Section

2 Specific requirements for ship hull structure and machinery

2.1 Scope

2.1.2 The shipyard

and manufacturer’s works are to be assessed to give assurance

that they have the facilities, equipment, personnel and quality control

procedures to produce work of the required quality.

2.2 Welding consumables

2.2.1 Welding

consumables used for hull construction are to be approved in accordance

with Ch 11 Approval of Welding Consumables and are to be suitable

for the type of joint and grade of material to be welded.

2.2.2 Steel welding

consumable approvals, up to and including Grade Y40, and Y47, are

considered acceptable for hull construction in line with Table 11.1.1 Welding consumable grades

appropriate to structural and low temperature service steel grades in Chapter 11, Ch 12, 2.2 Welding variables 2.2.2 and the following:

-

Consumables up to

Grade Y are acceptable for welding steels up to 3 strength levels

below that for which the approval applies, e.g. a consumable with

approval grading 3Y is acceptable for welding EH36, EH32 and EH27S

higher tensile ship steels and grade E normal strength ship steel.

-

Consumables for Grade

Y40 are acceptable for welding steels up to two strength levels below

that for which the approval applies. Consumables for Grade Y47 are

acceptable for welding steels up to one strength level below that

for which the approval applies.

-

Consumables with an

approved impact toughness grading are acceptable for welding steels

with lower specified impact properties subject to (a) above, e.g.

a consumable with approval grading 3Y is acceptable for welding EH,

DH and AH materials.

-

For welding steels

of different grades or different strength levels, the welding consumables

may be of a type suitable for the lesser grade or strength being connected.

The use of a higher grade of welding consumable may be required at

discontinuities or other points of stress concentration.

2.2.3 In general,

the use of preheating and hydrogen controlled welding consumables

for welding of ship steels up to strength grade H40 is to be in accordance

with Table 13.2.1 Preheat and consumable

requirements for welding of carbon and carbon manganese steels up to strength grade

H40. The carbon

equivalent is to be calculated from the ladle analysis using the formula

given below:

|

Carbon equivalent

|

= |

|

Preheat and the use of low hydrogen controlled consumables

will be required for welding of steel grades higher than Grade H40.

Table 13.2.1 Preheat and consumable

requirements for welding of carbon and carbon manganese steels up to strength grade

H40

| Carbon equivalent C

eq

|

Preheat

|

Hydrogen controlled

consumables

|

|

C

eq equal to or less than 0,41%

|

Not required

|

Not required, see Note 3

|

|

C

eq above 0,41 but not exceeding 0,45%

|

Not required, see Notes 1 and

2

|

Required

|

|

C

eq greater than 0,45%

|

Required

|

Required

|

Note

2. Under conditions of high restraint or

low ambient temperature preheat may need to be applied.

Note

3. Hydrogen controlled consumables may

need to be considered for welding of

(a) Thicker materials (i.e. > 35 mm).

(b) Higher strength materials.

(c) Welds subject to high restraint.

|

2.2.5 All austenitic

stainless steel and duplex stainless steel welding consumables are

to be approved in accordance with the Ch 11 Approval of Welding Consumables and are suitable for welding the grades of material as shown

in Table 13.2.3 Welding of austenitic stainless

and duplex stainless steels - Consumable requirements.

Table 13.2.3 Welding of austenitic stainless

and duplex stainless steels - Consumable requirements

| Consumable approval

grade

|

Suitable for welding

material alloy grades

|

| Austenitic stainless steels

|

| 321

|

321

|

| 347

|

347 and 321

|

| Austenitic stainless steel – Low carbon

|

| 304L (see Note 3)

|

304L

|

| 304LN (see Note 3)

|

304LN and 304L

|

| 316L

|

316L and 304L

|

| 316LN

|

316LN, 316L, 304LN and 304L

|

| 317L

|

317L, 316LN, 316L, 304LN and

304L

|

| 317LN

|

317LN, 317L, 316LN, 316L, 304LN and

304L

|

| Super

austenitic stainless steels, see Note 2

|

| S31254

|

S31254 and N08904

|

| N08904

|

N08904

|

| Duplex

stainless steels, see Note 1

|

| S31260

|

S31260 and S31803

|

| S31803

|

S31803

|

| S32550

|

S32550

|

| S32750

|

S32750 and S32550

|

| S32760

|

S32760, S32550, S31260 and

S31803

|

| Stainless steels welded to carbon steels

|

| SS/CMn

|

Carbon steel to all steels in

Sections 1, 2 and 3

|

| Duplex/CMn

|

Carbon steel to all duplex stainless

steel in Section 4

|

Note

1. The use of a different welding

consumable grade from that of the base material may require

demonstration of acceptable corrosion properties.

Note

2. May be used for welding low carbon

austenitic grades provided measures are taken to prevent

solidification cracking from occurring.

Note

3. These are LR Grades and do not

correspond to any National or International Standards/Grades.

|

2.3 Welding procedure and welder qualifications

2.3.1 Welding

procedures and welder qualifications are to be tested and approved

in accordance with the requirements of Ch 12 Welding Qualifications.

2.4 Construction and workmanship

2.4.1 Weld preparations and openings may be formed by thermal cutting, machining

or chipping. Chipped surfaces that will not be subsequently covered by weld metal are to

be ground smooth.

