Section

10 Hull strengthening requirements for navigation in multi-year

ice conditions Ice Classes PC1, PC2, PC3, PC4, PC5, PC6, PC7

and Icebreaker

10.1 Definitions

10.1.1 The length LUI is the distance, in m, measured horizontally from

the fore side of the stem at the intersection with the upper ice waterline (UIWL) to

the after side of the rudder post, or the centre of the rudder stock if there is no

rudder post. LUI is not to be less than 96 per cent, and need not

be greater than 97 per cent, of the extreme length of the upper ice waterline (UIWL)

measured horizontally from the fore side of the stem. In ships with unusual stern

and bow arrangement the length LUI will be specially

considered.

10.1.2 The ship displacement ΔUI is the displacement, in kilo tonnes, of the ship

corresponding to the upper ice waterline (UIWL). Where multiple waterlines are used

for determining the UIWL, the displacement is to be determined from the waterline

corresponding to the greatest displacement.

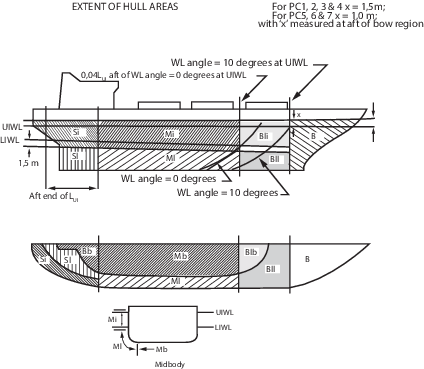

10.2 Hull areas

10.2.1 The hull of all polar class ships is divided into areas reflecting the

magnitude of the loads that are expected to act upon them, see

Figure 2.10.1 Extent of hull areas. In the longitudinal direction,

there are four regions:

-

bow, (B);

-

bow intermediate, (B

i);

-

midbody, (M), and

-

stern (S).

The bow intermediate, midbody and stern regions are further divided in the

vertical direction into three regions:

-

bottom, (b)

-

lower, (l) and

-

icebelt (i).

10.2.3 In addition to Figure 2.10.1 Extent of hull areas, at no time is the boundary

between the bow and bow intermediate regions to be forward of the intersection point of

the line of the stem and the ship baseline.

10.2.4 In addition to Figure 2.10.1 Extent of hull areas, the aft boundary of

the bow region need not be more than 0,45LUI aft of the fore side of

the stem at the intersection with the upper ice waterline (UIWL)

10.2.5 The forward boundary of the stern region is to be at least a distance

Z from the aft end of LUI, where Z is 0,7b or

0,15L UI whichever is greater. b is the distance from the

aft end of LUI to the maximum half breadth at the UIWL and

LUI is defined in Pt 8, Ch 2, 10.1 Definitions.

10.2.6 The boundary between the bottom and lower regions is to be taken at the

point where the tangent to the shell is inclined 7° from horizontal.

10.2.8 In addition to Figure 2.10.1 Extent of hull areas if the ship is assigned the

additional notation Icebreaker the forward boundary of the stern region is to be

at least 0,04L forward of the section where the parallel ship side at the upper

ice waterline (UIWL) ends.

Figure 2.10.1 Extent of hull areas

10.3 Design ice loads General

10.3.1 For ships of all Polar Classes, a glancing impact on the bow is the design

scenario for determining the scantlings required to resist ice loads.

10.3.2 The design ice load is characterised by an average pressure, P

a, uniformly distributed over a rectangular load patch of height, b,

and width, w.

10.3.3 Within the bow area of all polar classes, and within the bow intermediate

icebelt area of polar classes PC6 and PC7, the ice load parameters are

functions of the actual bow shape. To determine the ice load parameters,

Pa

, b and w, it is required to calculate the following ice load

characteristics for sub-regions of the bow area; shape coefficient, f

ai, total glancing impact force, F

i, line load, Q

i, and pressure, P

i.

10.3.4 For polar classes PC6 and PC7 the ice load parameters,

Pa, b and w, determined as a function of the bow

shape in bow region, B, are also to be applied to bow intermediate icebelt

region, BIi.

10.3.5 In other ice-strengthened areas, the ice load parameters, Pa

, b

NB and w

NB, are determined independently of the hull shape and based on a fixed load

patch aspect ratio, AR = 3.6.

10.3.10 Ship structures that are not directly subjected to ice loads may still

experience inertial loads of stowed cargo and equipment resulting from ship/ice

interaction. These inertial loads are to be considered in the design of these

structures.

10.4 Glancing impact load characteristics

10.4.1 The parameters defining the glancing impact load characteristics are

reflected in the class factors listed in Table 2.10.1 Class factors for icebreaking bow

forms and Table 2.10.2 Class factors for vertical side

bow forms.

