Section

6 Miscellaneous openings

6.1 Small hatchways on exposed decks

6.1.1 Hatches

which:

- are designed for access to spaces below the deck;

- are capable of being closed weathertight or watertight, as applicable;

- have an opening 2,5 m2 or less;

- are located on the exposed deck over the forward 0,25L of

the ships rule length;

- are on a ship of sea-going service of length 80 m or more, where

the height of the exposed deck in way of the hatch is less than 0,1L or 22 m above the summer load waterline, whichever is the

lesser;

are to comply with the requirements of Pt 3, Ch 11, 6.6 Small hatchways on exposed fore decks. All other small hatchways or

access openings in the positions defined in Pt 3, Ch 11, 1.1 Application 1.1.6 are to comply with the following

requirements.

6.1.2 The

number and size of hatchways and other access openings are to be kept

to the minimum consistent with the satisfactory operation of the ship.

6.1.3 The

height of coamings is to be in accordance with Pt 3, Ch 11, 5.1 General 5.1.1. Lower heights may be considered

in relation to operational requirements and the nature of the spaces

to which access is given.

6.1.4 Rope

hatches may be accepted with reduced coamings, but generally not less

than 380 mm, provided they are well secured and closed before the

ship leaves port. A suitable notice is to be displayed at the hatch

stating that it is to be closed whilst the ship is at sea.

6.1.5 The

thickness of the coamings is to be not less than the Rule minimum

thickness for the deck inside line of openings for that position,

or 11 mm, whichever is the lesser. Stiffening of the coaming is to

be appropriate to its length and height.

6.1.6 Hatch

covers are to be of steel, weathertight and generally hinged. The

means of securing are to be such that weathertightness can be maintained

in any sea condition. Where toggles are fitted, their diameter and

spacing are to be in accordance with ISO Standard or equivalent.

6.1.7 Hinges

are not to be used as securing devices unless specially considered.

6.1.8 The

thickness of covers is to be not less than the Rule minimum thickness

inside the line of openings for the deck at that point, or 8 mm, whichever

is the lesser.

6.1.9 The

covers are to be adequately stiffened.

6.1.10 To

facilitate a swift and safe means of escape to the lifeboat and life

raft embarkation deck, the following provisions apply to overhead

hatches fitted along the escape routes addressed by SOLAS Regulation 13 - Means of escape:

-

escape hatches

and their securing devices shall be of a type which can be opened

from both sides;

-

the maximum

force needed to open the hatch cover should not exceed 150 N; and

-

the use of a

spring equalising, counterbalance or other suitable device on the

hinge side to reduce the force needed for opening is acceptable.

6.1.11 Small

hatches, including escape hatches, are to be situated clear of cargo

containment areas, particularly in the case of offshore supply ships.

6.1.12 Where

portable plates are required in decks for unshipping machinery, or

for other similar reasons, they may be accepted provided they are

of equivalent strength to the unpierced deck and are secured by gaskets

and closely spaced bolts at a pitch not exceeding five diameters.

6.1.14 Where

permitted by the National Authority, access hatch coaming heights

may be reduced on ships engaged on protected or extended protected

water service. Coaming heights are to be as high as practicable with

a minimum height of 230 mm.

6.2 Manholes and flush scuttles

6.2.1 Manholes

and flush scuttles fitted in Positions 1 and 2, or within superstructures

other than enclosed superstructures, are to be closed by substantial

covers capable of being made watertight. Unless secured by closely

spaced bolts, the covers are to be permanently attached.

6.3 Hatchways within enclosed superstructures or 'tween decks

6.3.2 Access

hatches within a superstructure or deckhouse in Position 1 or 2 need

not be provided with means for closing if all openings in the surrounding

bulkheads have weathertight closing appliances.

6.4 Companionways, doors and accesses on weather decks

6.4.1 Companionways on exposed decks are to be of equivalent construction,

weathertightness and strength to a deckhouse in the same position and effectively

secured to the deck.

