Section

4 Survey during construction

4.1 Quality control and quality assurance

4.1.1 Surveyors should

discuss and establish with the Builder, a satisfactory routine for

quality control and survey throughout the various stages of construction.

Records should be kept by the Builders, and made available to the

Surveyors.

4.1.2 Builders may

apply for approval under the Quality Assurance Scheme for Hull Construction.

4.2 Ship construction standards

4.2.1 The general

tolerance and construction standards are to be in accordance with

the requirements of this section, and other approved standards agreed.

4.2.2 Tolerances

to be used for construction misalignment for all material are to be

discussed between Owners/ Builders and the Surveyor, and acceptable

Standards agreed, subject to the requirements of this Chapter or Naval

Authority requirements where applicable. The permitted degree of inaccuracy/

misalignment will vary according to whether the defect is:

-

In primary structure.

-

In secondary structure.

-

Required for equipment

alignment.

-

Cosmetic.

4.2.3 In addition,

certain critical locations identified by the plan approval process

may be subject to specific construction tolerances which will require

to be recorded in accordance with the procedures.

4.2.4 All workmanship

is to be of good quality and in accordance with good shipbuilding

practice. Any defect is to be rectified to the satisfaction of the

Surveyor before the material is covered with paint, cement or other

composition. The materials and welding are to be in accordance with

the requirements of the Rules for Materials. Plates which have been

subjected to excessive heating while being worked are to be satisfactorily

heat treated before being erected in the hull.

4.2.5 In shipyards

certified under the LR Quality Assurance Scheme, the standards will

have received general approval as part of the certification procedures

and their application to particular vessels should be included in

the Quality Plan submitted to the local Surveyors for approval.

4.3 Prefabrication

4.3.1 Surveyors will

attend in the early stages of construction to ensure that undesirable

procedures and faulty workmanship are avoided, and possible consequences

minimized. When the existence of defects is noticed, prompt and suitable

measures should be taken to ensure rectification. Where, due to circumstances,

major prefabrication of units has been carried out without inspection

by LR, then Headquarters should be advised immediately, such advice

including details of the circumstances.

4.3.2 Throughout

the preparation of material and assembly of prefabricated units, workmanship

is to be inspected to ensure that correct procedures are being followed.

Surveyors will liaise with the Design Offices and the Quality Control

Departments to ensure that any plan approval comments are incorporated

and that attention is given to details which are not shown on the

approved plans (e.g. air and drainage holes, etc.) during early material

preparation stages.

4.3.3 Surveyors should

bear in mind that visual examination of welds and plating of a finished

structure does not necessarily ensure a complete and satisfactory

survey. Surveyors should ensure that adequate inspection is made of

joint preparation before welding. Attention is drawn to the guidance

on welding and structural details in Vol 1, Pt 6, Ch 6 Material and Welding Requirements of the Rules for Naval Ships. Regular examination,

in conjunction with the Builder, of radiographic records provides

a check on the quality of welding operations and any decline in standards

should be investigated, including additional tests as considered necessary.

4.3.4 It is essential

that a good standard of cleaning be achieved for these surveys. Welding

slag should be removed and rusting of weld deposits should be removed

by wire brushing. Work should not be surveyed if presented insufficiently

prepared for inspection.

4.4 Assembly of units

4.4.1 Surveyors must

ensure, by regular and systematic examination, that the control exercised

up to the stage of block assembly is maintained by the efficient erection

of blocks at the berth. It is particularly necessary at this point

to ensure that fit up, alignment, adjustment and welding of blocks

is in accordance with the approved plans and building standards. Attention

is to be given to the sequence of erection and of welding.

4.5 Structural misalignment and fit

4.5.2

Table 3.4.2 Structural misalignment and fit

(see continuation) defines the minimum limits

of accuracy required to be achieved in the various welded joint designs.

When these values are not achieved, the defects are to be discussed

and rectification agreed between the Builder and the Surveyor before

remedial action is taken.

