4.2.2 Fairleads

and their supporting structures are to be designed for a load equivalent

to the rated minimum break strength of the anchor line.

4.2.3 Maximum allowable stresses for the design criteria given in Pt 7, Ch 8, 4.2 Fairleads 4.2.1 and Pt 7, Ch 8, 4.2 Fairleads 4.2.2 are to be based on the following factors of

safety:

| Shear

|

1,89

|

Factors relate to tensile yield stress

|

Tension, compression

or

bending

|

1,25

|

Factors relate to tensile yield stress

|

| Combined

|

1,11

|

Factors relate to tensile yield stress

|

(combined stress =  ) )

|

Where σX and σY are the combined axial and bending stresses in the X and Y

directions respectively and τ is the combined shear stress due

to torsion and/or bending in the X-Y plane.

4.2.4 Materials

and steel grades are generally to comply with the requirements given

in Pt 7, Ch 8, 5.2 Materials for Type P components.

4.2.5 Chain

cable fairleads are to have a minimum of five pockets.

4.2.6 Wire

rope fairleads are generally to have a minimum diameter of 20 times

the wire rope diameter.

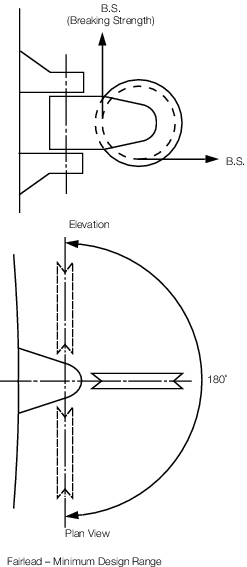

Figure 8.4.1 Minimum operating range and design loading of fairlead