Section

2 Welding procedure qualification tests for steels

2.1 General

2.1.1 The requirements

of this Section relate to welding procedure test requirements of carbon,

carbon-manganese steels and low alloys steels. Additional requirements

for austenitic and austenitic/ferritic duplex stainless steels, aluminium

and copper alloys are specified in Sections 3 and 4 respectively.

2.1.2 Prior to

performing the welding procedure qualification test, the manufacturer

is to present to the Surveyor a preliminary Welding Procedure Specification

(pWPS) detailing the welding processes, positions, joint types, materials

and heat treatments to be performed during the test. The pWPS is to

be presented for information prior to commencing the test.

2.1.3 The type

and extent of testing to be applied to each welding procedure test

is to be in accordance with subsequent Sections of this Chapter.

2.1.4 For the

welding procedure approval, the welding procedure qualification tests

given in this Section are to be carried out with satisfactory results.

Welding procedure specifications are to refer to the test results

achieved during welding procedure qualification testing.

2.2 Welding variables

2.2.1 In order

that the conditions of the qualification test may be applied to production

welding operations, the appropriate variables are to be recorded by

the manufacturer during welding and testing from the following list:

-

The unique qualification

reference number and the date of welding;

-

The material type,

grade, product form, dimensions and identification;

-

Welding process(es),

including tack welds;

-

Joint type, dimensions

and surface condition;

-

Welding position(s);

-

Welding technique(s),

weaving, multiple electrodes, etc;

-

Welding consumables

including fluxes, shielding gases, etc;

-

Control of consumables,

baking or drying conditions, etc;

-

Welding parameters,

current, voltages, travel speeds, etc;

-

Number and sequence

of weld runs;

-

Backing materials

including any backing gas;

-

Preheats and interpass

temperatures;

-

Methods used for cleaning

and inspection of root deposits;

-

Post-weld heat treatment,

temperature and cycle times;

-

Special weld profiling

requirements.

2.2.2 Other variables

may need to be recorded depending on the particular welding process

or application and are to be agreed with the Surveyor, for example

the peak and base current and cycle times for pulse welding, electrode

type and nozzle size for GTAW welding, etc.

2.3 Steel test assemblies

2.3.1 Tests are to be performed using the welding process and positions

anticipated for actual construction. The weld test assemblies are to be representative

of construction conditions and are to be welded in the same manner as intended for the

actual production welds. Where prefabrication primers are used in the shipyard, these

are to be included in the test assemblies.

2.3.2 For plate

tests, the direction of plate rolling relative to the weld direction

is to be considered. Where the material used for the test requires

longitudinal impact tests, the plate rolling direction is to be perpendicular

to the weld direction and for material which requires impact testing

in the transverse direction, the rolling direction is to be parallel

to the weld direction. For weld tests intended for liquefied gas storage

or cargo tanks and associated process pressure vessels, the direction

of plate rolling is to be parallel to the weld direction in all cases.

2.3.4 Welding

procedure test assemblies are to be welded separately from production

welds and are to be marked with the unique test identification number.

The individual pieces of the test assembly may be held together to

maintain their relative joint conditions by means of suitable tack

welds, clamps or strongbacks.

2.3.5 Welding

of the test assemblies and testing of test specimens is to be monitored

by the Surveyor.

2.3.7 Designations

for equivalent welding positions shown by different standards are

shown in Table 12.2.1 Equivalent designations of welding

positions.