4.5.3 Limits for

weld undercut and remedial action to be taken depends on plate thickness

and are to be discussed and rectification agreed between the Builder

and the Surveyor prior to commencement of repairs.

4.6 Post-welding plate deformation

4.6.1 Post-welding

deformation of steel construction should be kept to a minimum.

4.6.3 Controlled

and localized heating of steel is not to exceed 900°c (red heat).Where

water cooling is employed the steel temperature is to be below 600°c

before any water is applied.

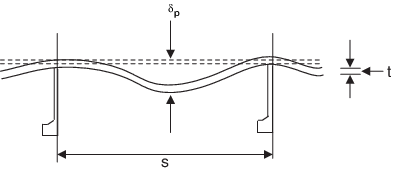

Table 3.4.1 Plate deformation limits

| Position

|

s/t

|

δp/s

|

| from 0,2L

R to 0,8L

R

|

≤ 80

>

80

|

1/100

1/75

|

| Remainder

|

all

|

1/50

|

where

|

L

R

|

= |

Rule length in m |

|

s |

= |

stiffener spacing, in mm |

|

t |

= |

plating thickness, in mm |

|

δp

|

= |

actual panel deflection, in mm |

|

Figure 3.4.1 Measurement of plate deformation

4.6.4 With the assembly

of large blocks, careful attention should be paid to the areas in

way of lifting lugs. It is not unusual to find small fractures in

the vicinity of the weld area after removal of lugs. Where lugs are

removed, the dressing of the plate must be thorough and magnetic particle

or dye penetrant detection of the finished surface is good practice.

Repair of any cracks found must be carried out by qualified welders

under strict control.

4.6.5 Any unusual

incidents during construction, such as fracturing of plates, should

be noted and brought to the attention of the local Manager with a

view to a suitable report being made. It will be necessary to have

full information on the circumstances affecting such cases, such as

the position and extent of the fracture relative to adjacent structure

and welds, atmospheric temperature, details of joints, precise stage

and sequence of welding, type of electrode used, whether or not pre-heating

was used, grades of steel involved and any other factors considered

to have had a possible influence. Test details of affected plates

and proposals for remedial measures should also be reported. Where

doubt exists in establishing the source of such incidents, the assistance

of LR Headquarters may be sought.

4.7 Accessibility

4.7.1 Surveyors in

building yards should bear in mind the need for accessibility in a

vessel in service. Surveyors should ensure, as far as possible, that

access is adequate for future maintenance and surveys. In many cases,

the only reasonable sized access holes available have access restricted

by pipe runs.

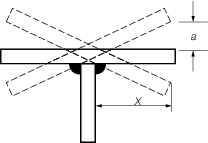

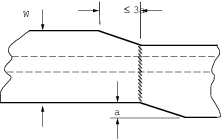

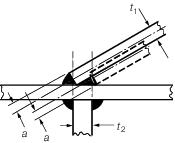

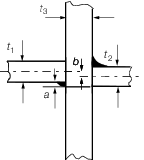

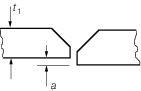

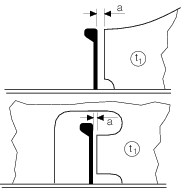

Table 3.4.2 Structural misalignment and fit

(see continuation)

| Joint

|

Location

|

Multiple

defects

|

Isolated

defects

|

Remedial action

|

| Built section

flanges

|

All areas

|

a ≤ ± 0,015 x

|

a ≤ ± 0,03 x

|

|

Realign

|

|

| Flange

alignment

|

|

|

|

|

|

|

Primary

structure

|

-

|

a ≤ 0,03W

(max 6 mm)

|

a > 0,03W

|

Release over

50a

and realign

|

Secondary

structure

|

a ≤ 0,03W

max 6 mm)

|

a ≤ 0,04W

(max 8 mm)