6.4.2 Access openings in:

-

bulkheads at ends of enclosed superstructures;

-

deckhouses or companionways protecting openings leading into enclosed

superstructures or to spaces below the freeboard deck; and

-

deckhouse on a deckhouse protecting an opening leading to a space

below the freeboard deck

are to be fitted with doors of steel or other equivalent material,

permanently and strongly attached to the bulkhead and framed, stiffened and fitted so

that the whole structure is of equivalent strength to the unpierced bulkhead, and

weathertight when closed. The doors are to be gasketed and secured weathertight by means

of clamping devices or equivalent arrangements, permanently attached to the bulkhead or

to the door. Doors are generally to open outwards and are to be capable of being

operated and secured from both sides. The sill heights are to be as required by Pt 3, Ch 11, 6.4 Companionways, doors and accesses on weather decks 6.4.6. See also

Pt 3, Ch 11, 7 Tanker access arrangements and closing appliances and Pt 4, Ch 9, 13 Access arrangements and closing appliances and Pt 4, Ch 11, 1 General and the Rules for Ships for Liquid Chemicals, Ship ArrangementsChapter 3 concerning access

openings in tankers, chemical tankers and ore or oil ships. Double doors are to be

equivalent in strength to the unpierced bulkhead, and in Position 1, a centre pillar is

to be provided which may be portable.

6.4.3 Elsewhere doors may be of hardwood not less than 50 mm in thickness or of

equivalent material and strength.

6.4.5 The height of doorway sills above deck sheathing of access openings in bulkheads at ends

of enclosed superstructures is to be not less than 600mm in Position 1 and not less than

380mm otherwise.

6.4.6 The height of doorway sills above deck sheathing, if fitted, is to be not

less than 600 mm in Position 1, and not less than 380 mm in Position 2.

6.4.7 Where access is provided from the deck above as an alternative to access

from the freeboard deck, the height of sill into a bridge or a poop is to be not less

than 380 mm. The same requirement applies to deckhouses on the freeboard deck. The sill

height for doorways in a forecastle, if protecting a companionway, is to be 600 mm

regardless of whether or not access is provided from above. If not protecting a

companionway, the sill height may be 380 mm.

6.4.9 Where an access opening, in the top of a deckhouse situated on a raised

quarterdeck, gives access below the freeboard deck or to an enclosed superstructure, the

closing appliances in the surrounding bulkheads are not required to be gasketed,

provided the raised quarterdeck is at least standard height, and the deckhouse is at

least standard superstructure height.

6.4.10 The height of door sills may be required to be increased on ships of Type

`A', Type `B-100' or Type `B-60' where this is shown to be necessary by the floatability

calculations required by the International Convention on Load Lines, 1966.

6.4.11 Where doors in locations above Position 2 are included in the consideration

of intact and damage stability or are in critical locations above Position 2, then the

height of door sills is to be specially considered.

6.4.12 Direct access from the freeboard deck to the machinery space through

exposed casings is not permitted on ships of Type `A', Type `B-100' or Type `B-60'. A

door complying with Pt 3, Ch 11, 6.4 Companionways, doors and accesses on weather decks 6.4.2 may, however, be fitted in an exposed machinery

casing on these ships, provided that it leads to a space or passageway which is of

equivalent strength to the casing and is separated from the machinery space by a second

weathertight door complying with Pt 3, Ch 11, 6.4 Companionways, doors and accesses on weather decks 6.4.2. The outer and inner weathertight doors are to have

sill heights of not less than 600 mm and 230 mm, respectively and the space between is

to be adequately drained by means of a screw plug or equivalent.

6.4.13 For a Type `A' ship with freeboards assigned greater than, or equal to,

Type `B', inner doors are not required for direct access to the engine-room.

6.4.14 If internal access is provided from a wheelhouse in Position 2, or below,

to spaces below the weather deck either directly or through other spaces, the opening

should be protected by a hinged weathertight cover adequately secured, fitted on a

coaming appropriate to its position, or by an equivalent arrangement, and the space

adequately drained.

6.4.15 In way of a moonpool, where a working or platform deck is provided below

the weather deck, openings in the surrounding bulkheads are to be kept to a minimum.

