Section

2 Hull strengthening requirements

2.1 Application

2.1.1 Where

the notation 'Ice Class 1AS, 1A, 1B, or 1C'

as specified in Vol 1, Pt 1, Ch 2, 3.10 Other notations 3.10.15 is desired, the ship is to comply with the requirements

of this Section, in addition to those for sea-going service, so far

as they are applicable.

2.1.2 The

vertical extent of the ice strengthening is related to the ice light

and ice load waterlines, which are defined in Vol 3, Pt 1, Ch 1, 2.2 Definitions . The maximum and minimum Ice Class

draughts at both the fore and aft ends will be stated on the Class

Certificate.

2.1.3 The

ballast capacity of the ship is to be sufficient to give adequate

propeller immersion in all ice navigating conditions without trimming

the ship in such a manner that the actual waterline at the bow is

below the ice light waterline.

2.1.4 Fresh-water

and sea-water ballast tanks, the tops of which are situated above

the minimum operating condition waterline and adjacent to the shell,

and which are intended to be used in ice and cold navigation conditions,

are to be provided with means to prevent freezing. It is to be demonstrated

that such means protect against the following:

-

Hull structural

damage caused by tank contents being pumped from beneath a layer of

ice, thereby drawing a vacuum into the tank.

-

Hull structural

damage caused by ice expansion.

-

Tank internal piping

and other components being damaged by ice expansion or blockage by

ice.

-

Tank internal piping

and other components being mechanically damaged by falling pieces

of ice.

Heating coils are considered effective means for tanks entirely

above the waterline. Heating coils, continuous circulation, air bubbling

or alarms and instrumentation are considered effective means for tanks

partially below the waterline. Alternatively, submission of documentary

evidence of service experience, testing, calculations or a combination

thereof may be used to demonstrate that the above hazards have been

mitigated.

2.1.5 The

requirements of this Section are formulated for both transverse and

longitudinal framing systems but it is recommended that, whenever

practicable, transverse framing is selected.

2.1.6 The

requirements of this Section assume that when approaching ice infested

waters the ship’s speed will be reduced appropriately. The vertical

extent of ice strengthening for ships intended to operate at speeds

exceeding 15 knots in areas containing isolated ice floes will be

specially considered.

2.1.7 An icebreaking

ship is to have a hull form at the fore end adapted to break ice effectively.

It is recommended that bulbous bows are not fitted to Ice Class 1AS ships.

2.1.8 The

stern of an icebreaking ship is to have a form such that broken ice

is effectively displaced.

2.1.9 Where

it is desired to make provision for short tow operations, the bow

area is to be suitably reinforced. Similarly, ice breakers may require

local reinforcement in way of the stern fork.

2.2 Definitions

2.2.1 The Ice

Deep Waterline corresponds to the Deep Draught Waterline. Where

specially requested, an Ice Deep Waterline may be specified which

differs from the foregoing, but corresponds to the deepest condition

in which the ship is expected to navigate in ice. See

Vol 1, Pt 3, Ch 1, 5.3 Margins for margins.

2.2.2 The Ice Light Waterline is that

corresponding to the lightest condition in which the ship is expected to navigate in

ice. However, it is recommended that the minimum draught at the fore end is not to be

less than:

where

2.2.3 The

Ice Deep Waterline and the Ice Light Waterline are to be indicated

on the plans.

2.2.5 The Forward

Region extends from the stem to aft of the forward borderline

of the flat side of the hull by a distance equal to the greater of

0,04L

R or 5 m for ice classes 1AS and 1A, or the greater of 0,02L

R or 2 m

for ice classes 1B and 1C. Where no clear

forward borderline of the flat side of the hull is discernible, the

aft boundary of the forward region is to be taken 0,4L

R aft of the forward perpendicular.

2.2.6

Forefoot

Region 1 is the area below the main ice belt zone extending

from the stem, or the fore end of the bulb where a bulbous bow is

fitted, to a position five frame spaces aft of the point of intersection

between the level keel line and the raked stem.