Table 12.2.1 Equivalent designations of welding

positions

| Weld position

|

Standard

|

| ISO

6947

|

AWS

|

|

Plate butt welds

|

|

|

|

| Flat

|

D

|

PA

|

1G

|

| Horizontal

|

X

|

PC

|

2G

|

| Vertical, weld up

|

Vu

|

PF

|

3G

|

| Vertical,

weld down

|

Vd

|

PG

|

3G

|

| Overhead

|

O

|

PE

|

4G

|

|

Pipe butt welds

|

|

|

|

| Pipe

horizontal, rotated, weld horizontal

|

D

|

PA

|

1G

|

| Pipe

vertical, not rotated, weld horizontal

|

X

|

PC

|

2G

|

| Pipe

horizontal, not rotated, weld flat, vertical and overhead

|

D+Vu+O

|

PH

|

5G

|

|

|

D+Vd+O

|

PJ

|

|

| Pipe

inclination fixed, not rotated

|

45o

|

H-L045

|

6G

|

|

|

|

J-L045

|

|

|

Plate fillet welds

|

|

|

|

| Flat

|

D

|

PA

|

1F

|

| Horizontal

|

X

|

PB

|

2F

|

| Vertical

up

|

Vu

|

PF

|

3F

|

| Vertical

down

|

Vd

|

PG

|

3F

|

| Overhead

|

O

|

PD

|

4F

|

|

Pipe fillet welds

|

|

|

|

| Flat,

pipe rotated

|

D

|

PA

|

1FR

|

| Horizontal, pipe fixed

|

X

|

PB

|

2F

|

| Horizontal, pipe rotated

|

D

|

PB

|

2FR

|

| Overhead,

pipe fixed

|

O

|

PD

|

4F

|

| Multiple, pipe fixed

|

D+Vu+O

|

PF

|

5F

|

| D+Vd+O

|

PG

|

|

2.4 Welding of steel test assemblies

2.4.1 Welding

of the test assembly is to be carried out in accordance with the agreed

pWPS. Where, during the progress of the test, it is found necessary

to change the conditions specified on the pWPS, this is to be brought

to the attention of the Surveyor. If agreed, the test may be permitted

to continue with the new conditions and these are to be recorded.

2.4.2 Where the

production work requires welding over tack welds, the test is to simulate

this condition and the tack welds are to be included in the inspection

length of the test weld and their position recorded.

2.4.3 For manual

and semi-automatic welding processes, weld stops and re-starts are

to be included in the inspection length of the test weld.

2.4.4 Fillet weld

test assemblies are welded on one side only.

2.4.5 Where the

construction welding is predominately fillet welding, in addition

to the butt weld qualification test, a fillet weld qualification test

is to be performed to confirm that acceptable weld quality is achieved.

2.5 Non-destructive examination (NDE)

2.5.1 On completion

of welding, prior to sectioning for mechanical tests, the inspection

length of the test assembly is to be subjected to both visual examination

and surface crack detection.

2.5.2 Butt weld

assemblies are also to be subjected to radiographic or ultrasonic

examination over the whole inspection length of the weld.

2.5.3 For welds in steels with specified yield strength less than 420

N/mm2, and with carbon equivalent less than or equal to 0,41 per cent, NDE

may be performed as soon as the test assembly has cooled to ambient temperature. For

other steels, NDE is to be delayed for a period of at least 48 hours after the test

assembly has cooled to ambient temperature.

2.5.4 Where post-weld

heat treatment is required, NDE is to be performed after the heat

treatment is complete.

2.5.5 All NDEs

are to be carried out in accordance with the requirements of Ch 1, 5 Non-destructive examination. Assessment of results is to be in

accordance with ISO 5817 Level B except for excess convexity and excess

throat thickness where Level C will apply. Linear porosity is not

permitted.

2.5.7 Where the

test assembly does not satisfy the nondestructive examination acceptance

criteria, the test is to be rejected. A duplicate test assembly may

be welded using the original welding conditions. If this fails NDE,

the welding procedure is to be considered as incapable of achieving

the requirements without modification.

2.5.8 Subject

to prior agreement with the Surveyor, where unacceptable imperfections

are of a volumetric nature and are localised in one small area of

the test assembly, the test may be permitted to continue and specimens

for destructive testing may be removed, avoiding this area.

2.6 Destructive tests General requirements

2.6.1 The weld

test assembly may only be sectioned for destructive testing after

any heat treatment and the required non-destructive examinations have

been completed successfully.

2.6.4 Where a

weld test is made between materials of different grades, the acceptance

criteria that are to be applied are those applicable to the lower

grade material.

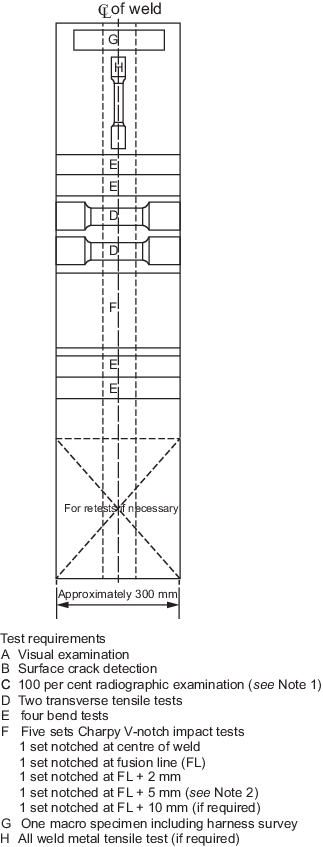

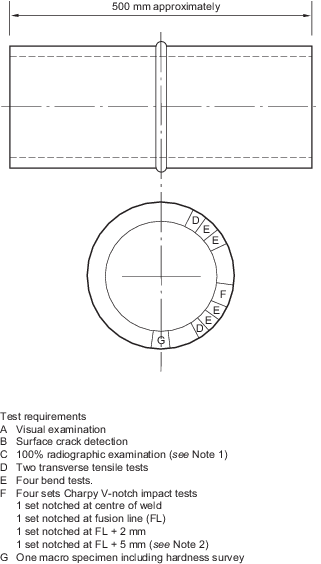

2.7 Destructive tests for steel butt welds

2.7.1 The test assembly is to be sectioned for mechanical testing in accordance

with Figure 12.2.8 Butt welds in plate or Figure 12.2.9 Butt welds in pipe less than 750

mm diameter.