2.4.2 Prior to welding, the alignment of plates and stiffeners forming part of

the hull structure is to be in accordance with the tolerances specified in the relevant

part of the Rules.

2.4.3 When welding from one side only, care is to be exercised to ensure the root

gap and fit up are in accordance with the approved welding procedure and the root is

properly fused.

2.4.4 Where it is proposed to use permanent backing strips, the intended locations

and welding procedures are to be submitted for consideration.

2.4.5 Temporary backing strips may be used provided they are in accordance with

approved welding procedures and are subsequently removed on completion of welding.

2.4.6 The outer surfaces of completed welds are to blend smoothly with the base

materials and provide a smooth transition and gradual change of section.

2.4.7 Weld joints in parts of oil engine structures that are stressed by the main

gas or inertia loads are to be designed as continuous full penetration welds. They are

to be arranged so that welds do not intersect, and that welding can be effected without

difficulty.

2.4.8 When modifications or repairs have been made which result in openings

having to be closed by welded inserts, particular care is to be given to the fit of the

insert and the welding sequence. The welding is also to be subject to non-destructive

examination.

2.4.9 Where welding of aluminium alloy is employed, the following additional

requirements are to be complied with so far as they are applicable:

-

Welding is to be performed by fusion welding using inert gas or

tungsten inert gas process or by the friction stir welding process. Where it is

proposed to use other welding processes, details are to be submitted for

approval.

-

The weld joint surfaces should be scratch brushed, preferably

immediately before welding, in order to remove oxide or adhering films of dirt,

filings, etc.

2.4.10 For steel grades EH47, EH47-BCA1 and EH47-BCA2, the following additional requirements

are applicable:

- When the ambient temperature is 5°C or less, or where moisture

resides on the surfaces to be welded, due care is to be taken to pre-heat the joint

to a minimum of 50°C, unless a higher pre-heat temperature is specified. Alternative

preheat requirements will be specially considered where Pcm of the material being

welded is less than or equal to 0,19 and the air temperature is below 5°C but above

0°C.

- The tack length may be 25 mm where Pcm of the material being

welded is less than or equal to 0,19.

2.5 Butt welds

2.5.1 Where the

ship hull is constructed of plates of different thicknesses, the thicker

plates are to be chamfered in accordance with the approved plans.

In all cases the chamfer is not to exceed a slope of 1 in 3 so that

the plates are of equal thickness at the weld seam. Alternatively,

if so desired, the width of the weld may be included as part of the

smooth taper to the thicker plate provided the difference in thickness

is not greater than 3 mm.

2.5.2 Where stiffening

members are attached by continuous fillet welds and cross completely

finished butt or seam welds, these are to be made flush in way of

the fillet weld. Similarly for butt welds in webs of stiffening members,

the butt weld is to be complete and generally made flush with the

stiffening member before the fillet weld is made. Where these conditions

cannot be complied with, a scallop is to be arranged in the web of

the stiffening member, see

Figure 13.2.1 Weld dimensions and types. Scallops are to be of such a size and in such a position

that a satisfactory weld can be made.

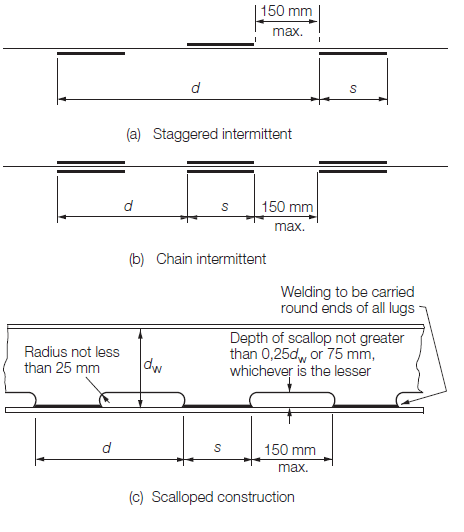

Figure 13.2.1 Weld dimensions and types

2.6 Lap connections

2.6.1 Overlaps

are generally not to be used to connect plates which may be subjected

to high tensile or compressive loading and alternative arrangements

are to be considered. However, where plate overlaps are adopted, the

width of the overlap is not to exceed four times, nor be less than

three times the thickness of the thinner plate and the joints are

to be positioned to allow adequate access for completion of sound

welds. The faying surfaces of lap joints are to be in close contact

and both edges of the overlap are to have continuous fillet welds.

2.7 Closing plates

2.7.1 For the

connection of plating to internal webs, where access for welding is

not practicable, the closing plating is to be attached by continuous

full penetration welds or by slot fillet welds to face plates fitted

to the webs. Slots are to have a minimum length of 90 mm and a minimum

width of twice the plating thickness, with well rounded ends. Slots

cut in plating are to be smooth and clean and are to be spaced not

more than 230 mm apart, centre to centre. Slots are not to be filled

with welding.

2.7.2 For the

attachment of rudder shell plating to the internal stiffening of the

rudder, slots are to have a minimum length of 75 mm and, in general,

a minimum width of twice the side plating thickness. The ends of the

slots are to be rounded and the space between them is not to exceed

150 mm.

2.8 Stud welding

2.8.1 Where permanent

or temporary studs are to be attached by welding to main structural

parts in areas subject to high stress, the proposed location of the

studs and the welding procedures adopted are to be approved.