Table 2.10.1 Class factors for icebreaking bow

forms

| Polar Class

|

Crushing failure class

factor

|

Flexural failure class

factor

|

Load patch dimensions class

factor

|

Displacement class factor

|

Longitudinal strength class

factor

|

|

C

C

|

C

F

|

C

D

|

C

DI

|

C

L

|

|

PC1

|

17,69

|

68,60

|

2,01

|

250

|

7,46

|

|

PC2

|

9,89

|

46,80

|

1,75

|

210

|

5,46

|

|

PC3

|

6,06

|

21,17

|

1,53

|

180

|

4,17

|

|

PC4

|

4,50

|

13,48

|

1,42

|

130

|

3,15

|

|

PC5

|

3,10

|

9,00

|

1,31

|

70

|

2,50

|

|

PC6

|

2,40

|

5,49

|

1,17

|

40

|

2,37

|

|

PC7

|

1,80

|

4,06

|

1,11

|

22

|

1,81

|

Table 2.10.2 Class factors for vertical side

bow forms

| Polar Class

|

Crushing failure class factor

|

Line load class factor

|

Pressure class factor

|

| CCV

|

CQV

|

CPV

|

| PC6

|

3,43

|

2,82

|

0,65

|

| PC7

|

2,60

|

2,33

|

0,65

|

10.5 Bow area

10.5.1 In

the bow area, the force, F, line load, Q,

pressure, P, and load patch aspect ratio, AR,

associated with the glancing impact load scenario are functions of

the hull angles measured at the upper ice waterline, UIWL. The influence

of the hull angles is captured through calculation of a bow shape

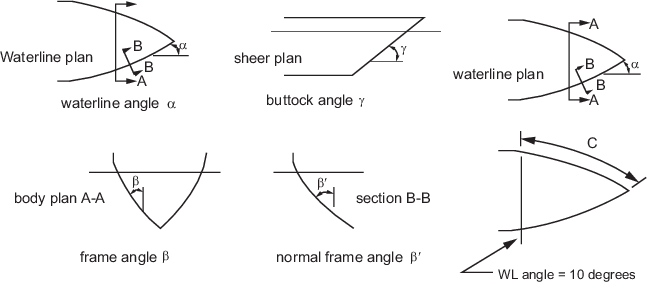

coefficient, fa. The hull angles are defined in Figure 2.10.2 Definition of hull angles.

where

|

β' |

= |

normal frame angle at upper ice waterline, in degrees |

|

α |

= |

normal frame angle at upper ice waterline, in degrees |

|

γ |

= |

buttock angle at upper ice waterline (angle of buttock line measured from

horizontal), in degrees |

|

tan(β) |

= |

|

|

tan(β') |

= |

tan (β) cos(α) |

|

C |

= |

waterline length of the bow region

|

Figure 2.10.2 Definition of hull angles

10.5.2 The waterline length of the bow region, C, is generally to be divided

along the UIWL into four sub-regions of equal length. The force, F, line load,

Q, pressure, P, and load patch aspect ratio, AR, are to be

calculated with respect to the mid - length position of each sub-region (each maximum of

F, Q and P is to be used in the calculation of the ice load

parameters Pa

, b and w).

10.5.3 The bow area load characteristics for icebreaking bow forms, as defined in

Pt 8, Ch 2, 10.3 Design ice loads General 10.3.6, are

determined as follows:

-

The shape coefficient, fai

, is to be taken as:

- fa

i,2

- fa

i,3 whichever is the lesser

where

|

fa

i,1

|

= |

|

|

fa

i,2

|

= |

|

|

i

|

= |

sub-region

considered |

|

x

|

= |

distance from the fore side of the stem at the intersection

with the upper ice waterline (UIWL) station under consideration, in

metres |

-

Force, Fi

:

where

|

i

|

= |

sub-region

considered |

|

fai

|

= |

shape coefficient of sub-region, i

|

-

Load patch aspect

ratio, ARi

:

where

|

i

|

= |

sub-region

considered |

|

β'i

|

= |

normal

frame angle of sub-region i, in degrees

|

-

Line load, Q

i:

|

Q

i

|

= |

MN/m MN/m |

where

|

i

|

= |

sub-region

considered |

|

F

i

|

= |

force of sub-region i, in MN

|

|

AR

i

|

= |

load patch aspect ratio of sub-region i

|

-

Pressure, P

i:

|

P

i

|

= |

F

i

0,22

C

D

2

AR

i

0,3 MPa

|

10.5.4 The bow area load characteristics for bow forms with vertical sides, as defined in Pt 8, Ch 2, 10.3 Design ice loads General 10.3.7, are

determined as follows:

- The shape coefficient, fai, is to be taken as:

- Force, Fi:

- Line load, Qi:

- Pressure, Pi:

10.6 Hull areas other than the bow

10.6.1 In the hull areas other than the bow, the force, FNB, and

line load, QNB, used in the determination of the load patch

dimensions, bNB, wNB, and design pressure, P

a, are determined as follows:

-

Force, F

NB:

where

|

ΔF

|

= |

ship displacement factor |

|

|

= |

CDI

0,64 + 0,10 (ΔDI CDI) if

ΔUI ≤ CDI

|

-

Line Load, Q

NB:

|

Q

NB

|

= |

0,639F

NB

0,61

C

D MN/m

|

where

10.7 Design load patch

10.7.1 In

the bow area, and the bow Intermediate Icebelt area for ships with

class notation PC6 and PC7, the design load

patch has dimensions of width, w

B, and height, b

B, defined as follows:

|

w

B

|

= |

m m

|

|

b

B

|

= |

m m

|

where

|

F

B

|

= |

maximum F

i in the bow area, in MN

|

|

Q

B

|

= |

maximum Q

i in the bow area, in MN/m

|

|

P

B

|

= |

maximum P

i in the bow area, in MPa.

|

10.7.2 In

hull areas other than those covered by Pt 8, Ch 2, 10.7 Design load patch 10.7.1, the design load patch has dimensions of width, w

NB, and height, b

NB, defined as follows:

|

w

NB

|

= |

m m |

|

b

NB

|

= |

m m |

where

10.8 Pressure within the design load patch

10.8.1 The

average pressure, P

a, within a design load

patch is determined as follows:

|

P

a

|

= |

MPa MPa

|

where

|

F

|

= |

F

B or F

NB as appropriate for the hull

area under consideration, in MN

|

|

b

|

= |

b

B or b

NB as appropriate for the hull

area under consideration, in metres

|

|

w

|

= |

w

B or w

NB as appropriate for the hull

area under consideration, in metres.

|

10.8.2 Areas of higher, concentrated pressure exist within the load patch. In

general, smaller areas have higher local pressures. Accordingly, the peak pressure

factors listed in Table 2.10.3 Peak pressure factors are used to account for the pressure

concentration on localised structural members.