Note 1 Radiographic examination may be

replaced by ultrasonic examination for test assembly thickness of 8 mm or

above.

Figure 12.2.8 Butt welds in plate

Note 1 Radiographic examination may be replaced by ultrasonic examination for test

assembly thickness of 8 mm or above.

Figure 12.2.9 Butt welds in pipe less than 750

mm diameter

2.7.2 The longitudinal

all weld metal tensile test specimen is to be of circular cross-section

as detailed in Ch 11, 2.1 Dimensions of test specimens 2.1.1. Where

more than one welding process or type of consumable has been used

to make the weld, test specimens are to be removed from each respective

area of the weld. This does not apply to the process or consumables

used to make the root or first weld run. During the test, the yield

or proof stress, ultimate tensile strength, and elongation to failure

are to be recorded.

2.7.3 Where approved

welding consumables have been used, the longitudinal all weld metal

tensile test may be omitted. For Type C independent tanks intended

for liquefied gases, the all weld tensile test is mandatory for all

welding procedure tests.

2.7.5 Where the

maximum load required to fracture the transverse tensile specimen

is likely to exceed the capacity of the tensile testing equipment,

several tensile specimens may be removed through the thickness and

tested. Specimens are to be prepared such that they overlap in the

thickness direction so that the full plate thickness is tested.

2.7.6 Transverse

bend specimens of rectangular section are to be prepared with the

weld centred in the middle of the specimen as shown in Figure 12.2.10 Transverse bend test specimens. For material of thickness

12 mm or greater, the face and root bends may be substituted by side

bend tests. Where there is a significant difference between the strength

of the weld and base material, longitudinal bend specimens may be

used. The weld reinforcement may be removed by grinding or machining

prior to testing and the edges rounded to a radius not exceeding 10

per cent of the specimen thickness. Each specimen is to be bent through

an angle of at least 180°. The bend test ratio is to be the lesser

of the following:

-

or

-

|

D

f

|

= |

100/E

m (rounded up to the next whole number) |

2.7.9 For offshore

structures and pressure vessels, impact test specimens are not required

to be notched at the FL + 10 mm location. Where more than one welding

process or type of consumable has been used to make the weld, test

specimens are to be removed from the respective areas of the weld.

This does not apply to the process or consumables used solely to make

the root or first weld run.

2.7.11 At least

one macro examination specimen is to be removed from the test plate,

near the end where welding started. The specimen is to include the

complete cross-section of the weld and the heat affected zone and

be prepared and etched to clearly reveal the weld runs and the heat

affected zone. Examination is to be performed under a magnification

of between x5 and x10.

2.7.12 A chemical

analysis of the weld metal is to be performed on the macro specimen

where approved welding consumables have not been used. The results

are to comply with the limits given in the welding consumable specification.

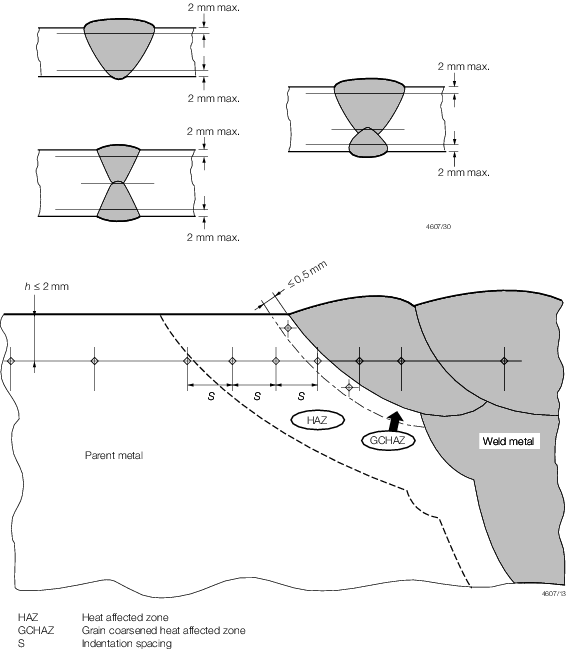

2.7.13 Hardness surveys:

- A Vickers hardness survey is to be performed on the macro

specimen taken from the weld start end of the test assembly in accordance with that

shown in Figure 12.2.14 Hardness testing locations for butt welds, using a test load not in excess of 10 kg. For each

row of indents, there are to be a minimum of 3 individual indentations in the weld

metal, the heat affected zones (both sides), the base metal (both sides), and in

addition, 2 indentations are required in the grain coarsened heat affected zone, one

above and one below the hardness survey row. The recommended distance between indents

is 1,0 mm, but the distance between indents should not be less than the minimum

specified in ISO 6507-1.

