Section

8 Bow doors and inner doors

8.1 Symbols

8.1.1 The

symbols used in this Section are defined as follows:

|

h

|

= |

height

of the door, in metres, between the levels of the bottom of the door

and the upper deck or between the bottom of the door and the top of

the door, whichever is the lesser, see

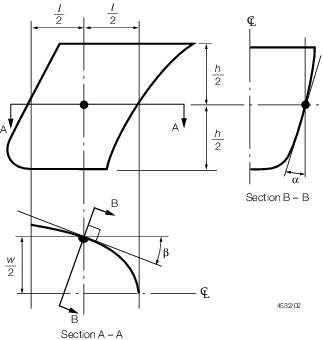

Figure 2.8.2 Definition of α and β

|

|

k

|

= |

material

factor (see

Pt 3, Ch 2, 1.2 Steel),

but is not to be taken less than 0,72 unless demonstrated otherwise

by a direct strength analysis with regard to relevant modes of failure

|

|

w

|

= |

width

of bow door at half height, in metres |

|

A

z

|

= |

area, in m2, of the horizontal projection of the

bow door, between the bottom of the door and the top of the upper

deck bulwark, or between the bottom of the door and the top of the

door, including the bulwark, where it is part of the door,whichever

is the lesser, see

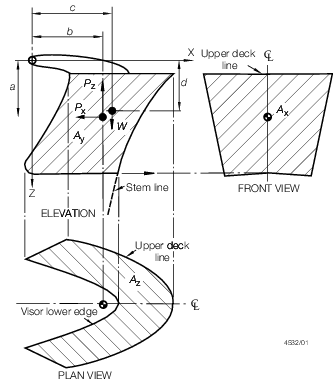

Figure 2.8.1 Bow door (upward hinging). Where the flare angle of the bulwark is at least 15

degrees less than the flare angle of the adjacent shell plating, the

height from the bottom of the door may be measured to the upper deck

or to the top of the door, whichever is the lesser

|

|

A

s

|

= |

area of stiffener web, in cm2

|

|

A

x

|

= |

area, in m2, of the transverse vertical projection

of the bow door, between the bottom of the door and the top of the

door or between the bottom of the door and the upper deck bulwark,

or between the bottom of the door and the top of the door, including

the bulwark, where it is part of the door, whichever is the lesser, see

Figure 2.8.1 Bow door (upward hinging) Where

the flare angle of the bulwark is at least 15 degrees less than the

flare angle of the adjacent shell plating, the height from the bottom

of the door may be measured to the upper deck or to the top of the

door, whichever is lesser. In determining the height from the bottom

of the door to the upper deck or to the top of the door, the bulwark

is to be excluded

|

|

A

y

|

= |

area, in m2, of the longitudinal vertical projection

of the bow door, between the bottom of the door and the top of the

upper deck bulwark, or between the bottom of the door and the top

of the door, including the bulwark, where it is part of the door,

whichever is the lesser, see

Figure 2.8.1 Bow door (upward hinging) Where the flare angle

of the bulwark is at least 15 degrees less than the flare angle of

the adjacent shell plating, the height from the bottom of the door

may be measured to the upper deck or to the top of the door, whichever

is the lesser

|

|

W

|

= |

weight

of bow visor, in tonnes |

|

q

|

= |

distance,

in metres, from the centroid of the hydrostatic head profile, to the

top of the cargo space |

|

C

H

|

= |

0,0125L where L < 80 m

|

| = |

1,0 where L ≥ 80 m

|

|

L

|

= |

length

of ship, but need not be taken greater than 200 m |

|

λ |

= |

coefficient

depending on the area where the ship is intended to be operated |

| = |

1,0 for sea-going ships |

| = |

0,8 for ships operated in coastal waters |

| = |

0,5 for ships operated in sheltered waters |

|

σ |

= |

bending stress, in N/mm2

|

|

σe

|

= |

equivalent stress, in N/mm2

|

|

|

= |

|

|

σy

|

= |

yield stress of the bearing material, in N/mm2

|

|

τ

|

= |

shear stress, in N/mm2. |

Figure 2.8.1 Bow door (upward hinging)

Figure 2.8.2 Definition of α and β

8.2 General

8.2.1 Bow

doors are defined by the following types:

-

Visor doors opened

by rotating upwards and outwards about a horizontal axis through two

or more hinges located near the top of the door and connected to the

primary structure of the door by longitudinally arranged lifting arms.

