Section

3 Bottom structure

3.1 General

3.1.1 Requirements

are given in this Section for both transversely and longitudinally

framed bottoms.

3.1.3 Provision

is to be made for free passage of water, oil and air from all parts

of single or double bottoms, and account being taken of the pumping

rates required.

3.2 Girders

3.2.1 A centreline

girder is to be arranged in ships having a breadth of more than 6

m, and is to be carried as far forward and aft as practicable, and

is to comply with the requirements of Table 5.3.1 Single bottom construction forward

and aft or Table 5.3.2 Double bottom construction forward

and aft.

Table 5.3.1 Single bottom construction forward

and aft

| Item

|

Parameter

|

Requirements

|

| Transverse framing system

|

|

(1) Floors

|

Web depth at centreline

|

|

|

|

Modulus

|

|

Z

|

= |

6 × k × D

1 × s × lf

2 cm3

|

|

|

|

Web

thickness

|

mm mm

|

|

(2) Centreline girder

|

Web and face plate thickness

|

mm mm

|

|

|

Face plate

width

|

|

| Longitudinal framing system

|

|

(3) Centreline girder

|

Modulus

|

|

Z

|

= |

8,5 × k × D1 × S ×

le

2 cm3

|

|

|

|

Web

thickness

|

|

|

(4) Bottom transverses

|

Modulus

|

|

Z

|

= |

7 × k × D

1 × S × le

2 cm3

|

|

|

|

Web

thickness

|

|

| Symbols

|

B, D, T, S, s, le,

Z and t are as defined in Pt 3, Ch 5, 1.4 Symbols and definitions 1.4.1

|

D1

|

= |

D, but need not be taken greater than T + 0,4 m for

Zone 3, T + 0,7 m for Zone 2, T + 1,0 m for Zone

1 |

|

df

|

= |

depth of floor or bottom transverse at centreline, in

mm |

|

lf

|

= |

span of the floor, and is normally the breadth of the

ship measured on the top of the floor under consideration, in

metres. If longitudinal bulkheads or equivalent floor supports are

provided an equivalent breadth may be used, but this should be not

less than 0,4B

|

|

w

|

= |

width of face plate of a member, in mm |

|

Note The thickness of plates forming the single bottom

structure is to be not less than 5 mm.

|

Table 5.3.2 Double bottom construction forward

and aft

| Item

|

Parameter

|

Requirements

|

| Transverse and longitudinal framing system

|

|

(1) Centre girder

|

Least depth

|

The greater of:

|

d

f

|

= |

mm mm |

|

| Thickness

|

|

|

(2) Inner bottom plating

|

Thickness for dry spaces

|

|

| Thickness for tanks

|

The greater of:

|

| (3) Struts

|

Cross-sectional area

|

|

Area

|

= |

2 × le × D1 ×

s cm2

|

|

|

(4) Watertight floors

|

Thickness

|

The thickness of plate floors + 0,5

mm

|

| Transverse framing system

|

|

(5) Plate floors and brackets of bracket floors

|

Thickness

|

mm mm

|

|

(6) Bottom frames in bracket floors

|

Modulus

|

|

Z

|

= |

6 × k × s × D

1 × le

2 + 1,5 + 0,05L cm3

|

|

|

(7) Reverse frames in bracket floors

|

Modulus

|

|

Z

|

= |

5,5 × k × s × h ×

le

2 + 1,5 + 0,05L cm3

|

|

| Longitudinal framing system

|

|

(8) Plate floors

|

Thickness

|

mm mm

|

|

(9) Tank top longitudinal

|

Modulus

|

|

Z

|

= |

5,5 × k × s × h ×

le

2 + 1,5 + 0,05L cm3

|

|

| Symbols

|

L, D, T, S, s, t, and Z are

as defined in Pt 3, Ch 5, 1.4 Symbols and definitions 1.4.1

|

D1

|

= |

D, but need not be taken greater than T + 0,4 m or

Zone 3, T + 0,7 m for Zone 2, T + 1,0 m for Zone

1 |

|

df

|

= |

depth of bottom in way of centre girder, in mm |

|

h

|

= |

load head, which is to be taken as the greater of

h

4 or h

5, in metres |

|

h5

|

= |

distance, in metres, from mid point of span to the

deck at side or to a point T + 0,4 m above the baseline,

whichever is the lesser, but is to be taken as not less than 1 m |

|

lb

|

= |

the width of the double bottom, in metres, and is

normally the breadth of the ship. If longitudinal bulkheads or

equivalent support is provided, an equivalent breadth may be used,

but this should be not less than 0,8B

|

|

t1

|

= |

thickness of inner bottom plating or bottom plating,

whichever is the lesser, in mm |

|

Note The thickness of plating forming the double bottom

structure is to be not less than:

5 mm for dry tanks and oil tanks

5,5 mm for water ballast tanks

|

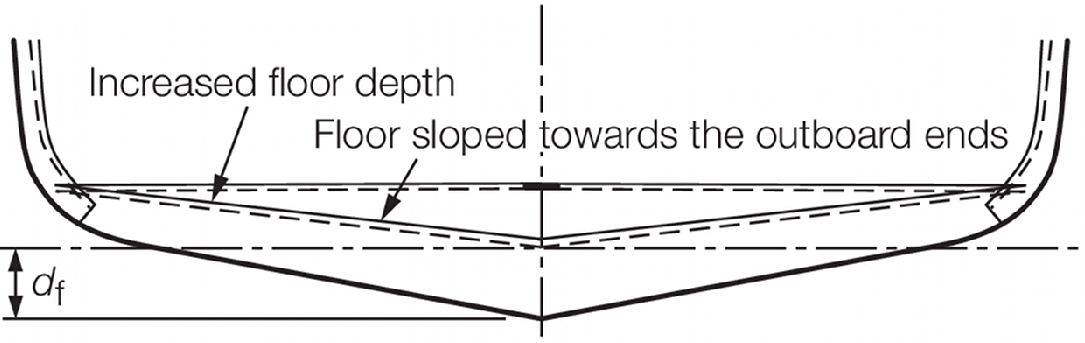

3.3 Single bottom – Transverse framing

3.3.1 Plate floors

are to be fitted at every frame and the scantlings are to comply with

the requirements of Table 5.3.1 Single bottom construction forward

and aft.

The depth of floors at the centreline is to be as required in Table 5.3.1 Single bottom construction forward

and aft, but in ships having considerable

rise of floor towards the ends, the depth of floors may require to

be increased, or the top edge sloped upwards towards the outboard

end, see

Figure 5.3.1 Basic floor arrangements.

If required floors may be cut at the centreline, with the girder web

plate continuous, but the strength of the floors is to be maintained

in way of the centre girder connection. Notwithstanding the requirements

for the fitting of a centreline girder as per Pt 3, Ch 5, 3.2 Girders 3.2.1, suitable arrangements to prevent

tripping of the floors, e.g. riders or tripping brackets, are to be

provided, where the unsupported length of the top edge of the floors

exceeds 20b m;

where

b is the width in metres of the

face plate of the floor.

Figure 5.3.1 Basic floor arrangements

3.3.2 The centre

girder is to have the same depth as the floors.

3.4 Single bottom - Longitudinal framing

3.4.1 Longitudinals

are to be supported by transverses spaced not more than 3,5 m apart.

The transverses are to be supported by a primary centreline girder

or a centreline bulkhead. Tripping brackets connecting transverse

to longitudinal are to be fitted between the centreline girder and

shell at intervals not exceeding 3,5 m. The centreline girder may

be omitted, provided the scantlings of the transverses are suitable

for a span from side to side of the ship, and tripping brackets are

fitted about 3,5 m or 20b m apart, whichever is the lesser,

where b is the width in metres of the face plate of the

transverse. Longitudinals are to be determined from Table 5.4.1 Shell frames and longitudinals

forward and aft. The scantlings of the

centreline girder and bottom transverses are to be determined from Table 5.3.1 Single bottom construction forward

and aft.

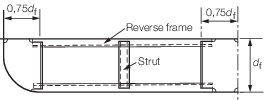

3.5 Double bottoms

3.5.2 Plate floors

in a transverse framing system are generally to be fitted at every

frame and the scantlings are to comply with the requirements of Table 5.3.2 Double bottom construction forward

and aft. Vertical stiffeners having

a depth of 80d

f mm are to be fitted to the

floors and spaced not more than 2,5 m apart. The ends of these stiffeners

may be sniped. Alternatively, bracket floors may be fitted, see

Figure 5.3.2 Bracket floor, in which case the spacing

of the plate floors is not to exceed 2,5 m.

Figure 5.3.2 Bracket floor

3.5.3 Where bracket

floors are fitted the unsupported span of bottom frames and reverse

frames is not to exceed 2,5 m. Struts may be fitted to reduce the

unsupported span. If a strut is fitted at approximately half-span,

the modulus of bottom and reverse frames may be reduced by 50 per

cent. Struts are to comply with the requirements of Table 5.3.2 Double bottom construction forward

and aft. Watertight or plate floors

are to be fitted below or in the vicinity of watertight bulkheads.

3.5.4 Where a

longitudinal framing system is adopted in a double bottom, the scantlings

of tank top longitudinals and plate floors are to comply with the

requirements given in Table 5.3.2 Double bottom construction forward

and aft.

Vertical stiffeners having a depth not less than 50 mm are to be fitted

to the floors at every fourth longitudinal. The plate floors are to

be spaced not more than 3,5 m apart. The centre girder may require

to be stiffened when the height of the bottom is excessive. If a strut

is fitted at approximately half-span the modulus of bottom and tank

top longitudinals may be reduced by 50 per cent. Struts are to comply

with the requirements of Table 5.3.2 Double bottom construction forward

and aft.

3.6 Swim end forward

3.6.1 Where a

longitudinal framing system is adopted, the transverses or floors

supporting longitudinals are to be spaced not more than 2,5 m apart,

and the moduli of longitudinals and transverses are to be increased

by 40 per cent.

3.6.2 Where a

transverse framing system is adopted in swim ends, the modulus of

plate floors is to be increased by 40 per cent.

3.6.3 The draught

for calculation of the structural members may be taken as the actual

draught in way of the respective member.

|