Section

7 Construction details and minimum thickness

7.1 Symbols

7.2 Compartment minimum thickness

7.3 Geometric properties and proportions of members

7.3.1 The

depth of the web of any primary member is to be not less than 2,5

times the depth of the cut-outs for the passage of secondary members,

except where compensation is arranged to provide satisfactory resistance

to deflection and shear buckling in the web.

7.3.2 The

area of material in the face plate of any primary member is not to

exceed:

nor is it to be less than:

7.3.3 The

geometric properties of rolled stiffeners and built sections are to

be calculated in association with an effective width of attached plating

in accordance with Pt 3, Ch 3, 3 Structural idealisation.

7.4 Continuity of primary members

7.4.1 Primary

members are to be so arranged as to ensure effective continuity of

strength throughout the range of tank structure. Abrupt changes of

depth or section are to be avoided. Where members abut on both sides

of a bulkhead or on other members, arrangements are to be made to

ensure that they are in alignment.

7.4.2 The

members are to have adequate end fixity, lateral support and web stiffening,

and the structure is to be arranged to minimize hard spots or other

sources of stress concentration. Openings are to have well rounded

corners and smooth edges and are to be located having regard to the

stress distribution and buckling strength of the plate panel.

7.5 Primary member web plate stiffening

7.5.1 The

webs of primary members are to be supported and stiffened in accordance

with the following requirements, which are designated as requirements

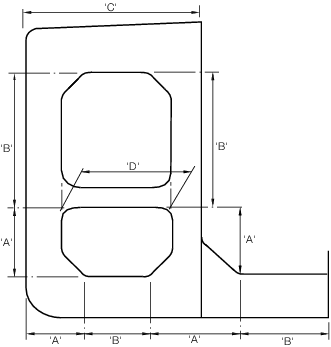

`A', `B', `C' and `D'. The application of these requirements is detailed

in Pt 4, Ch 10, 7.5 Primary member web plate stiffening, and the corresponding

locations indicated in Figure 10.7.1 Key to application requirements.

Where webs are slotted for the passage of secondary members, the web

stiffeners are to be arranged to provide adequate support for the

loads transmitted, see

Pt 3, Ch 10, 5.2 Arrangements at intersections of continuous secondary and primary members.

Figure 10.7.1 Key to application requirements

7.5.2 Where

higher tensile steel is used for the primary members, the maximum

spacing of stiffeners given in this Section is to be multiplied by  . .

7.5.4 For

requirement `A' stiffening:

-

The thickness, t

w of the web is to be not less than

-

Stiffening is

generally to be fitted normal to the face plate of the member, but

the stiffeners parallel to the face plate will be required when the

web depth, d

w, exceeds a value, d

max which is to be taken as:

-

Where stiffening

parallel to the face plate is required, the distance from the face

plate of the member to the nearest stiffener is not to exceed 65t

w. Further stiffeners are to be fitted at similar spacing so

that the distance between the last stiffener and the shell or bulkhead

plating does not exceed d

max. In way of end

brackets to transverse bulkhead primary structure, stiffeners are

to be fitted normal to the face plate of the member so that web plate

panel dimensions parallel to the face plate do not exceed 80t

w.

7.5.5 For

requirement `B` stiffening:

-

The thickness,

tw of the web is to be not less than

-

Stiffening is

generally to be fitted normal to the face plate of the member, but

stiffeners parallel to the face plate will be required when the web

depth, d

w, exceeds a value d

max, which is to be taken as:

-

Where stiffening

parallel to the face plate is required, the distance from the face

plate of the member to the nearest stiffener is not to exceed 80t

w. Further stiffeners are to be fitted at similar spacing so

that the distance between the last stiffener and the shell or bulkhead

plating does not exceed d

max.

7.5.6 For

requirement `C' stiffening:

-

Stiffening is

generally to be fitted normal to the face plate of the member in line

with alternate secondary members, but stiffeners parallel to the face

plate will be required, when the web depth, d

w exceeds

a value, d

max which is to be taken as:

-

Where stiffening

parallel to the face plate is required, the distance from the face

plate of the member to the nearest stiffener is not to exceed 90t

w. Further stiffeners are to be fitted at similar spacing so

that the distance between the last stiffener and the deck plating

does not exceed d

max.

