4.1.1 The

minimum depth of the centre girder and its thickness are to be at

least the same as required in way of cargo space amidships, see

Pt 4, Ch 1, 8 Double bottom structure. A greater depth is recommended

in way of large engine-rooms when the variation in draught between

light and load conditions is considerable. For passenger ships, see

Pt 4, Ch 2, 6 Double bottom.

4.1.2 In machinery

spaces situated adjacent to the after peak, the double bottom is to

be transversely framed. Elsewhere transverse or longitudinal framing

may be adopted, but see also

Pt 4, Ch 1, 8 Double bottom structure.

4.1.3 Where

the double bottom is transversely framed, plate floors are to be fitted

at every frame in the engine-room. In way of boilers, plate floors

are to be fitted under the boiler bearers, and elsewhere as required

by Pt 4, Ch 1, 8 Double bottom structure.

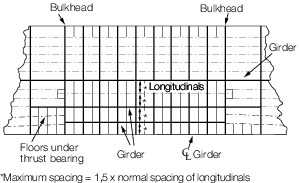

4.1.4 Where

the double bottom is longitudinally framed, plate floors are to be

fitted at every frame under the main engines and thrust bearing. Outboard

of the engine seating, floors may be fitted at alternate frames, see

Figure 7.4.1 Engine-room with longitudinal framing.

Figure 7.4.1 Engine-room with longitudinal framing

4.1.6 Sufficient

fore and aft girders are to be arranged in way of the main machinery

to effectively distribute its weight and to ensure adequate rigidity

of the structure. In midship machinery spaces these girders are to

extend for the full length of the space and are to be carried aft

to support the foremost shaft tunnel bearing. This extension beyond

the after bulkhead of the engine-room is to be for at least three

transverse frame spaces, aft of which the girders are to scarf into

the structure. Forward of the engine-room bulkhead, the girders are

to be tapered off over three frame spaces and effectively scarfed

into the structure. In machinery spaces situated at the aft end the

girders are to be carried as far aft as practicable and the ends effectively

supported by web frames or transverses. For recommended scantlings

of engine girders, see

Pt 3, Ch 7, 6.2 Seats for engines 6.2.1.

4.1.7 Outboard

of the engines, side girders are to be arranged, where practicable,

to line up with the side girders in adjacent cargo spaces. These are

to have scantlings as required by Pt 4, Ch 1, 8 Double bottom structure.

4.1.8 Where

the double bottom is longitudinally framed and transverse floors are

fitted in way of the engine seatings as required by Pt 3, Ch 7, 4.1 Double bottom structure 4.1.4, no additional longitudinal

stiffening is required in way of the engines other than the main engine

girders, provided that the spacing of girders does not exceed 1,5

times the normal spacing of longitudinals. Where this spacing of girders

is exceeded, shell longitudinals are to be fitted. These are to scarf

into the longitudinal framing clear of the machinery spaces. The scantlings

of the longitudinals are to be determined as required by Pt 4, Ch 1, 6 Shell envelope framing using a minimum span of

1,3 m, see

Figure 7.4.1 Engine-room with longitudinal framing.

4.1.10 Where

the height of inner bottom in the machinery spaces differs from that

in adjacent spaces, continuity of longitudinal material is to be maintained

by sloping the inner bottom over an adequate longitudinal extent.

The knuckles in the plating are to be arranged close to plate floors.