Section

3 Machinery and engineering systems

3.1 General

3.1.1 Where

the notation, Ice Class 1AS, 1A, 1B or 1C is desired, the requirements of this Section, in addition

to those for open water service, are to be complied with so far as

they are applicable.

3.2 Symbols and definitions

3.2.1 The

symbols used in this Section are defined as follows:

|

B

|

= |

moulded

breadth of ship, in metres |

|

D

P

|

= |

diameter of the propeller, in metres |

|

H

M

|

= |

thickness of the brash ice in mid channel, in metres |

|

H

F

|

= |

thickness of the brash layer displaced by the bow, in metres |

|

L

WL

|

= |

length of ship at deep draught waterline, in metres |

|

T

ICE

|

= |

maximum ice class draught amidships, in metres, corresponding

to the deep draught waterline |

|

∆ |

= |

displacement,

in tonnes, on the maximum Ice Class draught amidships on the deep

draught waterline, see

Vol 3, Pt 1, Ch 1, 2.2 Definitions 2.2.1. This displacement need not be taken as greater than 80 000

tonnes

|

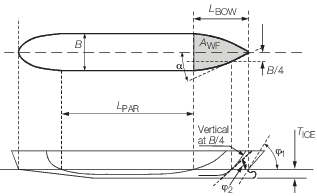

Figure 1.3.1 Definition of angles, areas and length

3.3 Engine output

3.3.1

Definition. The total engine output, P in Vol 3, Pt 1, Ch 1, 3.3 Engine output 3.3.2, is the maximum output the

propulsion machinery can continuously deliver to the propulsion system

with the propeller(s) operating at the revolutions per minute at the

maximum torque for which the system is to be classed. If the output

of the machinery is restricted by technical means or by any Regulations

applicable to the ship, P, shall be taken as the restricted

output.

3.3.2 Required

engine output:

-

For Ice

Class 1AS and 1A, the total engine output is not

to be less than determined by the following formula:

|

P

|

= |

K

E

kW kW

|

where K

E is as shown in Table 1.3.1 Coefficient of propulsion,

K

E

R

CH, in N, is the resistance of the

ship in a channel with brash ice and a consolidated layer, using the

following equation:

|

R

CH

|

= |

C

1 + C

2 + 845

(H

F + H

M)2

• •

|

(0,15 cos + sinψ • sinα) + 42L

PAR

H

F

2 + 825K

d + sinψ • sinα) + 42L

PAR

H

F

2 + 825K

d

where

|

Kd

|

= |

|

but is not to be taken as more than 20 or less than

5

|

H

F

|

= |

0,26 +

|

|

H

M

|

= |

1,0 for Ice Classes 1A and 1AS

|

C

1 and C

2 take

into account a consolidated upper layer of the brash ice and can be

taken as zero for Ice Class 1A. For Ice Class 1AS:

|

C

1

|

= |

23 + (1 + 0,021 + (1 + 0,021 )(45,8B + 14,7L

BOW +

29BL

BOW) )(45,8B + 14,7L

BOW +

29BL

BOW)

|

|

C

2

|

= |

(1 + 0,063 )(1530 + 170B) +(400 + 480 )(1530 + 170B) +(400 + 480 ) )

|

|

Ψ |

= |

arctan

|

-

For Ice

Class 1B and 1C, the total engine output is not

to be less than that determined by the following formula and in no

case less than 740 kW:

|

P

|

= |

f

1

f

2

f

3 ( f

4 ∆ + P

o ) kW

|

where

|

f

1

|

= |

1,0 for a fixed pitch propeller |

| = |

0,9 for a controllable pitch propeller |

|

f

2

|

= |

+ 0,675 but not more than 1,1 + 0,675 but not more than 1,1 |

|

f

2

|

= |

1,1 for a bulbous bow |

The product, f

1

f

2, is not to be taken as less than 0,85.

|

f

3

|

= |

but not less than 1,0 but not less than 1,0

|

f

4 and P

0 are

to be taken as shown in Table 1.3.2 Values of f

4 and P

0

:

∆ is as defined in Vol 3, Pt 1, Ch 1, 3.2 Symbols and definitions.