-

Side-opening doors

opened either by rotating outwards about a vertical axis through two

or more hinges located near the outbound edges or by horizontal translation

by means of linking arms arranged with pivoted attachments to the

door and the ship. It is expected that side-opening bow doors will

be arranged in pairs.

Other bow door types will be specially considered.

8.2.2 Bow

doors are to be situated above the freeboard deck. A watertight recess

in the freeboard deck located forward of the collision bulkhead and

above the deepest waterline, fitted for arrangement of ramps or other

related mechanical devices, may be regarded as a part of the freeboard

deck for the purpose of this requirement.

8.2.3 Where

bow doors lead to a complete or long forward enclosed superstructure,

or to a long non-enclosed superstructure which is fitted to attain

minimum bow height equivalence, an inner door is to be fitted. The

inner door is to be part of the collision bulkhead. Where a sloping

vehicle ramp forming the collision bulkhead above the freeboard deck

is arranged, the inner door may be omitted if the ramp is weathertight

over its complete length and fulfils the requirements of Pt 3, Ch 3 Structural Design concerning the position of

the collision bulkhead.

8.2.4 Bow

doors are to be fitted with arrangement for ensuring weathertight

sealing, such as gaskets, and to give effective protection to inner

doors.

8.2.5 Inner

doors forming part of the collision bulkhead are to be watertight

over the full height of the cargo space and arranged with fixed sealing

supports on the aft side of the doors.

8.2.6 Bow

doors and inner doors are to be arranged so as to preclude the possibility

of the bow door causing structural damage to the inner door or to

the collision bulkhead in the case of damage to or detachment of the

bow door. If this is not possible, a second separate inner weathertight

door, complying with Pt 4, Ch 2, 8.2 General 8.2.5,

is to be installed.

8.2.7 The

requirements for inner doors are based on the assumption that vehicles

and cargo are effectively lashed and secured against movement from

the stowed position.

8.2.8 For

ships complying with the requirements of this Section, the securing,

supporting and locking devices are defined as follows:

-

A securing device

is used to keep the door closed by preventing it from rotating about

its hinges.

-

A supporting device

is used to transmit external and internal loads from the door to a

securing device and from the securing device to the ship's structure,

or a device other than a securing device, such as a hinge, stopper

or other fixed device, that transmits loads from the door to the ship's

structure.

-

A locking device

locks a securing device in the closed position.

8.3 Scantlings

8.3.2 For

bow doors, including bulwark, of unusual form or proportions, the

areas and angles used for the determination of design values of external

forces are to be specially considered.

8.3.3 Bow

doors of the visor or hinged opening type are to be adequately stiffened,

and means are to be provided to prevent lateral or vertical movement

of the doors when closed. Care is to be taken to ensure that adequate

strength is provided in the connections of the hinge or linking arms

to the door structure and to the ship structure.

8.3.4 The

thickness of the bow door plating is not to be less than the side

shell plating calculated with the door stiffener spacing, and in no

case to be less than the minimum shell plate end thickness or forecastle

side thickness as appropriate.

8.3.5 The

section modulus of horizontal or vertical stiffeners is not to be

less than required for end framing. Consideration is to be given,

where necessary, to differences in fixity between ship frames and

bow door stiffeners.

8.3.6 The

stiffener webs are to have a net sectional area not less than:

τ is to be taken as

8.3.7 Bow

door secondary stiffeners are to be supported by primary members constituting

the main stiffening elements of the door.

8.3.8 The

scantlings of such primary members are to be based on direct strength

calculations. Normally, formulae for simple beam theory may be applied

to determine the bending stress. Members are to be considered to have

simply supported end connections. The design load, P

e,

is the uniformly distributed external sea pressure. The formulae for P

e given in Pt 4, Ch 2, 8.6 Design of securing and supporting devices 8.6.1,

may be used with α and β defined as:

|

α |

= |

flare angle,

in degrees, generally to be measured normal to the shell between the

vertical axis and the vertical tangent to the outer shell of the door

measured at the point on the bow door, one half of the projected length

( /2) aft of the stern line on the plane at the half height

of the door (h/2) (see

Figure 2.8.2 Definition of α and β) /2) aft of the stern line on the plane at the half height

of the door (h/2) (see

Figure 2.8.2 Definition of α and β)

|

|

β |

= |

entry angle,

in degrees, generally to be measured on the outer shell of the door

between the longitudinal axis and the waterplane tangent measured

at the point on the bow door, one half of the projected length ( /2) aft of the stem line on the plane at the half height

of the door (h/2) (see

Figure 2.8.2 Definition of α and β) /2) aft of the stem line on the plane at the half height

of the door (h/2) (see

Figure 2.8.2 Definition of α and β)

|

The permissible stresses are as follows:

8.3.9 The

webs of primary members are to be adequately stiffened, preferably

in a direction perpendicular to the shell plating.