|

a > 0,04W

|

Taper over 3a

|

|

|

|

|

a > 0,08W

|

Release over

5w

and realign

|

| Stiffener but

|

All areas

|

|

|

|

|

|

For angle or

tee

longitudinal

a ≤ 0,2t

1

|

For angle or

tee

longitudinal

a ≤ 0,2t

1

|

a > 0,2t

1

|

Reject

|

For offset

bulb

longitudinal

a ≤ 0,2t

2

|

For offset

bulb

longitudinal

a ≤ 0,2t

2

|

a > 0,2t

2

|

Reject

|

| Angled intersection

|

All

areas

|

-

|

a ≤ t

1/2

|

a > t

1/2

|

Realign

|

|

| Cruciform joint

|

|

|

|

|

|

|

Strength members

members

|

-

|

a ≤ t

2/3

|

a ≤ t

2/2

|

Increase weld

leg

length of welds by

10%

|

Other

members

|

-

|

a ≤ t

2/2

|

a > t

2/2

|

Realign

|

HT steel

joints

in

designated

critical

areas

|

-

|

b ≤ t

2/3

|

b > t

2/3

|

Realign

|

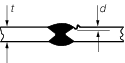

Table 3.4.3 Structural misalignment and fit (continued)

| Joint

|

Location

|

Multiple

defects

|

Isolated

defects

|

Remedial action

|

| Undercut

|

All areas

|

-

|

d ≤ 0,1t

1

(max 0,8 mm)

|

d > 0,1t

1

|

Repair by welding or

grinding

depends on thickness ‘t

1’

in

accordance with Ch 3, 2.3 Defects in steel products

|

|

| Undercut

|

All areas

|

-

|

d ≤ 0,1t

(max

0,8 mm)

|

d >

0,1t

|

As above

|

|

| Fillet weld

|

|

|

|

|

|

|

|

|

|

a ≤ 0,5t1

|

Increase weld leg length

by ‘a’

|

All areas

(continuous)

|

a ≤ 1,5 mm

|

a ≤ 0,25t

1

|

a ≤ t

1

|

Vee

material to +/–45°. Fit backing strip and weld. Remove backing

strip and complete weld.

|

| (max 16 mm)

|

|

|

a > t

1

|

Cut back 300mm and replace

|

All areas

(intermittent)

|

a ≤1,5 mm

|

a ≤ 0,25t

1

|

a ≤ 0,5t

1

(max 1,5 mm)

|

Increase weld lengths by 50%

|

a ≤ 0,5t

1

(max 5 mm)

|

Continuous weld

|

|

a > 0,5t

1

|

As for continuous weld above

|

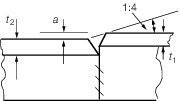

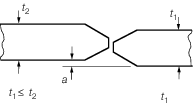

| Butt joint

|

|

|

|

|

|

|

Strength

members

|

-

|

a ≤ 0,15t

1

(max

3 mm)

|

a >

0,15t

1

|

Realign

|

| Others

|

a ≤ 0,15t

1

(max 3

mm)

|

a ≤

0,2 t

1

(max 3 mm)

|

a > 0,2t

1

|

Realign

|

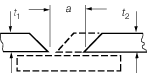

| Butt weld

|

|

|

|

|

|

|

Strength

members

|

a ≤

0,15t

1

(max 3,0 mm)

|

a ≤ 0,15t

1

(max 3,0 mm)

|

a > 0,15t

1

|

Realign

|

| Other

|

a ≤ 0,2t

1

(max 3,0 mm

|

a ≤ 0,2t

1

(max

3,0 mm)

|

a >

0,2t

1

|

Realign

|

| Butt

joint repair

|

|

|

|

|

|

|

All areas

|

-

|

a in accordance with

weld

procedure

|

a ≤ t

1

|

Build

one side of butt until a in

accordance with weld

procedure

|

a > t

1

(max 3 mm)