Table 2.10.3 Peak pressure factors

| Structural member

|

Peak

pressure factor, K

i

|

| Plating

|

Transversely framed

|

K

p = (1,8 s) ≥ 1,2

|

|

|

Longitudinally framed

|

K

p = (2,2 1,2s) ≥ 1,5

|

| Frames in transverse framing

systems

|

With load distributing stringers

see Note 1

|

K

t = (1,6 s) ≥ 1,0

|

|

|

With no load distributing stringers

see Note 1

|

K

t = (1,8 s) ≥ 1,2

|

| Frames in

bottom structures

|

Ks = 1

|

| Load carrying stringers see Note 2

|

K

s = 1

|

if S

w ≥ 0,5w

|

Side

longitudinals

Web frames

|

K

s = 2

|

if S

w < 0,5w

|

| Symbols

|

|

s

|

= |

frame or longitudinal spacing, in metres |

|

|

S

w

|

= |

web frame spacing, in metres |

|

|

w

|

= |

ice load patch width, in metres |

|

|

Note 1. Load distributing stringers are intercostal. Load distributing

stringer web height hlds is to be at least 80 per cent

of the adjacent main frame web height (hlds ≥

0,8h).

|

10.9 Hull area factors

10.9.1 Associated

with each hull area is an area factor that reflects the relative magnitude

of the load expected in that area. The area factor, AF,

for each hull area is listed in Table 2.10.4 Hull area factors (AF) .

10.9.2 In

the event that a structural member spans across the boundary of a

hull area, the largest hull area factor is to be used in the scantling

determination of the member.

10.9.3 Due to their increased manoeuvrability, ships having propulsion arrangements

with azimuth thruster(s) or podded propellers are to have specially considered stern

icebelt, Si, and stern lower, Sl, hull area factors.

See the Rules for the Classification of Stern First Ice Class Ships, July 2022.

Table 2.10.4 Hull area factors (AF)

| Hull

area

|

Area

|

Polar Class

|

|

PC1

|

PC2

|

PC3

|

PC4

|

PC5

|

PC6

|

PC7

|

| Bow (B)

|

All

|

B

|

1,00

|

1,00

|

1,00

|

1,00

|

1,00

|

1,00

|

1,00

|

| Icebelt

|

BI

i

|

0,90

|

0,85

|

0,85

|

0,80

|

0,80

|

1,00

|

1,00

|

|

|

|

|

|

|

see Note 1

|

see Note 1

|

| Bow

intermediate (BI)

|

Lower

|

BI

l

|

0,70

|

0,65

|

0,65

|

0,60

|

0,55

|

0,55

|

0,50

|

| Bottom

|

BI

b

|

0,55

|

0,50

|

0,45

|

0,40

|

0,35

|

0,30

|

0,25

|

| Midbody (M)

|

Icebelt

|

M

i

|

0,70

|

0,65

|

0,55

|

0,55

|

0,50

|

0,45

|

0,45

|

| Lower

|

M

l

|

0,50

|

0,45

|

0,40

|

0,35

|

0,30

|

0,25

|

0,25

|

| Bottom

|

M

b

|

0,30

|

0,30

|

0,25

|

see Note 2

|

see Note 2

|

see Note 2

|

see Note 2

|

| Stern

(S)

|

Icebelt

|

S

i

|

0,75

|

0,70

|

0,65

|

0,60

|

0,50

|

0,40

|

0,35

|

| Lower

|

S

l

|

0,45

|

0,40

|

0,35

|

0,30

|

0,25

|

0,25

|

0,25

|

| Bottom

|

S

b

|

0,35

|

0,30

|

0,30

|

0,25

|

0,15

|

see Note 2

|

see Note 2

|

Note

2. Indicates that strengthening for ice

loads is not necessary.

|

10.9.4 Area

factors to be applied to ships assigned the notation Icebreaker are

given in Table 2.10.5 Hull area factors (AF) for

icebreaker.

Table 2.10.5 Hull area factors (AF) for

icebreaker

|

|

B

|

BIi

|

BIl

|

BIb

|

Mi

|

Ml

|

Mb

|

Si

|

Sl

|

Sb

|

|

PC1

|

1

|

0,90

|

0,70

|

0,55

|

0,70

|

0,50

|

0,30

|

0,94

|

0,56

|

0,35

|

|

PC2

|

1

|

0,85

|

0,65

|

0,50

|

0,65

|

0,45

|

0,30

|

0,88

|

0,50

|

0,30

|

|

PC3

|

1

|

0,85

|

0,65

|

0,45

|

0,55

|

0,40

|

0,25

|

0,81

|

0,44

|

0,30

|

|

PC4

|

1

|

0,85

|

0,65

|

0,45

|

0,55

|

0,40

|

0,25

|

0,81

|

0,44

|

0,30

|

|

PC5

|

1

|

0,85

|

0,65

|

0,45

|

0,55

|

0,40

|

0,25

|

0,81

|

0,44

|

0,30

|

|

PC6

|

1

|

1

|

0,65

|

0,45

|

0,55

|

0,40

|

0,25

|

0,81

|

0,44

|

0,30

|

|

PC7

|

1

|

1

|

0,65

|

0,45

|

0,55

|

0,40

|

0,25

|

0,81

|

0,44

|

0,30

|

10.10 Shell plate requirements

10.10.1 The

required minimum shell plate thickness, t, is given by:

where

10.10.2 The thickness of shell plating required to resist the design ice load,

t

net, depends on the orientation of the framing. The plating net thickness is

given by Table 2.10.6 Shell plate thickness.

