Section

2 Fittings

2.1 Gooseneck and derrick heel assemblies

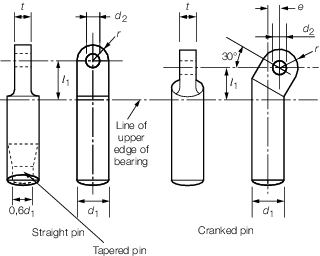

2.1.1 The safe working

load of the gooseneck and derrick heel assembly is to be taken as

the least of the values determined separately for the gooseneck pin,

the derrick heel lugs and the derrick heel crosspin. Standard dimensions

for these items and for the gooseneck bearing bracket, with corresponding

safe working loads, are given in Table 8.2.1 Dimensions of gooseneck

pins and the items are illustrated in Figure 8.2.1 Gooseneck pins.

Table 8.2.1 Dimensions of gooseneck

pins

| Boom

axial thrust, in tonnes

|

Straight pins

|

Cranked pins

|

|

|

|

|

|

d

1

|

l1

|

d

1

|

l1

|

e

|

d

2

|

r

|

t

|

| 1,6

|

50

|

60

|

|

|

|

24

|

25

|

26

|

| 2,0

|

50

|

60

|

|

|

|

26

|

25

|

28

|

| 2,5

|

60

|

60

|

55

|

60

|

35

|

29

|

30

|

30

|

| 3,2

|

70

|

85

|

60

|

65

|

38

|

32

|

35

|

33

|

| 5,0

|

70

|

70

|

65

|

70

|

40

|

35

|

35

|

36

|

| 5,0

|

80

|

85

|

70

|

80

|

46

|

41

|

40

|

40

|

| 6,3

|

90

|

100

|

80

|

85

|

49

|

44

|

45

|

45

|

| 8,0

|

100

|

105

|

90

|

90

|

52

|

47

|

50

|

50

|

| 10,0

|

110

|

120

|

100

|

100

|

58

|

54

|

55

|

57

|

| 12,5

|

120

|

125

|

110

|

105

|

61

|

58

|

60

|

64

|

| 16,0

|

140

|

150

|

120

|

110

|

64

|

67

|

70

|

73

|

| 20,0

|

155

|

170

|

130

|

115

|

67

|

75

|

75

|

82

|

| 25,0

|

170

|

200

|

140

|

125

|

72

|

79

|

80

|

92

|

| 32,0

|

190

|

210

|

155

|

140

|

78

|

83

|

85

|

102

|

| 40,0

|

190

|

220

|

170

|

155

|

85

|

93

|

95

|

112

|

| 50,0

|

200

|

220

|

|

|

|

103

|

100

|

124

|

| 63,0

|

225

|

245

|

|

|

|

113

|

113

|

140

|

| 80,0

|

250

|

275

|

|

|

|

129

|

125

|

150

|

| 100,0

|

275

|

290

|

|

|

|

144

|

138

|

160

|

|

|

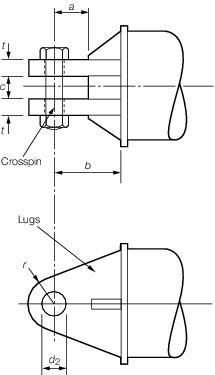

Table 8.2.2 Dimensions of derrick heel

assemblies

| Boom axial thrust, in

tonnes

|

a

|

b

|

c

|

r

|

t

|

d

2

|

d

crosspin

|

| 1,6

|

32

|

80

|

28

|

25

|

16

|

24

|

22

|

| 2,0

|

35

|

90

|

30

|

28

|

16

|

26

|

24

|

| 2,5

|

45

|

107

|

32

|

30

|

22

|

29

|

27

|

| 3,2

|

50

|

112

|

35

|

32

|

22

|

32

|

30

|

| 4,0

|

50

|

120

|

38

|

35

|

25

|

35

|

33

|

| 5,0

|

55

|

135

|

42

|

42

|

25

|

41

|

39

|

| 6,3

|

60

|

145

|

47

|

45

|

32

|

44

|

42

|

| 8,0

|

65

|

153

|

53

|

48

|

32

|

47