|

Cut back 300 mm and fit

insert

plate

|

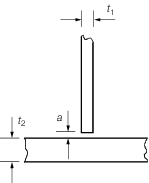

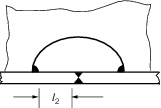

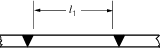

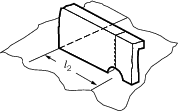

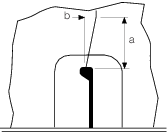

Table 3.4.4 Structural misalignment and fit

(conclusion)

| Joint

|

Location

|

Multiple

defects

|

Isolated

defects

|

Remedial

action

|

|

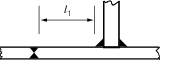

| Butt and fillet weld

|

|

|

|

|

|

|

All areas

|

-

|

l1 ≥ 40 mm

|

–

|

Adjust to

suit

|

| Butt and cutout

|

|

|

|

|

|

|

All areas

|

-

|

l 2 ≥ 20 mm

|

-

|

Adjust to suit

|

| Adjacent butts

|

|

|

|

|

|

|

All areas

|

l 1 ≥ 50 mm

|

l 1 ≥ 30 mm

|

l 1 < 30 mm

|

add insert

|

| Plate and stiffener butt

|

|

|

|

|

|

|

All areas

|

l 2 ≥ 20 mm

|

l 2 ≥ 15 mm

|

l 2 < 15 mm

|

Adjust to suit

|

| Lapped connection

|

|

|

|

|

|

|

All areas

|

a ≤ 1,0

|

a ≤ 2,0

|

a > 2

|

Increase weld leg length

by

actual ‘a’

|

|

|

|

|

a ≥ 5

|

Release and

realign

|

| Siffener connection

|

|

|

|

|

|

|

All areas

|

b ≤ 0,02a

|

|

b > 0,02a

|

Release and realign

|

| lug and bracket connection

|

|

|

|

a ≤ 0,5t

1

(max 5 mm)

|

Increase weld leg length by ‘a’

|

|

|

|

|

a ≤ t

1

|

Vee material to +/–45°. Fit backing strip and

weld. Remove backing strip and complete weld.

|

| All areas

|

a ≤ 2 mm

|

a ≤ 0,25t

1

|

(max 16 mm)

|

|

|

|

|

|

a > t

1

|

Cut back 300 mm and replace

|

4.7.2 While attention

is drawn to the need for adequate access, Surveyors should also be

alert for additional or enlarged access holes which should not be

permitted in highly stressed areas and which are sometimes fitted

at a late stage in construction.

4.7.3 It should also

be borne in mind that the lack, or bad positioning, of ladders, walkways

and manholes may render access under service conditions extremely

difficult and dangerous. The Builder’s attention should be drawn

to these considerations. In this respect, National Regulations may

specify requirements for ladders, walkways and the minimum size of

access openings.

4.7.4 Where significant

proportions of the ship’s structure are removed for access,

the Builder’s calculations demonstrating the adequacy of the

remaining structure are to be submitted.

4.8 Departures from approved arrangements

4.8.1 It is the Surveyor’s

duty to be alert through all stages of work to ensure that any significant

modifications or departures from approved arrangements are noted promptly

and dealt with as necessary. It should be clearly understood that

deviations from the Rule requirements or approved plans, other than

those of a minor nature and not affecting the structural strength

of the ship, must not be accepted by the local Surveyor without consultation

with the Surveyor-in-charge of the local LR office who, if he considers

it appropriate, should submit plans showing the proposed arrangements

to the relevant Plan Approval Office.

4.8.2 Large openings

not indicated on approved plans are not to be arranged in decks without

prior consultation with the Plan Approval Office. Small openings for

access, ventilation, etc. may be accepted by the Surveyor who should

ensure that they are adequately framed, and when necessary suitably

compensated. Requirements for compensation of loss of deck plating,

transverse cross-sectional area, and/or edge reinforcement are stated

in the appropriate sections of the Rules.

