Section

11 Hatch covers

11.1 General

11.1.2 The

primary structure of hatch covers normally consists of an arrangement

of deep beams and girders including hatch cover top plating.

11.1.3 For

hatch covers subjected to point loads from containers, the primary

structure scantlings are to be verified by direct calculation in accordance

with Pt 4, Ch 8, 11.2 Direct calculations.

11.2 Direct calculations

11.2.1 Direct

calculations are to be based on 2D or 3D finite element analysis.

Simplified boundary constraints may be applied in the modelling, provided

this does not compromise the overall structural response.

11.2.3 The load P in kN, applied at each corner of a container stack, and resulting from

heave and pitch (i.e. ship in upright condition) is to be determined as follows:

|

P |

= |

|

where:

11.2.4 The loads applied at each corner of a container stack, and resulting from

heave, pitch, and the ship's rolling motion (i.e. ship in heeled condition) are to be

determined as follows, see

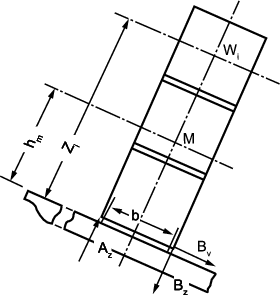

Figure 8.11.1 Forces due to container

loads:

The loads due to single forces resulting from heave and pitch are also to be considered,

as defined in Pt 3, Ch 11, 2.3 Load model 2.3.5, where

|

a

v

|

= |

acceleration addition according to Pt 3, Ch 11, 2.3 Load model 2.3.4

|

|

b

|

= |

distance between midpoints of foot points, in metres |

|

h

m

|

= |

designed height of centre of gravity of stack above hatch cover top,

in metres, may be calculated as weighted mean value of the stack, where the centre

of gravity of each tier is assumed to be located at the centre of each container, |

| = |

|

|

Zi |

= |

distance from the hatch cover top to the centre of ith

container, in metres |

|

mi |

= |

mass of ith container, in t |

|

A

z, B

z

|

= |

support forces in z-direction at the forward and aft stack corners,

in kN |

|

B

y

|

= |

support force in y-direction at the forward and aft stack corners, in

kN |

|

M

|

= |

maximum designed mass of container stack, in t. |

When strength of the hatch cover structure is assessed by grillage analysis

according to Pt 3, Ch 11, 2.11 Buckling strength of hatch cover structures

hm and zi need to be taken above the hatch cover

supports. Force By does not need to be considered in this case. Values of

Az and Bz applied for the assessment of hatch

cover strength are to be shown in the drawings of the hatch covers. It is recommended

that container loads as calculated above are considered as maximum load limits for foot

point loads of container stacks in the calculations of cargo securing (container

lashings).

Figure 8.11.1 Forces due to container

loads

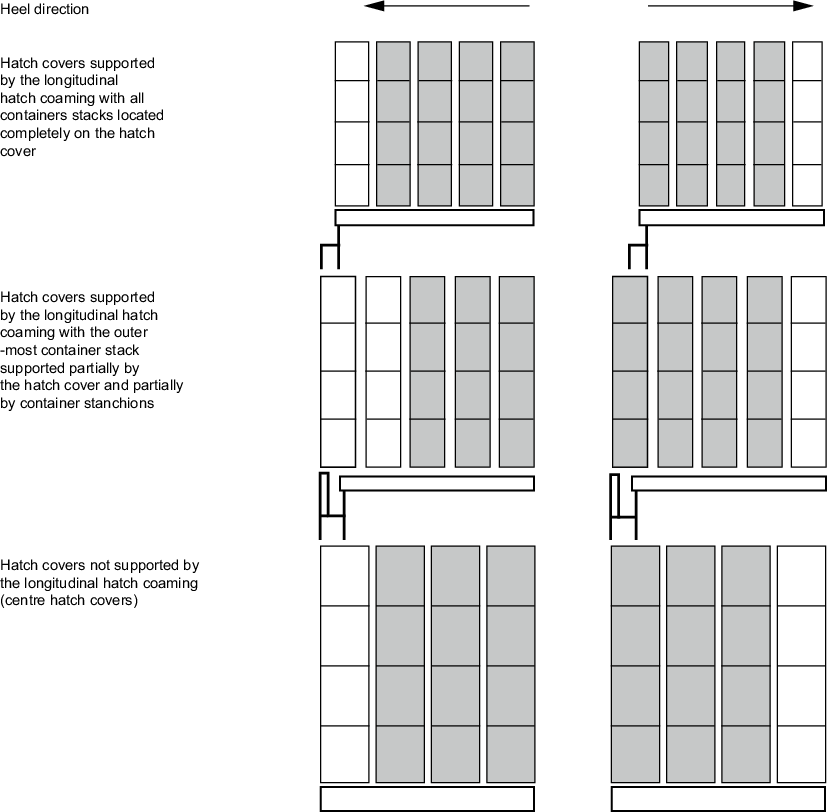

11.2.5 Load cases defined in Pt 4, Ch 8, 11.2 Direct calculations 11.2.3 and Pt 4, Ch 8, 11.2 Direct calculations 11.2.4 are also to be considered for partial

non-homogeneous loading which may occur in practice, e.g. where specified container

stack places are empty. For each hatch cover, the heel directions as shown in Figure 8.11.2 Partial loading of a container

hatch cover are to be considered.

