Section

4 Shell envelope framing

4.1 General

4.1.1 Requirements

are given in this Section for both longitudinal and transverse framing

systems. Where longitudinal framing is adopted in the midship region

it is to be carried forward and aft to at least the fore end and aft

end of the cargo space, including cofferdams in the case of tankers.

4.2 Shell framing

4.2.1 The scantlings

of side frames in the forward and aft regions are to comply with the

requirements given in Table 5.4.1 Shell frames and longitudinals

forward and aft.

Table 5.4.1 Shell frames and longitudinals

forward and aft

|

|

Location

|

Modulus, in cm3

|

4 4

|

| (1)

|

Frames clear of tanks

|

Z1 = 1,2D1 x k x s

(2,5H2 + 0,03B2 + 6)

|

|

| (2)

|

Frames in way of fuel oil

or water tanks

|

The greater of the following:

|

|

| (a)

|

Z2 = Z1

|

|

| (b)

|

Z2 = as required by Pt 3, Ch 7 Bulkheads

|

|

| (3)

|

Bottom and side shell longitudinals

clear of tanks

|

Z3 = 6 x k x s x h5 x

le

2 + 1,5 + 0,05L

|

|

| (4)

|

Bottom and side shell

longitudinals in way of tanks

|

The greater of the following:

|

|

| (a)

|

Z4 = Z3

|

|

| (b)

|

Z4 = as required by Pt 3, Ch 7 Bulkheads

|

|

| Symbols

|

L, B, D, T, s, Z and I are

as defined in Pt 3, Ch 5, 1.4 Symbols and definitions 1.4.1

|

D1

|

= |

D, but need not be taken greater than T + 0,4 m for

Zone 3, T + 0,7 m for Zone 2, T + 1,0 m for Zone 1 |

|

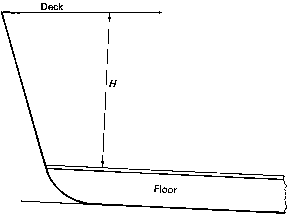

H

|

= |

vertical framing depth, in metres, from the top edge

of floor or tank top, to the deck at side as shown in Figure 5.4.1 Framing depth, see also Note 1,

but is to be taken as not less than 1,2 m |

|

h5

|

= |

distance, in metres, from mid point of span to the

deck at side or to a point T + 0,4 m above the baseline,

whichever is the lesser, but is to be taken as not less than 1 m |

|

Note

1. Where frames are supported by fully

effective horizontal stringers, these may be considered as decks for

the purpose of determining H.

Note

2. The web depth of frames is to be not

less than 45 mm.

|

4.2.3 Where,

due to the shape of the vessel at the ends, the distance between frames

measured along the shell exceeds the frame spacing, the scantlings

of side shell plating and supporting framing structure are to be based

on the frame spacing as measured along the shell; alternatively intermediate

frames may be fitted or the frame spacing decreased.

4.2.4 The angle

between the frame web and the shell plating is to be not less than

50°. Where this angle varies between 70° and 50° the required

modulus of the frame is to be corrected as per Pt 3, Ch 3, 3.2 Geometric properties of section.

4.2.5 In ships

where the angle between the frame web and the shell plating would

become less than 50°, the transverse framing, together with attached

floors and beams, is to be inclined at an angle to the centreline

of ship so that the frames lie as near normal to the shell plating

as possible.

4.2.6 Where,

due to the curvature or slope of the shell panel, the actual span

of the frame measured along the shell is five per cent more than the

vertical framing depth as per Figure 5.4.1 Framing depth,

the modulus of the frame is to be proportionally increased taking

into consideration the shape of the frame.

Figure 5.4.1 Framing depth

4.3 Shell longitudinals

4.4 Web frames and side transverses

4.4.1 Web frames

are, in general, to be fitted in a transverse framing system, and

the scantlings are to comply with the requirements of Table 5.4.2 Web frames, side transverses and

stringers forward and aft.

Table 5.4.2 Web frames, side transverses and

stringers forward and aft

| Location

|

Modulus, in

cm3

|

Inertia, in

cm4

|

|

(1) Web frames in a transverse framing system

|

Z = 2,5 ×

k × (2 + n) × s × D

2

3

|

|

|

(2) Side transverses in a longitudinal framing system

|

Z = 7 ×

k × S × D

2

3

|

|

|

(3) Side stringers (fully effective)

|

Z = 8 ×

k × S × h × le

2

|

|

| Symbols

|

D, T, S, s, Z and I are as defined

in Pt 3, Ch 5, 1.4 Symbols and definitions 1.4.1

|

D2

|

= |

D but need not be taken greater than 1,5 × the effective

span of the stiffening member |

|

n

|

= |

number of frame spaces between the web frames or

equivalent structure |

|

h

|

= |

load head, which is to be taken as h

4 or h

5 whichever is the greater, in metres |

|

h5

|

= |

distance, in metres, from mid point of span to the

deck at side or to a point T + 0,4 m for Zone 3, T +

0,7 m for Zone 2, or T + 1,0 m for Zone 1 above the

baseline, whichever is the lesser, with a minimum of 1 m |

|

Note

1. The web depth of side transverses is

to be not less than twice the depth of the slot for the

longitudinal.

