Section

8 Welding

8.1 General

8.1.1 The plans

to be submitted for approval are to indicate clearly details of the

welded connections of main structural members, including the type

and size of welds. This requirement includes welded connections to

steel castings. The information to be submitted should include the

following:

-

Whether weld sizes

given are throat thicknesses or leg lengths.

-

Grades and thicknesses

of materials to be welded.

-

Location, types

of joints and angles of abutting members.

-

Reference to welding

procedures to be used.

-

Sequence of welding

of assemblies and joining up of assemblies, see

Pt 2, Ch 1, 8.4 Welding of primary and secondary member end connections.

8.1.2 Unless

otherwise indicated, all welding is to be in accordance with the requirements

of Ch 13 Requirements for Welded Construction of the Rules for

the Manufacture, Testing and Certification of Material (hereinafter

referred to as the Rules for Materials).

8.2 Fillet welds

8.2.1 The throat

thickness of fillet welds is to be determined from:

where

|

s

|

= |

the

length, in mm, of correctly proportioned weld fillet, clear of end

craters, and is to be not less than 75 mm |

|

d

|

= |

the

distance between start positions of successive weld fillets, in mm |

|

t

p

|

= |

plate thickness, on which weld fillet size is based, in mm, see

also

Figure 1.8.1 Weld types

|

Weld factors are given in Table 1.8.1 Details of various fillet weld

connections.

Figure 1.8.1 Weld types

8.2.2 Where

double continuous fillet welding is proposed, the throat thickness

is to be determined taking equal to 1,0. The leg length of the weld is to be not

less than equal to 1,0. The leg length of the weld is to be not

less than  the specified throat thickness. the specified throat thickness.

8.2.3 The plate

thickness, t

p, to be used in the above calculation

is, generally, to be that of the thinner of the two parts being joined.

Where the difference in thickness is considerable, the size of fillet

will be considered.

8.2.4 Where

the thickness of the abutting member of the connection (e.g. the web

of a stiffener) is greater than 15 mm and exceeds the thickness of

the table member (e.g. plating), the welding is to be double continuous

and the throat thickness of the weld is to be not less than the greatest

of the following:

-

0,21 x thickness

of the table member;

-

0,21 (0,27 in tanks)

× half the thickness of the abutting member;

-

as required by Item

3 in Table 1.8.3 Throat thickness limits.

Table 1.8.1 Details of various fillet weld

connections

| Item

|

Weld factor

|

Remarks

|

| Bottom and side frames and transverse

to shell

|

0,13

|

continuous in way of beam

|

| Bottom and

side longitudinals to shell

|

0,13

|

|

| Bottom and

side longitudinals of flat bar or plate type to shell

|

0,25

|

|

| Longitudinal and

transverse watertight and oiltight bulkhead boundaries

|

0,39

|

at

bottom

|

| 0,34

|

at deck and

side

|

| Stiffeners

on watertight and oiltight bulkheads

|

0,13

|

|

| Longitudinal and transverse non-watertight bulkhead boundaries

|

0,13

|

|

| Stiffeners

on non-watertight bulkheads

|

0,10

|

|

| Pontoon girders to

shell

|

0,27

|

in way of

end brackets

|

| 0,27

|

clear of end

brackets

|

| Pontoon

girders to girder brackets

|

0,21

|

|

| Girder webs

to face bars

|

0,13

|

|

|

|

|

|

| Strength

deck plating or shell

|

-

|

see

Table 1.8.2 Weld connection of strength deck

plating to sheerstrake

|

| Safety deck

plating to shell

|

0,21

|

continuous

|

| Beams and

longitudinals at crown of tanks to deck

|

0,13

|

|

| Beams and

longitudinals to deck

|

0,10

|

|

| Deck longitudinals of

flat bar or plate type to deck plating

|

0,25

|

see

Pt 2, Ch 1, 8.2 Fillet welds

|

| continuous

|

|

|

|

|

|

| Deck

transverses to plating

|

0,21

|

continuous

in way of end brackets

|

|

|

|

|

| Deck

transverses to end brackets

|

0,21

|

generally

continuous

|

| Webs of

transverses to face bars

|

0,13

|

face bar

area in excess of 39 cm2

|

|

|

|

|

| Ventilator

coamings and air pipes to deck plating

|

0,34

|

| Pillars

built of rolled sections of plates

|

0,10

|

8.2.6 Continuous

welding is to be adopted in the following locations, and may be used

elsewhere if desired:

-

Boundaries of weathertight

decks and erections, including hatch coamings, companionways and other

openings.