2.2.7

Forefoot

Region 2 is the area below the main ice belt extending from

the aft boundary of Forefoot Region 1 to the aft boundary of the forward

region and encompasses both side and bottom shell plating.

2.2.8 The Shoulder

Region is a part of the main ice belt zone in the forward region

and extends from the aft boundary of the forward region to forward

of the forward borderline of the flat side of the hull by a distance

of 0,04L

R for ice classes 1AS and 1A or 0,02L

R for ice classes 1B and 1C. Where no clear forward borderline of the flat side of the

hull is discernible, the forward boundary of the shoulder region is

to be taken 0,32L

R aft of the forward perpendicular

for ice classes 1AS and 1A or 0,36L

R aft of the forward perpendicular for ice classes 1B and 1C. The extent of the shoulder region forward of its aft boundary

is not to be taken as less than 10 m for ice classes 1AS and 1A or 4 m for ice classes 1B and 1C.

2.2.9 The Midship

Region extends from the aft boundary of the forward region

to aft of the aft borderline of the flat side of the hull by a distance

equal to the greater of 0,04L

R or 5 m for

ice classes 1AS and 1A or the greater of

0,02L

R or 2 m for ice classes 1B and 1C. Where no clear aft borderline of the flat side of the hull

is discernible, the aft boundary of the midship region is to be taken

0,2L

R forward of the aft perpendicular.

2.2.10 The Aft Region extends from the aft boundary of the midship region

to the stern.

2.2.11

Displacement ∆ is the displacement, in tonnes, at the Ice Deep Waterline

when floating in water having a relative density of 1,0.

2.2.12

Shaft

power, P

0 , is the maximum propulsion

shaft power, in kW, for which the machinery is to be classed.

2.3 Powering of ice strengthened ships

2.3.2 Ice

strengthened ships which are to be considered to have an independent

icebreaking capability are to be able to develop sufficient thrust

to permit continuous mode icebreaking at a speed of at least five

knots in ice having a thickness equal to the nominal value specified

in Vol 1, Pt 1, Ch 2, 3.10 Other notations 3.10.15 for

the desired Ice Class and a snow cover of at least 0,3 m.

2.3.3 The

requirements of Vol 3, Pt 1, Ch 1, 2.4 Shell plating are

formulated on the assumption that the shaft power necessary to provide

an independent icebreaking capability as described in Vol 3, Pt 1, Ch 1, 2.3 Powering of ice strengthened ships 2.3.2 can be determined by the equation:

|

P

1

|

= |

0,736C

1

C

2

C

3

C

4 [240B

h (1

+ h + 0,035v2) +70S

c

)] )]

|

where

|

B

|

= |

breadth

as defined in Vol 1, Pt 3, Ch 1, 5 Definitions

|

|

C

1

|

= |

,

but is not to be taken as less than 1,0 ,

but is not to be taken as less than 1,0 |

|

C

2

|

= |

0,9 if the ship is fitted with a controllable pitch propeller,

otherwise 1,0 |

|

C

3

|

= |

0,9 if the rake of the stem is 45º or less, otherwise 1,0.

The product C

2

C

3 is

not to be taken as less than 0,85

|

|

C

4

|

= |

1,1 if the ship is fitted with a bulbous bow, otherwise 1,0 |

|

h

|

= |

ice

thickness as defined in Vol 3, Pt 1, Ch 1, 2.2 Definitions 2.2.2

|

|

S

c

|

= |

depth of snow cover |

|

v

|

= |

ship

speed, in knots, when breaking ice of thickness h

|

2.3.4 The

ice strengthening requirements of Vol 3, Pt 1, Ch 1, 2.4 Shell plating include a power-displacement correction factor, γ,

which is to be determined as follows:

-

Forward region

|

γ |

= |

0,653 +

3,217  x 10-5 x 10-5

|

|

or γ |

= |

0,876

+ 9,908  × 10-6 × 10-6

|

|

or γ |

= |

1,0 whichever

is the least |

where P

0 and Δ are

as defined in Vol 3, Pt 1, Ch 1, 2.2 Definitions .