Note

2. The web depth of fully effective

stringers is to be not less than twice the depth of the slot for the

frames.

|

4.4.2 The spacing

of the web frames in a transverse framing system should not exceed

10 frame spaces, but the web frames may be omitted, provided the overall

strength is maintained.

4.4.4 Frames

are to be reinforced in way of hatch end beams and deck transverses,

and the section modulus should be not less than 0,4 times the section

modulus of the deck transverse.

4.5 Stringers

4.5.1 On ships

frequently berthing under adverse conditions and where the span of

the frames exceeds 2,5 m, an effective stringer is to be fitted in

a suitable position.

4.6 Stem arrangement for pushing purposes

4.6.1 The structural

arrangements are to be such that the stem is adequately supported

and integrated into the fore peak structure.

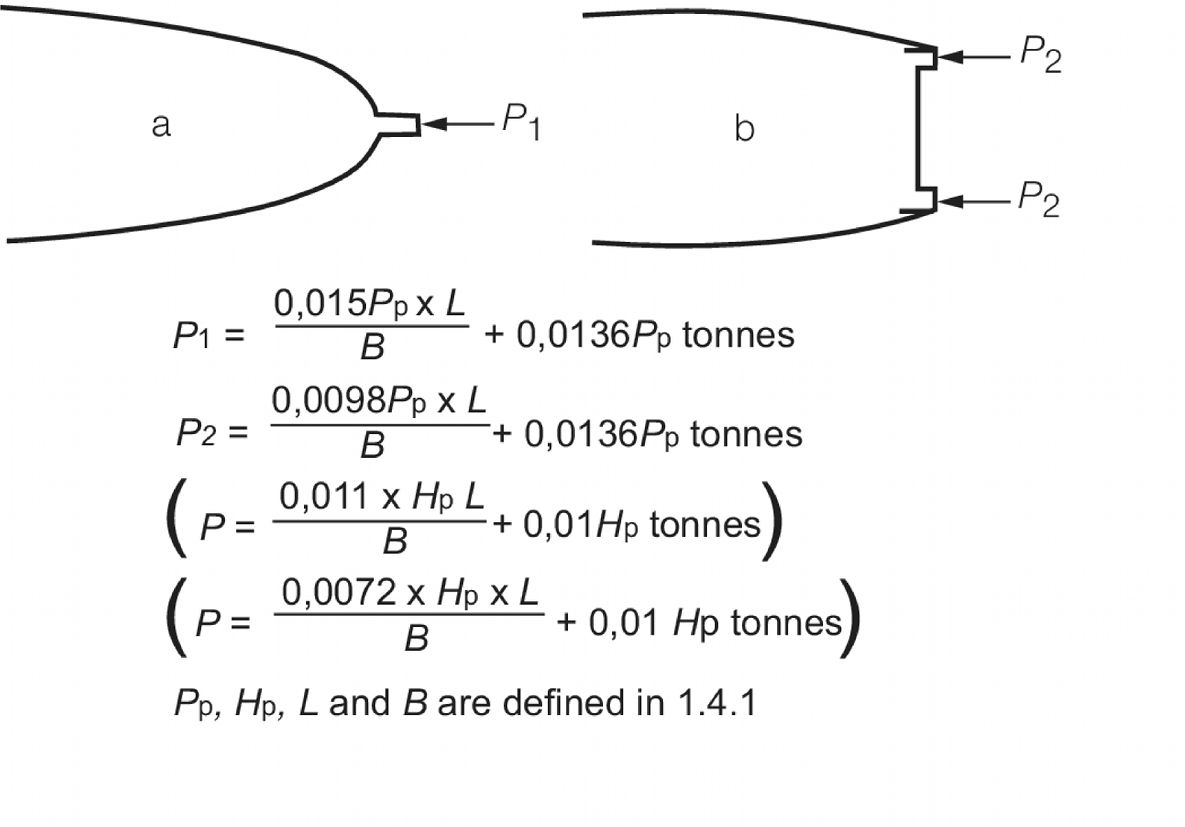

4.6.2 The structure

of the stem and the fore peak in way is to be calculated using horizontal

loads P

1 or P

2 on

the stem as shown in Figure 5.4.2 Loads on stem for pushing purposes. The maximum compressive stresses in this structure are

not to exceed 78,4 N/mm2 (800 kg/cm2).

Figure 5.4.2 Loads on stem for pushing purposes

|