Section

10 Miscellaneous openings

10.1 General

10.2 Openings in main vehicle deck

10.2.1 Where

the main vehicle deck is enclosed, all companionways and openings

in the deck which lead to spaces below are generally to be protected

by steel doors or hatch covers. Approved fire doors may be accepted

in lieu of steel doors. The sills or coamings are to be not less than

230 mm above the main vehicle deck, with the exception of those leading

to machinery spaces which are to have sills or coamings not less than

380 mm. Exceptionally, when such openings are to be kept closed at

sea, sills or coamings may be reduced in height, provided that the

sealing arrangements are adequate. In such cases, the doors or hatch

covers are to be secured weathertight by gaskets and a sufficient

number of clamping devices. Such items as portable plates in the main

vehicle deck arranged for the removal of machinery parts, etc. may

be arranged flush with the deck, provided they are secured by gaskets

and closely spaced bolts at a pitch not exceeding five diameters.

10.2.2 Scuppers

from vehicle or cargo spaces above the bulkhead deck fitted with an

approved fixed pressure water spray fire-extinguishing system are

to be led directly overboard and are to be fitted with means of preventing

water from passing inboard in accordance with Pt 3, Ch 12, 4.2 Closing appliances.

10.2.3 Inboard

draining scuppers do not require valves but are to be led to suitable

drain tanks (not engine room or hold bilges) and the capacity of the

tanks is to be sufficient to hold approximately 20 minutes of drenching

water. The arrangements for emptying these tanks are to be approved

and suitable high level alarms provided.

10.2.4 A

drainage system is to be arranged in the area between bow door and

ramp, or where no ramp is fitted, between the bow door and inner door.

The system is to be equipped with an audible and visual alarm function

to the navigation bridge being set off when the water levels in these

areas exceed 0,5 m or the high water level alarm, whichever is the

lesser.

10.2.5 The

drainage arrangement for each area is to have sufficient capacity

to prevent accumulation of water in case of leakage. Scuppers are

to be provided on both sides of the ship with a diameter not less

than 50 mm and in accordance with Pt 3, Ch 12, 4 Scuppers and sanitary discharges. Alternatively, a bilge suction should be provided.

10.2.7 Air

pipes from cofferdams or void spaces may terminate in the enclosed

'tween deck space on the main vehicle deck provided the space is adequately

ventilated and the air pipes are provided with weathertight closing

appliances.

10.2.8 Between

the bow door and the inner door a television surveillance system is

to be fitted with a monitor on the navigation bridge and in the engine

control room. The system must monitor the position of doors and a

sufficient number of their securing devices. Special consideration

is to be given for lighting and contrasting colour of objects under

surveillance, see also

Pt 4, Ch 2, 8.5 Arrangements for the closing, securing and supporting of doors 8.5.7.

10.3 Strength assessment of windows in large passenger ships

10.3.1 On

windows in the second tier and higher above the freeboard deck, a

glazing equivalent may be fitted in lieu of deadlights/storm covers.

The thicknesses and arrangements are to be acceptable to the National

Authority with whom the ship is registered and/or by the Administration

within whose territorial jurisdiction the ship is intended to operate.

For arrangements of glazing acceptable to LR, see

Table 2.10.1 Acceptable arrangements of glazing

in lieu of portable storm covers/deadlights. Alternative arrangement

of glazing in lieu of deadlights/storm covers may be accepted provided

details are submitted for consideration.

10.3.4 Toughened safety glass of laminated construction will also be accepted,

provided the requirements of Pt 3, Ch 11, 6.5 Side scuttles, windows and skylights 6.5.29 are complied with.

Table 2.10.1 Acceptable arrangements of glazing

in lieu of portable storm covers/deadlights

Table 2.10.2 Design pressure,

Hd, on windows

| Window location

|

Design pressure head

H

d in metres

|

| Between the design waterline and a

point Z

1,5 m above the waterline

|

Per BS MA 25: 1973

|

| Between a

point Z

1,5 m above the waterline and the deck immediately above (at

Z

d1,5)

|

1,5

|

| Over the

next 2 'tween deck heights

|

|

| For

subsequent decks to the top of the navigation bridge

|

0,25 sides

and aft ends

0,75 house fronts

|

| From the top

of the navigation bridge to the uppermost deck, for house fronts

|

0,75 at top

of navigation bridge 0 at uppermost continuous deck, with linear variation

between, but not less than 0,25

|

| From the top

of the navigation bridge to the uppermost deck, at sides and aft

ends

|

0,25

|

| Symbols

|

|

f

w

|

= |

1,25 in way of sides and ends of superstructures |

| = |

0,75 in way of house fronts |

|

Z

1,5

|

= |

the vertical location in metres above the waterline at

which the BS MA:25 pressure as given in Annex E of BS MA:25 (1973)

is 1,5 t/m2

|

|

Z

w

|

= |

the vertical location in metres above the waterline

to the point under consideration |

|

H

t1 + H

t2

|

= |

sum of the appropriate 'tween deck heights in

metres |

|

Table 2.10.3 Thickness of toughened

glass

| Window type

|

Thickness, t

o, in mm

|

| Rectangular

|

|

| Circular

|

|

| Semi-circular

|

|

| Symbols

|

|

b

|

= |

length of shorter side of window, in mm |

|

β |

= |

0,54A

R – 0,078A

R

2 – 0,17 for A

R ≤ 3 |

| = |

0,75 for A

R > 3 |

|

A

R

|

= |

aspect ratio of window, in mm |

| = |

a/b

|

|

a

|

= |

length of longer side of window, in mm |

|

r

|

= |

the radius of the window, in mm |

|

10.4 Frame design and testing

10.4.1

Application. The testing requirements contained in this Section are for all

exterior window designs on all tiers for passenger ships regardless of length. The

testing is to be carried out for characteristic window sizes (largest, smallest) and

forms (circular, semicircular and rectangular) for each passenger ship. Window designs

which are not covered by Type Approval Certification will require prototype testing in

order to confirm structural integrity and weather or water tightness as required. Tests

are to be carried out to the satisfaction of the Surveyor.

