Section

2 Hull girder strength

2.1 Application

2.1.1 The

requirements for longitudinal strength of trimarans are contained

within this Section.

2.1.2 Longitudinal

strength calculations are to be carried out for all vessels, covering

the range of load and ballast conditions proposed, in order to determine

the required hull girder strength. Still water, static wave and dynamic

bending moments and shear forces are to be calculated for both departure

and arrival conditions.

2.2 Section modulus calculation

2.2.1 In general,

the effective sectional area of continuous longitudinal strength members,

after deduction of openings, is to be used for the calculation of

the midship section modulus.

2.2.2 Initially,

the side hulls and deck structure extending outside the breadth of

the main hull may only be considered effective if the cross-deck length

is greater than 0,4L. Additional structure may be incorporated

into the section modulus calculations if proven effective by a global

finite element analysis. This analysis must be submitted to and approved

by LR.

2.2.3 In general,

sections are to be evaluated along the length of the ship to adequately

represent structural transitions. If portions of the side hull and

decks outside the breadth of the main hull are considered longitudinally

effective according to Vol 1, Pt 6, Ch 3, 2.2 Section modulus calculation 2.2.2,

additional sections are to be calculated at amidships of the side

hull, at side hull terminations, and at any other appropriate sections

to capture the transitions of the side hulls.

2.2.6 Structural

members which contribute to the overall hull girder strength are to

be carefully aligned so as to avoid discontinuities resulting in abrupt

variations of stresses and are to be kept clear of any form of opening

which may affect their structural performance.

2.2.7 In general,

short superstructures or deckhouses will not be accepted as contributing

to the global longitudinal or transverse strength of the ship. However,

where it is proposed to include substantial, continuous stiffening

members, special consideration will be given to their inclusion on

submission of the designer's/builder's calculations.

2.2.8 Where

continuous deck longitudinal or deck girders are arranged above the

strength deck, special consideration may be given to the inclusion

of their sectional area in the calculation of the hull section modulus.

2.2.9 Adequate

transition arrangements are to be fitted at the ends of effective

continuous longitudinal strength members in the deck and bottom structures.

2.2.10 Structural

material which is longitudinally continuous but which is not considered

to be fully effective for longitudinal strength purposes will need

to be specially considered. The global longitudinal strength assessment

must take into account the presence of such material when it can be

considered effective. The consequences of failure of such structural

material and subsequent redistribution of stresses into or additional

loads imposed on the remaining structure must be considered.

2.2.11 In

particular, all longitudinally continuous material will be fully effective

in tension whereas this may not be so in compression due to a low

buckling capability. In this case, it may be necessary to derive and

apply different hull girder section moduli to the hogging and sagging

bending moment cases.

2.2.12 Openings

in decks, longitudinal bulkheads and other longitudinal effective

material having a length in the fore and aft directions exceeding

0,1B m or 2,5 m or a breadth exceeding 1,2 m or 0,04B m

whichever is the lesser, are in all cases to be deducted from the

sectional areas used in the section modulus calculation. B is

as defined in Vol 1, Pt 1, Ch 1, 5.2 Principal particulars.

2.2.13 Openings

smaller than stated in Vol 1, Pt 6, Ch 3, 2.2 Section modulus calculation 2.2.9,

including manholes, need not be deducted provided they are isolated

and the sum of their breadths or shadow area breadths, see

Vol 1, Pt 6, Ch 3, 2.2 Section modulus calculation 2.2.14, in one transverse section

does reduce the section modulus at deck or bottom by more than 3 per

cent.

2.2.14 The

expression 0,06 (B

1 – b

1),

where B

1 equals the breadth of the ship at

the section considered and equals the sum of the breadths of deductible

openings, may be used for deck openings in lieu of the 3 per cent

limitation of reduction of section modulus in Vol 1, Pt 6, Ch 3, 2.2 Section modulus calculation 2.2.13.

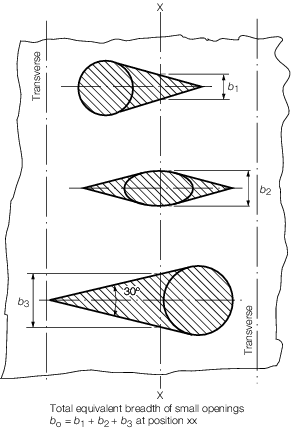

2.2.15 Where

calculating deduction-free openings, the openings are assumed to have

longitudinal extensions as shown by the shaded areas in Figure 3.2.3 Isolated openings. The shadow area is obtained

by drawing two tangent lines to an opening angle of 30°. The section

to be considered is to be perpendicular to the centreline of the ship

and is to result in the maximum deduction in each transverse space.

Figure 3.2.3 Isolated openings

2.2.16 Isolated

openings in longitudinals or longitudinal girders need not be deducted

if their depth does not exceed 25 per cent of the web depth or 75

mm, whichever is the lesser.

2.2.17 Openings

are considered isolated if they are spaced more than 1 m apart.

