Section

4 Fittings for offshore mooring chain

4.1 Scope

4.1.1 Provision is made in this Section for five grades, R3, R3S, R4, R4S and R5 of

fittings for offshore mooring chain. Fittings include, but are not limited to,

shackles, triplates, end shackles, swivels, and swivel shackles.

4.2 Manufacture

4.2.1 The materials from which the fittings are made are to be manufactured at works

approved by LR, in accordance with the appropriate requirements of Ch 4, 1 General requirements or Ch 5, 1 General requirements, and the requirement in this

Section. Alternative arrangements may be agreed provided that full details

concerning the manufacturer are submitted to LR.

4.2.2 Steel used for fittings must be manufactured by an approved process, and be killed

and fine grain treated.

4.2.3 The austenite grain size of steel used for fittings must be 6, or finer, as measured

in accordance with ASTM E112 or equivalent grain size index in accordance to ISO

643. Measurements for circular sections are to be taken at one-third of the radius.

Measurements for non-circular sections are to be taken at one-quarter of the

thickness.

4.2.4 Steel used for forgings or castings for grades R4S and R5 must be vacuum degassed.

4.2.5 For steel used for forgings or castings for grades R4S and R5 the following tests are

to be carried out on each heat:

- assessment and quantification of the level of non-metallic

micro inclusions. These must be acceptable for the final product.

- macro-etching on a representative sample, in

accordance with ASTM E381 or equivalent; this must be free from any

injurious segregation or porosity.

- hardenability tests in accordance with ASTM A255 or

equivalent.

The results of these tests are to be supplied by the steel manufacturer, and the

results are to be included in the final fitting documentation.

4.2.6 Fittings for chain are to be heat treated in accordance with procedures that have

been approved by LR.

4.3 Testing of fittings

4.3.1 For fittings for mooring chain, a batch is defined as fittings from the same

steel-making heat that have been heat treated together in the same furnace.

4.3.2 All fittings are to be subjected to proof load tests, non-destructive examination,

sample break load tests and sample mechanical tests after final heat treatment in

the presence of a Surveyor. In addition to the requirements stated in this section,

attention must be given to any relevant statutory requirements of the National

Authority of the country in which the ship is to be registered.

4.4 Proof and break load tests

4.4.1 All chain cable fittings, including spares, are to be subjected to the proof loads

appropriate to the grade and size of cable for which they are intended, see

Table 10.3.1 Test loads for mooring chain

cables. Prior to this

test, the fittings are to be shot or sand blasted to ensure that their surfaces are

free from scale, paint or any other coating which could interfere with any

subsequent inspection.

4.4.3 If the sample fails to withstand the breaking load without fracture, or in the event

of failure of any other test, then the entire batch is to be rejected unless the

cause of failure has been determined and it can be demonstrated that the condition

causing failure is not present in any of the other fittings in the batch. If this

can be demonstrated, then two more samples from the same batch may be tested. If

either of these samples fails, the batch is to be rejected.

4.4.4 For very large fittings where the required breaking load is greater than the capacity

of the testing machine and for individually produced fittings or fittings produced

in small batches (less than five), proposals for an alternative method of testing

will be given special consideration. All proposals for alternative testing methods

are to be detailed in writing for approval and the following additional conditions

may apply:

- Alternative testing is described in a written procedure and manufacturing

specification.

- A finite element analysis is provided at the break load and demonstrates that

the fitting has a safety margin over and above the break load of the chain.

- Strain age testing (in accordance with a procedure approved by LR) is carried

out on the material grade produced to the same parameters at the time of

qualification.

- If a fitting is of a large size that will make heat treating in batches

unfeasible or has a unique design, strain gauges are to be applied during the

proof and break load tests during initial qualification and during production.

The strain gauge results from production are to be comparable with the results

from qualification.

4.4.5 All fittings are to be subjected to close visual examination after proof load

testing, particular attention being paid to machined surfaces and highly stressed

regions.

4.4.6 Each fitting is subject to fluorescent magnetic particle or dye penetrant inspection

on all surfaces and ultrasonic testing in accordance with a recognised Standard. As

a minimum requirement surfaces must be free from:

- relevant linear indications exceeding 1,6 mm in transverse direction;

- relevant linear indications exceeding 3,2 mm in longitudinal direction;

- relevant non-linear indications exceeding 4,8 mm.

When required by LR, ultrasonic testing is to be carried out on 100 per cent of cast

or forged fittings. The acceptance/rejection criteria established for the design is

to be met.

4.4.8 Fittings of increased dimensions or higher grade material may be used subject to

approval by LR.

4.4.9 Where fittings with increased dimensions, or fittings of a higher material grade are

included in an outfit:

- each item must be successfully tested at the required breaking load for the

chain cable for which it is intended; and

- strain age properties must have been carried out on the material grade produced

to the same parameters;

- strain gauges are to be applied during the break load test in the high stress

locations to monitor that the strains stay within allowable limits.

