Section

5 Design loading

5.1 General

5.1.1 This

Section contains the design heads/pressures to be used in the derivation

of scantlings for decks, tank tops and transverse bulkheads. These

are given in Table 3.5.1 Design heads and permissible cargo

loadings.

Table 3.5.1 Design heads and permissible cargo

loadings

| Structural

item and position

|

Component

|

Standard

stowage rate C, in m3/tonne

|

Design

loading p, in kN/m2

|

Equivalent design head h

i in metres

|

Permissible cargo loading in kN/m2

|

Equivalent

permissible head, in metres

|

| Design heads and permissible cargo loadings (SI

units)

|

| Weather deck (general cargo)

|

|

|

|

h

1

|

|

|

| (a) Loading for minimum scantlings

|

|

|

|

|

|

|

| Forward of 0,075L from F.P.

|

Beams and longitudinals

|

1,39

|

12,73

|

1,8

|

8,5

|

1,2

|

| Primary structure

|

29,64 +

14,41E

|

4,2 + 2,04E

|

| Between 0,12L and 0,075L from F.P.

|

Beams and longitudinals

|

1,39

|

10,61

|

1,5

|

8,5

|

1,2

|

| Primary structure

|

22,59

+ 14,41E

|

3,2 + 2,04E

|

| Aft of 0,12L from F.P.

|

Beams and longitudinals

|

1,39

|

8,5 + 14,41E

|

1,2 + 2,04E

|

8,5

|

1,2

|

| Primary structure

|

| (b) Specified cargo loading

|

|

|

|

|

|

|

| Forward of 0,075L from F.P.

|

Beams and

longitudinals

|

1,39

|

2,47p

a + 14,41E or as (a),

whichever is larger

(Note 1)

|

0,35p

a + 2,04E

(Note 1)

|

p

a

|

0,14p

a

|

| Primary

structure

|

3,5p

a + 14,41E or as (a),

whichever is larger

(Note 1)

|

0,5p

a + 2,04E

(Note 1)

|

|

|

| Between 0,12L and 0,075L from F.P.

|

Beams and

longitudinals

|

1,39

|

1,98p

a + 14,41E or as (a),

whichever is larger

(Note 1)

|

0,28p

a + 2,04E

(Note 1)

|

|

|

| Primary

structure

|

2,67p

a + 14,41E or as (a),

whichever is larger

(Note 1)

|

0,38p

a + 2,04E

(Note 1)

|

p

a

|

0,14p

a

|

| Aft of 0,12L from F.P.

|

Beams and longitudinals

|

1,39

|

p

a + 14,41E

(Note 1)

|

0,14p

a + 2,04E

(Note 1)

|

p

a

|

0,14p

a

|

| Primary structure

|

| Cargo decks

|

|

|

|

h

2

|

|

|

| General cargo (standard loads)

|

All structure

|

1,39

|

7,07H

td

|

H

td

|

7,07H

td

|

H

td

|

| Special cargo (specified loads)

|

C

|

p

a

|

|

p

a

|

|

| Machinery space, workshop and stores

|

1,39

|

18,37

|

2,6

|

-

|

-

|

| Ship stores

|

1,39

|

14,14

|

2,0

|

-

|

-

|

Accomodation decks

(clear of tanks)

|

All structure

|

1,39

|

8,5

|

h

3

|

-

|

-

|

| 1,2

|

| Superstructure decks (Note 2)

|

|

|

|

h

3

|

|

|

| 1st tier

|

Beams and

longitudinals

|

|

|

0,9

|

Where

the deck is exposed to the weather, add 2,04E

|

|

|

| 2nd tier

|

0,6

|

| 3rd tier and above

|

0,45

|

| Decks forming crown of

tunnels and deep tanks

|

Plating and stiffeners

|

C

|

|

h

4

|

|

|

| h

|

| where h = ½ height of stand pipe above

crown

|

| (c) Bulk carrier (see

Pt 3, Ch 3, 1.1 Application 1.1.3) with topside tanks

|

|

|

|

|

|

|

|

| Weather deck outside

line of hatchways in way of cargo hold region, when topside tanks

empty

|

Beams

and longitudinals

|

1,39

|

|

|

7,06h

|

h = the lesser of

(i) 0,22B

(ii)