2.9 Fillet welds

2.9.1 T-connections

are generally to be made by fillet welds on both sides of the abutting

plate, the dimensions and spacing of which are shown in Figure 13.2.1 Weld dimensions and types. Where the connection is

highly stressed, deep penetration or full penetration welding may

be required. Where full penetration welding is required, the abutting

plate may be required to be bevelled.

2.9.2 Where an

approved deep penetration procedure is used, the fillet leg length

calculated may be reduced by 15 per cent provided that the manufacturer

is able to meet the following requirements:

-

Use of a welding consumable approved for deep penetration welding in

accordance with Ch 11 Approval of Welding Consumables for either the ‘p’ or ‘T’ techniques.

-

Demonstrations by way of production weld testing that the minimum

required penetration depths (i.e. throat thicknesses) are maintained. This is to

be documented on a monthly basis by the manufacturer and be available to the

Surveyor.

2.9.3 The calculated

fillet leg length may be reduced by 20 per cent, provided that in

addition to the requirements of Ch 13, 2.9 Fillet welds 2.9.2.(a) and Ch 13, 2.9 Fillet welds 2.9.2.(b), the manufacturer is able to consistently

meet the following additional requirements:

-

The documentation

required in Ch 13, 2.9 Fillet welds 2.9.2.(b) is to be

completed and made available to the Surveyor upon request on a weekly

basis.

-

Suitable process selection

confirmed by satisfactory welding procedure tests covering both minimum

and maximum root gaps.

2.9.4 Where intermittent

welding is used, the welding is to be made continuous in way of brackets,

lugs and scallops and at orthogonal connections with other members.

2.10 Post-weld heat treatment

2.10.1 This section determines the requirements for post-weld stress relief heat treatment when

applied to ship structure and associated machinery.

2.10.2 Post-weld stress relief heat treatment is applied to improve resistance to

brittle fracture or fatigue performance. It is to be applied when the thickness limits

stated in Table 13.2.4 Post-weld stress relief heat treatment thickness limits are exceeded.

Table 13.2.4 Post-weld stress relief heat treatment thickness limits

| Typical

Application

|

Load Conditions

(See Note 1)

|

Material

Grade

(See Note 2)

|

Material

Thickness Limit (mm) (See Note 3)

|

| Ship

structure

|

Fatigue

non-critical / critical

|

Normal strength (A - E),

Higher strength (H27S - H40, [Excluding EH47])

|

150

|

| Ship

structure

|

Fatigue

non-critical / critical

|

Higher strength

(EH47)

|

100

|

| Machinery

|

Fatigue

non-critical

|

High strength (H42

- H69)

|

140

|

| Machinery

|

Fatigue

critical

|

High strength (H42

- H46)

|

100

|

| Machinery

|

Fatigue

critical

|

High strength (H50

- H69)

|

65

|

| Ship structure /

Machinery

|

Any

|

Other material

grades

|

Subject to special

consideration

|

Note 1. Fatigue analysis shall be approved by design appraisal according to

relevant rules for each application.

- Fatigue non-critical – Design assessment

confirms that there are cyclic stresses but the fatigue life is

reasonably greater than the design fatigue life and it is

anticipated that fatigue crack initiation and propagation are

unlikely to occur.

- Fatigue critical – Design assessment confirms

that there are cyclic stresses and the estimated fatigue life meets

the design requirements but it is not significantly higher. It is

anticipated that fatigue crack initiation and propagation are

likely to occur.

Note 2. Where steel grades based on national and international standards

are specially agreed for construction, they are to be procured from LR

approved works which hold current approval for the LR equivalent grade

and the same delivery condition as the steel to be procured.

Note 3. For all applications where material thickness is greater than 65 mm

(or greater than 100 mm for EH47), 100 per cent surface and volumetric

non-destructive examination of welds is required.

|

2.10.3 Post-weld heat treatment is to be applied to the following types of welded

construction:

-

Welding of steel castings where the thickness of the casting at the

weld exceeds 30 mm, except where castings are directly welded to the hull

structure.

-

Engine bedplates except for engine types where the bedplate as a

whole is not subjected to direct loading from the cylinder pressure. For these

types, only the transverse girder assemblies need to be stress relieved.

-

Welding of gear wheels.

-

Welding of gear cases associated with main or auxiliary engines,

see

Pt 5 Main and Auxiliary Machinery.

2.10.4 Consideration is to be given to applying post-weld heat treatment for all thicknesses of

complicated weld joints where there are high stress concentrations.

2.10.6 Special consideration may be given to omit the required post-weld heat treatment.

Evaluation is to be based on critical engineering assessment involving fracture

mechanics testing and proposals are to be submitted which include full details of the

application, materials, welding procedures, inspection procedures, design temperature

and stresses, fatigue loads and cycles. Evidence will be required to demonstrate that

the inspection techniques and procedures to be employed are able to detect flaws to the

sizes and tolerances (of length, through-wall height and through-wall position), as

determined from the fracture mechanics (and or fatigue) calculations. Alternative

procedures for the omission of post weld heat treatment will be subject to special

consideration.

2.11 Tolerances

2.11.1 Tolerances

after welding are to be in accordance with the relevant Part of the

Rules.