10.4.3

Structural testing. A hydrostatic test is to be carried out in order to examine

the capability of the frame, mullions and the retaining arrangement for the glazing.

This is carried out by applying a test pressure of 4Hd

(Hd as calculated in Pt 4, Ch 2, 10.3 Strength assessment of windows in large passenger ships for windows) to the external face of the window,

utilising an aluminium alloy plate of appropriate temper and thickness to simulate the

flexural response in lieu of the glazing. A full-scale test with actual glazing in place

may be acceptable provided that the stresses induced are within allowable limits.

Details of the calculations made and testing procedures are to be submitted for review

prior to the test. Alternative means of demonstrating adequacy of the frame, mullions

and the retaining arrangement for the glazing may be specially considered.

10.4.4 Equivalent

proposals for testing will be considered. Where alternative testing

procedures are proposed, these are to be agreed with LR before commencement.

10.4.5

Chemically

toughened glass.

-

Chemically toughened

glass may be used in lieu of thermally toughened glass provided it

can be demonstrated the strength of the arrangement is at least equivalent

in strength to that of thermally toughened glass.

-

The glazing system

is to be of laminated construction.

-

Method of testing

will be specially considered.

10.4.6 The

overlap between glazing and the retaining frame is not to be less

than 12 mm.

10.6 Bonded windows and side scuttles

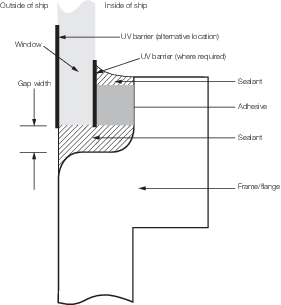

10.6.1 A

‘bonded window’ or ‘bonded side scuttle’ is

one in which the glazing material is secured in its frame from outside

of the ship by glue or other adhesive material. No mechanical fixing

is provided for the glazing. Bonded windows and side scuttles are

to comply with the requirements of Pt 4, Ch 2, 10 Miscellaneous openings. Proposals to secure glazing from the inside of the ship

are to be specially considered using the requirements in this Section

as a basis. It should be noted that bonding from the inside is not

recommended and where it is proposed, further testing will be required.

Non-load bearing secondary bonded glazing, e.g. glazing to improve

thermal insulation, is not required to comply with the requirements

of this sub- Section.

10.6.2 The

adhesive is to be flexible enough to support the glazing without holding

it firm. The glue strip is to be elastic, with width and thickness

designed to allow the glazing to move in both directions in the plane

of the glazing without undue forces on the bonding or the substrate.

The glass is to be free to settle under-load and not to be forced

to follow deflections in the supporting structure. If substantial

racking of the glazing opening under-load is expected, the bonding

is to be designed to accommodate such deflections.

10.6.3 Bonded

windows and side scuttles may be considered as acceptable, in general,

depending on their position, size of vessel and applicable statutory

requirements, noting the distinction between glazing and the frame,

which may have different requirements.

10.6.4 Bonded

windows are not permitted in galley areas, including glazing in galley

doors (internal or external). They are not permitted on escape routes

and evacuation routes where a fire rating is required. The fire integrity

of bulkheads is not to be impaired.

10.6.5 Bonded

windows and side scuttles are not acceptable on fire-fighting vessels,

i.e. those with a fire-fighting notation.

10.6.6 The failure of laminated glass is considered to pose a lower risk to safety

than that of single pane glass. In the event of breaking, laminated glass more readily

holds together and tends not to break up into large sharp pieces. Therefore, in general,

laminated glazing is preferred. When laminated glass is used, the sealant is to be

compatible with the interlayer. Lamination thickness is to be in accordance with Pt 3, Ch 11, 6.5 Side scuttles, windows and skylights 6.5.29. Special consideration will be given

to single pane toughened safety glass.

10.6.7 The

durability of the adhesive and the sealant in the long term marine

environment is to be considered in the approval process. Adhesive

is to be approved in accordance with Ch 14, 2.15 Adhesive and sealant materials of the Rules for Materials. The adhesive bead is to

be resistant to or protected from UV radiation, either by an optically

dense area at the edges of the glazing or by overlapping trim or UV

shielding tape. The adhesive bead is to be resistant to or protected

from fungal attack. Arrangements are to be in accordance with the

adhesive manufacturer’s published guidelines and relevant LR

Rules.

10.6.8 The

edges of the bonding recess are to be rounded to facilitate the application

of the sealant without air entrapment. The width of the gap between

the flange and the glazing is to be large enough to accommodate the

movement of the glazing as a result of hull deflection and thermal

expansion, see

Figure 2.10.1 Gap width between flange and window, bonded from outside of the ship. Recommended gap widths for bonded windows are to be

taken as:

|

|

Gap width

|

|

|

Length of longest side of window

|

|

|

10–15 mm

|

|

|

<1,5 m

|

|

|

15–20 mm

|

|

|

1,5–3,0 m.

|

Figure 2.10.1 Gap width between flange and window, bonded from outside of the ship

10.6.9 The

minimum adhesive width and thickness are to be in accordance with

the adhesive manufacturer’s published guidelines.

|