Table 2.10.6 Shell plate thickness

| Transversely framed plating

see Note 1

|

Obliquely framed plating

|

Longitudinally framed plating

|

| Ω ≥ 70°

|

70° > Ω >

20°

|

Ω ≤

20°

|

|

b ≥ s

|

b < s

|

|

linear interpolation

|

|

|

| Symbols

|

| where

|

|

s

|

= |

transverse frame spacing in transversely-framed ships

or longitudinal frame spacing in longitudinally-framed ships,

measured along the girth, in metres |

|

|

|

|

|

|

|

|

σ

y

|

= |

minimum upper yield stress of the material, in

N/mm2

|

|

|

b

|

= |

height of design load patch, in m, where b ≤

I  in the case of determination of the net

thickness for transversely framed plating in the case of determination of the net

thickness for transversely framed plating |

|

|

l |

= |

distance between frame supports, i.e. equal to the

frame span as given in Pt 8, Ch 2, 10.11 Framing General 10.11.5, but not reduced for any

fitted end brackets, in metres. When a load-distributing stringer

is fitted, the length, l, need not be taken larger than the

distance from the stringer to the most distant frame support. |

|

|

Note 1. Includes plating in hull areas BIb,

Mb and Sb regardless of actual

frame orientation.

|

Figure 2.10.3 Shell framing angle Ω

10.11 Framing General

10.11.2 The term framing member refers to transverse and longitudinal local

frames, load-carrying stringers and web frames in the areas of the hull exposed to ice

pressure, see

Figure 2.10.1 Extent of hull areas. Where load-distributing stringers

have been fitted, the arrangement and scantlings of these are to be suitably designed.

10.11.3 The

strength of a framing member is dependent upon the fixity that is

provided at its supports. Fixity can be assumed where framing members

are either continuous through the support or attached to a supporting

section with a connection bracket. In other cases, simple support

is to be assumed unless the connection can be demonstrated to provide

significant rotational restraint. Fixity is to be ensured at the support

of any framing which terminates within an ice-strengthened area.

10.11.4 The

details of framing member intersection with other framing members,

including plated structures, as well as the details for securing the

ends of framing members at supporting sections, are to be in accordance

with Pt 3, Ch 10 Welding and Structural Details.

10.11.5 The effective span of a framing member is to be determined on the basis of

its moulded length. If brackets are fitted, the effective span may be reduced in

accordance with Pt 3, Ch 3 Structural Design.

10.11.6 When

calculating the section modulus and shear area of a framing member,

the net thicknesses of the web, flange (if fitted) and attached shell

plating are to be used. The shear area of a framing member may include

that material contained over the full depth of the member, i.e. web

area including portion of flange, if fitted, but excluding attached

shell plating.

10.11.7 The actual net effective shear area, A

w, of a transverse or longitudinal local frame is given by:

where

|

t

wn

|

= |

net web thickness, in mm |

|

φw

|

= |

smallest angle between shell plate and stiffener web, measured at the

midspan of the stiffener, see

Figure 2.10.4 Stiffner geometry. The angle φw may be taken as

90° provided the smallest angle is not less than 75°. |

10.11.8 When the cross-sectional area of the attached plate flange exceeds the

cross-sectional area of the local frame, the actual net effective plastic section

modulus, Zp, of a transverse or longitudinal frame is given by:

|

Z

p

|

= |

cm3 cm3

|

where

|

A

pn

|

= |

net cross-sectional area of the local frame, in cm2

|

|

A

fn

|

= |

net cross-sectional area of local frame flange, in cm2

|

h, t

w, t

c and φw as given in Pt 8, Ch 2, 10.11 Framing General 10.11.7

s as

given in Pt 8, Ch 2, 10.10 Shell plate requirements 10.10.2

10.11.9 When

the cross-sectional area of the local frame exceeds the cross-sectional

area of the attached plate flange, the plastic neutral axis is located

a distance z

na above the attached shell plate,

given by:

|

z

na

|

= |

mm mm |

and the net effective plastic section modulus, Zp, of a

transverse or longitudinal frame is given by:

|

Z

p

|

= |

cm3 cm3

|

10.12 Framing Local frames in bottom structures

and transverse local frames in side structures

10.12.1 The local frames in bottom structures (i.e. hull

areasBIb, Mb and Sb) and

transversely-framed side structures are to be dimensioned such that the combined effects

of shear and bending do not exceed the plastic strength of the member. The plastic

strength is defined by the magnitude of midspan load that causes the development of a

plastic collapse mechanism. For bottom structures the load patch shall be applied with

the dimension b parallel to the frame direction.

10.12.2 The

actual net effective shear area of the frame, A

w,

as defined in Pt 8, Ch 2, 10.11 Framing General 10.11.7, is

to comply with the following condition:

where

|

A

t

|

= |

cm2 cm2

|

|

l

L

|

= |

length of loaded portion of span, in metres |

- need not exceed the lesser of a and b

|

a

|

= |

local frame span as defined in Pt 8, Ch 2, 10.11 Framing General 10.11.5, in metres |

|

b

|

= |

height of design ice load patch according to 10.6, in metres |

|

s

|

= |

spacing of local frame, in metres |

|

AF

|

= |

hull area factor from Table 2.10.4 Hull area factors (AF) or Table 2.10.5 Hull area factors (AF) for

icebreaker, as appropriate |

|

K

t

|

= |

peak pressure factor from Table 2.10.3 Peak pressure factors, as appropriate |

|

P

a

|

= |

average pressure within load patch according to Pt 8, Ch 2, 10.8 Pressure within the design load patch, in

MPa |

|

σy

|

= |

minimum upper yield stress of the material, in N/mm2

|

10.12.3 The actual net effective plastic section modulus of the plate/stiffener

combination, Z

p, as defined in Pt 8, Ch 2, 10.11 Framing General 10.11.8 or Pt 8, Ch 2, 10.11 Framing General 10.11.9, is to comply with the following conditions and is

to be the greatest of the two load conditions:

-

ice load acting at the midspan of the local frame, and

-

the ice load acting near a support.