|

45

|

| 10,0

|

70

|

173

|

60

|

55

|

40

|

54

|

52

|

| 12,5

|

75

|

188

|

67

|

60

|

40

|

58

|

56

|

| 16,0

|

85

|

208

|

76

|

68

|

45

|

67

|

64

|

| 20,0

|

95

|

235

|

85

|

75

|

50

|

75

|

72

|

| 25,0

|

100

|

260

|

95

|

80

|

60

|

79

|

76

|

| 32,0

|

105

|

270

|

105

|

85

|

70

|

83

|

80

|

| 40,0

|

115

|

300

|

115

|

95

|

70

|

93

|

90

|

| 50,0

|

125

|

325

|

127

|

105

|

80

|

103

|

100

|

| 63,0

|

135

|

340

|

144

|

115

|

80

|

113

|

110

|

| 80,0

|

160

|

350

|

154

|

130

|

100

|

129

|

125

|

| 100,0

|

175

|

370

|

164

|

145

|

100

|

144

|

140

|

Note

2. Values of a and b may be

adjusted for other forms of rib stiffening.

|

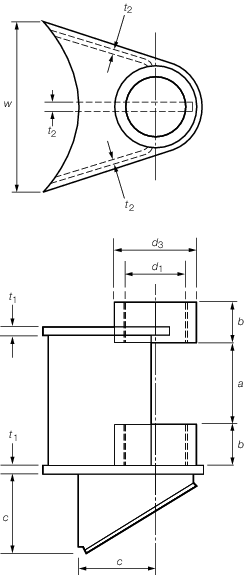

Table 8.2.3 Dimensions of gooseneck bearing

brackets

Gooseneck pin

diameter, d

1

|

a

|

b

|

c

|

d

3

|

t

1

|

t

2

|

| 50

|

95

|

45

|

70

|

85

|

12

|

10

|

| 55

|

95

|

45

|

80

|

90

|

12

|

10

|

| 60

|

95

|

50

|

90

|

100

|

12

|

10

|

| 65

|

120

|

50

|

100

|

110

|

12

|

10

|

| 70

|

120

|

60

|

115

|

120

|

12

|

10

|

| 80

|

140

|

60

|

130

|

130

|

12

|

10

|

| 90

|

140

|

70

|

145

|

140

|

12

|

10

|

| 100

|

175

|

70

|

160

|

160

|

15

|

10

|

| 110

|

175

|

80

|

175

|

170

|

20

|

12

|

| 120

|

215

|

80

|

190

|

190

|

20

|

12

|

| 130

|

215

|

90

|

205

|

200

|

22

|

12

|

| 140

|

215

|

90

|

225

|

210

|

25

|

12

|

| 155

|

235

|

100

|

235

|

230

|

30

|

15

|

| 160

|

235

|

100

|

240

|

235

|

30

|

15

|

| 170

|

235

|

100

|

250

|

250

|

30

|

15

|

| 180

|

235

|

100

|

270

|

260

|

30

|

15

|

| 190

|

255

|

110

|

285

|

280

|

33

|

18

|

| 200

|

255

|

110

|

300

|

290

|

35

|

18

|

| 225

|

255

|

120

|

315

|

325

|

40

|

20

|

| 250

|

275

|

130

|

330

|

360

|

40

|

20

|

| 275

|

275

|

140

|

345

|

395

|

40

|

20

|

Note

2. The width of bracket at the mast

(dimension w in Figure 8.2.3 Gooseneck bearing) is to be not less than 0,67

times the diameter of the mast at that point.

|

Figure 8.2.1 Gooseneck pins

Figure 8.2.2 Derrick heel assembly

Figure 8.2.3 Gooseneck bearing

2.1.3 Where arrangements

other than those covered by the Tables or by recognised Standards

are proposed, the dimensions of the components of the assembly are

to be such that the stresses given in Table 8.2.4 Stresses in gooseneck and

derrick are not exceeded.