- For steel grades EH47, EH47-BCA1 and EH47-BCA2 an additional row

of indents is required from the mid-thickness of macro specimen.

Figure 12.2.14 Hardness testing locations for butt welds

2.8 Destructive tests for steel fillet welds

2.8.2 Two fracture

test specimens are to be removed from the test weld and are to be

subjected to testing by bending the upright plate onto the through

plate to produce fracture, as shown in Figure 12.2.3 Fillet weld test assembly in plate.

2.8.3 At least

three macro examination specimens are to be removed from the test

plate. The specimens are to include the complete cross-section of

the weld and the heat affected zone and is to be prepared to clearly

reveal the weld runs and the heat affected zone. One of the specimens

is to include a weld stop/start position. Examination is to be performed

under a magnification of between x5 and x10.

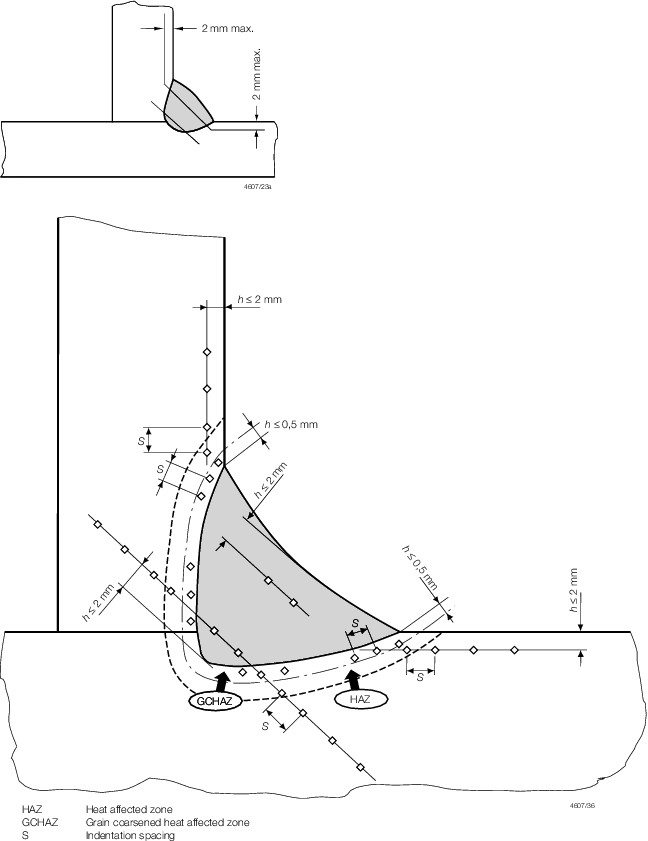

2.8.4 A Vickers

hardness survey is to be performed on the macro specimen taken from

the weld start end of the test assembly in accordance with that shown

in Figure 12.2.15 Hardness test locations for fillet welds, using a test

load not exceeding 10 kg.

Figure 12.2.15 Hardness test locations for fillet welds

2.9 Destructive tests for T, K, Y steel nozzle welds

2.10 Destructive tests for steel pipe branch welds

2.10.1 Pipe branch

welds may be by either full penetration, partial penetration or fillet

welded, depending on the application and the approved plans. Where

these types of welded joints are used, tests are to be performed which

simulate the construction conditions.

2.10.2 The test

weld assembly is to simulate the smallest angle between the branch

and main pipe and is to be subjected to macro-examination and hardness

testing, as follows:

-

For a branch weld

that is full penetration, testing is to be performed in accordance

with the requirements for T', K and Y

joints in Ch 12, 2.9 Destructive tests for T, K, Y steel nozzle welds.

-

For a branch weld

that is either a partial penetration or fillet weld, testing is to

be in accordance with the requirements for fillet welds in Ch 12, 2.8 Destructive tests for steel fillet welds.

2.11 Destructive tests for weld cladding of steel

2.11.2 Where

the weld cladding is not considered as contributing to the strength

of the component, but is required for corrosion or wear resistance,

the type and location of test specimens are to be in accordance with Figure 12.2.18 Type and location of test specimens for weld cladding, except that tensile and

impact tests are not required.

2.11.3 Where

the weld cladding is applied for corrosion resistance, in addition

to the above, weld metal analysis is to be performed on one of the

micro-sections, on the final weld surface but 2 mm deep. The analysis

is to be within the limits specified for the corrosion resistance

required.