2.2.18 A

reduction for drainage holes and scallops in beams and girder, etc.

is not necessary so long as the global section modulus at deck or

keel is reduced by no more than 0,5 per cent.

2.3 Higher tensile steel

2.3.1 Higher

tensile steel may be used for both deck and bottom structures or deck

structure only. Where fitted for global strength purposes, it is to

be used for the whole of the longitudinally continuous material for

the following vertical distances:

-

z

htd below the line of deck at side

-

z

htb above the top of keel

where

F

D and F

B are not to be taken as less than k

g and are defined in Vol 1, Pt 6, Ch 3, 2.3 Higher tensile steel 2.3.2

z

D, z

B and k

g and are defined in Vol 1, Pt 6, Ch 1, 1.3 Symbols and definitions.

2.3.2 Where

the maximum hull vertical bending stress at the deck or keel is less

than the permissible combined stress, σp, reductions in local

scantlings within to 0,3L

R to 0,7L

R may be permitted. The reduction factors are defined as follows:

-

For hull members

above the neutral axis

-

For hull member

below the neutral axis

where

σD, σB and σws are defined in Vol 1, Pt 6, Ch 1, 1.3 Symbols and definitions 1.3.1.

2.3.3 In general,

the values of σD and σB to be used are

the greater of the sagging or hogging stresses. F

D and F

B are not to be taken as less than 0,67 for plating

and 0,75 for longitudinal stiffeners.

2.4 Longitudinal bending strength

2.4.1 The

effective geometric properties of all critical sections along the

length of the ship are to be calculated directly from the dimensions

of the section using only effective material elements which contribute

to the global longitudinal strength irrespective of the grades of

steel incorporated in the construction, see

Vol 1, Pt 6, Ch 3, 2.2 Section modulus calculation.

2.4.2 Where

higher tensile steel is fitted to satisfy global strength requirements,

the extent of higher tensile steel is to be as specified in Vol 1, Pt 6, Ch 3, 2.3 Higher tensile steel. Where a mix of steel grades is

used for plating and associated stiffeners, then the lower of the

steel grades is to be used for the derivation of permissible stresses.

2.4.3 The

longitudinal strength of the ship is to satisfy the following criteria

for the hogging and sagging conditions:

where

|

σp

|

= |

fσhg

fhts σyd

|

|

fσhg

|

= |

0,75 from 0,3LR to 0,7LR

|

| = |

for continuous structural members aft of

0,3LR and forward of 0,7LR for continuous structural members aft of

0,3LR and forward of 0,7LR

|

where

|

X

|

= |

longitudinal distance, in metres, from the F.P. for locations within

the forward end region (forward of 0,7LR) and from the A.P. for

locations within the aft end region (aft of 0,3LR) |

|

fσws

|

= |

limiting working stress coefficient |

| = |

1,2 |

Note that the σws criteria may be relaxed if

it can be demonstrated that either:

- A continuous fatigue monitoring system is to be adopted for the

in-service life of the ship; or

- A fatigue design assessment procedure is applied which demonstrates

that a higher limiting working stress coefficient, f

σws, may be applied.

σB, σD and σp are

given in Table 3.2.1

fhts, fσhg, fσws,

MwHog, MwSag, Mtot,

σyd and σydMild are defined in Vol 1, Pt 6, Ch 1, 1.3 Symbols and definitions.

LR is defined in Vol 1, Pt 1, Ch 1, 5.2 Principal particulars.

| Component stress type

|

Nominal stress, N/mm2

|

| Hull girder bending stress at strength deck,

see Note 1

|

|

| Hull girder bending stress at keel, see

Note 1

|

|

| Hull girder bending stress range, see

Note 2

|

|

Note

1. The hogging and bending moments are to

be considered.

Note

2. The stress range at the keel or other

longitudinally effective material should be used if it is greater than

the stress range at the strength deck.

|

2.4.4 The

design stress due to hull girder bending, σhg, for

each structural member is given by:

2.4.5 Where

different grades of steel are used then it should be ensured that

the design stress in each structural member is less than the permissible

hull vertical bending stress, i.e.

2.5 Minimum hull section modulus

2.5.1 The

hull midship section modulus about the transverse neutral axis, at

the deck or the keel, is to be not less than:

2.6 Minimum hull moment of inertia

2.6.1 The

hull midship section moment of inertia about the transverse neutral

axis is to be not less than the following using the maximum total

bending moment, sagging or hogging:

2.7 Shear strength

2.7.1 The

shear strength of the vessel at any position along its length is to

satisfy the following criteria:

where

|

Q

tot

|

= |

is defined in Vol 1, Pt 5, Ch 1, 1.4 Symbols and definitions

|

|

A

τ

|

= |

is defined in Vol 1, Pt 6, Ch 1, 1.3 Symbols and definitions

|

|

τp

|

= |

0,72τyd

|

|

τyd

|

= |

is

defined in Vol 1, Pt 6, Ch 1, 1.3 Symbols and definitions.

|

|