for the installation of temporary intermediate cell guides for 20

ft containers. The permanent structure is to be designed such that it is suitable for

either loading pattern.

7.3.2 Alternatively, permanent means for the support of 20 ft containers at the

mid-length of a cell arranged for 40 ft containers will be considered. Such means may

include the following:

-

A pillar (inboard) and vertical rest bar (on the longitudinal

bulkhead) against which the container stack may rest. The pillar is to be

supported laterally by the deck structure over and is to be sufficiently stiff to

control lateral deflection of the container stacks.

-

Guide bars supported transversely by slim structure within the gap

between containers and with longitudinal ties as necessary.

Details of proposals will be individually considered, taking into account

the loads on the support structure and the resulting deflections.

7.3.3 Where it is desired to stow 20 ft containers without external support at the

mid-bay location with or without 40 ft overstow, so-called ‘mixed stowage’ arrangements

meeting the following requirements are applicable:

-

Maximum homogeneous container weights for 20 ft containers stowed in

cell guides with no 40 ft container overstowed can be derived from Table 14.7.1 Maximum container weights of

Wh 20 ft containers stowed in 40 ft cell guides with no

overstow, depending on the

transverse acceleration and the number of tiers in the stack.

- Maximum homogeneous container weights for 20 ft

containers stowed in cell guides with one or more 40 ft containers overstowed can be

derived from:

- Table 14.7.2 Maximum containers weights,

Wh of 20 ft containers stowed in 40 ft cell guides with

overstow, diagonal stacking cone arrangement

- Table 14.7.3 Maximum container weights

Wh of 20 ft containers stowed in 40 ft cell guides with

overstow, other stacking cone arrangement

- All inhold mixed stowage tables have been derived on

the basis of all 20 ft containers having the same weight. However it is acceptable to

carry non-homogeneous stacks provided the following two conditions are met:

- 20 ft containers heavier than specified in the weight

Wh can be loaded provided that the average container

weight excluding the lowest container in the stack does not exceed

Wh, i.e.

- The total moment of 20 ft containers in a stacks about the base is

not to be greater than the moment exerted by an equivalent homogeneous stack of

weight Wh, i.e.

where:

Wi weight of container i.

ci height of container i.

Wh is the homogeneous container weight as determined

from Table 14.7.1 Maximum container weights of

Wh 20 ft containers stowed in 40 ft cell guides with no

overstow,

Table 14.7.2 Maximum containers weights,

Wh of 20 ft containers stowed in 40 ft cell guides with

overstow, diagonal stacking cone arrangement or Table 14.7.3 Maximum container weights

Wh of 20 ft containers stowed in 40 ft cell guides with

overstow, other stacking cone arrangement

as applicable. Where Wh is corrected by Note 5 of the

tables, Wh is to be taken as Whc.

ca average height of the 20 ft containers in

the stack.

N Number of 20 ft containers.

- The weight of the lowest container in the stack may be increased to its

rated value.

- The force in the corner post in the lowest container is not to exceed

the permissible compression value given in Table 14.9.6 Allowable forces in

containers in stacks with the same base size. The force is to be determined

by:

where:

V is the

compressive force in the corner post

W40s is the total weight of the 40 ft containers,

in tonnes

W20S-1 is the total weight of the

20 ft containers excluding the weight of the lowest container, in tonnes

aZ is the maximum vertical acceleration of all

containers in the stack, see

Pt 3, Ch 14, 8.2 Ship motion, wind and green sea forces acting on containers 8.2.5

-

Means are to be provided to prevent transverse sliding of the bottom

of the stacks of 20 ft containers at the mid-bay position. This is to be in the

form of permanently attached chocks at the inner bottom or equivalent. The design

clearance is to be the same as for the cell guides and in accordance with Pt 3, Ch 14, 7.2 Arrangement and construction 7.2.4.

- 20 ft containers stowed with no stacking cones are to

be restrained to avoid transverse movement, e.g. all containers at the same tier

height in a bay are to be of the same height and structural constraints between the

containers and the hull are to be provided.

