Section

5 Single bottom structure and appendages

5.1 General

5.1.1 The requirements

of this Section provide for single bottom construction in association

with transverse and longitudinal framing systems.

5.1.2 All girders

are to extend as far forward and aft as practicable and care is to

be taken to avoid any abrupt discontinuity. Where girders are cut

at bulkheads, their longitudinal strength is to be maintained.

5.1.3 Particular

care is to be taken to ensure that the continuity of structural strength

in way of the intersection of transverse floors and longitudinal girders

is maintained. The face flats of such stiffening members are to be

effectively connected.

5.1.4 The single

bottom structure in way of the keel and girders is to be sufficient

to withstand the forces imposed by dry-docking the craft.

5.2 Keel

5.3 Centre girder

5.3.1 A centreline

girder is, in general, to be fitted throughout the length of the hull

in association with transverse frames, transverses supporting longitudinals

or where the breadth of floors at the upper edge is greater than 1,5

m.

5.3.2 Centreline

girders are to be formed of intercostal or continuous plate webs with

a face flat welded to the upper edge. In all cases the face flat is

to be continuous. Where girder webs are intercostal, additional bracketing

and local reinforcement will be required to maintain the continuity

of structural strength.

5.3.8 The face

flat thickness is to be not less than the thickness of the web.

5.3.9 The ratio

of the width to thickness of the face flat is to be not less than

8 but is not to exceed 16.

5.4 Side girders

5.4.1 Where the

floor breadth at the upper edge exceeds 6,0 m side girders are to

be fitted at each side of the centre girder such that the spacing

between the side and centre girders or between the side girders themselves

is not greater than 3 metres. Side girders where fitted are to extend

as far forward and aft as practicable and are, in general, to terminate

in way of bulkheads, deep floors or other primary transverse structure.

5.4.5 In the

engineroom, additional side girders are generally to be fitted in

way of main machinery seatings. Where fitted, they are to be integrated

into the structure of the craft and extended forward and aft as far

as practicable.

5.5 Floors general

5.5.1 In transversely

framed craft, plate floors are generally to be fitted at each frame.

5.5.2 In longitudinally

framed craft, plate floors are to be fitted at every transverse web

frame and generally at a spacing not exceeding 2 m. Additional transverse

floors or webs are in general to be fitted at half web-frame spacing

in way of engine seatings and thrust bearings, pillars, skegs, ballast/bilge

keels and the bottom of the craft forward.

5.5.5 If the

side frames of the craft are attached to the floors by brackets, the

depth of floor may be reduced by 15 per cent and the floor thickness

determined using the reduced depth. The brackets are to be flanged

and have the same thickness as the floors, and their arm lengths clear

of the frame are to be the same as the reduced floor depth given above.

5.5.7 The face

flat thickness is to be not less than the thickness of the web and

the ratio of the web to the thickness of the face flat is to be not

less than 8 but is not to exceed 16.

5.5.9 Floors

are generally to be continuous from side to side.

5.5.10 The tops

of floors, in general, may be level from side to side. However, in

craft having considerable rise of floor the depth of the floor plate

may require to be increased to maintain the required section modulus.

5.5.11 The floors in the aft peak are to extend over and provide effective support

to the sterntube(s) where applicable.

5.6 Floors in machinery spaces

5.6.2 The depth

and section modulus of floors anywhere between engine or gearbox girders

is to be not less than that required to maintain continuity of structural

integrity or 50 per cent of the depth given in Pt 6, Ch 3, 5.5 Floors general 5.5.3. The face flat area and web thickness

for such reduced floor heights are to be increased appropriately in

order to maintain continuity of structural strength, see also

Pt 6, Ch 3, 4.12 Grouped frames.

5.7 Machinery seatings

5.7.2 Engine

holding-down bolts are to be arranged as near as practicable to floors

and longitudinal girders. When this cannot be achieved, bracket floors

are to be fitted.

5.7.3 Welding

in way of machinery seatings is to be double continuous and/or full

penetration where appropriate.

5.8 Drainholes in bottom structure

5.8.1 Sufficient

limber holes are to be cut in the internal bottom structure to allow

for the drainage of water from all parts of the bilge to the pump

suctions.

5.8.2 Particular

care is to be given to the positioning of limber holes to ensure adequate

drainage and to avoid stress concentrations.

5.8.3 Suitable

arrangements are to be made to provide free passage of air from all

parts of tanks to the air pipes.

5.9 Rudder horns

5.9.1 The shell

plating thickness in way of the rudder horn is to be increased locally,

by generally not less than 50 per cent but need not to be taken as

greater than the keel thickness required by Pt 6, Ch 3, 3.2 Plate keel.

5.9.2 The scantlings

of the rudder horn are to be such that the section modulus against

transverse bending, Z

r, at any horizontal

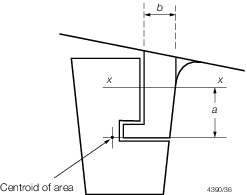

section XX (see

Figure 3.5.1 Rudder horn)

is not less than:

where

|

R

A

|

= |

total rudder area, in m2

|

|

V

|

= |

maximum

speed in the fully loaded condition, in knots |

|

K

V

|

= |

1,0 for displacement craft with

|

|

|

= |

(1,12 - 0,005 V)3 for planing and semi-planing craft with

|

|

a, b

|

= |

dimensions, in metres, as given in Figure 3.5.1 Rudder horn

|

|

L

WL

|

= |

is as defined in Pt 3, Ch 1, 6.2 Principal particulars 6.2.5

|

5.9.3 Rudder

horns are to be effectively integrated into the adjacent structure

and their design is to be such as to facilitate this.

Figure 3.5.1 Rudder horn

5.10 Sternframes

5.11 Skeg construction

5.11.1 Skegs

are to be effectively integrated into the adjacent structure and their

design is to be such as to facilitate this.

5.11.3 The scantlings

of skegs are to be sufficient to withstand any docking forces that

they may be subjected to.

5.12 Forefoot and stem

5.12.1 The thickness

of plate stems at the waterline is to comply with the requirements

for plate keels as given in Pt 6, Ch 3, 3.2 Plate keel.

5.12.2 The forefoot

and stem is to be additionally reinforced with floors.

5.13 Transom knee

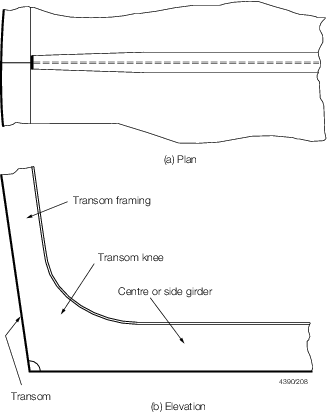

5.13.1 Centre

and side girders are to be bracketed to the transom framing members

by means of substantial knees. The face flat of the girders may be

gradually reduced to that of the transom stiffening members in accordance

with Figure 3.5.2 Transom knee.

5.13.2 Hard

spots are to be avoided in way of the end connections and care is

to be taken to ensure that the stiffening member to which the transom

knee is bracketed can satisfactorily carry the transmitted loads.

Figure 3.5.2 Transom knee

|