The load case partial loading of container hatch covers can be

evaluated using a simplified approach, where the hatch cover is loaded without the

outermost stacks that are located completely on the hatch cover. If there are additional

stacks that are supported partially by the hatch cover and partially by container

stanchions, then the loads from these stacks are also to be neglected. See Figure 8.11.2 Partial loading of a container

hatch cover. In addition, in order to consider the maximum

loads in the vertical hatch cover supports, the case where only the stack locations that

are partially supported by the hatch cover and partially supported by container

stanchions are left empty is to be assessed. Partial load cases where container stack

positions other than those shown in Figure 8.11.2 Partial loading of a container

hatch cover are left empty are to be considered.

Figure 8.11.2 Partial loading of a container

hatch cover

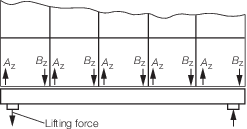

11.2.6 The securing devices of hatch covers, onto which cargo is to be lashed, are

to be designed for the lifting forces resulting from loads according to Pt 4, Ch 8, 11.2 Direct calculations 11.2.4, see

Figure 8.11.2 Partial loading of a container

hatch cover. Unsymmetrical loadings, which may occur in

practice, are to be considered. Under these loadings, the equivalent stress in the

securing devices is not to exceed:

where:

|

kl |

= |

|

|

σo |

= |

minimum yield stress, in N/mm2, of the material but not

to be taken greater than 0,7 σm

|

|

σm |

= |

minimum specified tensile strength, in N/mm2, of the material |

|

e |

= |

0,75 for σo > 235 N/mm2 |

| = |

1,0 for σo ≤ 235 N/mm2 |

Special consideration may be given for the omission of anti-lifting devices

for non-weathertight hatch covers.

The partial load cases given in Pt 4, Ch 8, 11.2 Direct calculations 11.2.5 may not cover all unsymmetrical loadings, critical

for hatch cover lifting.

Figure 8.11.3 Lifting forces at a hatch cover

11.2.7 Where hatch covers are arranged for carrying containers and mixed stowage

is allowed, i.e. a 40’ container stowed on top of two 20’ containers, the foot point

forces at the fore and aft end of the hatch cover are not to be higher than those

resulting from the design stack weight for 40’ containers, and the foot point forces at

the middle of the cover are not to be higher than those resulting from the design stack

weight for 20’ containers. Particular attention is to be paid to the deflections of

hatch covers. Furthermore, the possible contact of deflected hatch covers with in-hold

cargo is to be considered.

11.3 Dispensation of weathertight gaskets

11.3.1 For

hatch covers of cargo holds solely for the transport of containers,

upon request by the Owners and subject to compliance with the requirements

of this Section, the fitting of weathertight gaskets according to Pt 3, Ch 11, 4.4 Packing material may be dispensed

with.

11.3.2 The

hatchway coamings are not to be less than 600 mm in height.

11.3.3 The

exposed deck on which the hatch covers are located is situated above

a depth H(x). H(x) is to be shown to comply

with the following criteria:

|

H(x)

|

= |

≥ T

fb + f

b + h,

in metres

|

where

|

T

fb

|

= |

draught, in metres, corresponding to the assigned summer load

line |

|

f

b

|

= |

minimum required freeboard, in metres, determined in accordance

with ICLL Reg. 28 as modified by further regulations, as applicable |

|

h

|

= |

4,6

m for  ≤ 0,75 ≤ 0,75

|

|

|

= |

6,9 m for  > 0,75 > 0,75

|

11.3.4 Labyrinths,

gutter bars or equivalents are to be fitted proximate to the edges

of each panel in way of the coamings. The clear profile of these openings

is to be kept as small as possible.

11.3.5 Where

a hatch is covered by several hatch cover panels, the clear opening

of the gap in between the panels is to be not wider than 50 mm.

11.3.6 The

labyrinths and gaps between hatch cover panels shall be considered

as unprotected openings with respect to the requirements of intact

and damage stability calculations.

11.3.7 Bilge

alarms are to be provided in each hold fitted with non-weathertight

covers.

11.4 Omission of hatch covers

|