2.12 Mechanical test acceptance criteria for steels

2.12.1

Longitudinal

all weld metal tensile test:

-

In general, the longitudinal all weld tensile test is to meet the

minimum properties specified in Table 11.3.2 Requirements for deposited metal

tests (covered electrodes) or Table 11.4.2 Requirements for deposited metal

tests (wire-flux combinations), as appropriate to the grade of steel and

welding process used in the test.

-

Where the application

is such that no consumable approvals are specified in Ch 11 Approval of Welding Consumables, the longitudinal all weld tensile

test tensile is to meet the minimum properties specified for the base

materials used in the test.

-

For pressure vessels

manufactured from carbon or carbon/manganese steels, the tensile strength

from the longitudinal all weld tensile test is not to be less than

the minimum specified for the plate material and is not to be more

than 145 N/mm2 above this value,see

Ch 13, 4.8 Mechanical requirements 4.8.3.

-

For tanks intended

for liquefied gases, the weld metal strength may be lower than the

minimum specified for the base metal provided that the application

has design approval. In such cases the strength is not to be less

than that specified in the approved design.

-

For base metal grades with minimum specified yield strength level of 890 and 960

N/mm2, the weld metal strength may be lower than the minimum

specified for the base metal provided that the application has design approval for

the undermatching weld metal. In such cases the weld metal strength is not to be

less than that specified in the approved design.

2.12.3

Bend

tests:

-

In general, bend

tests are to exhibit no defects exceeding 3,0 mm measured in any direction

across the tension face of the specimen after being bent over the

required diameter of former to the appropriate angle.

-

Bend tests for pressure

vessel applications are to exhibit no defects exceeding 3,0 mm measured

along the specimen or 1,5 mm measured transverse to the specimen axis,

after bending.

-

In all cases, premature

failure of the bend tests at the edges of the specimen is to not be

cause for rejection unless these are associated with a weld defect.

2.12.4

Impact

toughness tests:

-

Impact test specimens

for hull construction are to be tested at the temperature, and are

to achieve the minimum impact energy, as specified in Table 12.2.2 Impact test requirements for butt

joints (t ≤ 50 mm) see Notes 1 and 2 and Table 12.2.3 Impact test requirements for butt

joints (t > 50 mm) see Notes 1 and 2 .

-

Impact test specimens

for applications other than hull construction are to be tested at

the same temperature and achieve the same minimum energy values, as

specified for the base materials used in the test.

-

Impact test acceptance

criteria are to be in accordance with the above unless the Rules applicable

to the particular construction specify more stringent requirements.

-

For quench and tempered steels, the required test temperature and

absorbed energy are to be in accordance with that specified for the parent

materials. For base metal grades with minimum specified yield strength level of

890 and 960 N/mm2, the weld metal absorbed energy may be lower than the

minimum specified for the base metal provided that the application has design

approval for the undermatching weld metal. In such cases the absorbed energy is

not to be less than that specified in the approved design.

Table 12.2.2 Impact test requirements for butt

joints (t ≤ 50 mm) see Notes 1 and 2

| Grade of steel

|

Test temperature (°C)

see Note 4

|

Average energy (J) minimum, see Note 4

|

| Manual or

semi-automatic welded joints

|

Automatically welded joints

|

| Downhand, Horizontal, Overhead

|

Vertical upward, Vertical

downward

|

| A,

see Note 3

|

20

|

47

|

34

|

34

|

| B,

see Note 3, D

|

0

|

| E

|

-20

|

| AH32,

AH36

|

20

|

| DH32,

DH36

|

0

|

| EH32,

EH36

|

-20

|

| FH32,

FH36

|

-40

|

| AH40

|

20

|

39

|

39

|

| DH40

|

0

|

| EH40

|

-20

|

| FH40

|

-40

|

Note

2. These requirements are to apply to

test piece of which butt weld is perpendicular to the rolling

direction of the plates.

Note

3. For grade A and B steels average

absorbed energy on fusion line and in heat affected zone is to be a

minimum of 27 J.