where

W

b = weight of water ballast in the topside tank per frame space,

in kN

A = Corresponding area, (m2), of deck

in way over one hold frame space

|

| Primary Structure

|

1,39

|

|

|

| Cargo hatch covers (standard

loading)

|

|

|

|

h

H

|

|

|

| Steel cover

|

Webs, stiffeners and plating

|

1,39

|

7,07H

td

|

H

td

|

7,07H

td

|

H

td

|

| Wood cover

|

|

1,39

|

|

|

7,07H

td

|

H

td

|

| Inner bottom

|

|

|

|

H

|

|

|

| Ship without heavy cargo

notation

|

Plating and stiffeners

|

1,39

|

|

|

9,82T

|

1,39T

|

| Ship with heavy cargo notation

|

C but ≤ 0,865

|

|

H

|

|

H

|

| Watertight bulkheads

|

Plating and stiffeners

|

0,975

|

10,07h

4

|

h

4 from Fig 3.5.2

|

|

|

| Deep tank bulkhead

|

Plating and stiffeners

|

C but ≤ 0,975

|

|

h

4 from Fig 3.5.2

|

|

|

Note

1. In the case of beams and

longitudinals, the equivalent design head is to be used in conjunction

with the appropriate formulζ.

|

Note

2. For forecastle decks forward of

0,12L from F.P., see Weather decks.

|

|

|

|

|

|

|

5.2 Symbols

5.2.1 The

symbols used in this Section are defined as follows:

L, L

pp, C

b, B, D and T as defined in Pt 3, Ch 1, 6.1 Principal particulars

|

h

i

|

= |

appropriate design head, in metres |

e

e

|

= |

span of stiffener |

|

p

|

= |

design loading, in kN/m2

|

|

p

a

|

= |

applied loading, in kN/m2

|

|

C

|

= |

stowage rate, in m3/tonne |

| = |

generally generally |

| = |

volume of the hold, in m3 excluding the volume contained

within the depth of the cargo hatchway, divided by the weight of cargo, in tonnes,

stowed in the hold, for inner bottom |

|

E

|

= |

correction factor for height of platform |

| = |

, but not less than zero nor more than 0,147 , but not less than zero nor more than 0,147 |

|

H

|

= |

height from tank top to deck at side, in metres |

|

H

c

|

= |

'tween deck height measured vertically on the centreline of the ship

from 'tween deck to underside of hatch cover stiffeners on deck above, in

metres |

|

H

td

|

= |

cargo head in 'tween deck, in metres, as defined in Figure 3.5.1 Heads for 'tween decks. |

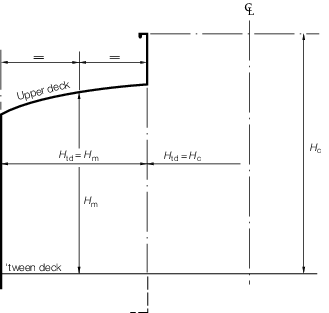

Figure 3.5.1 Heads for 'tween decks

Figure 3.5.2 Heads for watertight and deep tank bulkheads

5.2.2 The

following symbols and definitions apply in particular to the design

pressures for partially filled tanks:

Lpp and C

b as defined in Pt 3, Ch 1, 6.1 Principal particulars

|

b

|

= |

height

of internal primary bottom members, in metres |

|

F

|

= |

fill

height, in metres |

|

F

r

|

= |

effective filling ratio |

| = |

|

|

GM

|

= |

transverse

metacentric height, in metres, including free surface correction,

for the loading condition under consideration |

|

H

t

|

= |

tank depth, in metres, measured from the bottom of the tank

to the underside of the deck at side. In the case of holds, the depth

is measured from the inner bottom to the underside of the deck at

hatch side, except in double skin ships with hatch coaming in line

with the inner skin, in which case, the depth is measured to the top

of the hatch coaming |

|

n

|

= |

number

of internal primary bottom members |

|

L

s

|

= |

the effective horizontal free surface length, in metres, in

the direction of angular motion (i.e. tank breadth for roll, tank

length for pitch) |

|

S

nr

|

= |

ship's natural rolling period |

| = |

seconds seconds

|

| = |

for ships for which either r or GM varies

significantly between loading conditions (for example, bulk carriers

and tankers, see

Pt 3, Ch 3, 1.1 Application 1.1.3), S

nr should be evaluated for each representative

loading condition considered

|

|

r

|

= |

radius

of gyration of roll, in metres, and may be taken as 0,34B

|

|

S

np

|

= |

ship's natural pitching period |

| = |

seconds seconds

|

| = |

for ships for which either T or C

b varies

significantly between loading conditions (for example, bulk carriers

and tankers, see

Pt 3, Ch 3, 1.1 Application 1.1.3), S

np should be evaluated for each representative

loading condition considered

|

|

T

np

|

= |

fluid natural period of pitch |

| = |

seconds seconds

|

|

T

nr

|

= |

fluid natural period of roll |

| = |

seconds seconds

|

|

θmax

|

= |

maximum `lifetime' pitch angle, in degrees: |

| = |

|

|

φmax

|

= |

maximum

`lifetime' roll angle, in degrees: |

| = |

|

5.3 Stowage rate and design loads

5.3.1 Unless

it is specifically requested otherwise, the following standard stowage

rates are to be used:

-

1,39 m3/tonne

for weather or general cargo loading on deck and inner bottom.

-

0,975 m3/tonne

for liquid cargo of density of 1,025 tonne/m3 or less on

watertight and tank divisions. For liquid of density greater than

1,025 tonne/m3 the corresponding stowage rates are to be

adopted.

5.3.2 Proposals

to use a stowage rate greater than 1,39 m3/tonne for permanent

structure will require special consideration, and will normally be

accepted only in the case of special purpose designs such as fruit

carriers, etc.

5.4 Design pressure for partially filled tanks

5.4.1 When

partial filling of tanks or holds is contemplated for sea-going conditions,

the risk of significant loads due to sloshing induced by any of the

ship motions is to be considered. An initial assessment is to be made

to determine whether or not a higher level of sloshing investigation

is required, using the following procedure which corresponds to the

Level 1 investigation outlined in the SDA Procedure for Sloshing

loads and scantling assessment, on tanks partially filled with

liquids.

5.4.2 In general,

significant dynamic magnifications of the sloshing pressures are considered

unlikely for the following cases:

-

For internally

stiffened tanks:

-

Where two (or

more) deck girders (in the case of rolling) or deck transverses (in

the case of pitching) are located not more than 25 per cent of the

tank breadth or length respectively from the adjacent tank boundary,

and the fill level is greater than the tank depth minus the height

of the deck girders or transverses;

-

Where the

deck girders or transverses, at any location, are less than 10 per

cent of the tank depth, and the fill level is greater than the tank

depth minus the height of the deck girders or transverses;

-

Where the

fill level is less than the height of any bottom girders or transverses.

-

For smooth tanks:

where the fill level is less than 10 per cent or more than 97

per cent of the tank depth.

5.4.3 Significant

dynamic magnification of the fluid motions, and hence the sloshing

pressure, can occur if either of the following conditions exist:

-

The natural rolling period, Tnr, of the fluid and

the ship's natural rolling period, Snr, are within five seconds

of each other.

-

The natural pitching period, Tnp, of the fluid is

greater than a value of three seconds below the ship natural pitching period,

Snp.

These values define the limits of the critical fill range for

each tank.

5.4.5 The

natural periods of the ship for a given motion type are to be determined

for the service loading conditions agreed between the Shipbuilder

and Clasifications Register. From this aspect, the storm-ballast and the

segregated ballast conditions and the condition with all tanks partially

filled could be the most critical.

5.4.6 When

a ship is to be approved for Unrestricted Filling Levels - Unspecified

Loading Conditions, many arbitrary ship loading conditions are possible.

