Section

3 Longitudinal strength

3.1 General

3.1.2 The requirements of Pt 3, Ch 4, 8.3 Loading instrument

regarding loading instruments are not applicable to general cargo ships under 120 m with

the exception of ships with the notation Hatch Covers may be omitted in Hold (No(s)

...).

3.2 Fast cargo ships

3.2.1 The

hull section modulus for ships of length, L, between

120 m, and 170 m, and maximum service speed greater than 17,5 knots

in association with a bow shape factor, ψ, of more

than 0,15, is to comply with the requirements of this sub-Section.

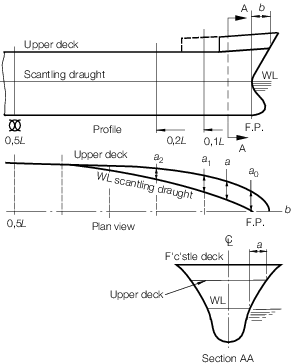

3.2.2 The

bow shape factor is defined as:

where

|

a

0

|

= |

projection of upper deck at waterline (F.P.), in metres |

|

a

1

|

= |

projection of upper deck at waterline (0,1L from

F.P.), in metres

|

|

a

2

|

= |

projection of upper deck at waterline (0,2L from

F.P.), in metres

|

|

b

|

= |

projection

of upper deck at waterline (F.P. to bow line), in metres |

|

|

= |

|

See also

Figure 1.3.1 Derivation of bow shape factor.

3.2.3 For

longitudinal strength requirements, the Rule minimum hull midship

section modulus and the distribution of longitudinal material in the

forward half-length will be considered. In general, the following

requirements are to be complied with:

-

The vertical hull

midship section modulus, about the horizontal neutral axis, at deck

is to be not less than 331LkΣA

b cm3, or that required by Pt 3, Ch 4, 5 Hull bending strength, whichever is the greater. ΣA

b is

defined in Pt 4, Ch 1, 3.2 Fast cargo ships 3.2.2.

-

The horizontal

hull midship section modulus, about a vertical axis through the ship

centreline, is to be not less than 32,5 L

2

D cm3.

-

In the forward

half-length, the hull section modulus is not to be a lesser percentage

of the midship value than that shown in Table 1.3.1 Fast cargo ships.

-

Any load or ballast

condition resulting in a sagging still water bending moment, or a

hogging moment less than 80 per cent of the Rule value of still water

bending moment, will be specially considered with a view to minimising

the compressive stresses in the deck in waves.

Figure 1.3.1 Derivation of bow shape factor

Table 1.3.1 Fast cargo ships

| Position

|

Percentage of midship vertical modulus(modulus about horizontal

axis)

|

Percentage of midship horizontal modulus(modulus about vertical

axis)

|

| Station

10 (mid-L

pp)

|

100

|

100

|

| 12

|

98

|

87

|

| 14

|

95

|

62

|

| 16

|

81

|

38

|

| 18

|

44

|

17

|

| 20

(F.P.)

|

0

|

0

|

Note

1. Intermediate values to be obtained by

interpolation.

|

3.2.4 For

local strength, in general the following requirements are to be complied

with:

-

Longitudinal deck

stiffening is to be carried forward to the fore peak bulkhead or as

far forward as practical. Where a long forecastle is fitted, the buckling

strength of the proposed structure will be specially considered.

-

Substantial web

frames in way of deck transverses are to be fitted in the forward

half-length. Scantlings of webs and frames are to be based on actual

lengths, not 'tween deck heights, and collars are to be fitted at

ends of members in way of high shear.

-

Scantlings of

bottom structure in forward part are to be specially considered.

-

Deck and side

shell panels forward of 0,5L from F.P. are to be examined

to establish the critical buckling stress from the following formula:

- where

|

s

|

= |

length

of shorter edge, in mm |

|

t

|

= |

thickness

of plating, in mm |

|

E

|

= |

Young's modulus, in N/mm2

|

|

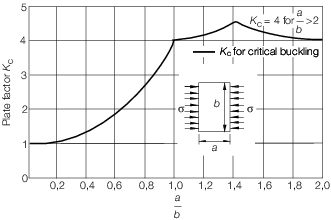

K

c

|

= |

a factor depending on aspect ratio and boundary restraint |

|

|

= |

4 for longitudinally

stiffened plating or as shown in Figure 1.3.2 Plate factor, K

c

for transversely stiffened plating

|

|

ν |

= |

Poisson's ratio

(0,3 for steel and aluminium alloy). |

Where the buckling stresses, as evaluated, exceed 50 per cent

of yield stress, the actual critical buckling stress is given by:

- where

|

σac

|

= |

corrected critical buckling stress, in N/mm2

|

|

σo

|

= |

yield stress, in N/mm2

|

The critical buckling stress from the above formulae must be not less

than 176,6 N/mm2 within 0,4L amidships, nor less than 147,2

N/mm2 for the deck forward of this, nor less than 117,7

N/mm2 for the side shell between the first and second deck forward

of 0,5L from F.P. For higher tensile steel plating, the above permissible

stresses are to be divided by k.

-

In order to obtain

the necessary critical buckling strength, either of the following

is to be applied:

-

plate thickness

to be increased, or

-

panel aspect

ratio to be altered by the fitting of additional panel stiffening.

Figure 1.3.2 Plate factor, K

c

|

| Copyright 2022 Clasifications Register Group Limited, International Maritime Organization, International Labour Organization or Maritime

and Coastguard Agency. All rights reserved. Clasifications Register Group Limited, its affiliates and subsidiaries and their respective

officers, employees or agents are, individually and collectively, referred to in this clause as 'Clasifications Register'. Clasifications

Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance

on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant

Clasifications Register entity for the provision of this information or advice and in that case any responsibility or liability is

exclusively on the terms and conditions set out in that contract.

|

|

|