Access or companionway openings are to be provided with weathertight closing appliances

as for an exposed superstructure bulkhead, with 600 mm high coamings.

6.4.16 Where portable plates are required in casings for unshipping machinery, or

for other similar reasons, they may be accepted provided they are of equivalent strength

to the unpierced bulkhead and are secured by gaskets and close spaced bolts at a pitch

not exceeding five diameters.

6.4.17 The sill heights of accesses closed by covers which are secured by closely

spaced bolts or otherwise kept permanently closed at sea will be specially

considered.

6.4.18 Where permitted by the National Authority, companionway coaming heights may

be reduced on ships engaged on protected or extended protected water service. Coaming

heights are to be as high as practicable with a minimum height of 230 mm. Where the

wheelhouse is on the freeboard deck, or located in the forward quarter of the ship's

length, with internal access below, a weathertight cover, fitted to a coaming not less

than 230 mm high, is to be provided for the access. Alternatively, storm covers are to

be provided for windows in exposed positions. The wheelhouse is to be adequately

drained.

6.5 Side scuttles, windows and skylights

6.5.1 Side scuttles are defined as being round or oval openings with an area not exceeding

0,16 m2.

6.5.2 Windows are defined as being rectangular openings generally, having a radius at each

corner relative to the window size in accordance with a recognised National or

International Standard, and round or oval openings with an area exceeding 0,16

m2.

6.5.3 Deadlights are fitted to the inside of windows and side scuttles while storm covers,

of comparable specifications to deadlights, are fitted to the outside of windows,

where accessible. Deadlights can be hinged and storm covers can be hinged or

portable.

6.5.4 A plan showing the location of side scuttles and windows is to be submitted.

Attention is to be given to any relevant Statutory Requirements of the National

Authority of the country in which the ship is to be registered.

6.5.5 Side scuttles and windows together with their glasses, deadlights and

storm covers if fitted, are to be of an approved design or in accordance with a

recognised National or International Standard. The minimum design pressures to which

windows and side scuttles are to be designed are to be in accordance with Pt 3, Ch 8 Superstructures, Deckhouses and Bulwarks unless otherwise

specified by the relevant requirements of Pt 4 Ship Structures (Ship Types)

6.5.7 Side scuttles to spaces below the freeboard deck, or to spaces within the first tier

of enclosed superstructures, or to first tier deckhouses on the freeboard deck

protecting openings leading below or considered buoyant in stability calculations,

are to be fitted with efficient, hinged, inside deadlights.

6.5.8 Deadlights are to be capable of being closed and secured watertight if fitted below

the freeboard deck or weathertight if fitted above.

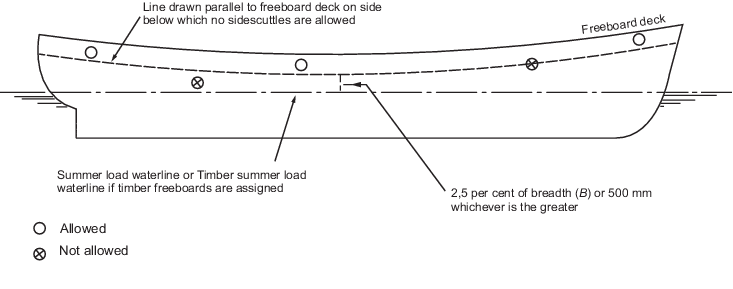

6.5.9 No side scuttle is to be fitted in such a position that its sill is

below a line drawn parallel to the freeboard deck at side and having its lowest

point 2,5 per cent of the breadth B above the load waterline corresponding to

the summer freeboard (or timber summer freeboard if assigned), or 500 mm, whichever

is the greater distance, see

Figure 11.6.1 Side Scuttle Positioning

6.5.10 If the required damage stability or floatability calculations indicate that the side

scuttles would become immersed at any intermediate stages of flooding or the final

equilibrium waterline, these are to be of the non-opening type.

