Section

3 Sternframes and appendages

3.1 General

3.1.1 Sternframes,

rudder horns and boss end brackets may be constructed of cast or forged

steel, cast or forged aluminium alloy, fabricated from aluminium or

steel plate or moulded from fibre reinforced plastic dependent upon

the material of construction of the craft. Where shaft brackets are

fitted these may be either fabricated, cast or forged from steel or

aluminium alloy as applicable to the material of construction of the

main hull.

3.1.2 In castings,

sudden changes of section or possible constrictions to the flow of

metal during casting are to be avoided. All fillets are to have adequate

radii, which, in general, are to be not less than 50 to 75 mm, depending

on the size of the casting.

3.1.4 Sternframes,

rudder horns, shaft brackets, etc. are to be effectively integrated

into the craft structure, and their design is to be such as to facilitate

this.

3.2 Sternframes

3.2.1 The scantlings

of sternframes are to be determined from Table 3.3.1 Sternframes. In the case of very large craft, the scantlings and

arrangements may be required to be verified by direct calculations.

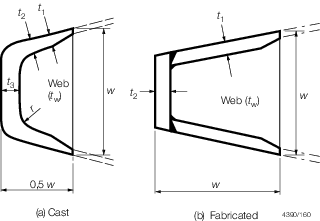

Table 3.3.1 Sternframes

| Item

|

Parameter

|

Requirement

|

| (1) Propeller posts

|

|

Cast steel

(see

Figure 3.3.1 Propeller posts)

|

Forged

steel

(see

Figure 3.3.1 Propeller posts)

|

Fabricated mild

steel

(see

Figure 3.3.1 Propeller posts)

|

|

|

l

|

165

|

-

|

200  mm mm

|

|

|

r

|

20

|

-

|

18  mm mm

|

|

|

tw

|

8

|

-

|

6  mm mm

|

|

|

|

(need

not exceed 38 mm)

|

|

(need

not exceed 30 mm)

|

|

|

|

(see Notes 1 and 2)

|

|

(see Notes 1 and 2)

|

|

|

t1

|

12  (min 19 mm) (min 19 mm)

|

-

|

12  mm mm

|

|

|

t2

|

16  (min 25 mm) (min 25 mm)

|

-

|

-

|

|

|

W

|

115  mm mm

|

40  mm mm

|

140  mm mm

|

|

|

A

|

-

|

(10 +

0,5L

R)T cm2

|

-

|

|

|

|

|

where

L

R ≤ 60 m

|

|

|

|

|

|

40T cm2

|

|

|

|

|

|

where

L

R ≤ 60 m

|

|

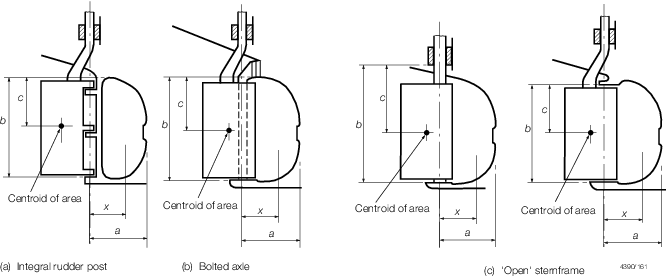

| (2) Propeller boss (see Note 3 and

Figure 3.3.2 Propeller boss)

|

tb

|

mm, but need not

exceed mm, but need not

exceed

|

| (3) Rudder posts or

axles

|

|

Single screw with integral solepiece,

see

Figure 3.3.5 Solepiece

|

Single screw with bolted rudder axle,

see

Figure 3.3.3 Rudder axle

|

Twin screw, integral with hull,

see

Figure 3.3.4 Rudder post for twin screw craft

|

| n

|

-

|

6

(see Note 4)

|

-

|

| r

|

-

|

-

|

20  mm mm

|

| rb

|

-

|

Amm Amm

|

-

|

| tF

|

-

|

bmm bmm

|

-

|

| t1

|

-

|

-

|

12  mm mm

|

| t2

|

-

|

-

|

15  mm mm

|

| t3

|

-

|

-

|

18 mm mm

|

| w

|

-

|

-

|

120  mm mm

|

| zPB1, zPB2

|

-

|

mm mm

|

-

|

| ZT

|

|

-

|

-

|

A A

|

-

|

mm mm

|

-

|

|

|

|

but

need not exceeded

|

|

|

|

|

mm mm

|

|

b b

|

-

|

mm or mm or

|

-

|

|

|

|

mm mm

|

|

|

|

|

whichever is the greater

|

|

PL1, PL1,  PL2 PL2

|

-

|

As for

rudder pintles

|

-

|

| bearing

pressure and pintle clerance

|

|

(see

Table 3.2.10 Pintle requirements)