Note

4. For Naval ships both the test

temperature and value of minimum energy absorbed are to be those

specified for the parent material.

|

Table 12.2.3 Impact test requirements for butt

joints (t > 50 mm) see Notes 1 and 2

| Grade of steel

|

Test temperature (ēC)

See Note 2

|

Average energy (J) minimum, see Note 2

|

| Manual or semi-automatic welded joints

|

Automatically welded

joints

|

Downhand, Horizontal,

Overhead

|

Vertical upward,

Vertical downward

|

| A

|

20

|

34

|

34

|

34

|

| B

|

0

|

34

|

34

|

34

|

| D

|

0

|

47

|

38

|

38

|

| E

|

20

|

47

|

38

|

38

|

| AH32, AH36

|

20

|

47

|

41

|

41

|

| DH32, DH36

|

0

|

47

|

41

|

41

|

| EH32, EH36, EH36-BCA1

|

20

|

47

|

41

|

41

|

| FH32, FH36

|

40

|

47

|

41

|

41

|

| AH40

|

20

|

50

|

46

|

46

|

| DH40

|

0

|

50

|

46

|

46

|

| EH40, EH40-BCA1, EH40-BCA2

|

20

|

50

|

46

|

46

|

| FH40

|

40

|

50

|

46

|

46

|

| EH47, EH47-BCA1, EH47-BCA2

|

20

|

64

|

64

|

64

|

Note

1. These requirements are to apply to

test piece of which butt weld is perpendicular to the rolling

direction of the plates.

Note

2. For the Naval ships, both the test

temperature and value of minimum absorbed energy are to be those

specified for the parent material.

|

2.12.5

Macro-examination:The macro-section is to reveal an even weld profile blending

smoothly with the base material. The weld dimensions are to be in

accordance with the requirements of the pWPS and any defects present

are to be assessed against the non-destructive examination acceptance

criteria given in Ch 12, 2.5 Non-destructive examination (NDE) 2.5.5.

2.12.6 Hardness surveys:

- The maximum hardness value is not to exceed 350 Hv for steel

grade EH47 and 380 Hv for steel grades EH47-BCA1 and EH47-BCA2.

- For all other steel grades, themaximum hardness value is not to

exceed 350 Hv for steels with a specified minimum yield strength up to ≤420

N/mm2, nor exceed 420 Hv for steels with a specified minimum yield

strength in the range 420 N/mm2 t o690 N/mm2.

2.12.7

Weld

fracture or break tests (for pressure vessel test welds): The

faces of the broken fillet weld fracture or weld break test are to

be examined for defects and assessed in accordance with the non-destructive

acceptance criteria given in ISO 5817 Level B, except for excess convexity

and excess throat thickness where Level C will apply.

2.13 Failure to meet requirements (Retests)

2.13.1 Where

a tensile, bend or hardness specimen fails to meet requirements, further

test specimens may be removed and tested in accordance with the requirements

of Ch 2, 1.4 Re-testing procedures 1.4.1.

2.13.2 Where

an impact specimen fails to meet requirements, a further set of three

specimens may be removed and tested in accordance with the requirements

of Ch 2, 1.4 Re-testing procedures 1.4.4.

2.13.3 Where

a macro specimen reveals a defect that is planar in nature, the welding

procedure test is to be considered as not satisfying the requirements

and a new test assembly is required.

2.13.4 Where

a macro specimen does not meet requirements as a result of a volumetric

imperfection exceeding the permitted size, two additional specimens

may be removed from the same test weld and examined. If either of

these macro-sections also fails to satisfy the requirements, the welding

procedure is to be considered as not having met the requirements.

2.13.5 If there

is a single hardness value above the maximum values specified, additional

hardness tests are to be carried out, either on the reverse of the

specimen, or after sufficient grinding of the tested surface. None

of the additional hardness values is to exceed the maximum hardness

values specified, otherwise the welding procedure is to be considered

as not having met the requirements.

2.13.6 Where

there is insufficient material available in the welded test assembly

to provide re-test specimens, subject to prior agreement with the

Surveyor, a second assembly may be welded using the same conditions

as the original test weld.

2.14 Test records

2.14.1 The procedure

qualification record (PQR) is to be prepared by the manufacturer and

is to include details of the welding conditions used in the test specified

in Ch 12, 2.2 Welding variables and the results of all the

non-destructive examinations and destructive tests, including re-tests.

2.14.2 Provided

that the PQR lists all the relevant variables and there are no inconsistent

features and the results satisfy the requirements, the PQR may be

endorsed by the Surveyor as satisfying the requirement of the Rules, see also

Ch 12, 1.1 General 1.1.4.

2.15 Range of approval

2.15.1 A welding

procedure qualification test that has successfully met the requirements

may be used for a wider range of applications than those used during

the test.

2.15.2 Changes

outside of the ranges specified are to require a new welding procedure

test.

2.15.3 Other

ranges of approval from those specified in this Section may be agreed

with the Surveyor, provided that they are in accordance with recognised

National or International Standards.

2.15.4

Manufacturer. A welding procedure qualified by a manufacturer is valid for

welding in workshops under the same technical and quality management.