6.5.11 Windows are not to be fitted below the freeboard deck, in first tier end bulkheads or

sides of enclosed superstructures, or in first tier deckhouses that are considered

buoyant in stability calculations or protecting openings leading below.

6.5.12 Where windows are fitted in a deckhouse in the first tier, they are to

be provided with strong, hinged, steel, weathertight storm covers. However, if there

is an opening leading below deck in this deckhouse, this opening is to be treated as

being on an exposed deck and is to be protected as required by Pt 3, Ch 11, 6.4 Companionways, doors and accesses on weather decks 6.4.2.

6.5.13 Where windows are permitted in an exposed bulkhead on the weather deck in the forward

0,25 of the load line length, strong external storm covers which can be portable and

stored adjacent are to be provided.

Figure 11.6.1 Side Scuttle Positioning

6.5.14 Side scuttles and windows at the side shell in the second tier protecting direct

access below or spaces considered buoyant in stability calculations are to be

provided with efficient inside deadlights capable of being effectively closed and

secured weathertight.

6.5.15 Side scuttles and windows set inboard from the side shell in the second

tier protecting direct access below to spaces listed in Pt 3, Ch 11, 6.5 Side scuttles, windows and skylights 6.5.7, are to be provided with either efficient hinged inside deadlights

or, where they are accessible, permanently attached external storm covers of

approved design and of substantial construction and capable of being effectively

closed and secured weathertight.

6.5.16 Cabin bulkheads and doors in the second tier separating side scuttles and windows

from a direct access leading below may be accepted in place of deadlights or storm

covers fitted to the side scuttles or windows.

6.5.17 Side scuttles and windows set inboard from the side shell in the second tier, not

protecting direct access below or spaces considered buoyant in the stability

calculations, do not require deadlights or storm covers.

6.5.18 If fitted in a deckhouse in the second tier located within the forward

0,25 of the load line length windows are to be provided with strong, hinged, steel,

weathertight storm covers. However, if there is an opening leading below deck in

this deckhouse, this opening is to be treated as being on an exposed deck and is to

be protected as required by Pt 3, Ch 11, 6.4 Companionways, doors and accesses on weather decks 6.4.2.

6.5.19 Where the wheelhouse is in the second tier located abaft the forward 0,25 of the load

line length, in lieu of storm covers being provided for the wheelhouse windows, a

weathertight cover, fitted to a coaming of not less than 230 mm in height around the

internal stairway opening within the wheelhouse, can be accepted. If this

arrangement is accepted, adequate means of draining the wheelhouse are to be

provided.

6.5.20 Deckhouses or superstructure situated on a raised quarter deck or on the deck of a

superstructure of less than standard height or on the deck of a deckhouse of less

than standard height can be regarded as being in the second tier as far as the

provision of deadlights is concerned, provided that the height of the raised quarter

deck, superstructure or deckhouse is equal to, or greater than, the standard quarter

deck height.

6.5.21 Where the wheelhouse is in the third tier located in the forward 0,25 of the load

line length, in lieu of storm covers being provided for the wheelhouse windows, a

weathertight cover, fitted to a coaming of not less than 230 mm in height around the

internal stairway opening within the wheelhouse, can be accepted. If this

arrangement is accepted, adequate means of draining the wheelhouse are to be

provided.

6.5.22 Windows at the side shell in the third tier are to be provided with strong portable

internal storm covers for 25 per cent of each size of window, with means of securing

being provided at each window.

6.5.23 Windows at the side shell in the fourth tier located in the forward 0,25 of the load

line length are to be provided with strong portable internal storm covers for 25 per

cent of each size of window, with means of securing being provided at each

window.

6.5.24 If necessary, for practical considerations, storm covers can be in two parts.

6.5.25 For windows in the second tier and higher above the freeboard deck, a

glazing equivalent can be fitted in lieu of deadlights/storm covers. The thicknesses

and arrangements are to be acceptable to the National Authority with whom the ship

is registered. For arrangements of glazing acceptable to LR, see

Table 11.6.1 Acceptable arrangements of glazing in lieu of portable storm

covers/deadlights. Other glazing

equivalents will be considered on a case-by-case basis.