In order to cover the complete range of loading conditions, the fully

loaded and ballast conditions are to be considered. These two conditions

give an upper and lower limit for the possible range of natural periods

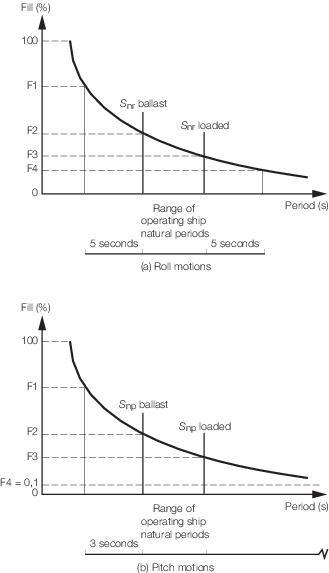

of the ship as shown in Figure 3.5.3 Natural periods diagrams.

Both the roll and pitch motion modes are to be examined.

Because of the unrestricted filling level requirement, the critical

sloshing ranges extend from [SnrBallast - 5] to [S

nrLoaded + 5] seconds in roll and from [SnpBallast - 3] to

[SnpLoaded] in pitch. Also, because of unrestricted filling levels,

the ship natural period range extends from [S

nBallast] to [S

nLoaded] for both pitch and roll.

For sloshing in the roll motion mode shown in Figure 3.5.3 Natural periods diagrams, the critical fill range extends from

F

1 to F4. All fill levels between F1 and

F4 are to be investigated:

- For fill levels between F1 and F2,

SnrBallast is to be used.

- For fill levels between F3 and F4,

SnrLoaded is to be used.

- For fill levels between F2 and F3,

Snr is to be equal to T

nr.

Similarly, for sloshing in the pitch motion mode shown in Figure 3.5.3 Natural periods diagrams, the critical fill range extends from

F1 to F4. All fill levels between

F1 and F4 are to be investigated.

- For fill levels between F1 and F2,

SnpBallast is to be used.

- For fill levels between F2 and F3,

Snp is to be equal to Tnp.

- For fill levels between F3 and F4,

Snp loaded is to be used.

Figure 3.5.3 Natural periods diagrams

5.4.7 When

a ship is to be approved for Restricted Filling Levels - Unspecified

Loading Conditions, many arbitrary ship loading conditions are possible

within the restrictions imposed. In order to cover the complete range

of loading conditions, the fully loaded and ballast conditions are

to be considered. These two conditions give an upper and lower limit

for the possible range of ship natural period. It is recognised that

there might be ship natural period bands which will not be applicable

as a result of the limitations on the fill levels. However, it is

recommended that the Unrestricted Filling Levels - Unspecified Loading

Conditions procedure outlined in Pt 3, Ch 3, 5.4 Design pressure for partially filled tanks 5.4.6 be

applied.

5.4.8 When

a ship is to be approved for Unrestricted Filling Levels - Specified

Loading Conditions, each specified loading condition is to be examined

for the complete fill ranges to determine the critical sloshing fill

range for each tank in both roll and pitch motion modes.

5.4.9 When

a ship is to be approved for Restricted Filling Levels - Specified

Loading Conditions, each specified loading condition is to be examined

for the restricted fill ranges to determine the critical sloshing

fill range for each tank in both roll and pitch motion modes.

5.4.10 Where

the assessment indicates that all the intended fill levels are outside

the critical fill ranges and, therefore, significant sloshing will

not occur, no further evaluation is required with regard to sloshing

pressure. In such cases, the scantlings of the tank boundaries are

to be determined in accordance with the relevant Rule requirements.

5.4.12 The

structural capability of the tank boundaries to withstand the dynamic

sloshing pressures is to be examined. The magnitude of the predicted

loads, together with the scantling calculations may be required to

be submitted.