Table 8.2.4 Stresses in gooseneck and

derrick

| Item

|

Boom axial thrust, T, in tonnes

|

|

|

T ≤ 25

N/mm2

|

25 < T ≤

50

N/mm2

|

50 < T

N/mm2

|

| Gooseneck pin:

|

|

|

|

|

|

Bending plus direct stress

|

90

|

40 + 2T

|

140

|

|

|

Bearing pressure

|

20 + 0,5T

|

20 + 0,5T

|

45

|

|

|

|

|

|

|

| Derrick heel crosspin:

|

|

|

|

|

|

Shear stress

|

25 +

0,4T

|

35

|

35

|

|

|

Bending plus shear stress

|

90 + T

|

90 + T

|

140

|

|

|

Bearing pressure

|

20 + 0,5T

|

20 + 0,5T

|

45

|

|

|

|

|

|

|

| Gooseneck pin collar:

|

|

|

|

|

|

Horizontal bearing

pressure

|

10 N/mm2

|

|

|

Minimum diameter

|

1,15d

1 mm

|

|

|

|

|

|

|

| Bearing bracket

|

Total stress in any part is not to exceed 0,45σy

|

2.1.4 Where a gooseneck

pin is supported by two bearings, the diameter of the pin in way of

the lower bearing may be reduced to 0,6d

1,

provided the bearings are spaced such that (a + b)

is greater than 3,0d

1, see

Figure 8.2.3 Gooseneck bearing for illustration of these terms.

Proposals for a greater reduction on large gooseneck pins will be

specially considered.

2.2 Swivel bearing assemblies

2.2.1 The safe working

load of the assembly is to be taken as the least of the values determined

separately for the individual components. Standard dimensions for

the trunnion, pin and bearing bracket with corresponding safe working

loads are given in Table 8.2.5 Dimensions of swivels and Table 8.2.6 Dimensions of swivel bearing

brackets and the items are illustrated

in Figure 8.2.4 Swivel bearing assemblies.

Table 8.2.5 Dimensions of swivels

| SWL, in tonnes

|

a

|

b

|

d

1

|

d

2

|

d

3

|

r

1

|

t

1

|

d

pin

|

| 2,0

|

75

|

90

|

34

|

65

|

25

|

25

|

22

|

32

|

| 4,0

|

95

|

110

|

42

|

80

|

33

|

33

|

30

|

40

|

| 6,3

|

110

|

130

|

47

|

90

|

42

|

43

|

40

|

45

|

| 8,0

|

120

|

150

|

52

|

100

|

48

|

48

|

45

|

50

|

| 10,0

|

130

|

170

|

57

|

110

|

52

|

55

|

50

|

55

|

| 12,5

|

140

|

190

|

62

|

120

|

56

|

60

|

55

|

60

|

| 16,0

|

150

|

215

|

68

|

130

|

65

|

65

|

60

|

65

|

| 20,0

|

170

|

240

|

78

|

150

|

74

|

70

|

65

|

75

|

| 25,0

|

180

|

270

|

83

|

160

|

78

|

75

|

70

|

80

|

| 32,0

|

190

|

300

|

93

|

180

|

86

|

85

|

80

|

90

|

| 40,0

|

210

|

330

|

103

|

200

|

96

|

95

|

90

|

100

|

| 50,0

|

235

|

380

|

113

|

220

|

106

|

105

|

100

|

110

|

| 63,0

|

260

|

410

|

123

|

240

|

116

|

115

|

110

|

120

|

| 80,0

|

295

|

480

|

134

|

260

|

131

|

135

|

125

|

130

|

| 100,0

|

330

|

540

|

144

|

280

|

146

|

148

|

140

|

140

|

Note

2. SWL is the required SWL of the bearing

assembly.