-

The 20 ft containers are to have closed steel walls and top (no open

frame containers, e.g. tank or bulk containers).

Table 14.7.1 Maximum container weights of

Wh 20 ft containers stowed in 40 ft cell guides with no

overstow

|

|

Maximum homogeneous container weights, in

tonnes

(number of 20 ft containers)

|

Lowest

tier transverse

acceleration

(= a

y/g), see

Pt 3, Ch 14, 8.2 Ship motion, wind and green sea forces acting on containers 8.2.5

|

3 tiers

|

4 tiers

|

5 tiers

|

6 tiers

|

7 tiers

|

8 tiers

|

9 tiers

|

10 tiers

|

11 tiers

|

12 tiers

|

| 0,20

|

30,5

|

30,5

|

30,5

|

30,5

|

22,9

|

19,6

|

18,3

|

15,5

|

13,5

|

11,7

|

| 0,21

|

30,5

|

30,5

|

30,5

|

30,2

|

22,5

|

19,2

|

17,9

|

15,2

|

13,3

|

11,5

|

| 0,22

|

30,5

|

30,5

|

30,5

|

29,2

|

22,0

|

18,8

|

17,6

|

14,9

|

13,1

|

11,4

|

| 0,23

|

30,5

|

30,5

|

30,5

|

28,3

|

21,6

|

18,5

|

17,2

|

14,6

|

12,9

|

11,2

|

| 0,24

|

30,5

|

30,5

|

30,5

|

27,4

|

21,2

|

18,1

|

16,9

|

14,4

|

12,7

|

11,1

|

| 0,25

|

30,5

|

30,5

|

30,5

|

26,6

|

20,8

|

17,8

|

16,5

|

14,1

|

12,5

|

10,9

|

| 0,26

|

30,5

|

30,5

|

30,5

|

25,8

|

20,4

|

17,4

|

16,2

|

13,9

|

12,3

|

10,8

|

| 0,27

|

30,5

|

30,5

|

30,5

|

25,0

|

20,0

|

17,1

|

15,8

|

13,6

|

12,1

|

10,6

|

| 0,28

|

30,5

|

30,5

|

30,5

|

24,3

|

19,6

|

16,7

|

15,5

|

13,4

|

11,9

|

10,5

|

| 0,29

|

30,5

|

30,5

|

29,5

|

23,6

|

19,2

|

16,4

|

15,2

|

13,1

|

11,7

|

10,4

|

| 0,30

|

30,5

|

30,5

|

28,7

|

23,0

|

18,8

|

16,1

|

14,9

|

12,9

|

11,5

|

10,2

|

| 0,31

|

30,5

|

30,5

|

27,8

|

22,3

|

18,4

|

15,8

|

14,6

|

12,6

|

11,4

|

10,1

|

| 0,32

|

30,5

|

29,9

|

27,1

|

21,7

|

18,1

|

15,5

|

14,3

|

12,4

|

11,2

|

9,9

|

| 0,33

|

30,5

|

29,3

|

26,3

|

21,2

|

17,7

|

15,2

|

14,0

|

12,2

|

11,0

|

9,8

|

| 0,34

|

30,5

|

28,6

|

25,7

|

20,7

|

17,4

|

14,9

|

13,7

|

12,0

|

10,8

|

9,7

|

| 0,35

|

30,5

|

28,1

|

25,0

|

20,2

|

17,3

|

14,8

|

13,4

|

11,6

|

10,6

|

9,5

|

| 0,36

|

30,5

|

27,6

|

24,4

|

19,7

|

16,9

|

14,5

|

13,2

|

11,5

|

10,5

|

9,3

|

| 0,37

|

30,5

|

27,0

|

23,9

|

19,3

|

16,5

|

14,1

|

13,0

|

11,3

|

10,3

|

9,2

|

| 0,38

|

30,5

|

26,4

|

23,3

|

18,8

|

16,1

|

13,8

|

12,7

|

11,2

|

10,2

|

9,1

|

| 0,39

|

30,5

|

25,9

|

22,7

|

18,4

|

15,8

|

13,5

|

12,5

|

11,0

|

10,0

|

9,0

|

| 0,40

|

30,5

|

25,4

|

22,2

|

18,0

|

15,4

|

13,2

|

12,3

|

10,8

|

9,9

|

8,9

|

| 0,41

|

30,5

|

25,0

|

21,8

|

17,6

|

15,1

|

13,0

|

12,0

|

10,7

|

9,7

|

8,8

|

| 0,42

|

30,5

|

24,7

|

21,3

|

17,3

|

14,8

|

12,7

|

11,7

|

10,4

|

9,6

|

8,7

|

| 0,43

|

30,5

|

24,3

|

20,9

|

17,0

|

14,6

|

12,5

|

11,4

|

10,2

|

9,4

|

8,6

|

| 0,44

|

30,5

|

24,0

|

20,6

|

16,8

|

14,4

|

12,4

|

11,1

|

10,0

|

9,3

|

8,5

|

| 0,45

|

30,5

|

23,7

|

20,2

|

16,5