For ships assigned ice classes 1AS and 1A, in which the installed shaft power P

0 exceeds

the shaft power P

1 determined in accordance

with Vol 3, Pt 1, Ch 1, 2.3 Powering of ice strengthened ships 2.3.3 when the ship speed

is taken as five knots, the ice thickness, h, as defined

in Vol 1, Pt 1, Ch 2, 3.10 Other notations 3.10.15 and

the snow cover S

c is taken as 0,3 m, γ

for the forward region is to be multiplied by the following factor:

-

for shell plating

1 + 0,1

-

for framing,

stringers and web frames

1 + 0,05

but γ need not be taken greater than 1,1.

-

Midship and aft

regions

|

γ |

= |

0,653 +

9,908 × 10-6 × 10-6

|

|

or |

= |

0,79, whichever

is the lesser. |

2.4 Shell plating

2.4.1 In way

of the main ice belt zone, the thickness of the shell plating is not

to be less than:

|

t

|

= |

As αp β γ + c mm + c mm

|

where

|

c

|

= |

corrosion-abrasion

increment to be taken as 2 mm for first-year ice classes, see

also

Vol 3, Pt 1, Ch 1, 2.4 Shell plating 2.4.3

|

|

s

|

= |

distance

to the adjacent main or intermediate frame, in mm |

|

A

|

= |

0,40

in association with transverse framing |

|

|

= |

0,41 in association

with longitudinal framing |

|

αp

|

= |

longitudinal

distribution factor, dependent on Ice Class and longitudinal position,

as given in Table 1.2.2 Longitudinal distribution

factor-shell plating

|

|

β |

= |

vertical distribution

factor, to be taken as 1,0 for all first-year ice classes |

|

γ |

= |

power-displacement

factor determined in accordance with Vol 3, Pt 1, Ch 1, 2.3 Powering of ice strengthened ships 2.3.4

|

|

σo

|

= |

specified

minimum yield stress of the steel, in N/mm2. For mild steel

the value 235 N/mm2 is to be used.

|

Table 1.2.2 Longitudinal distribution

factor-shell plating

| Ice Class

|

αp

|

| Forward

|

Midship

|

Aft

|

1AS

1A

1B

1C

|

1,00

0,98

0,93

0,86

|

0,95

0,86

0,71

0,53

|

0,85

0,73

0,57

0,38

|

2.4.2 Where

operation in first-year ice is an emergency feature as recognised

by Vol 1, Pt 1, Ch 2, 3.10 Other notations 3.10.15 with

a * annotated to the Ice Class notation, consideration will be given

to the use of fully plastic design criteria for the shell plating.

2.4.4 For

ice classes 1AS and 1A, where the hull form

includes a pronounced shoulder, the value of the corrosion-abrasion

increment in the shoulder region will be specially considered.

2.4.5 For

ice classes 1AS and 1A, the thickness of

shell plating is to be as follows:

-

In Forefoot Region

1 – not less than that determined in accordance with Vol 3, Pt 1, Ch 1, 2.4 Shell plating 2.4.1 for the main ice belt zone

in the forward region.

-

In Forefoot Region

2 – 2 mm greater than that required by Vol 1, Pt 6, Ch 3 Scantling Determination or Vol 1, Pt 7 Enhanced Structural Assessment (Provisional) for

ships with TLA notation.

-

For the forward

0,2L

R, the region 2 m above the main ice belt

zone in ships having an open water speed equal to and exceeding 17,5

knots (9 m/sec) – not less than that required in the ice belt

in the Midship Region.