2.12 Non-destructive examination of steel

welds

2.12.1 All finished

welds are to be sound and free from cracks and substantially free

from lack of fusion, incomplete penetration, porosity and slag. The

surfaces of welds are to be reasonably smooth and substantially free

from undercut and overlap. Care is to be taken to ensure that the

specified dimensions of welds have been achieved and that both excessive

reinforcement and under-fill of welds is avoided.

2.12.2 Welds

forming part of the hull and superstructure may be coated with a thin

layer of protective primer prior to inspection provided it does not

interfere with inspection and is removed, if required by the Surveyor,

for closer interpretation of possible defective areas.

2.12.3 All welds are to be visually inspected by personnel designated by the

builder. Visual inspection of all welds may be supplemented by other non-destructive

examination techniques in cases of unclear interpretation, as considered necessary. The

acceptance criteria for visual testing are given in Table 13.2.5 Acceptance criteria for visual testing, magnetic particle and liquid penetrant

testing.

Table 13.2.5 Acceptance criteria for visual testing, magnetic particle and liquid penetrant

testing

| Surface

discontinuity

|

Classification

according to ISO 6520-1

|

Acceptance criteria

|

| Crack

|

100

|

Not accepted

|

| Lack of

fusion

|

401

|

Not accepted

|

| Incomplete root

penetration in butt joints welded from one side

|

4021

|

Not accepted

|

| Surface

pore

|

2017

|

Visual inspection

|

| Thickness (t)

|

| 0,5 mm < t

≤ 3,0 mm

Not permitted

|

t > 3,0

mm

Butt welds: d ≤ 0,2 t (max of 2,0 mm)

Fillet

welds: d ≤ 0,2 a (max of 2,0 mm)

See Notes

4, 5 & 6

|

| Liquid penetration inspection

|

| Single pore indication diameter d ≤ 6 mm see

Notes 1, 2, 3 & 4

|

| Magnetic particle inspection

|

| Single pore diameter d ≤ 3 mm see Notes 1, 3

& 4

d = major axis of dimension

|

| Undercut

|

5011

(Continuous)

5012 (Intermittent)

|

Thickness (t)

|

| 0,5 mm < t

≤ 3,0 mm

|

t > 3,0

mm

|

| Short imperfections

only see Notes 7 & 8:

h ≤ 0,1 t

see Note 9

|

Short imperfections

only see Notes 7 & 8:

h ≤ 0,1 t (max 0,5 mm)

see Note 9

|

| Smooth transition to parent material is required and

imperfection is not to be regarded as systematic.

|

|

Note 1. A pore is defined as an indication having

a length less than or equal to three times its width.

Note 2. A penetrant indication refers to the size

of the bleed out from the discontinuity resulting in the

indication.

Note 3. Indications that are approximately in

line, which are separated by less than the length of the smaller

indication, are to be considered as a single indication.

Note 4. d = diameter.

Note 5. t = thickness of thinner

material.

Note 6. a = throat thickness.

Note 7. For either continuous or intermittent

undercut, only short imperfections are allowed.

Note 8. The definitions of short imperfections are

as follows:

- For welds 100 mm long or longer: Imperfections whose total

length is not greater than 25 mm in the 100 mm of the weld which

contains the greatest number of imperfections.

- For welds less than 100 mm long: Imperfections whose total

length is not greater than 25 per cent of the length of the

weld.

Note 9. h = height or width of

imperfection.

|

2.12.4 In addition to visual inspection, where required by either LR Rules, the NDE

checkpoint plan, the contract inspection and test plan, or as warranted for further

testing either by the manufacturer or the surveyor, welded joints are to be examined

using any one or a combination of ultrasonic, radiographic, magnetic particle, eddy

current, dye penetrant or other acceptable methods appropriate to the configuration of

the weld.

2.12.5 The method to be used for the volumetric examinations of welds is the

responsibility of the builder; however, the following technical considerations shall be

noted for the choice concerning the selected method:

- For full penetration butt welds, advanced NDE (ANDE) methods

may be used in lieu of (or complementary to) existing ultrasonic or radiographic

testing methods. These methods may additionally be used on other weld

configurations, with some limitations, as specified in Table 13.2.9 Applicable methods for testing

of materials and weld joints.

- Radiography (using film or RT-D methods) may be used for the

examination of welds for any thickness range, as applicable to the penetrating

capability of the radiation energy and the radiation source, and within any limits

as identified in the procedure in order to achieve the specified quality level.

The applicable material and joint types are given in Table 13.2.9 Applicable methods for testing

of materials and weld joints.

- Ultrasonic testing may be used for the examination of welds,

generally for 8 mm thickness or greater, and advanced methods (such as PAUT or

TOFD) for thicknesses of 6 mm or greater (as appropriate). The applicable material

and joint types are given in Table 13.2.9 Applicable methods for testing

of materials and weld joints.

- Where there is a requirement for enhanced NDE acceptance

criteria to be applied to thick plate sections in the hatch coaming region of

container ships, as per the Measure 3 requirement in Table 8.2.1 Chemical composition,

percentage, as

described in Pt 4, Ch 8, 2.3 Requirements for use of thick steel plates 2.3.10 of the Rules and Regulations for the Classification of Ships, July 2022, the

UT and PAUT acceptance criteria are to be derived from the ShipRight Procedure for

the Use of Enhanced NDE in Container Ships. These derived acceptance

criteria are project specific, and the acceptance criteria stated in Table 13.2.7 Acceptance criteria for

ultrasonic and phased array testing are not applicable.