|

Table 8.2.6 Dimensions of swivel bearing

brackets

| SWL, in tonnes

|

c

|

d

1

|

e

|

g

|

h

|

t

2

|

t

3

|

r

2

|

| 2,0

|

75

|

34

|

75

|

140

|

95

|

21

|

10

|

35

|

| 4,0

|

95

|

42

|

80

|

160

|

115

|

15

|

10

|

43

|

| 6,3

|

115

|

47

|

90

|

180

|

135

|

20

|

10

|

48

|

| 8,0

|

140

|

52

|

110

|

200

|

155

|

25

|

10

|

55

|

| 10,0

|

160

|

57

|

125

|

230

|

175

|

25

|

12

|

60

|

| 12,5

|

175

|

62

|

140

|

260

|

195

|

30

|

12

|

65

|

| 16,0

|

190

|

68

|

150

|

290

|

223

|

30

|

12

|

70

|

| 20,0

|

205

|

78

|

160

|

320

|

248

|

35

|

15

|

80

|

| 25,0

|

220

|

83

|

180

|

240

|

278

|

35

|

15

|

85

|

| 32,0

|

220

|

93

|

190

|

370

|

308

|

40

|

15

|

95

|

| 40,0

|

245

|

103

|

190

|

410

|

338

|

45

|

15

|

105

|

| 50,0

|

270

|

113

|

210

|

450

|

388

|

45

|

18

|

115

|

| 63,0

|

300

|

123

|

230

|

500

|

420

|

50

|

20

|

125

|

| 80,0

|

335

|

134

|

260

|

560

|

490

|

50

|

20

|

135

|

| 100,0

|

375

|

144

|

300

|

630

|

550

|

55

|

20

|

148

|

Note

2. SWL is the required SWL of the bearing

assembly.

|

Figure 8.2.4 Swivel bearing assemblies

2.2.3 Where arrangements

other than those covered by the Tables or by recognised Standards

are proposed, the dimensions of the components of the assembly are

to be such that the stresses given in Table 8.2.7 Stresses in swivel bearing

assemblies are not exceeded.

Table 8.2.7 Stresses in swivel bearing

assemblies

| Item

|

Safe working load, in tonnes

|

|

|

SWL ≤ 25,

N/mm2

|

25 <

SWL,

N/mm2

|

| Swivel

pin:

|

|

|

|

|

Shear stress

|

25 + 0,4 SWL

|

35

|

|

|

Bearing pressure

|

40 + 0,6 SWL

|

55

|

|

|

|

|

|

| Trunnion

eyeplate:

|

|

|

|

|

Shear pullout at hole

|

50

|

|

|

|

Bearing bracket

|

Total

stress on any part is not to exceed 0,45σy

|

Note Safe working load is the required SWL of the bearing

assembly

|

2.3 Fixed eyeplates

2.3.1 Fixed eyeplates

at the derrick boom head are generally to be in accordance with the

dimensions given in Table 8.2.8 Dimensions of fixed eyeplates at

the derrick boom head

Table 8.2.8 Dimensions of fixed eyeplates at

the derrick boom head

| SWL, in tonnes

|

Oval

eye

a

|

Round

eye

b

|

e

1

|

t

1

|

d

|

r

2

|

e

2

|

t

2

|

| 2,0

|

50

|

27

|

50

|

25

|

25

|

25

|

40

|

22

|

| 2,5

|

55

|

29

|

54

|

25

|

27

|

28

|

40

|

25

|

| 3,2

|

66

|

33

|

57

|

30

|

30

|

30

|

45

|

28

|

| 4,0

|

77

|

36

|

65

|

35

|

33

|

33

|

50

|

30

|

| 5,0

|

87

|

41

|

70

|

40

|

39

|

38

|

55

|

35

|

| 6,3

|

91

|

45

|

75

|

40

|

42

|

43

|

60

|

40

|

| 8,0

|

101

|

51

|

80

|

50

|

48

|

48

|

70

|

45

|

| 10,0

|

117

|

56

|

90

|

50

|

52

|

55

|

75

|

50

|

| 12,5

|

128

|

61

|

100

|

60

|

56

|

60

|

80

|

55

|

| 16,0

|

145

|

67

|

115

|

60

|

65

|

65

|

85

|

60

|

| 20,0

|

157

|

73

|

125

|

70

|

74

|

70

|

95

|

65

|

| 25,0

|

170

|

80

|

135

|

80

|

78

|

75

|

100

|

70

|

| 32,0

|

194

|

88

|

150

|

90

|

86

|

85

|

110

|

80

|

| 40,0

|

220

|

98

|

170

|

100

|

96

|

95

|

120

|

90

|

Note

2. The dimensions e

1 and e

2 are to be measured from the outside surface of the

derrick boom tube, or the outside surface of the doubling plate, if

fitted.