- where

|

Z

pt

|

= |

|

|

Y

|

= |

1

|

|

A

1

|

= |

reflects the two conditions and is to be taken as the

greater of A

1A orA

1B

|

|

A

1A

|

= |

|

|

A

1B

|

= |

|

|

j

|

= |

1 for a local frame with one simple support outside the ice

strengthened areas |

| = |

2 for a local frame without any simple supports |

|

a

1

|

= |

|

|

A

t

|

= |

rule minimum shear area of the local frame as given in

Pt 8, Ch 2, 10.12 Framing Local frames in bottom structures and transverse local frames in side structures 10.12.2, in cm2

|

|

A

w

|

= |

effective net shear area of the local frame (calculated

according to Pt 8, Ch 2, 10.11 Framing General 10.11.7), in cm2

|

|

k

w

|

= |

|

|

A

fn

|

= |

as given in Pt 8, Ch 2, 10.11 Framing General 10.11.8

|

|

k

z

|

= |

in general in general |

| = |

0 when the frame is arranged with end bracket |

|

z

p

|

= |

sum of individual plastic section modulii of flange and

shell plate as fitted, in cm3

|

| = |

|

|

b

f

|

= |

flange breadth, in mm, see

Figure 2.10.4 Stiffner geometry

|

|

t

fn

|

= |

net flange thickness, in mm |

| = |

tf - tc

|

|

t

c

|

= |

as given in Pt 8, Ch 2, 10.11 Framing General 10.11.7

|

|

t

f

|

= |

as-built flange thickness, in mm, see

Figure 2.10.4 Stiffner geometry

|

|

t

pn

|

= |

the fitted net shell plate thickness, in mm, but is not to

be less than t

n as given in Pt 8, Ch 2, 10.10 Shell plate requirements

|

|

b

e

|

= |

effective width of shell plate flange, in mm |

| = |

500s

|

|

Z

p

|

= |

net effective plastic section modulus of the local frame

(calculated according to Pt 8, Ch 2, 10.11 Framing General 10.11.8 or Pt 8, Ch 2, 10.11 Framing General 10.11.9), in cm3

|

AF, K

t, P

a, l

L, b, s, a and σy are as given in

Pt 8, Ch 2, 10.12 Framing Local frames in bottom structures and transverse local frames in side structures 10.12.2.

10.13 Framing Longitudinal local frames in side

structures

10.13.1 Longitudinal local frames in side structures are to be dimensioned such

that the combined effects of shear and bending do not exceed the plastic strength of the

member. The plastic strength is defined by the magnitude of midspan load that causes the

development of a plastic collapse mechanism.

10.13.2 The

actual net effective shear area of the frame, A

w,

as defined in Pt 8, Ch 2, 10.11 Framing General 10.11.7, is

to comply with the following condition:

A

w ≥ A

L

where

|

A

L

|

= |

|

|

AF

|

= |

hull area factor from Table 2.10.4 Hull area factors (AF) or Table 2.10.5 Hull area factors (AF) for

icebreaker, as appropriate |

|

K

s

|

= |

peak pressure factor from Table 2.10.3 Peak pressure factors, as appropriate |

|

P

a

|

= |

average pressure within load patch according to Pt 8, Ch 2, 10.8 Pressure within the design load patch 10.8.1, in MPa |

|

b

1

|

= |

k

o

b

2 m |

|

k

o

|

= |

|

|

b'

|

= |

|

|

b

|

= |

height of design ice load patch from Pt 8, Ch 2, 10.7 Design load patch, in metres |

|

s

|

= |

spacing of longitudinal frames, in metres |

|

b

2

|

= |

b(1-0,25b') m if b'<2 |

10.13.3 The

actual net effective plastic section modulus of the plate/stiffener

combination, Z

p, as defined in Pt 8, Ch 2, 10.11 Framing General 10.11.8 or Pt 8, Ch 2, 10.11 Framing General 10.11.9, is to comply with the

following condition:

AF, K

s, P

a, b

1, a and σy are

as given in Pt 8, Ch 2, 10.13 Framing Longitudinal local frames in side structures 10.13.2.

10.14 Framing Web frame and load carrying stringers

10.14.1 Web frames and load-carrying stringers are to be designed to withstand the

ice load patch as defined in Pt 8, Ch 2, 10.8 Pressure within the design load patch. The load patch is to be applied at locations where

the capacity of these members under the combined effects of bending and shear is

minimised.

10.14.2 Web frames and load-carrying stringers are to be dimensioned to take into

account the combined effects of shear and bending. Where the structural configuration is

such that members do not form part of a grillage system, the appropriate peak pressure

factor, K

i, from Table 2.10.3 Peak pressure factors is to be used. Special attention is to be paid

to the shear capacity in way of lightening holes and cut-outs in way of intersecting

members.

10.14.3 For determination of scantlings on load carrying stringers, web frames supporting local

frames, or web frames supporting load carrying stringers forming part of a structural

grillage system, appropriate methods as outlined in Pt 8, Ch 2, 10.28 Direct calculations are normally to be

used.

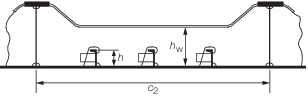

10.15 Framing Structural stability

10.15.1 To

prevent local buckling in the web, the ratio of web height, h

w, to net web thickness, t

wn, of any

framing member is not to exceed:

For flat bar sections:

For bulb, tee and angle sections:

where

|

h

w

|

= |

web height |

|

t

wn

|

= |

net web thickness |

|

σy

|

= |

minimum upper yield stress of the shell plate in way of the framing

member, in N/mm2

|

10.15.2 Framing members for which it is not practicable to meet the requirements of

Pt 8, Ch 2, 10.15 Framing Structural stability 10.15.1(e.g. load carrying stringers or deep web frames) are

required to have their webs effectively stiffened. The scantlings of the web stiffeners

are to ensure the structural stability of the framing member. The minimum net web

thickness for these framing members is given by:

10.15.3 In

addition, the following is to be satisfied:

-

t

wn ≥

where

|

σy

|

= |

minimum

upper yield stress of the shell plate in way of the framing member,

in N/mm2

|

|

t

wn

|

= |

net thickness of the web, in mm |

|

t

pn

|

= |

net thickness of the shell plate in way the framing member, in

mm. |

10.15.4 To

prevent local flange buckling of welded profiles, the following are

to be satisfied:

-

The flange width, b

f, in mm, is not to be less than five times the

net thickness of the web, t

wn.