|

|

| 4) Solepieces (see Notes 5,6 and 7)

|

|

With integral rudder

post, see

Figure 3.3.5 Solepiece

|

With bolted axle,

see

Figure 3.3.5 Solepiece

|

Open type (no rudder

post), see

Figure 3.3.5 Solepiece

|

| (a) Cast Steel

|

ZT

|

0,50W

cm3

|

0,95W

cm3

|

1,00W

cm3

|

|

|

ZV

|

0,35W

cm3

|

0,40W

cm3

|

0,50W

cm3

|

| (b) Fabricated mild

steel

|

ZT

|

0,42W

cm3

|

0,81W

cm3

|

0,85W

cm3

|

| Symbols

|

|

L

R, T as defined in Pt 3, Ch 1, 6.2 Principal particulars

|

|

n

|

= |

number of bolts in palm coupling |

|

|

r

b

|

= |

mean distance of bolt centres from centre of palm, in

mm |

|

|

t

b

|

= |

finished thickness of boss, in mm |

|

|

x |

= |

distance, in metres, from centre of rudder stock to

section under consideration |

|

|

A

|

= |

cross-sectional area of forged steel propeller post,

in cm2

|

|

|

A

R

|

= |

total rudder area, in m2

|

|

|

L

1

|

= |

L

R, but is to be taken not less than 90 m |

|

|

V

|

= |

maximum service speed, in knots, with the craft in

the loaded condition |

|

|

W

|

= |

|

|

|

Z

T

|

= |

section modulus against transverse bending, in

cm3

|

|

|

Z

V

|

= |

section modulus against vertical bending, in

cm3

|

|

|

δb

|

= |

diameter of coupling bolts, in mm |

|

|

δTS

|

= |

diameter of tail shaft, in mm |

|

Note

1. Where scantlings and proportions of

the propeller post differ from those shown in Item 1, the section

modulus about the longitudinal axis of the proposed section normal to

the post is to be equivalent to that with Rule scantlings. t

1 is to be not less than 8 (minimum of 19mm for cast steel sternframes) (minimum of 19mm for cast steel sternframes)

|

Note

2. On sternframes without solepieces, the

modulus of the post below the propeller boss, about the longitudinal

axis may be gradually reduced to not less than 85% of that required by

Note 1, subject to the same thickness limitations.

|

Note

3. In fabricated sternframes the

connection of the propeller post to the boss is to be by full

penetration welds.

|

Note

4. If more than six bolts are fitted, the

arrangements are to provide equivalent strength.

|

Note

5. In fabricated solepieces, transverse

webs are to be fitted spaced not more than 760 mm apart. Where the

breadth of the solepiece exceeds 900 mm, a centreline vertical web is

also to be fitted.

|

|

|

Note

7. For dredging and reclamation craft in

restricted service Groups G1, G2 or G3, the scantlings of an `open'

type solepiece are to be such that:

(a) Z

T = 0,625W cm3

(b) The cross-sectional area is not less than

18 cm2.

(c) The depth is not less than two-thirds of

the width at any point.

|

3.2.2 Fabricated

and cast propeller posts and rudder posts of twin screw craft are

to be strengthened at intervals by webs. In way of the upper part

of the sternframe arch, these webs are to line up with the floors.

3.3 Rudder horns

3.4 Shaft bossing

3.4.1 Where the

propeller shafting is enclosed in bossings extending back to the bearings

supporting the propellers, the aft end of the bossings and the bearings

are to be supported by substantially constructed boss end castings

or fabrications. These are to be designed to transmit the loading

from the shafting efficiently into the craft's internal structure.

3.4.2 For shaft

bossings attached to shaft brackets, the length of the boss is to

be adequate to accommodate the aftermost bearing and to allow for

proper connection of the shaft brackets.

3.4.3 Cast steel

supports are to be suitably radiused where they enter the main hull

to line up with the boss plating radius. Where the hull sections are

narrow, the two arms are generally to be connected to each other within

the craft. The arms are to be strengthened at intervals by webs.

3.4.4 Fabricated

supports are to be carefully designed to avoid or reduce the effect

of hard spots. Continuity of the arms into the craft is to be maintained,

and they are to be attached to substantial floor plates or other structure.