-

Boundaries of tanks

and watertight compartments.

-

All lap welds in

tanks.

-

Primary and secondary

members to bottom shell.

-

Primary and secondary

members to plating in way of end connections, and end brackets to

plating in the case of lap connections.

-

Where Pt 2, Ch 1, 8.2 Fillet welds 8.2.4 applies.

-

Other connections

or attachments, where considered necessary, and in particular the

attachment of minor fittings to higher tensile steel plating.

-

Fillet welds where

higher tensile steel is used.

8.2.7 Where

structural members pass through the boundary of a tank, and leakage

into the adjacent space could be hazardous or undesirable, full penetration

welding is to be adopted for the members for at least 150 mm on each

side of the boundary. Alternatively, a small scallop of suitable shape

may be cut in the member close to the boundary outside the compartment,

and carefully welded all round.

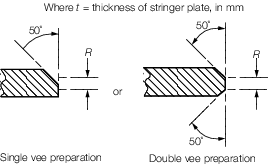

Table 1.8.2 Weld connection of strength deck

plating to sheerstrake

| Item

|

Stringer plate

thickness

|

Weld type

|

| 1

|

t ≤ 15

|

Double continuous fillet weld with a

weld factor of 0,44

|

| 2

|

15 <

t ≤ 20

|

Single vee

preparation to provide included angle of 50º with root R ≤ 1/3

t in conjunction with a continuous fillet weld having a weld

factor of 0,39 or Double vee preparation to provide included angles of 50º

with root R ≤ 1/3 t

|

| 3

|

t > 20

|

Double vee preparation to provide

included angles of 50º with root R ≤ 1/3 t but not to exceed

10 mm

|

|

Note

1. Welding procedure, including joint

preparation, is to be specified. Procedure is to be qualified and

approved for individual Builders.

Note

2. For thickness t in excess of 30

mm, the stringer plate may be bevelled to achieve a reduced thickness

at the weld connection. The width of bevel is, in general, to be not

less than twice the thickness of stringer plate and the reduced

thickness, in general, to be not less than 0,65 times the thickness of

stringer plate or 20 mm, whichever is the greater.

Note

3. Alternative connections will be

considered.

|

8.3 Welding of primary structure

8.3.1 The weld

connection to shell, deck or bulkhead is to take account of the material

lost in the notch where longitudinals or stiffeners pass through the

member.

8.3.2 Where

the width of notch exceeds 15 per cent of the stiffener spacing, the

weld factor is to be multiplied by:

8.3.3 Where

direct calculation procedures have been adopted, the weld factors

for the 0,2 x overall length at the ends of the members will be considered

in relation to the calculated loads.

8.3.4 The throat

thickness limits given in Table 1.8.3 Throat thickness limits are

to be complied with.

Table 1.8.3 Throat thickness limits

| Item

|

Throat thickness, in mm

|

| Minimum

|

Maximum

|

|

(1) Double continuous welding

|

0,21t

p

|

0,44t

p

|

|

(2) Intermittent welding

|

027t

p

|

0,44t

p or 4,5

|

|

(3) All welds, overriding minimum:

|

|

|

|

(a) Plate thickness t

p ≤ 7,5 mm

|

|

|

|

Hand or automatic welding

|

3,0

|

-

|

|

Automatic deep penetration welding

|

3,0

|

-

|

|

(b) Plate thickness t

p > 7,5 mm

|

|

|

|

Hand or automatic welding

|

3,25

|

-

|

|

Automatic deep penetration welding

|

3,0

|

-

|

Note

1. In all cases, the limiting value is to

be taken as the greatest of the applicable values given above.

Note

2. Where t

p exceeds 25 mm, the limiting values may be calculated

using a notional thickness equal to 0,5 (t

p + 25) mm.