-

The flange outstand, b

o, in mm, is to meet the following requirement:

- where

|

t

fn

|

= |

net thickness of flange, in mm |

|

σy

|

= |

minimum upper yield stress of the material, in

N/mm2. |

Figure 2.10.5 Parameter definition for web stiffening

10.16 Plated structures

10.16.1 Plated

structures are those stiffened plate elements in contact with the

hull and subject to ice loads. These requirements are applicable to

an inboard extent which is the lesser of:

-

web height of

adjacent parallel web frame or stringer; or

-

2,5 times the

depth of framing that intersects the plated structure.

10.16.2 The

thickness of the plating and the scantlings of attached stiffeners

are to be such that the degree of end fixity necessary for the shell

framing is ensured.

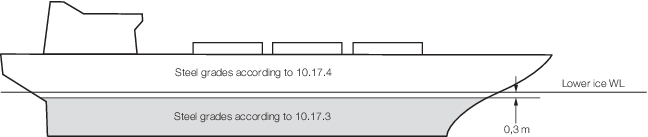

10.17 Corrosion/abrasion additions and steel renewal

10.17.1 Effective protection against corrosion and ice-induced abrasion is

recommended for all external surfaces of the shell plating for Polar Class ships.

10.17.3 Polar Class ships are to have a minimum corrosion/abrasion addition of

ts = 1,0 mm applied to all internal structures within the ice

strengthened hull areas, including plated members adjacent to the shell, as well as

stiffener webs and flanges.

10.17.4 Steel renewal for ice strengthened structures is required when the gauged

thickness is less than tn + 0,5 mm.

Figure 2.10.6 Steel grade requirements for submerged and weather exposed shell plating

Table 2.10.7 Corrosion/abrasion additions for shell plating

| Hull

area

|

t

s, in

mm

|

| With effective protection

|

Without effective protection

|

|

PC1 to PC3

|

PC4 and PC5

|

PC6 and PC7

|

PC1 to PC3

|

PC4 and PC5

|

PC6 and PC7

|

| Bow;

Bow Intermediate Icebelt

|

3,5

|

2,5

|

2,0

|

7,0

|

5,0

|

4,0

|

| Bow Intermediate

Lower; Midbody & Stern Icebelt

|

2,5

|

2,0

|

2,0

|

5,0

|

4,0

|

3,0

|

| Midbody and

Stern Lower; Bottom

|

2,0

|

2,0

|

2,0

|

4,0

|

3,0

|

2,5

|

10.18 Materials

10.18.5 Castings

are to have specified properties consistent with the expected service

temperature for the cast component.

Table 2.10.8 Material classes for structural

members of polar ships

| Structural members

|

Material Class

|

| Shell plating

within the bow and bow intermediate icebelt hull areas (B, BIi

)

|

II

|

| Plating materials

for stem and stern frames, rudder horn, rudder, propeller nozzle, shaft

brackets, ice skeg, ice knife and other appendages subject to ice impact

loads

|

II

|

| All weather and sea

exposed SPECIAL, as defined in Table 2.2.1 Material classes and

grades inPt 3, Ch 2 Materials, structural members within

0,2L from FP

|

II

|

| All weather and sea

exposed SECONDARY and PRIMARY, as defined in Table 2.2.1 Material classes and

grades inPt 3, Ch 2 Materials, structural members outside

0,4L amidships

|

I

|

| All inboard framing

members attached to the weather and sea-exposed plating including any

contiguous inboard member within 600 mm of the plating

|

I

|

| Weather-exposed

plating and attached framing in cargo holds of ships which by nature of

their trade have their cargo hold hatches open during cold weather

operations

|

I

|

Table 2.10.9 Steel grades for weather exposed

plating

|

Thickness, t

mm

|

Material Class I

|

|

PC1 to 5

|

PC6 and 7

|

| MS

|

HT

|

MS

|

HT

|

|

t ≤ 10

|

B

|

AH

|

B

|

AH

|

| 10 < t ≤ 15

|

B

|

AH

|

B

|

AH

|

| 15 < t ≤ 20

|

D

|

DH

|

B

|

AH

|

| 20 < t ≤ 25

|

D

|

DH

|

B

|

AH

|

| 25 < t ≤ 30

|

D

|

DH

|

B

|

AH

|

| 30 < t ≤ 35

|

D

|

DH

|

B

|

AH

|

| 35 < t ≤ 40

|

D

|

DH

|

D

|

DH

|

| 40 < t ≤ 45

|

E

|

EH

|

D

|

DH

|

| 45 < t ≤ 50

|

E

|

EH

|

D

|

DH

|

Note Includes weather exposed plating of hull structures and

appendages, as well as their outboard framing members, situated above

a level of 0,3 m below the lowest ice waterline.

|

Table 2.10.10 Steel grades for weather exposed

plating

|

|

Material Class II

|

|

Thickness, t

mm

|

PC1 to 5

|

PC6 and 7

|

|

|

MS

|

HT

|

MS

|

HT

|

|

t ≤ 10

|

B

|

AH

|

B

|

AH

|

| 10 < t ≤ 15

|

D

|

DH

|

B

|

AH

|

| 15 < t ≤ 20

|

D

|

DH

|

B

|

AH

|

| 20 < t ≤ 25

|

D

|

DH

|

B

|

AH

|

| 25 < t ≤ 30

|

E

|

EH, see

Note 2

|

D

|

DH

|

| 30 < t ≤ 35

|

E

|

EH

|

D

|

DH

|

| 35 < t ≤ 40

|

E

|

EH

|

D

|

DH

|

| 40 < t ≤ 45

|

E

|

EH

|

D

|

DH

|

| 45 < t ≤ 50

|

E

|

EH

|

D

|

DH

|

Note

1. Includes weather exposed plating of

hull structures and appendages, as well as their outboard framing

members, situated above a level of 0,3 m below the lowest ice

waterline.