The connection of the arms to the bearing boss is to be by full penetration

welding.

3.4.5 The scantlings

of supports will be specially considered. In the case of certain high

powered craft, direct calculations may be required.

3.4.6 The boss

plating is generally to be radiused into the shell plating and supported

at the aft end by diaphragms at every frame. These diaphragms are

to be suitably stiffened and connected to floors or a suitable arrangement

of main and deep web frames. At the forward end, the main frames may

be shaped to fit the bossing, but deep webs are generally to be fitted

not more than four frame spaces apart.

3.5 Shaft brackets

3.5.2 Where the

propeller shafting is exposed to the sea for some distance clear of

the main hull, it is generally to be supported adjacent to the propeller

by independent brackets having two arms. In very small craft the use

of single arm brackets will be considered.

3.5.3 Fabricated

brackets are to be designed to avoid or reduce the effect of hard

spots and ensure a satisfactory connection to the hull structure.

The connection of the arms to the bearing boss is to be by full penetration

welding.

3.5.4 Where bracket

arms are carried through the shell plating, they are to be attached

to floors or girders of increased thickness. The shell plating is

to be increased in thickness and connected to the arms by full penetration

welding.

3.5.5 In the

case of certain high powered craft direct calculations may be required.

3.5.7 The length

of the shaft bracket boss, lb

, is to be sufficient

to support the length of the required bearing. In general lb

is

not to be less than 4dt

, where dt

is

the Rule diameter of the screwshaft, in mm, see

Pt 11, Ch 2, 4.4 Screwshafts and tube shafts. Proposals for a reduction

in the required shaft bracket boss length will be considered in conjunction

with details of the bearing material, allowable bearing operating

pressure and installation arrangements, see

Pt 11, Ch 2, 4.16 Sternbushes and sterntube arrangements 4.16.2. However in no

case is lb

to be less than the greater of:

-

2dt

;

or

-

that recommended

by the bearing manufacturer; or

-

as required by Pt 3, Ch 3, 3.4 Shaft bossing 3.4.2.

Figure 3.3.4 Rudder post for twin screw craft

3.5.8 Where the shaft and the shaft bracket boss are

of the same material, the thickness of the shaft bracket boss is not to be less than

dt

/4. Where the shaft and the shaft bracket boss are of dissimilar materials, the

thickness of the boss, tb

, is to be not less than:

Note In no case is t

b to be taken as less than 12 mm.

where

|

d

t

|

= |

Rule diameter of the screwshaft, in the appropriate screwshaft

material, in mm, see

Pt 11, Ch 2, 4 Design and construction

|

|

f

1

|

= |

σS/σB but not less than 0,825 |

|

σS

|

= |

ultimate tensile strength of the shaft material, in N/mm2

|

|

σB

|

= |

ultimate tensile strength of the boss material, in N/mm2. |

3.5.9 The design

of the shaft brackets with regard to hydrodynamic effects causing

vibrational excitations as well as disturbance of the hydrodynamic

flow into the propeller and rudders is outside the scope of classification.

However, it is recommended that the effects of periodic excitation

caused by vortex shedding or other sources be carefully examined in

order to prevent excessive structural vibration. The responsibility

for such investigation rests with the designer.

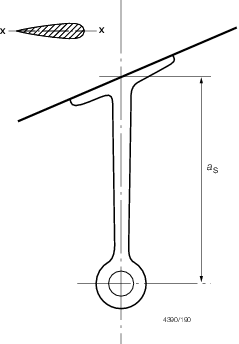

3.6 Single arm shaft brackets (`P' - brackets)

3.6.1 Single

arm shaft brackets are to have a section modulus, Z

xx,

at the palm of not less than that determined from the formula:

The cross-sectional area of the bracket at the boss is to be

not less than 60 per cent of the area of the bracket at the palm.

3.6.2 For single

arm shaft brackets a vibration analysis may be required if deemed

necessary by LR.

Figure 3.3.5 Solepiece

Figure 3.3.6 Single arm shaft bracket

3.7 Double arm shaft brackets (`A' - brackets)

3.7.1 The angle

between the arms for double arm shaft brackets is to be generally

not less than 50o. Proposals for the angle between the

arms to be less than 50o will be specially considered with

supporting calculations to be submitted by the designers.