2.12.6 The acceptance criteria for volumetric weld testing as applied to the

appropriate methods are given in the following tables:

- Radiographic testing (including RT-D): Table 13.2.6 Acceptance criteria for

radiographic testing

- Ultrasonic testing and PAUT (based on length and amplitude of

indications): in Table 13.2.7 Acceptance criteria for

ultrasonic and phased array testing

- TOFD testing (based on length and height of indications):

Table 13.2.8 Acceptance criteria for TOFD

testing1. See also

Figure 13.2.5 General scheme for acceptance

conditions for the general approach to

acceptance/rejection and interpretation of signal parameters. Other acceptance

criteria, including project specific acceptance criteria, are to be specially

agreed with LR.

Table 13.2.6 Acceptance criteria for

radiographic testing

| Discontinuity

|

Classification according to ISO

6520-1

|

Acceptance criteria

|

| Crack

|

100

|

Not permitted

|

| Lack of fusion

|

401

|

Acceptable up to but only

intermittently and not breaking the surface, ∑ l ≤ 25 mm, L

= 100 mm. See Notes 1 & 9

|

| Lack of penetration

|

402

|

Not permitted

|

| Slag inclusions, Flux inclusions,

& Oxide inclusions

|

301, 302 & 303

|

h < 0,3 s (max

3,0 mm)

∑ l ≤ s (max 50 mm)

L = 100 mm

See Notes 1, 5 &

8.

|

| Porosity & Gas pore (Single

Layer)

|

2011 & 2012

|

A ≤ 1,5 %

d ≤ 0,3 s (max 4,0 mm)

L =

100 mm

See Notes 1, 3, 4, 5, 6 &

7.

|

| Porosity & Gas pore

(Multi-Layer)

|

2011 & 2012

|

A ≤ 3,0 %

d ≤ 0,3 s (max 4,0 mm)

L =

100 mm

See Notes 1, 3, 5, 6 & 7.

|

| Linear porosity

|

2014

|

I ≤ s, max 50 mm

d

≤ 0,3 s (max 3,0 mm)

L = 100

mm

See Notes 1, 3, 5, 6, 7 &

10.

|

| Clustered (localised)

porosity

|

2013

|

dA ≤ Wp

(max 20 mm)

L = 100 mm

See

Notes 1, 3, 7, 10 & 11.

|

| Elongated cavity &

wormholes

|

2015 & 2016

|

h < 0,3 s (max 3,0

mm)

∑ l ≤ s (max 50 mm)

L = 100 mm

See Notes 1,

4, 7, 8 & 10.

|

| Shrinkage cavity (other than

crater pipes)

|

202

|

Not permitted

|

| Crater pipe

|

2024

|

Not permitted

|

| Metallic inclusions other than

copper

|

304

|

l ≤ 0,3 s (max 3,0

mm)

See Notes 2 & 5

|

| Copper inclusions

|

3042

|

Not permitted

|

|

Note 1. L

= any 100 mm testing length within the radiograph.

Note 2. l

= Length of indication (mm).

Note

3. A = Sum of projected areas of indications related to

L x Wp, in %.

Note 4. h

= Width of indication, the width or height of surface imperfection

(mm).

Note 5. s =

Nominal butt weld thickness (mm).

Note 6. d =

Diameter of pore (mm).

Note 7.

Wp = Width of weld (mm).

Note 8. ∑ l

= Summary length of imperfections within L (mm).

Note 9. If the

length of the weld is below 100 mm then the maximum length of

indications is not to exceed 25% of that weld.