|

14,1

|

12,2

|

10,9

|

9,9

|

9,2

|

8,3

|

| 0,46

|

30,5

|

23,4

|

19,9

|

16,2

|

13,9

|

12,0

|

10,7

|

9,7

|

9,0

|

8,2

|

| 0,47

|

30,5

|

23,1

|

19,6

|

16,0

|

13,7

|

11,8

|

10,6

|

9,5

|

8,9

|

8,1

|

| 0,48

|

30,5

|

22,9

|

19,3

|

15,8

|

13,5

|

11,6

|

10,5

|

9,4

|

8,7

|

7,9

|

| 0,49

|

30,5

|

22,6

|

19,1

|

15,6

|

13,3

|

11,4

|

10,3

|

9,2

|

8,5

|

7,8

|

| 0,50

|

30,5

|

22,4

|

18,8

|

15,4

|

13,1

|

11,2

|

10,2

|

9,1

|

8,4

|

7,7

|

| 0,51

|

30,4

|

22,1

|

18,6

|

15,2

|

13,0

|

11,1

|

10,1

|

8,9

|

8,3

|

7,6

|

| 0,52

|

30,4

|

21,9

|

18,3

|

15,0

|

12,8

|

10,9

|

9,9

|

8,8

|

8,1

|

7,4

|

| 0,53

|

30,4

|

21,7

|

18,1

|

14,8

|

12,6

|

10,8

|

9,8

|

8,7

|

8,0

|

7,3

|

| 0,54

|

30,3

|

21,5

|

17,9

|

14,6

|

12,4

|

10,6

|

9,6

|

8,5

|

7,9

|

7,2

|

| 0,55

|

30,1

|

21,3

|

17,6

|

14,4

|

12,3

|

10,5

|

9,5

|

8,4

|

7,8

|

7,1

|

| 0,56

|

29,8

|

21,1

|

17,4

|

14,2

|

12,1

|

10,4

|

9,3

|

8,3

|

7,7

|

7,0

|

| 0,57

|

29,4

|

20,9

|

17,2

|

14,1

|

11,9

|

10,2

|

9,2

|

8,2

|

7,6

|

6,9

|

| 0,58

|

28,9

|

20,7

|

17,0

|

13,9

|

11,8

|

10,1

|

9,0

|

8,1

|

7,5

|

6,8

|

| 0,59

|

28,5

|

20,5

|

16,8

|

13,7

|

11,6

|

10,0

|

8,9

|

8,0

|

7,4

|

6,7

|

| 0,60

|

28,2

|

20,4

|

16,6

|

13,6

|

11,5

|

9,9

|

8,8

|

7,9

|

7,3

|

6,6

|

| 0,61

|

28,0

|

20,2

|

16,5

|

13,4

|

11,4

|

9,8

|

8,7

|

7,8

|

7,2

|

6,5

|

| 0,62

|

28,0

|

20,0

|

16,3

|

13,3

|

11,2

|

9,7

|

8,6

|

7,7

|

7,1

|

6,5

|

| 0,63

|

27,9

|

19,9

|

16,1

|

13,1

|

11,1

|

9,6

|

8,5

|

7,6

|

7,0

|

6,4

|

| 0,64

|

27,9

|

19,7

|

15,9

|

13,0

|

11,0

|

9,5

|

8,4

|

7,5

|

6,9

|

6,3

|

| 0,65

|

27,9

|

19,6

|

15,8

|

12,9

|

10,9

|

9,4

|

8,4

|

7,5

|

6,8

|

6,2

|

|

Note 1. Linear interpolation

is to be used to determine intermediate values.

Note 2. 40 ft overstow

containers not included in the number of tiers.

Note 3. Maximum container

weights for transverse acceleration and number of tiers outside of those

presented will be specially considered.

Note 4. The maximum

container weight should not exceed the rated weight of the

container.

5. Where the

homogeneous container weight ( Wh) derived from the

table is lower than the rated weight of the container, the maximum

homogeneous weight is to be corrected to account for the height of the

containers used, as follows:

Note

Where:

which is not to be taken greater than

1 which is not to be taken greater than

1

ca is the average height of the

20 ft containers

|

Table 14.7.2 Maximum containers weights,

Wh of 20 ft containers stowed in 40 ft cell guides with

overstow, diagonal stacking cone arrangement

| Lowest tier transverse acceleration

(=

ay/g), see

Pt 3, Ch 14, 8.2 Ship motion, wind and green sea forces acting on containers 8.2.5

|

Maximum homogeneous container weights, in

tonnes

(number of 20 ft containers)