8.3.10 The

primary members of the bow doors and hull structure in way are to

have sufficient stiffness to ensure the integrity of the boundary

support of the doors.

8.3.11 All

load transmitting elements in the design load path, from door through

securing arrangements and supporting devices into the ship structure,

including welded connections, are to be to the same strength standard.

These elements include pins, supporting brackets and back-up brackets.

Where cut-outs are made in the supporting structure, the strength

and stiffness will be specially considered.

8.3.12 For

bow doors and inner doors, the distribution of forces acting on the

securing devices and the supporting devices is to be supported by

direct calculations taking into account the flexibility of the structure

and the actual position and stiffness of the supports.

8.3.13 The

buckling strength of primary members is to be specially considered.

8.4 Vehicle ramps

8.5 Arrangements for the closing, securing and supporting of doors

8.5.1 Bow

doors are to be fitted with adequate means of closing, securing and

supporting so as to be commensurate with the strength and stiffness

of the surrounding structure. The hull supporting structure in way

of the bow doors is to be suitable for the same design loads and design

stresses as the securing and supporting devices. Where packing is

required, the packing material is to be of a comparatively soft type,

and the supporting forces are to be carried by the steel structure

only. Maximum design clearance between securing and supporting devices

is not to exceed 3 mm.

8.5.2 Securing

devices are to be simple to operate and easily accessible. They are

to be of a design approved by LR for the intended purpose.

8.5.3 Securing

devices are to be equipped with positive locking arrangements. Arrangements

are to be such that the devices are retained in the closed position

within design limits of inclination, vibration and other motion-induced

loads and in the event of loss of any actuating power supply.

8.5.4 Systems

for door opening/closing and securing/locking are to be interlocked

in such a way that they can only operate in a proper sequence. Hydraulic

systems are to comply with Pt 5, Ch 14, 9 Hydraulic systems.

8.5.5 Means

are to be provided to enable the bow doors to be mechanically fixed

in the open position taking into account the self-weight of the door

and a minimum wind pressure of 1,5 kN/m2 (0,153 tonne-f/m2) acting on the maximum projected area in the open position.

8.5.6 The

spacing for side and top cleats should not exceed 2,5 m and there

should be cleats positioned as close to the corners as practicable.

Alternative arrangements for ensuring weathertight sealing will be

specially considered.

8.6 Design of securing and supporting devices

8.6.1 The

external design forces for securing devices, supporting devices and

surrounding structure are to be taken not less than P,

taking the direction of the pressure into account:

where

|

p

e

|

= |

external sea pressure, not to be taken less than: |

-

For bow doors:

|

p

e

|

= |

0,8 (0,15V + 0,6 )2 kN/m2 )2 kN/m2

|

or

|

p

e

|

= |

2,75λ C

H (0,22 + 0,15 tan α)

(0,4V sin β + 0,6 )2 kN/m2 )2 kN/m2

|

whichever is the greater.

-

For inner doors:

or

whichever is the greater

The symbols are as defined in Pt 4, Ch 2, 8.1 Symbols 8.1.1.

8.6.2 The inner door internal design pressure, considered for the scantlings of

securing devices, is not to be less than 25 kN/m2 .

8.6.3 For

visor doors, the pivot arrangement is to be such that the visor is

self-closing under external loads. The closing moment, M

c, is to be taken as:

but is not to be less than:

8.6.4 For

visor doors, two securing devices are to be provided at the lower

part of the door, each capable of providing the full reaction force

required to prevent opening of the door within the permissible stresses

given in Pt 4, Ch 2, 8.6 Design of securing and supporting devices 8.6.7. The opening

moment M

o, to be balanced by this reaction

force, is to be taken as not less than:

8.6.6 For

side-opening doors, securing devices are to be provided such that

in the event of a failure of any single securing device the remainder

are capable of providing the full reaction force required to prevent

the opening of the door. The permissible stresses given in Pt 4, Ch 2, 8.6 Design of securing and supporting devices 8.6.7 are not to be exceeded. The

opening moment about the hinges to be balanced by this reaction force

is not to be less than that calculated when the following loads are

applied:

-

An internal pressure of 5 kN/m2.

