Section

2 Cylindrical shells and drums subject to internal pressure

2.1 Minimum thickness

2.1.3 Irrespective

of the thickness determined by the above formula, t is to be not less

than:

-

6,0 mm for cylindrical

shell plates.

-

For tube plates,

such thickness as will give a minimum parallel seat of 9,5 mm, or

such greater width as may be necessary to ensure tube tightness, see

Vol 2, Pt 8, Ch 1, 14.6 Fitting of tubes in water tube boilers

2.2 Efficiency of ligaments between tube holes

2.2.1 Where

tube holes are drilled in a cylindrical shell in a line or lines parallel

to its axis, the efficiency, J, of the ligaments is to

be determined as in Vol 2, Pt 8, Ch 1, 2.2 Efficiency of ligaments between tube holes 2.2.2, Vol 2, Pt 8, Ch 1, 2.2 Efficiency of ligaments between tube holes 2.2.3 and Vol 2, Pt 8, Ch 1, 2.2 Efficiency of ligaments between tube holes 2.2.4.

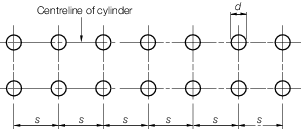

2.2.2

Regular

drilling. Where the distance between adjacent tube holes is

constant, see

Figure 1.2.1 Regular drilling,

where

|

d

|

= |

the

mean effective diameter of the tube holes, in mm, after allowing for

any serrations, counterboring or recessing, or the compensating effect

of the tube stub. See

Vol 2, Pt 8, Ch 1, 2.3 Compensating effect of tube stubs and Vol 2, Pt 8, Ch 1, 2.4 Unreinforced openings.

|

|

s

|

= |

pitch

of tube holes, in mm. |

Figure 1.2.1 Regular drilling

2.2.5 Where

the circumferential pitch between tube holes measured on the mean

of the external and internal drum or header diameters is such that

the circumferential ligament efficiency determined by the formula

in Vol 2, Pt 8, Ch 1, 2.2 Efficiency of ligaments between tube holes 2.2.2 and Vol 2, Pt 8, Ch 1, 2.2 Efficiency of ligaments between tube holes 2.2.3 is less than one-half of the

ligament efficiency on the longitudinal axis, J in Vol 2, Pt 8, Ch 1, 2.1 Minimum thickness is to be taken as twice the circumferential

efficiency.

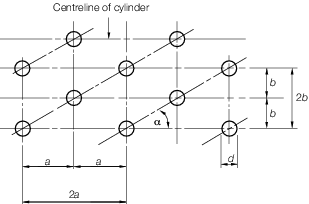

2.2.7 For

spacing of tube holes on a diagonal line as shown in Figure 1.2.3 Spacing of holes on a diagonal line, or in a regular saw-tooth

pattern as shown in Figure 1.2.4 Regular saw-tooth pattern of holes, J is to be determined from the formula in Vol 2, Pt 8, Ch 1, 2.2 Efficiency of ligaments between tube holes 2.2.8, where a and b, as shown in Figure 1.2.3 Spacing of holes on a diagonal line and Figure 1.2.4 Regular saw-tooth pattern of holes, are measured, in mm, on the

median line of the plate, and d is as defined in Vol 2, Pt 8, Ch 1, 2.2 Efficiency of ligaments between tube holes 2.2.2

2.2.9 For

regularly staggered spacing of tube holes as shown in Figure 1.2.5 Regular staggering of holes, the smallest value of

the efficiency, J, of all ligaments (longitudinal, circumferential

and diagonal) is to be used where a and b as

shown in Figure 1.2.5 Regular staggering of holes are measured,

in mm, on the median line of the plate, and d is as defined

in Vol 2, Pt 8, Ch 1, 2.2 Efficiency of ligaments between tube holes 2.2.2

2.2.10 For

irregularly spaced tube holes whose centres do not lie on a straight

line, the formula in Vol 2, Pt 8, Ch 1, 2.2 Efficiency of ligaments between tube holes 2.2.3 is

to apply, except that an equivalent longitudinal width of the diagonal

ligament is to be used. An equivalent longitudinal width is that width

which gives, using the formula in Vol 2, Pt 8, Ch 1, 2.2 Efficiency of ligaments between tube holes 2.2.2,

the same efficiency as would be obtained using the formula in Vol 2, Pt 8, Ch 1, 2.2 Efficiency of ligaments between tube holes 2.2.8 for the diagonal ligament

in question.