5.5 Flooded loads

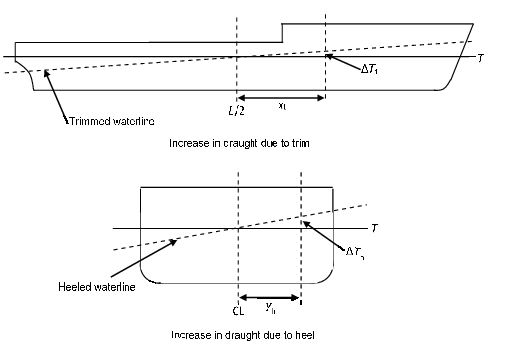

5.5.1 The distance to the flooded load point, ZFD, is to be

calculated as follows;

where

Δ Th,t is the increase in draught due to heel and trim,

in metres

-

|

ΔTh,t |

= |

|

Δ Th is the increase in draught due to heel, in

metres

Δ Tt is the increase in draught due to trim, in metres

- ΔTt = xttanφ

- xt is the distance from 0,5L to

the load point, in metres

- φ is the trim angle and is given by

Tf is the flooded draught, in metres, to be taken as

see also

Figure 3.5.4 Damage waterline at any location

5.5.2 For passenger ships, where the damage waterlines, see

Pt 3, Ch 1, 6.10 Damage waterlines, have not

been provided, the distance from the baseline to the deepest

equilibrium/intermediate waterline, whichever is the greater, and the intermittent

waterline can be estimated in accordance with Pt 3, Ch 3, 5.5 Flooded loads 5.5.1 using the

flooding angles and coefficients given in Table 3.5.3 Flooding angles and

coefficients for passenger ships. The flooded load point is to be measured

perpendicular to the damage waterline.

Table 3.5.2 Flooding angles and

coefficients

| Ship

type

|

Heel angle, θ

|

Trim coefficient, χ

|

Flooding coefficient,

ϕ

|

| Forward

|

Aft

|

Forward

|

Aft

|

| General cargo ships

|

30

|

2

|

3

|

1,10

|

1,10

|

| Container ships

|

30

|

1,5

|

2

|

1,05

|

1,05

|

| Ore carriers and bulk

carriers

|

30

|

3

|

1,5

|

1,05

|

1,10

|

| Ro-Ro cargo ships

|

30

|

3

|

2,5

|

1,10

|

1,30

|

| Gas Carriers

|

30

|

1

|

2,5

|

1,10

|

1,05

|

| Tankers

|

30

|

1

|

2

|

1,05

|

1,05

|

| Special purpose ships

carrying 200 personnel or fewer, see Note 1

|

12, see Note 2

|

2

|

2

|

1,10

|

1,10

|

| Other cargo ships

|

30

|

3

|

3

|

1,10

|

1,10

|

|

|

|

Note 2 The heel

angle is to be taken 7 degrees for locations aft of

0,5L

|

Table 3.5.3 Flooding angles and

coefficients for passenger ships

| Ship

type

|

Final/intermediate heel angle, θ

|

Intermittent heel angle, θ

|

Trim coefficient, χ

|

Flooding coefficient,

ϕ

|

| Forward

|

Aft

|

Forward

|

Aft

|

| Ro-Ro passenger

ships/ferries

|

15

|

26

|

3,5

|

3,5

|

1,15

|

1,15

|

| Multi-decked passenger

ships

|

15

|

22

|

0

|

0

|

1,15

|

1,15

|

| Other passenger ships and

ferries

|

15

|

22

|

0

|

0

|

1,15

|

1,15

|

| Special purpose ships

carrying more than 200 personnel, see Note

|

15

|

N/A

|

0

|

0

|

1,15

|

1,15

|

|

Note Special

purpose ships are as defined in the Code of Safety for

Special Purpose Ships Resolution A.534(13)

|

Figure 3.5.4 Damage waterline at any location

5.5.3 The heel angles and flooding coefficients given in Table 3.5.2 Flooding angles and

coefficients are based on one compartment damage. If required by the

Owner, additional flooding can be considered where the flooded load point is to be

determined based on the equilibrium damage waterline resulting from the damage

stability calculations, see

Pt 3, Ch 1, 6.10 Damage waterlines. The

flooded load point is to be measured perpendicular to the damage waterline.

5.5.4 Where the damage waterlines, see

Pt 3, Ch 1, 6.10 Damage waterlines, have been provided by

the designer, the methodology used to determine the damage waterlines is also to be

submitted as supporting information.

|