2.15.5

Welding

process and technique. The welding process and welding techniques

approved are to be those employed during the welding procedure qualification

test. Where multiple welding processes are used, these are to be employed

in the same order as that used in the welding procedure qualification

test. However, it may be acceptable to delete or add a welding process

where it has been used solely to make the first weld run in the root

of the joint, provided back gouging or grinding of the root weld is

specified on the WPS. For multi-process procedures, the welding procedure

approval may be carried out with separate welding procedure tests

for each welding process.

2.15.6

Welding

positions. Approval for a test made in any position is restricted

to that position. To qualify a range of positions, test assemblies

are to be welded for the highest heat input position, and the lowest

heat input position, and all applicable tests are to be made on those

assemblies. The above excludes welding in the vertical position with

travel in the downward direction which will always require separate

qualification testing and only be acceptable for that position.

2.15.7

Joint

types. A qualification test performed on a butt weld may be

considered acceptable for fillet and partial penetration welds, provided

the same welding conditions are used. The range of approval depending

on the type of joint for butt welds is given in Table 12.2.4 Range of approval for different

types of butt joints.

Table 12.2.4 Range of approval for different

types of butt joints

| Type of welded joint for test assembly

|

Range of

approval

|

| Butt

welding

|

One side

|

With

backing

|

A

|

A,C

|

| Without backing

|

B

|

A,B,C,D

|

|

|

|

|

|

| Both sides

|

With

gouging

|

C

|

C

|

| Without

gouging

|

D

|

C,D

|

2.15.8

Range

of material types:

-

For normal and higher strength steels, for each strength level,

welding procedures are considered applicable to the same and lower toughness

grades as that tested. For each toughness grade, welding procedures are considered

applicable to the same and two lower strength levels as that tested with the

exception of the two-run (T) or high welding heat input (A) techniques where

acceptance is limited to the strength level used in the test.

-

A qualification test performed on H47 strength grade steels may be

used to weld the steel of the same strength level or grade H40 and all lower

toughness grades to that tested.

-

The range of approval for the crack arrest steel grades is shown in

Table 12.2.5 Range of approval for crack arrest steel grades. Welding procedures qualified on non-brittle crack

steel grades are also considered applicable to corresponding brittle crack arrest

steel grades where production heat input does not exceed 50 KJ/cm. For higher heat

input, the welding procedures are to be qualified on crack arrest steel grades.

Guidance: As an example, the corresponding crack arrest steel grades

for non-brittle crack arrest steel grade EH40 are EH40-BCA1 and EH40-BCA2.

-

For high strength quenched and tempered steels, for each strength

level, welding procedures are considered applicable to the same and lower

toughness grades as that tested. For each toughness grade, welding procedures are

considered applicable to the same and one lower strength level as that tested. The

approval of quenched and tempered steels does not qualify thermo-mechanically

rolled steels (TMCP steels) and vice versa.

-

For weldable C and C-Mn steel forgings, welding procedures are

applicable to the same and lower strength level as that tested. The approval of

quenched and tempered steel forgings does not qualify other delivery conditions

and vice versa.

-

For weldable C and C-Mn steel castings, welding procedures are

applicable to the same and lower strength level as that tested. The approval of

quenched and tempered steel castings does not qualify other delivery conditions

and vice versa.

- Dissimilar materials. Where a qualification test has been performed

using dissimilar materials, acceptance is to be limited to the materials used in the

test.

2.15.9

Thickness

and diameter range:

-

For straight butt

welds, the material thickness range to be approved is to be based

on the thickness of the test piece and the type of weld as shown in Table 12.2.6 Welding procedure thickness

approval range - Butt welds.

-

For butt welds between

plates of unequal thickness, the lesser thickness is the ruling dimension.

-

For fillet welds

and T butt welds, Table 12.2.6 Welding procedure thickness

approval range - Butt welds is to be applicable to both the abutting and through

member thicknesses. In addition to the requirements of Table 12.2.6 Welding procedure thickness

approval range - Butt welds, the range of approval

of throat thickness a for fillet welds

is to be as follows:

- single run: 0,75a to 1,5a

- multi-run: as for butt welds with multi-run (i.e. a =t)

-

Notwithstanding any

of the above, the approval of maximum thickness of base metal for

any technique is to be restricted to the thickness of the test assembly

if three of the hardness values in the heat affected zone are found

to be within 25 Hv of the maximum permitted.

-

The material diameter

range to be approved is to be based on the diameter of the test piece

and type of weld as shown in Table 12.2.7 Diameter range approved.