2.4.6 Changes

in plating thicknesses in the longitudinal direction are to take place

gradually. Side scuttles are not to be situated in the ice belt.

2.4.7 If the

weather deck in any part of the ship is situated below the upper limit

of the ice belt, as may be the case of a raised-quarter decker, the

bulwark is to be reinforced to a standard required for the shell plating

in the main ice belt.

2.5 Transverse framing

2.5.1 The

increased requirements for transversely framed structures are normally

met by the addition of intermediate frames.

2.5.2 Ships

with shock enhanced notation transverse intermediate frames are not

to be fitted. The ice strengthening requirements are to be met by

the use of reduced main frame spacing.

2.5.3 The

section modulus of transverse main and intermediate frames (including

a width of attached plating equal to s), is to be determined

in accordance with the following formula:

|

Z

|

= |

Cs αt β γ2

(3 (3 2 – h

2) K cm3

2 – h

2) K cm3

|

where

|

d

|

= |

distance,

in metres, measured along the frame from the lower span point to the

ice deep waterline or from the upper span point to the ice light waterline,

whichever is the lesser. In no case is this distance to be taken greater

than

|

|

h

|

= |

nominal

ice thickness, in metres, for the Ice Class as defined in Vol 1, Pt 1, Ch 2, 3.10 Other notations 3.10.15

|

s, β, γ and σo are as

defined in Vol 3, Pt 1, Ch 1, 2.4 Shell plating 2.4.1

|

K

|

= |

but is not to be taken greater than 1,0 nor less than

0,3. If the lower span point is above the ice load waterline or the

upper span point is below the ice light waterline, then k is

to be taken as 0,3 but is not to be taken greater than 1,0 nor less than

0,3. If the lower span point is above the ice load waterline or the

upper span point is below the ice light waterline, then k is

to be taken as 0,3

|

|

= |

span, in metres, measured

along a chord at the side between the span points. For definitions

of span points, see

Vol 1, Pt 6, Ch 2, 2 Structural design. Where adjacent main and intermediate frames

have different end connections, resulting in different spans, a mean

value is to be used.

|

Table 1.2.3 Longitudinal distribution factor -

transverse framing

| Ice Class

|

αt

|

| Forward

|

Midship

|

Aft

|

1AS

1A

1B

1C

|

1,00

0,89

0,78

0,66

|

0,87

0,68

0,49

0,31

|

0,66

0,49

0,33

0,16

|

2.5.4 The inertia of transverse main and

intermediate frames including a width of attached plating equal to s is to be

determined in accordance with the following formula:

|

= |

4Z

cm4 cm4

|

where

2.5.5 The

cross-sectional shear resisting area of transverse main and intermediate

frames is to be determined in accordance with the following formula:

|

A

|

= |

Cs αt β γ2

K

s cm2

K

s cm2

|

where s, β, γ and σo are

as defined in Vol 3, Pt 1, Ch 1, 2.4 Shell plating 2.4.1

|

K

s

|

= |

0,5 if the upper span point is below the bottom edge of the

main ice belt zone or the lower span point is above the upper edge

of the main ice belt zone |

|

|

= |

1,0 for all other

cases |

2.5.6 Except

as allowed by Vol 3, Pt 1, Ch 1, 2.5 Transverse framing 2.5.7,

main and intermediate frames having scantlings as required by Vol 3, Pt 1, Ch 1, 2.5 Transverse framing 2.5.2 are to be continued

and bracketed to the first primary longitudinal member outside of

the minimum extent of ice framing given in Table 1.2.4 Minimum extent of ice

framing or to the top of floors

in ships having a single bottom. In the latter case intermediate frames

will require to be bracketed, or otherwise efficiently attached to

a gusset plate which is to be fitted at the level of top of floors.

The free edge of the horizontal gusset should be suitably supported.

In this context a primary longitudinal member is defined as either

a deck, inner bottom, margin plate, deep tank top or ice stringer

complying with the requirements of Vol 3, Pt 1, Ch 1, 2.8 Primary longitudinal members supporting transverse ice framing.