Note

3. The maximum throat thicknesses shown

are intended only as a design limit for the approval of fillet welded

joints. Any welding in excess of these limits is to be to the

Surveyors satisfaction.

|

8.4 Welding of primary and secondary member end connections

8.4.1 Welding

of end connections of primary members is to be such that the area

of welding is not less than the cross-sectional area of the member,

and the weld factor is to be not less than 0,34 in tanks or 0,27 elsewhere.

8.4.3 The area

of weld, A

w, is to be applied to each arm

of the bracket or lapped connection.

8.4.4 Where

a longitudinal strength member is cut at a primary support and the

continuity of strength is provided by brackets, the area of weld is

to be not less than the cross-sectional area of the member.

8.4.6 The throat

thickness limits given in Table 1.8.3 Throat thickness limits are

to be complied with.

Table 1.8.4 Primary and secondary member end

connection welds

| Connection

|

Weld area, A

w, in cm2

|

Weld factor

|

|

(1) Stiffener welded direct to plating

|

0,25A

s or 6,5 cm2 whichever is the greater

|

0,34

|

|

(2) Bracketless connection of stiffeners or stiffener lapped

to bracket or bracket lapped to stiffener:

|

|

|

|

(a) in dry space

|

1,2

|

0,27

|

|

(b) in tank

|

1,4

|

0,34

|

|

(c) main frame to tank side bracket in 0,15L forward

|

as (a) or (b)

|

0,34

|

|

|

|

|

|

(3) Bracket welded to face of stiffener and bracket

connection to plating

|

-

|

0,34

|

|

|

|

|

|

(4) Stiffener to plating for 0,1 x span at ends, or in way of

end bracket if that be greater

|

-

|

0,34

|

| Symbols

|

|

A

s

|

= |

cross-sectional area of the stiffener, in

cm2

|

|

A

w

|

= |

the area of weld, in cm2, and is

calculated as total length of weld, in cm, x throat thickness, in

cm |

|

Z

|

= |

the section modulus, in cm3, of the

stiffener on which the scantlings of the bracket are based |

|

|

|

8.5 Defined practices and welding sequence

8.5.1 Welding

is to be conducted in accordance with the requirements specified in

Ch 13,1 and 2 of the Rules for Materials

8.6 Welding consumables and equipment

8.6.1 Welding

consumables used and associated equipment are to be in accordance

with the requirements specified in Ch 13,1.8 and 2.2 of the Rules

for Materials.

8.7 Inspection of welds

8.7.2 The location

and number of welds to be examined by non-destructive examination

is to be agreed between the Builder and the Surveyor. Recommended

locations and the number of non-destructive examinations are shown

in Table 1.8.5 Inspection of welds

8.7.3 For docks

specially designed to operate in low temperature ambient conditions

such as those prevailing in Arctic areas, the extent of non-destructive

examination will be specially considered.

8.7.4 For structural

details, reference should be made to Pt 3, Ch 10 Welding and Structural Details of the Rules for Ships.

Table 1.8.5 Inspection of welds

Material

Class

See Note 1

|

Recommended locations and number of NDE to be applied

|

|

|

Intersections of butts

and seams of fabrication and erection welds

|

Butts and seams

See Note 2

|

| V &

IV

|

Minimum One in

two

|

Minimum One for each

10 m of weld length

|

| III

|

Minimum One in

three

|

Minimum One for each

20 m of weld length

|

| II

|

Minimum One in

four

|

Minimum One for each

30 m of weld length

|

| I

|

At selected locations

See Note 3

|

At selected locations

See Note 3

|

|

|

Butt

welds of hull envelope longitudinals are to be examined as follows:

|

|

= |

Within 0,4L amidships one in ten

|

|

|

= |

Outside 0,4L amidships one in twenty

|

|

Note

2. These are in addition to locations

selected at intersection of butts and seams of fabrication and

erection welds.

Note

3. Additional locations are to be

selected in the forward region.

Note

4. Selected NDE locations are to be

evenly distributed.

Note

5. Where radiographic examination is

carried out at weld intersections, the length of the film is to be in

the direction of the butt.

Note

6. Where defects are observed at or near

the ends of radiographs, additional radiography is to be carried out

to determine the full extent.

|

|