|

| 4 tiers

and fewer

|

5

tiers

|

6

tiers

|

7

tiers

|

8

tiers

|

9

tiers

|

10

tiers

|

11

tiers

|

| 0,20

|

30,5

|

30,5

|

30,5

|

29,2

|

28,2

|

24,8

|

22,6

|

21,0

|

| 0,21

|

30,5

|

30,5

|

30,5

|

29,2

|

28,2

|

24,8

|

22,5

|

20,7

|

| 0,22

|

30,5

|

30,5

|

30,5

|

29,2

|

28,2

|

24,8

|

22,4

|

20,5

|

| 0,23

|

30,5

|

30,5

|

30,5

|

29,2

|

28,2

|

24,8

|

22,3

|

20,3

|

| 0,24

|

30,5

|

30,5

|

30,5

|

29,2

|

28,2

|

24,8

|

22,1

|

20,0

|

| 0,25

|

30,5

|

30,5

|

30,5

|

29,2

|

28,2

|

24,8

|

22,0

|

19,8

|

| 0,26

|

30,5

|

30,5

|

30,5

|

29,2

|

28,2

|

24,7

|

21,9

|

19,6

|

| 0,27

|

30,5

|

30,5

|

30,5

|

29,1

|

28,0

|

24,6

|

21,8

|

19,6

|

| 0,28

|

30,5

|

30,5

|

30,5

|

29,0

|

27,8

|

24,4

|

21,7

|

19,5

|

| 0,29

|

30,5

|

30,5

|

30,5

|

28,9

|

27,7

|

24,3

|

21,6

|

19,4

|

| 0,30

|

30,5

|

30,5

|

30,5

|

28,8

|

27,5

|

24,2

|

21,5

|

19,3

|

| 0,31

|

30,5

|

30,5

|

30,5

|

28,7

|

27,4

|

24,0

|

21,4

|

19,2

|

| 0,32

|

30,5

|

30,5

|

30,5

|

28,6

|

27,2

|

23,9

|

21,2

|

19,1

|

| 0,33

|

30,5

|

30,5

|

30,5

|

28,6

|

27,1

|

23,8

|

21,1

|

19,0

|

| 0,34

|

30,5

|

30,5

|

30,5

|

28,5

|

27,0

|

23,7

|

21,0

|

18,8

|

| 0,35

|

30,5

|

30,5

|

30,5

|

28,2

|

26,5

|

23,4

|

20,9

|

18,9

|

| 0,36

|

30,5

|

30,5

|

30,5

|

27,9

|

26,0

|

23,1

|

20,8

|

18,9

|

| 0,37

|

30,5

|

30,5

|

30,5

|

27,7

|

25,5

|

22,8

|

20,6

|

18,8

|

| 0,38

|

30,5

|

30,5

|

30,5

|

27,4

|

25,1

|

22,4

|

20,2

|

18,4

|

| 0,39

|

30,5

|

30,5

|

30,5

|

27,2

|

24,7

|

22,0

|

19,8

|

18,1

|

| 0,40

|

30,5

|

30,5

|

30,5

|

26,9

|

24,3

|

21,6

|

19,4

|

17,7

|