Table 1.2.4 Minimum extent of ice

framing

| Ice Class

|

Region

|

Minimum extent of ice framing

|

| Above Ice Deep

Waterline (mm)

|

Below Ice Light

Waterline (mm)

|

| 1AS

|

Forward

(stem to 0,3L

R)

|

1200

|

To double

bottom or top of floors or 1600 mm, whichever is the greater

|

| Forward

(abaft 0,3L

R) and Midship

|

1200

|

1600

|

| Aft

|

1200

|

1200

|

1A,

1B,

1C

|

Forward

(stem to 0,3L

R)

|

1000

|

1600

|

| Forward

(abaft 0,3L

R) and Midship

|

1000

|

1300

|

| Aft

|

1000

|

1000

|

2.5.7 If a

primary longitudinal member is fitted within 0,25 m inside a boundary

of the minimum extent of ice framing, intermediate frames may be terminated

at that member.

2.5.8 If a

primary longitudinal member is fitted within 1 m inside a boundary

of the minimum extent of ice framing, the intermediate frames may

be terminated at that boundary, provided that their ends are attached

to the adjacent main frames by a horizontal intercostal member having

the same scantlings as the intermediate frames.

2.5.9 If primary

longitudinal members are not fitted, or are located more than 1 m

inside a boundary of the minimum extent of ice framing, then the intermediate

frames may be either:

-

extended to a

primary longitudinal member or equivalent as defined by Vol 3, Pt 1, Ch 1, 2.5 Transverse framing 2.5.6.

-

terminated at

the boundary of minimum extent of ice framing and attached by a horizontal

intercostal member, having the same scantlings as the intermediate

frames, to the adjacent main frames. The scantlings of the main frames

are to be based on the spacing and span of the main frames. The inertia

of the intermediate frames is to be not less than 75 per cent of the

main frames.

2.5.10 Except

where provided for in Vol 3, Pt 1, Ch 1, 2.5 Transverse framing 2.5.7 and Vol 3, Pt 1, Ch 1, 2.5 Transverse framing 2.5.9, the ends of intermediate

frames are to be bracketed or otherwise efficiently attached to a

primary longitudinal member or are to be attached to adjacent brackets,

floors or main frames by a longitudinal flat bar. see also

Vol 3, Pt 1, Ch 1, 2.7 Framing - General requirements 2.7.5.

2.5.11 In

twin screw ships, three intermediate frames forward of, and three

aft of, the propeller blade tips are to extend to the double bottom.

2.6 Longitudinal framing

2.6.1 The

section modulus of longitudinal frames (including a width of attached

plating equal to s), is to be determined in accordance

with the following formula:

|

Z

|

= |

Cs αl β γ2

2

2

cm3 cm3

|

where

|

h

|

= |

ice

thickness as defined in Vol 3, Pt 1, Ch 1, 2.2 Definitions 2.2.2

|

|

= |

is as defined in Vol 3, Pt 1, Ch 1, 2.5 Transverse framing 2.5.3

|

|

s

|

= |

spacing,

in mm, of longitudinal frames but need not be taken as greater than

1000h

|

|

C

|

= |

16,6 |

|

αl

|

= |

longitudinal

distribution factor, dependent on Ice Class and longitudinal position,

as given in Table 1.2.5 Longitudinal distribution

factor-longitudinal framing

|

β, γ and σo are as defined in Vol 3, Pt 1, Ch 1, 2.4 Shell plating 2.4.1.

Table 1.2.5 Longitudinal distribution

factor-longitudinal framing

| Ice Class

|

α1

|

| Forward

|

Midship

|

Aft

|

1AS

1A

1B

1C

|

1,00

0,90

0,80

0,68

|

0,95

0,74

0,51

0,32

|

0,71

0,53

0,34

0,16

|

2.7 Framing - General requirements

2.7.1 The

web thickness of ice frames is not, in general, to be less than half

that of the attached shell plating with a minimum of 9 mm.