Note

11. dA = Diameter of pore envelope

|

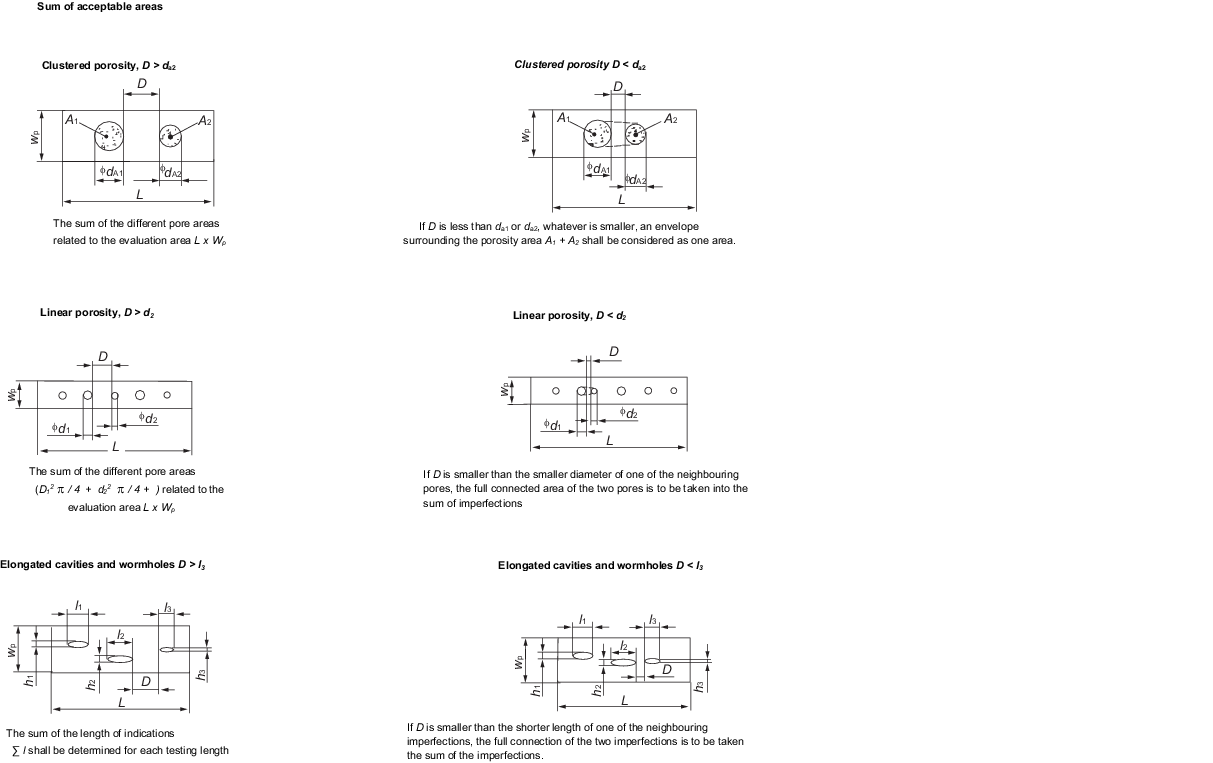

Figure 13.2.2 Sum of acceptable areas for

radiography

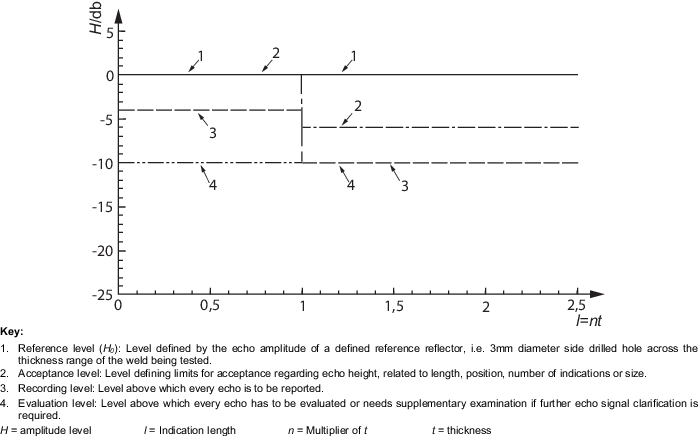

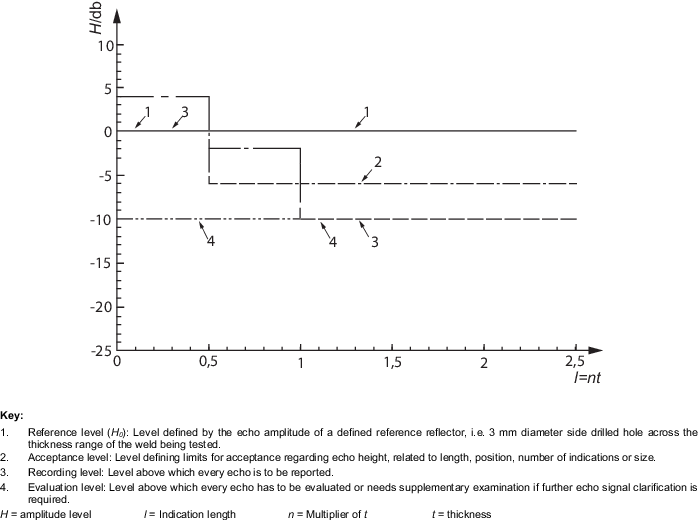

Table 13.2.7 Acceptance criteria for

ultrasonic and phased array testing

| Thicknesses (t) 8 mm – 15 mm

|

| Indications resulting in signal amplitudes in

excess of the reference level (H0) are unacceptable

regardless of length.

|

| Indications resulting in signal amplitudes above

the reference level H0 -6 dB, and up to the reference

level (H0), are acceptable providing their length does

not exceed the material thickness.

|

| Indications resulting in signal amplitudes up to

H0 -6 dB are acceptable regardless of their

length.

|

| Thicknesses (t) 15 mm – 100 mm

|

| Indications resulting in

signal amplitudes in excess of the reference level H0

+4 dB are unacceptable regardless of length.

|

| Indications resulting in signal amplitudes above

H0 -2 dB and up to H0 + 4 dB can

only have a length equal to, or less than, the half material thickness.

|

| Indications resulting in

signal amplitudes above H0 -6 dB and up to

H0 -2 dB can only have a length equal to, or less

than, the material thickness.

|

| Indications resulting in

signal amplitudes of H0 -6 dB are acceptable regardless

of their length.

|

Note 4. For

evaluation, a group of discontinuities is to be considered as a single

one if:

- the distance along the weld axis

(dx) between two discontinuities is less than twice

the length of the longer discontinuity;

- the distance (dy) across the weld

axis between two discontinuities is less than half of the

thickness but not more than 10 mm; and

- the distance (dz) vertically between

two discontinuities is less than half of the thickness but not

more than 10 mm.