For the purpose of this paragraph, items of increased dimensions are so designed that

their breaking strength is not less than 1,4 times the Rule minimum breaking load

for the chain cable for which it is intended, and this has been verified by

procedure tests.

4.4.10 Weld repairs of finished fittings are not permitted.

4.5 Dimensional inspection

4.5.1 At least one fitting from each batch of up to 25 is to be checked dimensionally after

proof load testing. The manufacturer is to provide a statement that the dimensions

comply with the specified requirements.

4.5.2 The following tolerances apply to the unmachined dimensions of all fittings;

- nominal diameter plus 5 per cent, minus 0 per cent; and

- other dimensions plus or minus 2,5 per cent.

4.6 Mechanical tests

4.6.1 All fittings are to be manufactured to a manufacturing specification

approved by LR, and provision is to be made for tensile and impact test specimens.

The test samples are to be subjected to heat treatment with the fittings they

represent. The mechanical test requirements are the same as those for the relevant

grade of chain cable, see

Table 10.3.5 Mechanical properties of chain

cable materials.

4.6.2 Mechanical tests for fittings are to be taken from full size fittings

that have been heat treated with the production batch they represent, and the tests

are to be taken after the fitting has been proof load tested. It is not permitted to

use separate representative coupons unless approved by LR in accordance with Ch 10, 4.6 Mechanical tests 4.6.6. At least one

fitting out of every batch of up to 25 is to be tested. Hardness tests are to be

carried out on finished fittings. The frequency and locations are to be agreed with

LR. The recorded values are for information only and used as an additional check to

verify that the heat treatment process has been stable during the fitting

production.

4.6.3 Forged shackle bodies and forged Kenter shackles are to have a set of

three Charpy impact tests and a tensile test taken from the crown of the shackle.

For smaller diameter shackles, where the geometry does not allow for the tensile

test to be taken from the crown, this may be taken from the straight portion from

the locations specified in Figure 10.4.1 Sampling of steel bars,

forgings and castings, with

the Charpy impact test specimens on the outside radius.

4.6.5 For fittings with complex geometries the locations of mechanical test pieces taken

are to be approved by LR. For non-circular sections, one-quarter of t (thickness)

from the surface is considered appropriate. Rolled plates are to be tested to the

standard to which they are produced.

4.6.6 Where fittings are individually heat treated or produced in small batches (less than

five), alternative testing may be approved; a proposal must be submitted in a

written procedure for consideration and the following additional conditions may

apply:

- If separately forged or cast coupons are used, they are to have a

cross-section and, for forged coupon, a reduction ratio similar to that of

the fittings represented, and are to be heat treated in the same furnace and

quenched in the same tank at the same time, as the actual forgings or

castings. Thermocouples are to be attached to the coupon and to the

fittings.

- If separately forged or cast coupons are agreed, it is to be verified by a

procedure test that coupon properties are representative of fitting

properties.

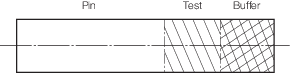

4.6.7 Mechanical tests of pins are to be taken as shown in Figure 10.4.1 Sampling of steel bars,

forgings and castings from

the mid- length of a sacrificial pin of the same diameter as the final pin. For oval

pins, the diameter taken is to represent the smaller dimension. Mechanical tests may

be taken from an extended pin of the same diameter as the final pin that

incorporates a test prolongation and a heat treatment buffer prolongation, where

equivalence with mid-length test values have been established. The length of the

buffer is to be at least equal to 1 pin diameter which is removed after the heat

treatment cycle is finished. The test coupon can then be removed from the pin. The

buffer and test are to come from the same end of the pin, as shown in Figure 10.4.2 Buffer and test piece location

for pins.

Figure 10.4.2 Buffer and test piece location

for pins

4.6.8 Manufacturers intending to supply fittings in the machined condition are to submit

detailed drawings for approval by LR. Machining of Kenter shackles must result in a

fillet radius of a minimum of 3 per cent of the nominal diameter.

4.7 Identification

4.7.1 Each fitting is to be permanently marked with the following information:

- identification number, cast number or other marking which will enable the

full history of the casting to be traced;

- manufacturer’s name or trade mark;

- LR or Clasifications Register, the abbreviated name of LR's local office, and

number of certificate;

- personal stamp of Surveyor responsible for inspection;

- date of final inspection; and

- chain grade.

4.7.2 Where small casting/forging fittings are manufactured in large numbers, modified

arrangements for identification may be specially agreed with the Surveyor.

4.8 Documentation

4.8.1 A complete Inspection and Testing Report in booklet form is to be provided by the

manufacturer for each order. This booklet include all dimensional checks, test and

inspection reports, NDE reports, process records and example photographs of

components positioned in furnaces, as well as any non-conformity, corrective action

and repair work.

4.8.2 Each type of fitting must be covered by separate certificates.

4.8.3 All documents, including reports and appendices, are to contain a reference to the

relevant certificate number.

4.8.4 The manufacturer is responsible for storing all the documentation in a safe and

retrievable manner for a period of at least 10 years.

4.9 Certification

|