2.7.2 Where

a frame intersects a boundary between two of the hull regions defined

in Vol 3, Pt 1, Ch 1, 2.2 Definitions , the scantling requirements

applicable will be those for the forward region if the forward midship

boundary is intersected or for the midship region if the aft midship

boundary is intersected.

2.7.3 Main

and intermediate frames within the minimum extent of ice framing given

in Table 1.2.4 Minimum extent of ice

framing are to be efficiently

supported to prevent tripping, e.g. as shown in Figure 1.2.2 Framing support. The distance between

anti-tripping supports is not to exceed 1500 mm. The extent of anti-tripping

supports is to be as given in Table 1.2.6 Extent of anti-tripping

supports.

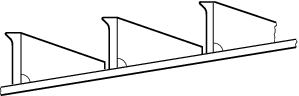

Figure 1.2.2 Framing support

Table 1.2.6 Extent of anti-tripping

supports

| Ice Class

|

Extent of

anti-tripping supports

|

1AS

1A

1B

1C

|

All regions

Forward and

midship region

Forward region

Forward

region

|

2.7.4 Ice

frames are to be attached to the shell plating by double continuous

welding and are not to be scalloped except at shell plating seams

or butts. However, in the case of the aft region for Ice Class 1A, 1B and 1C and the midship region for Ice Class 1B and 1C, consideration will be given to the

use of intermittent welding provided the requirements of Vol 1, Pt 6, Ch 6, 5.9 Intermittent and single sided fillet welding are complied

with.

2.7.5 Frames

are to be effectively attached to supporting structure by brackets.

In general, longitudinals are to be connected to both sides of cut-outs

in the webs of transverse structure.

2.7.7 Where

a bulkhead or deck is fitted instead of an ice strengthened frame,

the thickness of the bulkhead or deck adjacent to the shell is normally

to be that of the frame for a width sufficient to give an area equal

to the frame.

2.8 Primary longitudinal members supporting transverse ice framing

2.8.1 The

section modulus of ice stringers or of decks adjacent to hatchways,

including a width of attached plating determined in accordance with Vol 1, Pt 6, Ch 2, 2.3 Section properties and taken about

an axis parallel to the plating, is to be determined in accordance

with the following formula:

|

Z

|

= |

C αo β γ2

2

2

cm3 cm3

|

β, γ and σo are as defined in Vol 3, Pt 1, Ch 1, 2.4 Shell plating 2.4.1.

Table 1.2.7 Longitudinal distribution

factor-primary longitudinal members

| Ice Class

|

αo

|

| Forward

|

Midship

|

Aft

|

1AS

1A

1B

1C

|

1,00

0,87

0,78

0,68

|

0,98

0,75

0,64

0,53

|

0,89

0,64

0,51

0,37

|

2.8.3 Where

the span of a deck adjacent to a hatchway exceeds 10 times the width

of the deck strip the scantlings of the deck section may require special

consideration to ensure adequate stiffness.

2.8.4 The

webs of primary longitudinal members supporting transverse ice frames

are to be stiffened and connected to the main or intermediate frames

so that the distance, r, between such stiffening is not

to be greater than given according to the following formula:

|

r

|

= |

mm mm

|

where

|

t

|

= |

thickness,

in mm, of the primary longitudinal member adjacent to the shell plating |

Other symbols are as defined in Vol 3, Pt 1, Ch 1, 2.8 Primary longitudinal members supporting transverse ice framing 2.8.1.