Note 5. The

combined length of the group of two discontinuities is

l12 = l1 +

l2 + dx. The combined length

l12 and the larger maximum amplitude of the two

discontinuities is then to be assessed against the applicable

acceptance level.

Note 6. The length

of a single acceptable discontinuity above the recording level is to

be evaluated by assessing the cumulative length of all individually

acceptable discontinuities above the recording level, given as the sum

of the lengths of both single and linearly aligned discontinuities of

combined length within a given weld length. For any section of weld

length lw = 6t, the maximum cumulative length

lc of all individually acceptable discontinuities

above the recording level is not to exceed 30% of

lw.

Note 7. Guidance

on the information provided above can be referenced in ISO

11666.

|

Figure 13.2.3 Acceptance level for

thicknesses 8 mm to 15 mm

Figure 13.2.4 Acceptance level for

thicknesses 15 mm to 100 mm

Table 13.2.8 Acceptance criteria for TOFD

testing1

| Thickness range (see Note 2)

|

Acceptable length and height of

indications

|

| Maximum acceptable length if h < h2

lmax

mm

(see Notes 3, 5, 6, 7 & 8)

|

Maximum acceptable height if l ≤ lmax

h2 (for embedded discontinuities)

mm

(see Notes 3, 6, 7, &

8)

|

Maximum acceptable height

if l >

lmax

h1

mm

(see Notes 3, 4, 6, 7, &

8)

|

| 6 mm

< t ≤ 15 mm

|

t

|

2

|

1

|

| 15

mm < t ≤ 50 mm

|

t

|

4

|

1

|

| 50

mm < t ≤ 100 mm

|

50

|

5

|

2

|

| t > 100 mm

|

60

|

6

|

3

|

|

Note 2. Nominal

plate thickness. For welds joining two different thickness plates, the

thinnest plate is to be taken as the thickness.

Note 3. When

indications from surface‑breaking discontinuities are detected,

different techniques or methods are to be applied to determine the

type or nature of the discontinuity. Using these general (not ECA)

acceptance criteria, planar discontinuities such as lack of fusion,

lack of penetration, or cracks, are not acceptable if they are surface

breaking. If it is not possible to apply other techniques or methods,

or accurately determine the type or nature of the discontinuity, then

all indications from surface‑breaking discontinuities are to be

considered as unacceptable.

Note 4.

Indications with heights less than h1 are not to be

considered.

Note 5. The sum of

the lengths of the individual indications with height larger than

h1 measured along the weld over a length of 12

t is to be less than or equal to 4,0 t, with a

maximum of 200 mm.

Note 6. For

evaluation, a group of indications is to be considered as a single one

if:

- The distance between two individual

indications along the weld is less than the length of the longer

indication.

- The distance between two individual

indications in the thickness direction of the weld is less than

the height of the higher indication.

Note 7. In case of

an indication with varying height, the maximum local height, h,

shall be used.

Note 8. Point‑like

indications and indications with height smaller than

h1 are not considered for grouping of

indications. Further guidance on the grouping of heights (and local

heights), lengths and distance between indications can be referenced

in ISO 15626.

|

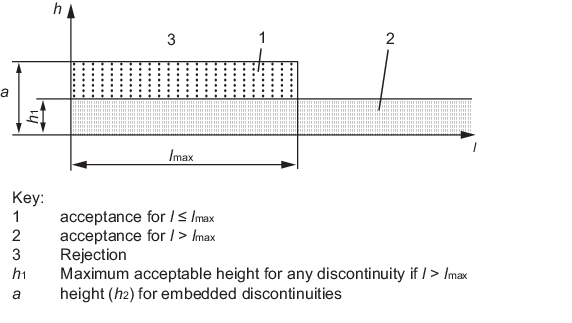

Figure 13.2.5 General scheme for acceptance

conditions

Table 13.2.9 Applicable methods for testing

of materials and weld joints

| Materials and weld joints

|

Parent material thickness

|

Applicable volumetric NDE test methods (see Notes 1 &

2)

|

| Ferritic and austenitic stainless steel butt welds with full

penetration

|

thickness < 6 mm

|

RT,

RT-D

|

| 6

mm ≤ thickness < 8 mm

|

RT,

RT-D, PAUT, TOFD

|

| thickness ≥ 8 mm

|

RT,

RT-D, UT, PAUT, TOFD

|

| Ferritic and austenitic stainless steel tee joints and

corner joints with full penetration

|

6 mm

≤ thickness < 8 mm

|

RT,

RT-D, PAUT (see Note 3)

|

| thickness ≥ 8 mm

|

RT, RT-D, UT, PAUT (see Note 3)

|

| Ferritic cruciform joints with full penetration

|

6 mm

≤ thickness < 8 mm

|

RT,

RT-D, PAUT (see Note 3)

|

| thickness ≥ 8 mm

|

RT, RT-D, UT, PAUT (see Note 3)

|

| Ferritic tee joints, corner joints and cruciform joints without full

penetration and fillet welds

|

All

|

UT,

PAUT, RT (see Notes 3 & 4)

|

|

Note 2. TOFD is

only applicable to ferritic welds.