-

A force of 10W kN acting forward at the centroid of mass.

8.6.7 Securing

devices and supporting devices are to be designed to withstand the

forces given above using the following permissible stresses:

8.6.8 The

arrangement of securing and supporting devices is to be such that

threaded bolts are not to carry support forces. The maximum tensile

stress in way of threads of bolts, not carrying support forces, is

not to exceed:

8.6.9 For

steel to steel bearings in securing and supporting devices, the nominal

bearing pressure is not to exceed 0,8σy. For other

bearing materials, the permissible bearing pressure is to be determined

according to the manufacturer’s specification. The nominal bearing

pressure is to be calculated by dividing the design force by the projected

bearing area.

8.6.10 The

reaction forces to be applied to the effective securing and supporting

devices are to be determined from the combination of external loads

defined in Table 2.8.1 Combination of external

loads.

Table 2.8.1 Combination of external

loads

| Bow door type

|

Combination of external loads

|

Case

1

(Head seas)

|

Case

2

(Quartering seas)

|

| Visor doors, see Notes 1 and 2

|

P

x and P

z

see Note 3

|

0,7P

y acting on each side separately, together with 0,7P

x and 0,7P

z

|

Side

opening,

see Notes 1 and 2

|

P

x, P

y and P

z acting on both doors, see Note 3

|

0,7P

x and 0,7P

z acting on both doors and 0,7P

y acting on each door separately

|

Note

2. The self-weight of the door is to be

included in the combination of external loads.

|

8.6.11 The

distribution of the reaction forces acting on the securing and supporting

devices is to be supported by direct calculations taking into account

the flexibility of the hull structure and the actual position and

stiffness of the supports. Small and/or flexible devices, such as

cleats, intended to provide load compression of the packing material

are not to be included in these calculations.

8.6.12 The hinge or linking arms of a bow door and its supports are to be designed

for the static and dynamic opening forces. A minimum wind pressure of 1,5

kN/m2, acting on the transverse projected area of the door is to be taken

into account.

8.6.13 For

side-opening doors, supporting devices are to be provided in way of

girder ends at the closing of the two doors to prevent one side shifting

towards the other under the effect of asymmetrical pressure. A typical

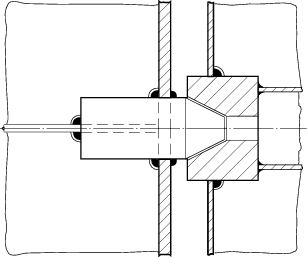

arrangement is shown in Figure 2.8.3 Typical supporting device between doors.

8.6.14 Inner

doors are to be gasketed and weathertight.

Figure 2.8.3 Typical supporting device between doors

8.6.15 Only

the active supporting and securing devices having an effective stiffness

in the relevant direction are to be included and considered to calculate

the reaction forces acting on the devices.

8.7 Operating and Maintenance Manual

8.7.1 An Operating

and Maintenance Manual for the bow doors and inner doors is to be

provided on board and is to contain the following information:

-

main particulars

and design drawings,

- special safety precautions;

- details of vessel;

- equipment and design loading for ramps;

- key plan of equipment for doors and ramps;

- manufacturers' recommended testing for equipment; and

- a description of the equipment for:

|

|

bow doors;

|

|

|

inner bow doors;

|

|

|

bow ramp/doors;

|

|

|

side doors;

|

|

|

stern doors;

|

|

|

central power pack;

|

|

|

bridge panel;

|

|

|

ramps leading down from the main deck;

|

|

|

engine control room panel.

|

-

service conditions:

- limiting heel and trim of the ship for loading/unloading;

- limiting heel and trim for door operations;

- operating instructions for doors and ramps; and

- emergency operating instructions for doors and ramps.

-

maintenance:

- schedule and extent of maintenance;

- troubleshooting and acceptable clearances; and

- manufacturers' maintenance procedures.

-

register of inspections,

including inspection of locking, securing and supporting devices,

repairs and renewals.

This Manual is to be submitted for approval, and is to contain

a note recommending that recorded inspections of the door supporting

and securing devices be carried out by the ship’s staff at monthly

intervals or following incidents that could result in damage, including

heavy weather or contact in the region of the doors. Any damages recorded

during such inspections are to be reported to LR.

8.7.2 Documented

operating procedures for closing and securing the bow doors and inner

doors are to be kept on board and posted at an appropriate place.

|