7.5.7 For

requirement `D' stiffening:

-

Stiffening parallel

to the face plate will be required such that the distance between

the stiffener and face plate, or between two stiffeners, does not

exceed:

80t

w where L ≤ 90 m

55t

w where L ≥ 190 m

with intermediate values by interpolation.

-

Brackets are

to be fitted to support the face plates and stiffeners.

7.6 Inertia and dimensions of stiffeners

7.6.1 The

moment of inertia is to be not less than:

-

For stiffeners

normal to the primary member face plate:

Where t

w need not be greater

than the values in Table 10.7.1 Maximum web thickness for

stiffener inertia and p is to be obtained from Table 10.7.2 Coefficient for stiffener

inertia.

-

For stiffeners

parallel to the primary member face plate:

On transverses, webs and stringers

On longitudinal deck and bottom girders

Table 10.7.1 Maximum web thickness for

stiffener inertia

| Requirement

|

Web thickness

t

w, in mm

|

| `A'

|

|

| `B' and `C'

|

|

| `D'

|

|

Note Intermediate values by interpolation

|

7.6.2 Where

stiffeners are fitted in both directions, the inertia of the stiffeners

parallel to the face plate of the member is to be not less than that

of the stiffeners fitted normally.

7.6.3 The

depth of web stiffeners is to be not less than 75 mm.

7.6.4 Where

flat bar stiffeners are used, the ratio of depth to thickness is not

to exceed 18  . .

Table 10.7.2 Coefficient for stiffener

inertia

Aspect ratio

of

plate panel,

|

1,0 or

more

|

0,9

|

0,8

|

0,7

|

0,6

|

0,5

|

0,4

|

0,3 or

less

|

|

p

|

1,5

|

2,1

|

2,9

|

4,2

|

6,1

|

9,2

|

14,6

|

30,0

|

Note

1. Intermediate values by

interpolation.

Note

2. The depth of panel, d, used in

calculating aspect ratio may be measured from the face of the

secondary member to which the primary member web stiffener is

attached.

|

7.7 Application of stiffening requirements

7.7.1 The

requirements as detailed in Pt 4, Ch 10, 7.5 Primary member web plate stiffening and Pt 4, Ch 10, 7.6 Inertia and dimensions of stiffeners are to be applied in the following

locations, see also

Figure 10.7.1 Key to application requirements.

-

For bottom transverses:

In the centre tank requirement `A' stiffening is to extend for

20 per cent of the breadth of the tank from the longitudinal bulkhead,

but at least beyond the toe of the end bracket. In the wing tank,

requirement `A' stiffening is to extend at least as far as the toes

of the end brackets from the longitudinal bulkhead and the shell.

Elsewhere, requirement `B' stiffening is to be fitted.

-

For transverses

at side shell and longitudinal bulkhead:

Requirement `A` stiffening is to extend at least as far as the

lower surface of the lower cross-tie. Elsewhere, requirement `B` stiffening

is to be fitted.

-

For deck transverses:

Requirement `C' stiffening is to be fitted.

-

For stringers

and horizontal girders:

Requirement `A' stiffening is to extend for a distance from

each end of 20 per cent of the span of the stringer or girder, but

at least beyond the toes of the end brackets. Elsewhere, requirement

`B' stiffening is to be fitted.

-

For cross-ties:

Cross-ties are to be suitably stiffened to prevent buckling

and twisting. Requirement `D' stiffening is to be fitted.

-

For shell stringers

and vertical webs in fore peak:

Requirement `A' stiffening is to extend the full length of the

member.

7.7.2 The

application of stiffening requirements to transverse wing structures

in wing tanks where no cross-ties are fitted is to be based on the

results of direct calculation and will be specially considered.

7.8 Stiffening of continuous longitudinal girders

7.8.1 The

webs of continuous longitudinal deck and bottom girders are to be

stiffened parallel to the girder face plate.

7.8.2 The

stiffeners are to be spaced not more than 55t

w mm

apart except in way of vertical webs and end brackets, where the spacing

is not to exceed 45t

w mm. Alternatively, a

combination of parallel stiffeners at 55t

w mm

spacing and normal stiffeners at 45t

w mm spacing

may be adopted. Particular attention is to be given to the stiffening

of the docking girder.

