Section

2 Structural modelling

2.1 Global model

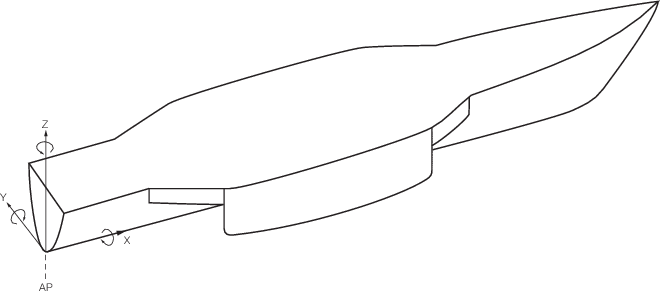

2.1.1 A 3-D

plate element model of the ship is to be used. This model should extend

over the full length, breadth and depth of the ship. In some cases,

a half breadth model may be used with the appropriate symmetrical

boundary conditions. However, to simplify the loading and boundary

conditions, it is recommended that a full breadth model be used.

2.1.2 The

scantlings to be modelled are to be in accordance with those required

by the Rules, as well as those required by the Complementary Rules.

If the Complementary Rules are the Rules and Regulations for

the Classification of Naval Ships (hereinafter referred to

as the Rules for Naval Ships) or the Rules and Regulations for

the Classification of Special Service Craft (hereinafter referred

to as the Rules for Special Service Craft), then these scantlings

are ‘net’ scantlings. If the Complementary Rules are the Rules and Regulations for the Classification of Ships (hereinafter

referred to as the Rules for Ships), the required scantlings are ‘gross’

scantlings. Any additional thicknesses added due to the Enhanced Scantlings

notation are not to be modelled.

2.1.3 The

model should represent, with reasonable accuracy, the actual geometric

shape of the hull. All effective longitudinal material is to be included.

Similarly, all transverse primary structure, i.e. web frames, watertight

and fire divisional bulkheads are to be represented in the model.

The superstructure should also be included in the model.

2.1.4 The

FE model is to be represented using a right handed Cartesian co-ordinate

system, depicted in Figure 2.2.1 FE Co-ordinate system,

where:

-

x is measured

in the longitudinal direction, positive forward from the aft perpendicular

-

y is measured

in the transverse direction, positive to port from the centreline

-

z is measured

in the vertical direction, positive upward from the baseline

Figure 2.2.1 FE Co-ordinate system

2.1.5 The

size and type of plate elements selected are to provide a satisfactory

representation of the deflection and stress distribution within the

ship's structure. In general, the plate element mesh is to follow

the primary stiffening. Typically, the following guidelines are applicable:

-

Longitudinally,

one element between web frames or intermediate floors, if applicable;

-

Vertically, two

elements between decks, stringers, or every second or third stiffener,

whichever is the smaller distance;

-

Transversely,

at least two elements spanning the cross-deck structure and elsewhere,

sufficient elements to maintain a satisfactory panel aspect ratio.

2.1.6 Plate

elements are to have an aspect ratio less than 3, particularly in

areas of interest in the model.

2.1.7 All

primary structure, such as deck plating, bottom and side shell plating,

longitudinal and transverse bulkhead plating, transverse floors, superstructure

blocks, deckhouse blocks and internal structural walls are to be represented

by plate elements. Primary girders, deep beams, web frames, etc. are

to be represented by at least three elements through the depth of

the member in areas of interest.

2.1.9 Secondary

stiffening members may be modelled using line elements having axial

and bending stiffness (bars). These elements may be grouped as necessary

at the plate boundaries.

2.1.10 Pillars

are to be represented by line elements having axial and bending stiffness.

2.1.11 Shell

openings, deck openings, door openings and window openings of a significant

size are to be represented in the model such that the deformation

pattern under hull torsion, shear and bending loads is adequately

represented in way of critical areas.

2.1.12 The

model is to accurately reflect shell and superstructure side recesses,

sweep brackets and superstructure breaks. The basic mesh, as described

in Vol 4, Pt 1, Ch 2, 2.1 Global model 2.1.5 may need to be further

refined in order to include these features.

2.2 Local models

2.2.1 In general,

detailed stress analysis is to be carried out in the following locations, see also Vol 4, Pt 1, Ch 2, 1.1 Application 1.1.4:

-

The connections

of the side hull to the ends of the cross-deck structure.

-

The connections

of the centre hull to the ends of the cross-deck structure.

-

The transverse

bulkhead where the highest shear stresses has been identified from

the global load cases.

-

Areas with discontinuities

in structure such as in way of openings or at the termination points

of major structure.

-

After reviewing

the results from the global load cases, areas in way of high stress

gradients and areas exceeding the stress criteria specified in Table 2.2.1 Stress acceptance criteria

permissible stresses.

Table 2.2.1 Stress acceptance criteria

permissible stresses

|

|

Permissible stresses

|

|

|

σvm

|

σ

|

τ

|

| Global model, coarse mesh

|

0,9σyd

|

0,75σyd

|

0,35σyd

|

| Fine mesh models, individual element

stresses

|

1,2σyd

|

—

|

—

|

| Fine mesh models, average

stress

|

1,0σyd

|

—

|

—

|

Note

2. σ, τ, are to be taken as membrane

stresses.

Note

3. σvm is to be calculated

based on the membrane shear and direct stresses of the plate element.

Note

4. Average von Mises stress is to be

calculated as the average of the von Mises stresses from the element

being assessed and the elements connected to its boundary nodes.

Averaging is not to be carried across structural discontinuity and

abutting structure.

|

2.2.2 Evaluation

of detailed stresses requires the use of refined finite element mesh

density in way of areas of high stress.

2.2.3 The

extent of the local finite element model is to be such that the calculated

stresses at the areas of interest are not significantly affected by

the imposed boundary conditions and application of loads. The boundary

of the fine mesh model is to coincide with main supporting structural

members.

2.2.4 The

mesh size in the fine mesh regions is not to be greater than 100 mm

x 100 mm. A finer mesh size, such as 50 mm x 50 mm, may be required

dependent on vessel size and the detail being considered. The extent

of the fine mesh region is to be in general not less than 10 elements

in all directions from the area under investigation. A smooth transition

of mesh density is to be maintained.

2.2.5 The

structural geometry, particularly in areas of concern is to be accurately

represented.

|