3.8 Intermediate shaft brackets

3.9 Attachment of shaft brackets by welding

3.9.1 Fabricated

supports are to be carefully designed to avoid or reduce the effect

of hard spots. Continuity of the arms into the craft is to be maintained,

and they are to be attached to substantial floor plates or other structure.

The connection of the arms to the bearing boss is to be by full penetration

welding.

3.10 Attachment of shaft brackets by bolting

3.10.1 The bottom

shell thickness in way of the double arm propeller bracket palms is

to be increased by 50 per cent. The bottom shell thickness in way

of single arm propeller brackets palms is to be doubled in thickness.

The insert plates, or reinforced shell laminate in FRP craft, are

to be additionally supported by substantial floor plates or other

structure.

3.10.2 Where

shaft brackets are attached by bolts, they are to be provided with

substantial palms securely attached to the hull structure which is

to be adequately stiffened in way. Where bolts are used, the nuts

are to be suitably locked.

3.10.3 The bracket

palms may be bolted directly onto the shell using a suitable bedding

compound. The palms may be bolted onto suitable shims or chocking

compound, of an approved type, to facilitate alignment.

3.10.4 Where

brackets are bolted onto resin chocks, plans indicating the following

information are to be submitted for approval:

-

The thrust and torque loads, where applicable,

that will be applied to the chocked item.

-

The torque load to be applied to the bracket

mounting bolts.

-

The material of the bracket mounting bolts.

-

The number, thread size, shank diameter and

length of the mounting bolts.

3.10.5 The minimum

thickness of a resin chock is to be 12 mm.

3.10.7 The diameter

of the propeller bracket mounting bolts is to be not less than:

and not less than the shell plate thickness in way

of the palm or 12 mm, whichever is greater

3.10.8 Where

the shaft bracket and the shaft bracket mounting bolts are of dissimilar

materials (which are galvanically compatible), the diameter of the

propeller bracket mounting bolts, as determined from Pt 3, Ch 3, 3.10 Attachment of shaft brackets by bolting 3.10.7, is to be modified in proportion

to the square root of the yield strengths of the particular materials.

The corrected bolt diameter of the dissimilar material is to be not

less than the propeller bracket boss thickness.

3.10.9 The propeller

bracket palms are to have fitted bolts, and suitable arrangements

provided to lock the nuts.

3.10.10 A washer

plate is to be provided, generally of equal dimensions to the bracket

palm with thickness t

b/6 mm, subject to a

minimum of 3 mm.

3.11 Attachment of shaft brackets by bonding

3.11.1 Proposals

to connect shaft brackets to FRP hulls by bonding will be the subject

of special consideration. Details of the following are to be submitted:

-

Preparation of the

hull penetration and internal bonding surface.

-

Details of transverse

through pinning of the shaft bracket strut.

-

Details of over

bonding of strut and pin arrangement and subsequent integration of

strut into primary hull structure.

3.12 Alignment of shaft brackets

3.12.1 Particular

care is to be paid to the alignment of shaft brackets to minimise

vibration and cyclic loadings being transmitted from the propulsion

shafting and propellers into the hull structure.

3.12.3 The alignment of shaft brackets connected by welding or bonding may be

facilitated by boring of the bracket boss after attachment of the shaft bracket and

sterntube.

3.13 Sterntubes

3.13.1 The sterntube

construction may be of aluminium alloy, steel, bronze or fibre reinforced

plastic.

3.13.2 The sterntube

scantlings are to be individually considered.

3.13.3 For steel

and aluminium hulls, the bottom shell, in way of the sterntube, is

to be additionally reinforced by means of an insert plate to increase

the bottom shell thickness by 50 per cent.

3.13.4 For FRP

hulls, the bottom shell laminate, in way of the sterntube, is to be

locally increased by 50 per cent by gradual tapering of the laminate.

The increased thickness in way of the sterntube need not exceed the

Rule keel thickness requirement.

3.13.5 For FRP

sandwich hulls the shell in way of the stern tube connection is to

be either:

-

Reduced from sandwich hull construction to

single skin laminate by removal of the core and by combining the inner

and outer skins. The single skin region is then to be additionally

reinforced by a minimum of 50 per cent of the sum of the inner and

outer sandwich laminate. The increased thickness in way of the sterntube

need not be greater than the Rule keel thickness requirement.

-

Reduced from the sandwich hull construction to a single skin laminate

by removal of the core and combining the inner and outer skins. After bonding in

the sterntube to the single skin laminate the foam core and the inner skin are to

be reinstated.