2.9 Web frames

2.9.1 The

section modulus of web frames supporting ice stringers or longitudinal

ice frames including a width of attached plating determined in accordance

with Vol 1, Pt 6, Ch 2, 2 Structural design and taken

about an axis parallel to the plating is to be determined in accordance

with the following formula:

|

Z

|

= |

Cs αo β γ2

cm3 cm3

|

where

|

s

|

= |

spacing

of web frames, in metres |

β, γ and σo are as defined

in Vol 3, Pt 1, Ch 1, 2.4 Shell plating 2.4.1.

2.9.3 Ice

stringers are to be bracketed or otherwise efficiently attached to

the web frames or transverse bulkheads.

2.9.4 The

thickness of the web is generally not to be less than one per cent

of the web depth.

2.10 Stem

2.10.1 The

stem is to be made of rolled, cast or forged steel or of shaped steel

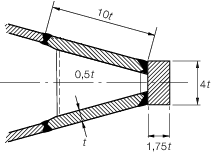

plates. A sharp edged stem, as shown in Figure 1.2.3 A sharp edged stem improves the manoeuvrability of the ship in ice.

Figure 1.2.3 A sharp edged stem

2.10.2 The

section modulus of the stem in the fore and aft direction is not to

be less than determined in accordance with the following formula:

|

Z

|

= |

cm3 cm3

|

where

β and γ are as defined in Vol 3, Pt 1, Ch 1, 2.4 Shell plating 2.4.1.

2.10.3 The

dimensions of a welded stem constructed as shown in Figure 1.2.3 A sharp edged stem are to be determined

in accordance with the following formula:

|

t

|

= |

31 mm mm

|

where

|

t

|

= |

thickness

of the side plates, in mm. |

2.10.4 The

plate thickness, t, of a shaped plate stem or a bulbous

bow is to be determined in accordance with the following formula:

|

t

|

= |

As αp β γ  + 2 mm + 2 mm

|

where

|

s

|

= |

the

distance, in mm, between horizontal webs diaphragm plates having a

thickness of at least 0,5t mm

|

αp, β, γ and σo are

as defined in Vol 3, Pt 1, Ch 1, 2.4 Shell plating 2.4.1.

2.10.5 The

reinforced stem is to extend from the keel plate to 750 mm above the

ice load waterline and is to be internally strengthened by floors,

brackets or webs having a thickness of at least 0,5t and

spaced not more than 600 mm apart.

2.10.6 In

bulbous bow constructions the extent of plating having the thickness, t, as specified in Vol 3, Pt 1, Ch 1, 2.10 Stem 2.10.4,

below the ice light waterline should be such as to cover that part

of the bulb forward of the vertical line originating at the intersection

of the ice light waterline and the stem contour at the centreline.

A suitably tapered transition piece should be arranged between the

reinforced stem plating and keel. However, in no case should the reinforced

stem plating extend vertically below the Ice Light Waterline for less

than 750 mm. The adjacent strake to the reinforced shaped stem plating

of the bulb should be in accordance with the requirements of Vol 3, Pt 1, Ch 1, 2.4 Shell plating 2.4.1.

2.10.7 Where

in the ice belt region the radius of the stem or bulb front plating

is large, one or more vertical stiffeners are to be fitted in order

to meet the section modulus requirement of Vol 3, Pt 1, Ch 1, 2.10 Stem 2.10.2. In addition, vertical ring

stiffening will be required for the bulb.

2.10.8 The

dimensions of the stem may be tapered to the requirements of Vol 1, Pt 6, Ch 3, 5.2 Plate keel at the upper

deck. The connections of the shell plating to the stem are to be flush.

2.10.9 For

towing purposes, a mooring pipe with an opening not less than 250

mm by 300 mm having inner surfaces at least 150 mm wide with a rounding

radius of not less than 100 mm is to be fitted in the bow bulwark

on the centreline. A bitt, or other convenient means of securing the

line, is to be dimensioned to withstand the breaking strength of the

ship’s towline.

2.11 Stern

2.11.1 Where

the screwshaft diameter exceeds the Rule diameter, the propeller post

is to be correspondingly strengthened. see

Vol 1, Pt 3, Ch 3, 2 Rudders.