Table 1.3.1 Coefficient of propulsion,

K

E

No. of

propellers

|

Propeller type

|

| Controllable pitch propeller

|

Fixed

pitch propeller

|

1

2

3

|

2,03

1,44

1,18

|

2,26

1,60

1,31

|

Table 1.3.2 Values of f

4 and P

0

|

|

1B

|

1C

|

1B

|

1C

|

| Δ < 30 000 t

|

Δ ≥ 30,000 t

|

|

f

4

|

0,22

|

0,18

|

0,13

|

0,11

|

|

P

0

|

370

|

0

|

3070

|

2100

|

3.4 Materials for shafting

3.4.1 All

components of the main propulsion system are to be of steel or other

approved ductile material.

3.4.2 For screwshafts in ships intended for the notation Ice Class 1AS or

1A and where the connection between the propeller and the screwshaft is by means

of a key, Charpy impact tests are to be made in accordance with the requirements of

Ch 5, 2.4 Mechanical tests.

3.5 Materials for propellers

3.5.1 Propellers

and propeller blades are to be of cast steel or copper alloys.

3.5.3 Spheroidal

cast iron load transmitting components of controllable-pitch mechanisms

are to be manufactured, tested and certified in accordance with the

requirements of Table 7.3.5 Mechanical properties: special

qualities in

Ch 7,3 of the Rules for Materials.

3.6 Determination of ice torque

3.6.1 Dimensions

of propellers, shafting and gearing are determined by formulae taking

into account the impact when a propeller blade hits ice. The ensuing

load is hereinafter defined by ice torque, M.

where

|

m

|

= |

21,10

for Ice Class 1AS

|

|

D

|

= |

diameter

of propeller, in metres. |

3.6.2 If the

propeller is not fully submerged when the ship is in ballast condition,

the ice torque for Ice Class 1A is to be used for Ice

Classes 1B and 1C.

3.7 Propeller blade sections

3.7.1 The

width, L, and thickness, T, of propeller

blade sections are to be determined so that:

-

at the radius

0,25D/2, for solid propellers

-

at radius 0,35D/2 for controllable pitch propellers

-

at the radius

0,6D/2

where

|

D

|

= |

diameter

of propeller, in metres |

|

L

|

= |

length

of the expanded cylindrical section of the blade, at the radius in

question, in mm |

|

P

r

|

= |

propeller pitch at the radius in question, for solid propellers,

in metres |

| = |

0,7 nominal pitch for controllable pitch propellers,

in metres |

|

R

|

= |

propeller

speed, in rev/min |

|

T

|

= |

the

corresponding maximum blade thickness, in mm |

|

σu

|

= |

specified

minimum tensile strength of the blade material, in N/mm2.

|

3.7.2 Where

the blade thickness derived from these formulae is less than the blade

thickness derived by Vol 2, Pt 4, Ch 1 Propellers,

the latter is to apply.

3.8 Propeller blade minimum tip thickness

3.9 Intermediate blade sections

3.10 Blade edge thickness

3.10.1 The

thickness of blade edges is to be not less than 50 per cent of the

derived tip thickness, t, measured at 1,25t from

edge. For controllable pitch propellers this applies only to the leading

edge.

3.11 Mechanisms for controllable pitch propellers

3.11.1 The

strength of mechanisms in the boss of a controllable pitch propeller

is to be 1,5 times that of the blade when a load is applied at the

radius 0,9D/2 in the weakest direction of the blade.

3.12 Keyless propellers

3.12.1 When

it is proposed to use keyless propellers, the fit of the propeller

boss to the screwshaft will be specially considered.