-

Proposals to replace the sandwich core with

a core having higher core shear strength and compressive strength

than that of the adjacent structure prior to bonding the tube to the

inner and outer skins will be the subject of special consideration.

3.13.6 The sterntube

may be connected to the shell by bonding, bolting or welding as applicable

depending upon the construction material of the shell.

3.13.7 When

bonding in sterntubes the bonding angle laminate weight is to be not

less than the Rule minimum bottom weight. FRP tubes are to be thoroughly

abraded and degreased prior to installation and laminating. Bonded

in metallic tubes are to be knurled in way of the bonding material

and thoroughly degreased prior to installation. During the bonding

operation particular care is to be given to maintaining the sterntube

alignment.

3.13.8 Where

sterntubes are to be retained by bolting, they are to be provided

with a substantial flange securely attached to the hull structure.

Where bolts are used, the nuts are to be suitably locked.

3.13.9 Where sterntubes are to be welded to hull insert plates full penetration

welding is required.

3.13.11 The

region where the shafting enters the craft, and the bearing in way,

are to be adequately supported by floors or deep webs.

3.13.12 The

shaft bearings are to be secured against rotation within the sterntube.

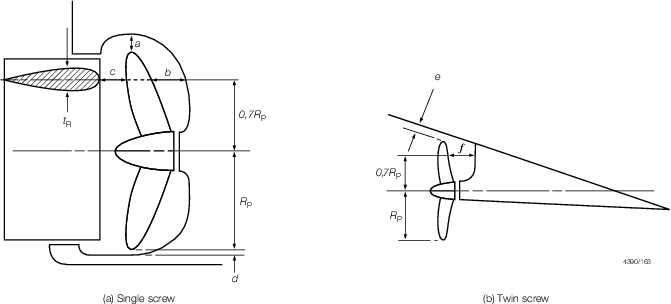

Figure 3.3.8 Propeller clearance

3.13.14 Where difficulty in welding or bonding of sterntube to the hull is anticipated due to

small clearances or tight angles, a local cofferdam or watertight compartment of

moderate volume is to be fitted enclosing the hull penetration and the sterntube. Where

the sterntube penetrates the inboard boundary of the watertight compartment or

cofferdam, it is to be suitably supported and sealed.

3.14 Solepieces

3.15 Propeller hull clearances

3.15.1 Recommended

minimum clearances between the propeller and the sternframe, rudder

or hull are given in Table 3.3.2 Recommended propeller hull

clearances.

These are the minimum distances considered desirable in order to expect

reasonable levels of propeller excited vibration. Attention is drawn

to the importance of the local hull form characteristics, shaft power,

water flow characteristics into the propeller disc and cavitation

when considering the recommended clearances.

Table 3.3.2 Recommended propeller hull

clearances

Number

of Blades

|

Hull clearances for single screw, in metres,

|

Hull clearances for twin screw

|

|

see

Figure 3.3.8 Propeller clearance

|

in metres, see

Figure 3.3.8 Propeller clearance

|

| a

|

b

|

c

|

d

|

e

|

f

|

| 3

|

1,20Kδ

|

1,80Kδ

|

0,12δ

|

0,03δ

|

1,20Kδ

|

1,20Kδ

|

| 4

|

1,00Kδ

|

1,50Kδ

|

1,12δ

|

0,03δ

|

1,00Kδ

|

1,20Kδ

|

| 5

|

0,85Kδ

|

1,275Kδ

|

0,12δ

|

0,03δ

|

0,85Kδ

|

0,85Kδ

|

| 6

|

0,75Kδ

|

1,125Kδ

|

0,12δ

|

0,03δ

|

0,75Kδ

|

0,75Kδ

|

|

|

|

|

|

|

|

|

| Minimum value

|

0,10δ

|

0,15δ

|

t

R

|

-

|

3 and 4 blades

|

0,15δ

|

|

|

|

|

|

|

0,20δ

|

|

|

|

|

|

|

|

5 and 6 blades

|

|

|

|

|

|

|

|

0,16δ

|

|

| Symbols

|

|

L

R and C

b as defined in Pt 3, Ch 1, 6.1 General

|

|

t

R

|

= |

thickness of rudder, in metres measured at

0,7R

p above the shaft centreline |

|

P

s

|

= |

designed power on one shaft, in kW |

|

R

p

|

= |

propeller radius, in metres |

|

δ |

= |

propeller diameter, in metres |

|

Note The above recommended minimum clearances also apply to

semi-spade type rudders.

|

|