|

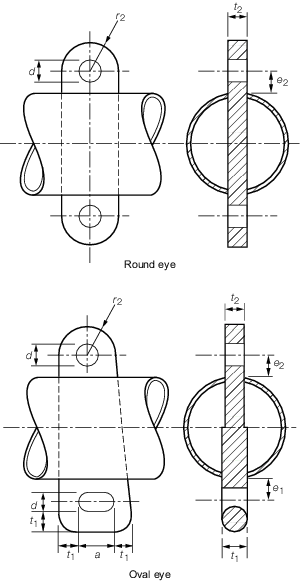

Figure 8.2.5 Fixed eyeplates at the derrick

boom head

2.3.2 The dimensional

details of the fittings may differ at opposite ends depending on the

loads to be carried. Where the fitting is made continuous and of the

larger thickness required by the Table, care is to be taken to ensure

that this thickness is suitable for the proposed shackle or other

attachment to the eyeplate.

2.3.3 It is highlighted

that an increase in the dimension e1 or e2 will result in an increased

bending moment on the derrick boom and this may result in increased

scantlings.

2.3.4 Fixed eyeplates

attached to the ships structure for use with the cargo gear

are to have dimensions generally in accordance with Table 8.2.9 Dimensions of eyeplates at

ship's. Attention is to be given

to the stresses which may arise from applied forces not in the plane

of the eyeplate. Where the dimensions of the eyeplate differ from

the Table values, the safe working load may be taken as:

where

dimensions a, b, d and t are illustrated in Figure 8.2.6 Fixed eyeplate at the ship's

structure.

Where the cross-section of the eyeplate

varies, the minimum value of (d x t) is

to be used for the calculation.

Table 8.2.9 Dimensions of eyeplates at

ship's

| SWL, in tonnes

|

a

|

b

|

d

|

t

|

| 1,0

|

35

|

22

|

16

|

16

|

| 1,6

|

42

|

24

|

20

|

20

|

| 2,0

|

50

|

27

|

25

|

25

|

| 2,5

|

55

|

29

|

25

|

25

|

| 3,2

|

66

|

33

|

30

|

30

|

| 4,0

|

77

|

36

|

35

|

35

|

| 5,0

|

87

|

41

|

40

|

40

|

| 6,3

|

91

|

45

|

40

|

40

|

| 8,0

|

101

|

51

|

50

|

50

|

| 10,0

|

117

|

56

|

50

|

50

|

| 12,5

|

128

|

61

|

60

|

60

|

| 16,0

|

145

|

67

|

60

|

60

|

| 20,0

|

157

|

73

|

70

|

70

|

| 25,0

|

170

|

80

|

80

|

80

|

| 32,0

|

194

|

88

|

90

|

90

|

| 40,0

|

220

|

98

|

100

|

100

|

| 50,0

|

240

|

108

|

110

|

110

|

|

|

Figure 8.2.6 Fixed eyeplate at the ship's

structure

2.3.5 Adequate support is to be provided by the ship structure in way of the

eyeplate. Arrangements to give effective spread of the load into the surrounding

structure may be required, see also

Ch 2, 8.9 Deck eyeplates.

2.4 Built-in sheaves

2.4.1 Where a built-in

sheave is fitted in the derrick boom, the diameter of the sheave is

to be not less than that required for the rope nor less than 1,2 times

the derrick boom diameter at that point. The material, construction

and design of the sheave, sheave pin and supports are to be in accordance

with Ch 8, 3 Blocks.

|