4.8.3 The corners

of openings, welded attachments to the sheerstrake (e.g. at bulwark

recesses) and small openings cut in decks may not be detailed on approved

plans and special attention should be paid to such areas to ensure

that no discontinuity, which may produce a notch effect, is built

into the structure. Adequate rounding of the corners of openings,

with grinding if necessary to a smooth finish, must be ensured to

eliminate possible sources of failure in service. The endings of bulwarks

should be smoothly tapered without any notch.

4.8.4 Defective welding

of seams or butts, with incomplete penetration, omission of sealing

runs or craters can result in fractures. When modifications have been

made which result in openings having to be closed by welded inserts,

particular attention should be paid to welding, with suitable NDE.

4.9 Marking of ship’s name, draught marks, etc. by welding

4.9.1 Draught marks

and paint lines are often permanently indicated on ships’ sides

by means of beads of welding or by letters or marks cut from steel

plate and welded to the sides.

4.9.2 Lettering on

the sheerstrake should be kept below a line 0,1D below

the deck, where D is the depth at side. Great care should

be taken in the application of the welding, which should be carried

out by qualified welders. Substantial runs should be laid continuously,

using large diameter low hydrogen electrodes and avoiding light runs

as these are more likely to promote fractures. Sharp corners in the

letters should be avoided and where the welding crosses a welded butt

or seam, the latter should be ground flat for about 75 mm each side

of the line of the weld bead before it is laid.

4.9.3 On steel of

Grade D or E or on higher tensile steel, low hydrogen electrodes should

be used of a grade suitable for the steel. In the case of higher tensile

steel, pre-heating to about 100°C should be adopted.

4.9.4 In the case

of midship draught marks which are located on special quality steel

similar precautions should be observed.

4.10 Acceptance testing on completion

4.10.2 Suitable

schedules should be produced. It is good practice to first test those

tanks which contain supporting structure, so that inspection is made

on the smooth, unencumbered sides of the bulkheads.

4.10.3 During testing,

the Surveyor should be accompanied by a responsible person and should

be satisfied that adequate lighting is available. Particular care

is to be exercised if testing is carried out during trial trips.

4.10.4 Attention

is drawn to the fact that internal boundary welds made by other than

automatic processes should not be coated before leak testing.

4.11 Launching

4.11.1 Surveyors

will normally attend and witness the launch of every vessel being

built under Special Survey. This applies also when ships are built

in a dry-dock and launching is only a symbolic inlet of water from

dock gates.

4.11.2 Under traditional

launching methods, if anything occurs which may affect the ship’s

structure, the Surveyor should carry out a careful examination for

possible damage, as circumstances require. Close attention should

be paid to examination of bottom structure in way of launching ways,

etc. after launch. Should any damage be found which is not satisfactorily

repaired before the completion of the ship, a suitable Condition of

Class should be imposed.

4.11.3 Anchors and

chain cables supplied for the equipment of a ship in service should

not be used as launching drags.

4.12 Fitting out

4.12.1 In the period

during fitting out of the accommodation, installation of electrical

conduits or ventilation trunking, particular vigilance is necessary

in order to ensure that the strength of structural members is not

impaired by the cutting. Where structural members are cut, adequate

reinforcement should be made of girders, brackets, stiffeners, etc.

It is also important that watertight or fire rated bulkheads are maintained

intact. Any doubts should be referred to the relevant Plan Approval

Office.

4.13 Completion of work after leaving the Builder’s yard

4.13.1 When a vessel

proceeds from the building port to another district for installation

of machinery, completion or dry-docking, it is required that the work

done be inspected and appropriately tested. This may be done by the

Surveyors in the port to which the ship has gone or, if the completing

port is within easy access of the building port, by the Surveyors

under whose inspection the ship was built. This is a matter for arrangement

between the LR offices concerned, the Owners and the Builders.

4.13.2 When the

survey is to be completed by the Surveyors at the port to which the

ship has gone, the building port Surveyors are to forward to them

all necessary plans and a detailed list of items outstanding for completion

of the ship and survey. Both offices are to make and agree arrangements

for the completion of reports and provision of certificates.

|