2.11.2 A

transom stern is not normally to extend below the ice load waterline.

Where this cannot be avoided, the transom is to be kept as narrow

as possible and the scantlings of plating and stiffeners are to be

as required for the midship region.

2.12 Bossings and shaft struts

2.12.1 Shaftings

and sterntubes of ships with two or more propellers are generally

to be enclosed within plated bossings. If detached supporting struts

are necessary, their design, strengthening and attachment to the hull

will be specially considered.

2.13 Rudder and steering arrangements

2.13.1 Rudder posts, rudder horns, solepieces, rudder stocks and pintles are to be

dimensioned in accordance with Vol 1, Pt 3, Ch 3, 2 Rudders and Vol 1, Pt 3, Ch 3, 2.9 Rudder strength calculation as appropriate. Rudder scantlings are to be determined

in accordance with Vol 1, Pt 3, Ch 3, 2 Rudders using the basic stock diameter, δs. The

speed used in the calculations is to be the service speed or that given in Table 1.2.8 Minimum speeds, whichever is the greater. When used in

association with the speed given in Table 1.2.8 Minimum speeds, the hull form factor and rudder profile

coefficients are to be taken as 1,0.

Table 1.2.8 Minimum speeds

| Ice Class

|

Minimum speed, in knots

|

1AS

1A

1B

1C

|

20

18

16

14

|

2.13.2 For

double plate rudders, the minimum thickness of plating and horizontal

and vertical webs in the main ice belt zone is to be determined as

for shell plating in the aft region in accordance with Vol 3, Pt 1, Ch 1, 2.4 Shell plating 2.4.1. For the horizontal and vertical

webs the corrosion-abrasion increment, c, need not be

added.

2.13.3 For

ice classes 1AS and 1A, the rudder head

and the upper edge of the rudder are to be protected against ice pressure

by an ice knife, or equivalent.

2.13.4 Due

regard is to be paid to the method of securing the rudder in the centreline

position when backing into ice. Where possible, rudder stoppers working

on the blade or rudder head are to be fitted.

2.13.5 Where an ice class notation is included in the class of a ship, the nozzle

construction requirements as defined in Vol 1, Pt 3, Ch 3, 5 Fixed and steering nozzles, bow and stern thrust units, ducted propellers are to be upgraded to include

abrasion allowance as follows:

|

Ice Class

|

Thickness increment

|

1AS

1A

1B

1C

|

5

mm

4 mm

3 mm

2 mm

|

However, the thickness of the shroud

plating is not to be less than the shell plating for the aft region

as obtained from Vol 3, Pt 1, Ch 1, 2.4 Shell plating 2.4.1 taking

frame spacing s in the formula as 500 mm.

2.13.7 Nozzles

with articulated flaps will be subject to special consideration.

2.14 Direct calculations

2.14.1 If,

as an alternative to the requirements of Vol 3, Pt 1, Ch 1, 2.8 Primary longitudinal members supporting transverse ice framing and Vol 3, Pt 1, Ch 1, 2.9 Web frames, the scantlings

of primary longitudinal members and web frames are determined by direct

calculation, as permitted by Vol 1, Pt 3, Ch 1, 2 Direct calculations, then:

-

the applied ice

load may be taken as 775αo β γ2 kN

per metre of ship length evenly distributed over a depth equal to

the nominal ice thickness, h, for the Ice Class;

-

the scantlings

are to be suitable for the centre of the load depth to be located

at any height between the ice load waterline and the ice light waterline;

-

the scantlings

determined in association with Vol 3, Pt 1, Ch 1, 2.14 Direct calculations 2.14.1 and Vol 3, Pt 1, Ch 1, 2.14 Direct calculations 2.14.1.(b) are to be sufficient to ensure

that the von Mises-Hencky combined stress does not exceed 90 per cent

of the yield stress of the steel.

|