Note

2. Grades D, DH are allowed for a single

strake of side shell plating not more than 1,8 m wide from 0,3 m below

the lowest ice waterline.

|

Table 2.10.11 Steel grades for weather exposed

plating

| Thickness, t mm

|

Material Class III

|

|

PC1 to 3

|

PC4 and 5

|

PC6 and 7

|

| MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

|

t ≤ 10

|

E

|

EH

|

E

|

EH

|

B

|

AH

|

| 10 < t ≤ 15

|

E

|

EH

|

E

|

EH

|

D

|

DH

|

| 15 < t ≤ 20

|

E

|

EH

|

E

|

EH

|

D

|

DH

|

| 20 < t ≤ 25

|

E

|

EH

|

E

|

EH

|

D

|

DH

|

| 25 < t ≤ 30

|

E

|

EH

|

E

|

EH

|

E

|

EH

|

| 30 < t ≤ 35

|

E

|

EH

|

E

|

EH

|

E

|

EH

|

| 35 < t ≤ 40

|

F

|

FH

|

E

|

EH

|

E

|

EH

|

| 40 < t ≤ 45

|

F

|

FH

|

E

|

EH

|

E

|

EH

|

| 45 < t ≤ 50

|

F

|

FH

|

F

|

FH

|

E

|

EH

|

Note Includes weather exposed plating of hull structures and

appendages, as well as their outboard framing members, situated above

a level of 0,3 m below the lowest ice waterline.

|

10.19 Longitudinal strength Application

10.19.1 A ramming impact on the bow is the design scenario for the evaluation of the

longitudinal strength of the hull.

10.19.3 Ice loads are only to be combined with still water loads. The combined

stresses are to be compared against permissible bending and shear stresses at different

locations along the ship's length. In addition, sufficient local buckling strength is

also to be verified.

10.20 Design vertical ice force at the bow

10.20.1 The design vertical ice force at the bow, FIB, is to be

taken as the lesser of FIB, 1 or FIB, 2:

|

FIB, 1

|

= |

|

where

|

K

I

|

= |

indentation parameter |

|

|

= |

|

|

K

f

|

= |

for blunt bow forms:

- for wedge bow forms (αs < 80 deg), eb = 1 and the

above simplifies to:

|

|

|

= |

An approximate eb determined

by a simple fit is acceptable

|

|

|

= |

1,0 for a simple

wedge bow form |

|

|

= |

0,4 to 0,6 for

a spoon bow form |

|

|

= |

0 for a landing

craft bow form |

|

γs

|

= |

stem

angle to be measured between the horizontal axis and the stem tangent

at the upper ice waterline, in degrees (buttock angle as per Figure 2.10.2 Definition of hull angles measured on the centreline)

|

|

C

|

= |

|

|

BUI |

= |

the greatest moulded breadth corresponding to the upper ice waterline

(UIWL), in metres |

|

L

B

|

= |

bow length, in m, used in the equation: |

|

A

wp

|

= |

waterplane area corresponding to the upper ice waterline (UIWL), in

m2

|

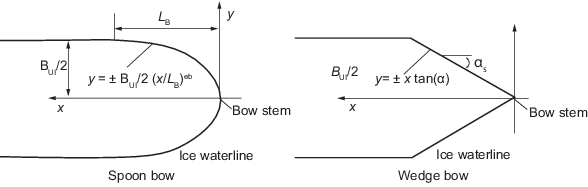

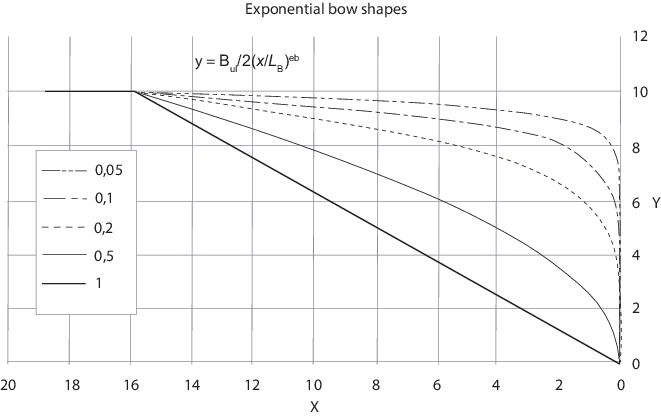

Figure 2.10.7 Bow shape definition

Figure 2.10.8 Illustration of effect on the bow

shape eb, for B = 20 and LB = 16

10.21 Design vertical shear force

10.21.1 The

design vertical ice shear force, F

I, along

the hull girder is to be taken as:

where

|

C

f

|

= |

longitudinal distribution factor to be taken as follows: |

- Positive shear force

|

C

f

|

= |

0,0 between the aft end of LUI and

0,6LUI from aft |

|

C

f

|

= |

1,0 between 0,9LUI from aft and the forward

end of L

UI |

- Negative shear force

|

Cf

|

= |

0,0 at the aft end of LUI

|

|

Cf

|

= |

-0,5 between 0,2LUI and 0,6

LUI from aft |

|

Cf

|

= |

0,0 between 0,8LUI from aft and the forward

end of LUI

|

Intermediate values are to be determined by linear

interpolation.

10.21.2 The

applied vertical shear stress, τa, is to be determined

along the hull girder in a similar manner as in Pt 3, Ch 4 Longitudinal Strength by substituting the design

vertical ice shear force for the design vertical wave shear force.

10.22 Design vertical ice bending moment

10.22.1 The design vertical ice bending moment, MI, along the hull

girder is to be taken as:

|

MI

|

= |

0,1 Cm

LUI sin0,2(γs) FIB MNm |

where

|

FIB

|

= |

design vertical ice force at the bow, in MN |

|

Cm

|

= |

longitudinal distribution factor for design vertical ice bending

moment to be taken as follows: |

|

Cm |

= |

0,0 at the aft end of LUI

|

|

Cm

|

= |

1,0 between 0,5LUI and 0,7LUI

from aft |

|

Cm |

= |

0,3 at 0,95LUI from aft |

|

C

m |

= |

0,0 at the forward end of LUI

|

- Intermediate values are to be determined by linear interpolation.