Table 12.2.5 Range of approval for crack arrest steel grades

| Material grade for

the test assembly

|

Range of

Approval

|

| EH36-BCA1

|

EH36-BCA1

|

| EH40-BCA1

|

EH40-BCA1

|

| EH40-BCA2

|

EH40-BCA2,

EH40-BCA1

|

| EH47-BCA1

|

EH47-BCA1

|

| EH47-BCA2

|

EH47-BCA2,

EH47-BCA1

|

Table 12.2.6 Welding procedure thickness

approval range - Butt welds

Test thickness,

see Note

1

(t in mm)

|

Range approved

|

All

multi-run butt welds and all fillet welds

see Notes 2

and 3

|

All single-run or two-run (T

technique) butt welds

|

| t ≤ 3

|

t to 2t

|

|

| 3 < t ≤ 12

|

3 to 2t

|

0,7t to

1,1t

|

| 12 < t ≤ 100

|

0,5t to

2t,

see Note 1

|

0,7t to

1,1t

see Note 4

|

|

t > 100

|

0,5t to

1,5t

|

0,7t to

1,1t

see Note 4

|

|

|

Note

1. Subject to a maximum limit of 150

mm.

|

Note

2. For multi process procedures, the

recorded thickness contribution of each process is to be used as a

basis for the range of approval of the individual welding process.

|

Note

3. For vertical down welding, the test

piece thickness, t, is the upper limit of the range of

application.

|

Note

4. For processes with heat input over 5,0

kJ/mm, the upper limit of the range of approval is to be 1,0 t.

|

Table 12.2.7 Diameter range approved

- Diameter used for test,

- see Note 1

|

Range of

diameters

approved

|

|

|

- 0,5D to 2D

- > 0,5D, see Note 2

|

Note

1.

D is the outside diameter of the pipe or the smallest side

dimension of rectangular hollow section.

Note

2. Lower diameter range limited to 25 mm

minimum.

Note 3. Qualification given for plates also

covers pipes when the outside diameter is greater than 500 mm or when the

diameter is greater than150 mm welded in the Downhand (D) or Horizontal (

X ) positions.

|

2.15.10

Welding

consumables:

-

For manual and semi-automatic

welding used for the fill and capping weld runs, it may be acceptable

to change the brand or trade name of the welding electrode or wire

from that used in the test, provided the proposed alternative has

the same or higher approval grading and the same flux type (e.g. basic

low hydrogen, rutile, etc.) as used in that test.

-

For the consumable

used to make the root weld of full penetration butt welds made from

one side only, no change in the type or trade name of the consumable

or backing material is permitted. Alternative backing materials may

be used provided they are equivalent to those used for approval. Where

the approved backing material is a low hydrogen grade and the steel

being welded requires a low hydrogen backing material, testing of

the alternative backing material is to confirm compliance with the

requirements of Ch 11, 7 Consumables for use in one-side welding with temporary backing materials.

-

For processes with

heat input over 5 kJ/mm, no change in the type or trade name of the

consumable is permitted.

2.15.11

Shielding

gas. For gas shielded welding processes, a change in shielding

gas composition from that used in the test will require a new qualification

test.

2.15.12

Heat

Input. The upper limit of heat input approved is 25 per cent

greater than that used in the test, or 5,5 kJ/mm, whichever is the

smaller. With heat input over 5,0 KJ/mm, the upper limit is 10 per

cent above that used in the test. In all cases, the lower limit of

heat input approved is 25 per cent lower than that used in the test.

2.15.13

Current

type. The current type used during the qualification test is

to be the only type approved. Additionally, changes from or to pulsed

current require new qualification tests.

2.15.14

Preheat

temperature. The temperature used during the test is to be

the minimum approved. Higher temperatures may be specified for production

welds up to the maximum interpass temperature. Where hardness tests

have been performed that exhibit results near the maximum permitted,

an increase in preheat temperature is required when welding material

of greater thickness than that used in the test.

2.15.15

Interpass

temperature. The maximum interpass temperature recorded during

qualification testing is to be the maximum approved. Lower temperatures

may be specified for production welding, but no lower than the minimum

preheat temperature.

2.15.16

Post-weld

heat treatment. A qualification test performed with no post

weld heat treatment is only acceptable for production welding where

no heat treatment is applied. Where the qualification test has included

a post weld heat treatment, this is to be applied to all welds made

with the welding procedure. The average specified soak temperature

may vary by up to 25°C from that tested.

2.15.17

Shop

primers. Welding procedure qualification with shop primers

qualifies welds without primer, but not vice versa.

2.16 Welding procedure specification (WPS)

2.16.1 A welding

procedure specification (WPS) is to be prepared by the manufacturer

detailing the welding conditions and techniques to be employed for

production welding. The WPS is to be based on the conditions and variables

used during the qualification test, and is to include all the ranges

of the essential variables specified in Ch 12, 2.2 Welding variables 2.2.1 and Ch 12, 2.15 Range of approval.

2.16.2 The WPS

should reference the procedure qualification record upon which it

is based and is to be approved by the Surveyor prior to commencing

production welding.

|