7.9 Stiffening of vertical webs on transverse bulkheads

7.9.1 Vertical

webs are to be fitted with stiffeners parallel to the face plate of

the web and spaced not more than 60t

w mm apart.

Stiffeners normal to the face plate are to be fitted when a vertical

web supports horizontal stiffeners on transverse bulkheads. The length

of stiffener is to be sufficient to distribute the load transmitted,

and the connection between web stiffener and bulkhead stiffener is

to comply with the relevant requirements of Pt 3, Ch 10, 5.2 Arrangements at intersections of continuous secondary and primary members.

7.10 Docking brackets on bottom centreline girder

7.10.1 Stiffened

docking brackets are to be fitted on both sides of the bottom centreline

girder, midway between transverses, and are to be connected to a suitable

bottom shell longitudinal. The bracket on one side is to be connected

to the face plate of the girder but the other may be stopped at a

suitable horizontal stiffener.

7.10.2 Additional

vertical stiffeners may be required on the bottom panels of the girder

to resist docking pressures.

7.11 Lateral stability of primary members

7.11.1 Tripping

brackets are generally to be fitted close to the toes of end brackets,

in way of cross-ties and elsewhere, so that the spacing between brackets

does not exceed the lesser of 4,5 m or 15 times the width of the face

plate (20 times in the case of deck transverses). Arrangements in

way of the intersections of primary members are to be such as to prevent

tripping. A closer spacing of brackets may be required to be adopted

with asymmetrical face plates.

7.11.2 To

maintain continuity of strength, substantial horizontal and vertical

brackets are to be fitted to transverses or stringers at ends of cross-ties.

Horizontal brackets are to be aligned with the cross-tie face plates,

and vertical end brackets are to be aligned with the cross-tie web.

7.11.3 Tripping

brackets are to be connected to the face plate of the bottom transverses.

Elsewhere, other than for docking girders, the bracket is to be connected

to the face plate whenever the unsupported width of the latter exceeds

150 mm. Where the width of symmetrically placed face plates exceeds

400 mm, a small bracket is to be fitted opposite, and in line with,

the tripping bracket. Equivalent support arrangements are to be provided

for cross-tie face plates. Particular attention is to be paid to the

support of continuous face plates in way of the radius at toes of

brackets.

7.11.4 Wide

face plates may require additional support between brackets.

7.11.5 In

the fore peak tank, if the angle to the normal of the shell plating

and the vertical webs exceeds 20°, double tripping brackets are

to be fitted to the web at about midspan, but in no case greater than

3,0 m apart.

7.12 Openings in web plating

7.12.1 Where

openings are cut in the webs of primary supporting members, the greatest

dimension of the opening is not to exceed 20 per cent of the web depth.

The opening is to be located so that the edges are not less than 40

per cent of the web depth from the face, and are equidistant from

the corners of notches for frames or stiffeners. Openings are to be

suitably framed where required.

7.12.2 Lightening

holes are not to be cut in horizontal girders on the ship's side and

longitudinal bulkheads, in symmetrical webs nor in side transverses

and vertical webs in way of cross-ties and their end connections.

7.12.3 Holes

cut in primary longitudinal members within 0,1D of the

deck and bottom are, in general, to be reinforced as required by Pt 4, Ch 9, 4.10 Deck openings. Access holes may be cut

in deep transverses and girders with suitable compensation to provide

satisfactory resistance to deflection and shear buckling in the web.

7.12.4 All

holes are to have smooth edges and are to be kept well clear of notches

and the toes of brackets.

7.12.5 Small

air and drain holes cut in primary members are to be kept clear of

the toes of brackets and are to be well rounded with smooth edges.

Where holes are cut in primary longitudinal members of higher tensile

steel, they are to be elliptical or equivalent to minimize stress

concentration.

7.12.6 Where

holes are cut for heating coils, the lower edge of the hole is to

be not less than 100 mm from the inside of the shell plating. Where

large notches are cut in the transverses for the passage of longitudinal

framing, adjacent to openings for heating coils, the longitudinal

notches are to be collared. Examination of the buckling strength of

the web plate panel between notches for longitudinals may be required.

7.13 Brackets connecting primary members

7.14 Arrangements at intersections of continuous secondary and primary

members

|