10.22.2 The applied vertical bending stress, σa, is to be determined

along the hull girder in a similar manner as in Pt 3, Ch 4 Longitudinal Strength, by substituting the design vertical ice bending moment for

the design vertical wave bending moment. The ship still water bending moment is to be

taken as the permissible still water bending moment in sagging condition.

10.23 Longitudinal strength criteria

10.23.1 The

strength criteria provided in Table 2.10.12 Longitudinal strength

criteria are to be satisfied. The design stress is not to exceed

the permissible stress.

Table 2.10.12 Longitudinal strength

criteria

| Failure mode

|

Applied stress

|

Permissible

stress

|

Permissible

stress

|

|

|

|

| Tension

|

σa

|

η σy

|

η

0,41(σu + σy)

|

| Shear

|

τa

|

|

|

| Buckling

|

σa

|

σ

|

for plating and

for web plating of stiffeners

|

|

|

|

|

for

stiffeners

|

|

|

τa

|

τc

|

| Symbols

|

|

σa

|

= |

applied vertical bending stress, in N/mm2

|

|

|

τa

|

= |

applied vertical shear stress, in N/mm2

|

|

|

σy

|

= |

minimum upper yield stress of the material, in

N/mm2

|

|

|

σu

|

= |

ultimate tensile strength of material, in

N/mm2

|

|

|

|

|

|

|

η |

= |

0,8 |

| = |

0,6 for ships which are assigned the additional

notation Icebreaker |

|

10.24 Stem and stern frames

10.25 Rudders

10.25.1 Rudder scantlings, posts, rudder horns, solepieces, rudder stocks,

steering engines, and pintles are to be dimensioned in accordance with Pt 3, Ch 6 Aft End Structure and Pt 3, Ch 13 Ship Control Systems as appropriate. The speed used in the calculations

is to be the maximum service speed or that given in Table 2.10.13 Minimum speed, whichever is the

greater. When used in association with the speed given in Table 2.10.13 Minimum speed, the rudder profile

coefficients are to be taken as 1,1.

10.25.2 For the astern condition the actual astern speed or half the minimum

speed defined in Table 2.10.13 Minimum speed is to

be used, whichever is greater.

10.25.4 Local scantlings of rudders are to be determined considering that the

rudder belongs to the stern ice belt/ice belt lower, depending on rudder location

with respect to the lower extent of the ice belt. Rudder local plating and framing

located above the lower extent of the main ice belt are to be dimensioned using the

stern ice belt area factor applicable to the relevant Polar Class. Rudder local

plating and framing located below the lower extent of the main ice belt are to be

dimensioned using the stern lower ice belt area factor applicable to the relevant

Polar Class.

10.25.5 For scantlings of the rudder blade the plate thickness is to be

determined in accordance with Pt 8, Ch 2, 10.10 Shell plate requirements using the

rudder web frame spacing. The aspect ratio of the panel under consideration is to be

used to determine the appropriate selection of formulae for transverse or

longitudinally framed plating. Where the aspect ratio is 1,0, the panel is to be

considered transversely framed.

10.25.6 The vertical and horizontal web thickness is not to be less than

0,7tR, but is not to be taken as less than 8 mm, where

tR is the rudder plate thickness.

10.25.7 The mainpiece is to be dimensioned in accordance with Pt 3, Ch 13 Ship Control Systems, utilising the basic stock diameter

derived using in the minimum speed in Table 2.10.13 Minimum speed.

Table 2.10.13 Minimum speed

| Ice

Class

|

Minimum

speed, in knots

|

Ice

Class

|

Minimum

speed, in knots

|

| PC7

|

18

|

Icebreaker,

PC7

|

22

|

| PC6

|

20

|

Icebreaker,

PC6

|

24

|

| PC5

|

22

|

Icebreaker,

PC5

|

28

|

| PC4

|

25

|

Icebreaker,

PC4

|

32

|

| PC3

|

28

|

Icebreaker,

PC3

|

35

|

| PC2

|

31

|

Icebreaker,

PC2

|

38

|

| PC1

|

34

|

Icebreaker,

PC1

|

42

|

10.26 Appendages

10.26.1 All

appendages are to be designed to withstand forces appropriate for

the location of their attachment to the hull structure or their position

within a hull area.

10.27 Local details

10.27.1 Local

design details are to be suitably designed to transfer ice-induced

loads to supporting structure (bending moments and shear forces).

10.27.2 The

loads carried by a member in way of cut-outs are not to cause instability.

Where necessary, the structure is to be stiffened.

10.28 Direct calculations

10.28.2 Direct calculations are to be used for load carrying stringers and web frames forming

part of a grillage system.

10.28.3 Where direct calculation is used to check the strength of structural

systems, the load patch specified in Pt 8, Ch 2, 10.3 Design ice loads General is

to be applied, without being combined with any other loads. The load patch is to be

applied at locations where the capacity of these members under the combined effects of

bending and shear is minimised. Special attention is to be paid to the shear capacity in

way of lightening holes and cut-outs in way of intersecting members.

10.28.5 If the structure is evaluated based on linear calculation methods, the

following are to be considered:

- Web plates and flange elements in compression and shear to fulfil

relevant buckling criteria in accordance with the applicable ShipRight SDA

procedures. See

Pt 3, Ch 16, 3 Structural design assessment.

- Nominal shear stresses in member web plates to be less than

sy/√3

- Nominal von Mises stresses in member flanges to be less than 1,15

sy

10.28.6 If the structure is evaluated based on non-linear calculation methods, the following are

to be considered:

- The analysis is to reliably capture buckling and plastic deformation of the

structure.

- The acceptance criteria are to ensure a suitable margin against fracture and

major buckling and yielding causing significant loss of stiffness.

- Permanent lateral and out-of plane deformation of considered member are to be

minor relative to the relevant structural dimensions.

10.29 Welding

10.29.1 All

welding within ice-strengthened areas is to be of the double continuous

type.

10.29.2 Continuity

of strength is to be ensured at all structural connections.

|