3.13 Screwshafts

3.13.1 The

diameter d

s at the aft bearing of the screwshaft

fitted in conjunction with a solid propeller is to be not less than:

|

d

s

|

= |

mm mm |

where

|

L and T

|

= |

proposed width and thickness respectively of the propeller blade

section at 0,25D/2, in mm

|

|

σo

|

= |

specified

minimum yield stress of the material of the screwshaft, in N/mm2

|

|

σu

|

= |

specified

minimum tensile strength of the blade material, in N/mm2.

|

3.13.2 The

diameter, d

s at the aft bearing of the screwshaft

fitted in conjunction with a controllable pitch propeller is to be

not less than:

|

d

s

|

= |

mm mm |

where

|

L and T

|

= |

proposed width and thickness respectively of the propeller blade

section at 0,35D/2, in mm.

|

3.13.3 Where

the screwshaft diameter as derived by Vol 3, Pt 1, Ch 1, 3.13 Screwshafts 3.13.1 or Vol 3, Pt 1, Ch 1, 3.13 Screwshafts 3.13.2 is less

than the diameter derived by Vol 2, Pt 3, Ch 2, 4.4 Screwshafts and tube shafts 4.4.3 or Vol 2, Pt 3, Ch 2, 4.4 Screwshafts and tube shafts 4.4.7 as

applicable the latter is to apply.

3.14 Intermediate and thrust shafts

3.15 Reduction gearing

3.15.1 Where

gearing is fitted between the engine and the propeller shafting, the

gearing is to be in accordance with Vol 2, Pt 3, Ch 1 Gearing, and is to be designed to transmit a torque, Y

i, determined by the following formula:

|

Y

i

|

= |

Y +  kN m kN m

|

where

|

u

|

= |

gear

ratio =

|

h

h

|

= |

mass moment

of inertia of machinery components rotating at higher speed |

l

l

|

= |

mass moment

of inertia of machinery components rotating at lower speed, including

propeller with an addition of 30 per cent of entrained water |

( h and

h and  l are to be expressed in the same units)

l are to be expressed in the same units)

|

Y

|

= |

9,55 . .

|

P and R are as defined

in Vol 2, Pt 1, Ch 3, 3.3 Calculations and specifications.

3.16 Starting arrangements

3.16.1 In addition to complying with the requirements of Vol 2, Pt 7, Ch 3, 12.11 Dead ship condition starting arrangements,Pt 10, Ch 1, 12.1 General, Vol 2, Pt 7, Ch 3, 12.12 Air receivers,

Vol 2, Pt 2, Ch 1, 8.5 Starting air pipe systems and safety fittings and Vol 2, Pt 2, Ch 1, 9.2 Electric starting where applicable, the capacity of the air compressors

is to be sufficient for charging the air receivers from atmospheric to full pressure in

half an hour for a ship with Ice Class 1AS where the propulsion engine has to be

reversed for going astern.

3.17 Sea inlet chests and cooling water systems

3.17.1 The

cooling water system is to be designed to ensure a supply of cooling

water when navigating in ice. For this purpose at least one cooling

water inlet chest is to be arranged as follows:

-

The sea inlet

chest is to be situated near the centreline of the ship and well aft

if possible.

-

As guidance for

design the volume of the chest shall be about one cubic metre for

every 750 kW engine output of the ship including the output of auxiliary

engines necessary for the ship’s service.

-

The chest shall

be of sufficient height to allow ice to accumulate above the inlet

pipe.

-

A recirculating

connection from the cooling water overboard discharge line, capable

of full capacity discharge, is to be led to the chest.

-

The net area

through the grating at the shell opening is to be not less than four

times the sectional area of the inlet pipe.

Where there are difficulties in meeting the requirements of Vol 3, Pt 1, Ch 1, 3.17 Sea inlet chests and cooling water systems 3.17.1.(b) and Vol 3, Pt 1, Ch 1, 3.17 Sea inlet chests and cooling water systems 3.17.1.(c) two smaller chests may be

arranged for alternating intake and discharge of cooling water. The

arrangement and situation otherwise shall be as above.

3.17.2 Heating

coils may be installed in the upper part of the chest or chests.

3.18 Fire pumps in motor ships

|