| 0,41

|

30,5

|

30,5

|

30,5

|

26,7

|

23,9

|

21,2

|

19,1

|

17,4

|

| 0,42

|

30,5

|

30,5

|

30,5

|

26,5

|

23,6

|

20,9

|

18,8

|

17,0

|

| 0,43

|

30,5

|

30,5

|

30,5

|

26,4

|

23,3

|

20,6

|

18,4

|

16,7

|

| 0,44

|

30,5

|

30,5

|

30,5

|

26,2

|

23,0

|

20,3

|

18,1

|

16,4

|

| 0,45

|

30,5

|

30,5

|

30,5

|

26,1

|

22,8

|

20,0

|

17,9

|

16,1

|

| 0,46

|

30,5

|

30,5

|

29,8

|

25,7

|

22,6

|

19,8

|

17,6

|

15,8

|

| 0,47

|

30,5

|

30,5

|

29,0

|

25,2

|

22,3

|

19,5

|

17,2

|

15,3

|

| 0,48

|

30,5

|

30,5

|

28,1

|

24,4

|

21,6

|

18,9

|

16,7

|

14,9

|

| 0,49

|

30,5

|

30,5

|

27,2

|

23,6

|

20,9

|

18,3

|

16,3

|

14,7

|

| 0,50

|

30,5

|

30,5

|

26,4

|

22,8

|

20,1

|

17,8

|

16,0

|

14,5

|

| 0,51

|

30,5

|

30,4

|

25,5

|

22,0

|

19,4

|

17,3

|

15,7

|

14,3

|

| 0,52

|

30,5

|

29,3

|

24,6

|

21,2

|

18,7

|

16,9

|

15,4

|

14,3

|

| 0,53

|

30,5

|

28,3

|

23,7

|

20,4

|

18,0

|

16,5

|

15,3

|

14,3

|

| 0,54

|

30,5

|

27,2

|

22,8

|

19,6

|

17,2

|

16,1

|

15,1

|

14,3

|

| 0,55

|

30,5

|

26,2

|

21,9

|

18,8

|

16,5

|

15,6

|

14,9

|

14,4

|

|

Note 1. Linear interpolation

is to be used to determine intermediate values.

Note 2.40 ft overstow

containers not included in the number of tiers

Note 3. Maximum container

weights for transverse acceleration and number of tiers outside of those

presented will be specially considered.

Note 4. The maximum

container weight should not exceed the rated weight of the

container.

5. Where the

homogeneous container weight ( Wh) derived from the

table is lower than the rated weight of the container, the maximum

homogeneous weight is to be corrected to account for the height of the

containers used, as follows:

Note

Where:

which is not to be taken greater than

1 which is not to be taken greater than

1

ca is the average height of the

20 ft containers

|

Figure 14.7.2 Diagonal stacking cone

arrangement

Table 14.7.3 Maximum container weights

Wh of 20 ft containers stowed in 40 ft cell guides with

overstow, other stacking cone arrangement

| Lowest tier transverse acceleration

(=

ay/g), see

Pt 3, Ch 14, 8.2 Ship motion, wind and green sea forces acting on containers 8.2.5

|

Maximum homogeneous container weights, in

tonnes

|

| 3

tiers

|

4

tiers

|

5

tiers

|

6

tiers

|

7

tiers

|

8

tiers

|

| 0,400

|

24,0

|

24,0

|

24,0

|

19,6

|

17,1

|

15,2

|

| 0,410

|

24,0

|

24,0

|

23,3

|

19,2

|

16,8

|

14,9

|

| 0,420

|

24,0

|

24,0

|

22,5

|

18,9

|

16,5

|

14,7

|

| 0,430

|

24,0

|

24,0

|

21,8

|

18,6

|

16,2

|

14,4

|

| 0,440

|

24,0

|

24,0

|

21,2

|

18,3

|

15,9

|

14,1

|

| 0,450

|

24,0

|

24,0

|

20,8

|

18,0

|

15,7

|

13,9

|

| 0,460

|

24,0

|

24,0

|

20,5

|

17,7

|

15,4

|

13,6

|

| 0,470

|

24,0

|

24,0

|

20,2

|

17,3

|

15,1

|

13,3

|

| 0,480

|

24,0

|

23,9

|

19,9

|

17,0

|

14,8

|

13,1

|

| 0,490

|

24,0

|

23,6

|

19,6

|

16,7

|

14,5

|

12,8

|

| 0,500

|

24,0

|

23,2

|

19,3

|

16,4

|

14,2

|

12,5

|

| 0,510

|

24,0

|

22,9

|

18,9

|

16,1

|

13,9

|

12,2

|

| 0,520

|

24,0

|

22,5

|

18,6

|

15,7

|

13,6

|

12,0

|

| 0,530

|

24,0

|

22,3

|

18,3

|

15,4

|

13,3

|

11,7

|

| 0,540

|

24,0

|

22,1

|

18,1

|

15,1

|

13,0

|

11,4

|

| 0,550

|

24,0

|

21,8

|

17,9

|

14,8

|

12,8

|

11,2

|

|

Note 1. Linear interpolation

is to be used to determine intermediate values.

Note 2.40 ft overstow

containers not included in the number of tiers.

Note 3. Maximum container

weights for transverse acceleration and number of tiers outside of those

presented will be specially considered.

Note 4. The maximum

container weight should not exceed the rated weight of the

container.

5. Where the

homogeneous container weight ( Wh) derived from the

table is lower than the rated weight of the container, the maximum

homogeneous weight is to be corrected to account for the height of the

containers used, as follows:

Note

Where:

which is not to be taken greater than

1 which is not to be taken greater than

1

ca is the average height of the

20 ft containers

|

7.3.4 Alternative proposals for stowage arrangements will be individually

considered and are to be accompanied by supporting calculations.

7.4 Cell guide systems on exposed decks

7.4.1 Analysis

methods for the strength of the cell guide structure are to take due

account of the interactive effects between guide structure and supporting

deck structure and also of the deformation of the hull girder.

7.4.2 At

its lower end the guide structure is to be efficiently connected to

the deck structure. Cross ties are to be arranged between guides in

a transverse direction at a spacing determined by the loading on the

guides but in general not more than 3 m apart. Cross-bracing members

of adequate strength and sufficient number are to be fitted in the

transverse and longitudinal directions to prevent excessive deflection

of the guide structure.

7.4.3 The

height of guide bars above the deck is to be sufficient to ensure

adequate restraint to the uppermost container tiers.

7.4.4 Where

the cell guide structure is attached to highly stressed hull or deck

elements, such as sheerstrakes, special attention is to be given to

the design of the connection and the grade and quality of steel utilised.

7.5 Entry guide devices

7.5.1 A device

to pre-centre the container and direct it into the cell guides is

normally to be fitted at the top of the guide bars. Such devices include:

- fixed even peaks,

- fixed high and low peaks,

- ‘flip-flop’ systems,

but other devices will be considered. The device is to be of

robust construction.

|