Note 3. RT and

RT-D may be applied; however, it is noted that for these

configurations, there may be limitations.

Note 4. UT and

PAUT may be used to check the extent of penetration in tee, corner and

cruciform joints.

|

2.12.7 Checkpoints

examined at the pre-assembly stage are to include ultrasonic testing

on examples of the stop/start points of automatic welding and magnetic

particle inspection of weld ends.

2.12.8 Checkpoints

examined at the assembly stage are generally to be selected from those

welds intended to be examined as part of the agreed quality control

programme to be applied by the builder. The locations and number of

checkpoints are to be approved by the Surveyor.

2.12.9 Where

components of the structure are subcontracted for fabrication, the

same inspection regime is to be applied as if the item had been constructed

within the main contractor’s works. In these cases, particular

attention is to be given to highly loaded fabrications (such as stabiliser

fin boxes) forming an integral part of the hull envelope.

2.12.10 Particular

attention is to be paid to highly stressed items. Magnetic particle

inspection is to be used at ends of fillet welds, T-joints, joints

or crossings in main structural members and at stern frame connections.

2.12.11 Special

attention is to be given to the examination of plating in way of lifting

eye plate positions to ensure freedom from cracks. This examination

is not restricted to the positions where eye plates have been removed,

but includes the positions where lifting eye plates are permanent

fixtures.

2.12.12 Checkpoints

for volumetric examination are to be selected so that a representative

sample of welding is examined.

2.12.13 Typical

locations for volumetric examination and number of checkpoints to

be taken are given in the relevant Sections of the Rules. A list of

the proposed items to be examined is to be submitted for approval.

2.12.15 For

all ship types, the builder is to carry out random non-destructive

examination at the request of the Surveyor.

2.12.16 Results

of non-destructive examinations made during construction are to be

recorded and evaluated by the builder on a continual basis in order

that the quality of welding can be monitored. These records are to

be available to the Surveyor.

2.12.17 The

extent of applied non-destructive examinations is to be increased

when warranted by the analysis of previous results.

2.13 Weld repairs

2.13.1 The full

extent of any weld defect is to be ascertained by applying additional

non-destructive examination where required. Unacceptable defects are

to be completely removed and, where necessary, re-welded and re-examined

in accordance with the requirements of Ch 13, 1.15 Rectification of welds defects.

2.13.2 During

the assembly of large components, root gaps in excess of those specified

in the approved welding procedure may be rectified by welding.

2.13.3 Rectification

of wide root gaps in butt welds, up to a maximum gap of 16 mm, may

be performed provided that the length of these areas is small in relation

to the whole weld length. Repairs may be executed by applying weld

buttering layers to one edge of the weld joint, followed by machining

or grinding to return the root opening to the required dimensions.

The weld buttering and filling of the joint are to be in accordance

with welding procedures qualified in accordance with Ch 12 Welding Qualifications.

2.13.4 For sub-assemblies,

rectification of wide root gaps may be performed using a backing strip,

provided that it is removed on completion of the welding.

2.13.5 Rectification

of wide root gaps in fillet welds may be carried out as follows:

-

where the root gap, g, is in excess of 3 mm, but not greater than 5 mm, the fillet

leg length, z, may be increased by g –

2,0 mm;

-

where the root gap

is in excess of 5 mm, the joint detail may be changed into a full

penetration weld.

2.13.6 Where

repair welds are made using small weld beads, suitable precautions

(including preheat) are to be taken to avoid high hardness and possible

cold cracking.

2.14 Welding afloat with water backing

2.14.1 Welding

afloat with water backing is not recommended due to the additional

precautions required during survey and therefore, is generally not

permitted. However consideration may be given to welding afloat with

water backing after specific LR approval has been obtained by the

yard or fabricator prior to such welding being carried out. Such approval

will only be given once all of the following conditions are satisfied:

-

The welding procedure

qualification tests are carried out on steel plates with water backing

and the water is maintained at the flow rate and minimum water temperature

anticipated during fabrication.

-

The carbon equivalent

of the steel plates used in the welding procedure qualification tests

are to be greater than 0,41 per cent based on the IIW formula. Where

it can be shown that all hull steel plates and new sections will have

a carbon equivalent value below this figure, steel plates with the

maximum carbon equivalent value may be used for the welding procedure

qualification tests.

-

Welding procedure

qualification tests are carried out without preheat.

-

The thickness of

steel plate used in the welding procedure qualification test is the

minimum hull plate thickness to be used during fabrication.

-

The maximum measured

hardness on the completed welding procedure qualification assembly

is less than or equal to 350 HV10. Following fabrication welding,

10 per cent of welds are to be hardness tested in way of heataffected

zones at weld starts to confirm compliance with the 350 HV10 limit.

-

The heat input used

in the welding qualification test is the minimum permitted heat input

during fabrication.

-

Only low hydrogen

welding consumables (H5) are used.

-

In addition to normal

non-destructive testing for welds, 10 per cent of the welds are additionally

subject to magnetic particle inspection 48 hours after welding is

complete.

-

The welding procedure

qualification tests for the repair of welds carried out afloat with

water backing are to be carried out on test pieces that have previously

been welded afloat and also meet the requirements above.

2.14.2 For new

construction, conversion or permanent repairs, wet underwater welding

is not permitted.

|