Figure 1.2.5 Regular staggering of holes

2.3 Compensating effect of tube stubs

2.3.1 Where

a drum or header is drilled for tube stubs fitted by strength welding,

either in line or in staggered formation, the effective diameter of

holes is to be taken as:

where

|

d

e

|

= |

the equivalent diameter of the hole, in mm |

|

d

a

|

= |

the actual diameter of the hole, in mm |

|

t

|

= |

the

thickness of the shell, in mm |

|

A

|

= |

the

compensating area provided by each tube stub and its welding fillets,

in mm2.

|

2.3.2 The

compensating area, A, is to be measured in a plane through

the axis of the tube stub parallel to the longitudinal axis of the

drum or header and is to be calculated as follows, see

Figure 1.2.7 Compensation of welded tube stubs and Figure 1.2.8 Compensation of welded tube stubs

- the cross-sectional area of the stub, in excess of that required

by Vol 2, Pt 8, Ch 1, 7.1 Minimum thickness for the minimum tube

thickness, from the interior surface of the shell up to a distance, b, from the outer surface of the shell;

- plus the cross-sectional area of the stub projecting inside the

shell within a distance, b, from the inner surface of

the shell;

- plus the cross-sectional area of the welding fillets inside and

outside the shell;

where

|

b

|

= |

|

|

t

b

|

= |

actual thickness of tube stub, in mm. |

2.4 Unreinforced openings

2.4.2 The

maximum diameter, d, of any unreinforced isolated openings

is to be determined by the following formula:

The value of K to be used is calculated

from the following formula:

where p, D

o and

σ are as defined in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

|

t |

= |

actual thickness

of shell, in mm. |

2.4.4 No unreinforced

opening is to exceed 200 mm in diameter.

2.4.5 Holes

may be considered isolated if the centre distance between two holes

on the longitudinal axis of a cylindrical shell is not less than:

|

d

|

= |

diameter

of openings in shell (mean diameter if dissimilarly sized holes involved) |

|

D

|

= |

mean

diameter of shell |

|

t

|

= |

actual

thickness of shell |

Where the centre distance is less than so derived,

the holes are to be fully compensated.

Where two holes

are offset on a diagonal line, the diagonal efficiency from Figure 1.2.6 Efficiency of ligaments between holes may be used to derive

an equivalent longitudinal centre distance for the purposes of this

paragraph.

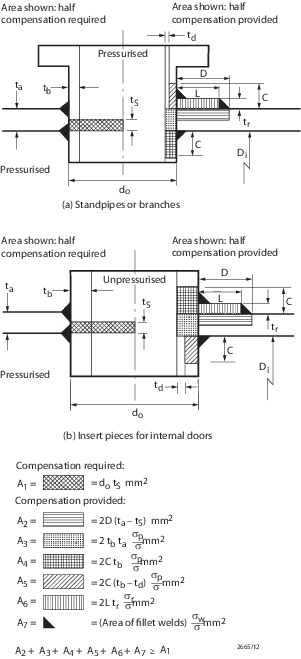

2.5 Reinforced openings

2.5.1 Openings

larger than those permitted by Vol 2, Pt 8, Ch 1, 2.4 Unreinforced openings are

to be compensated in accordance with Figure 1.2.9 Compensation for welded standpipes or branches in cylindrical shells(a) or (b). The following symbols are used in Figure 1.2.9 Compensation for welded standpipes or branches in cylindrical shells(a) and (b):

|

t

s

|

= |

calculated thickness of a shell without joint or opening or

corrosion allowance, in mm |

|

t

a

|

= |

actual thickness of shell plate without corrosion allowance,

in mm |

|

t

b

|

= |

actual thickness of standpipe without minus tolerances and corrosion

allowance, in mm |

|

t

r

|

= |

thickness of added reinforcement, in mm |

|

D

i

|

= |

internal diameter of cylindrical shell, in mm |

|

d

o

|

= |

diameter of hole in shell, in mm |

|

L

|

= |

width

of added reinforcement not exceeding D, in mm

|

|

C

|

= |

in mm in mm

|

|

D

|

= |

and is not to exceed 0,5 d

o, in

mm and is not to exceed 0,5 d

o, in

mm

|

|

σ |

= |

shell plate

allowable stress, N/mm2

|

|

σp

|

= |

standpipe

allowable stress, N/mm2

|

|

σr

|

= |

added

reinforcement allowable stress, N/mm2

|

|

σw

|

= |

weld

metal allowable stress, N/mm2

|

Note σp, σr and σw are

not to be taken as greater than σ.

Figure 1.2.9 Compensation for welded standpipes or branches in cylindrical shells

2.5.3 Compensation

is to be distributed equally on either side of the centreline of the

opening.

2.5.4 The

welds attaching standpipes and reinforcing plates to the shell are

to be of sufficient size to transmit the full strength of the reinforcing

areas and all other loadings to which they may be subjected.

|