6.5.26 Windows are not to be fitted in machinery space boundaries. However, this does not

preclude the use of glass in control rooms within the machinery space.

6.5.27 Skylights, where fitted, are to be of substantial construction and

securely attached to their coamings. The height of the lower edge of the opening is

to be as required by Pt 3, Ch 11, 5.1 General 5.1.1. The scantlings of the

coaming are to be as required by this Section or Pt 3, Ch 11, 5 Hatch coamings, as appropriate. The thickness of glasses

in fixed or opening skylights is to be appropriate to their size and position as

required for side scuttles or windows. Glasses in any position are to be protected

from mechanical damage and, where fitted in Positions 1 or 2, are to be provided

with robust deadlights or storm covers permanently attached. Cargo pump room and

machinery space skylights are not to contain glass.

6.5.28 Skylights to cargo pump rooms are to be capable of being closed from outside the pump

room.

Table 11.6.1 Acceptable arrangements of glazing in lieu of portable storm

covers/deadlights

6.5.29 Laminated toughened safety glass may also be used for windows but the total thickness

will need to be greater than that required for the equivalent sized window using

toughened safety glass. The equivalent thickness of laminated toughened safety glass

is to be determined from the following formula:

|

n |

= |

number of laminates |

|

TLi |

= |

thickness of glass laminate |

|

Ts |

= |

thickness of toughened safety glass |

Alternative arrangements that do not meet the above thickness requirement will be

specially considered, provided that equivalent strength and bending stiffness to

that of a single, thermally toughened pane of thickness, Ts, can

be demonstrated in a four-point bending test as described in EN-ISO 1288-3 or an

equivalent recognised National or International Standard, using not less than ten

samples. The lower limit of the 90 per cent confidence level interval for the

laminated pane shall not be less than the same for monolithic toughened safety

glass. Small scale punch test or ring-in-ring test methods shall not be used.

6.5.30 Non-metallic frames are not acceptable for windows in the first and second tiers, and

are not generally acceptable in any other position in external casings. Any

proposals to fit non-metallic frames are to be submitted for consideration, and are

to be acceptable to the Administration. The proposed locations, frame dimensions,

glass thicknesses and the results of any tests carried out, are to be forwarded.

6.6 Small hatchways on exposed fore decks

6.6.2 The

number and size of hatchways and other access openings are to be kept

to the minimum consistent with the satisfactory operation of the ship.

6.6.3 The

height of coamings is to be in accordance with Pt 3, Ch 11, 5.1 General 5.1.1. Lower heights may be considered

in relation to operational requirements and the nature of the spaces

to which access is given.

6.6.4 Rope

hatches may be accepted with reduced coamings, but generally not less

than 380 mm, provided they are well secured and closed before the

ship leaves port. A suitable notice is to be displayed at the hatch

stating that it is to be closed whilst the ship is at sea.

6.6.5 Where

permitted by the National Authority, access hatch coaming heights

may be reduced on ships engaged on protected or extended protected

water service. Coaming heights are to be as high as practicable with

a minimum height of 230 mm.

6.6.6 The

thickness of the coamings is to be not less than the Rule minimum

thickness for the deck inside line of openings for that position,

or 11 mm, whichever is the lesser.

6.6.7 The

upper edge of the hatchway coamings is to be suitably reinforced by

a horizontal section, normally not more than 170 to 190 mm from the

upper edge of the coamings.

6.6.8 Hatches

are to be fitted with primary securing devices such that their hatch

covers can be secured in place and weather-tight by means of a mechanism

employing any one of the following methods:

-

Butterfly nuts

tightening onto forks (clamps),

-

Quick acting

cleats, or

-

Central locking

device.

Emergency escape hatches are excluded from options (a) and (b).

6.6.9 Dogs

(twist tightening handles) with wedges are not acceptable as primary

securing devices.

6.6.10 Escape

hatches are to be capable of being opened from either side and are

to have a quick-acting type securing device, e.g. one action wheel

handle central locking device for latching/unlatching the hatch cover.

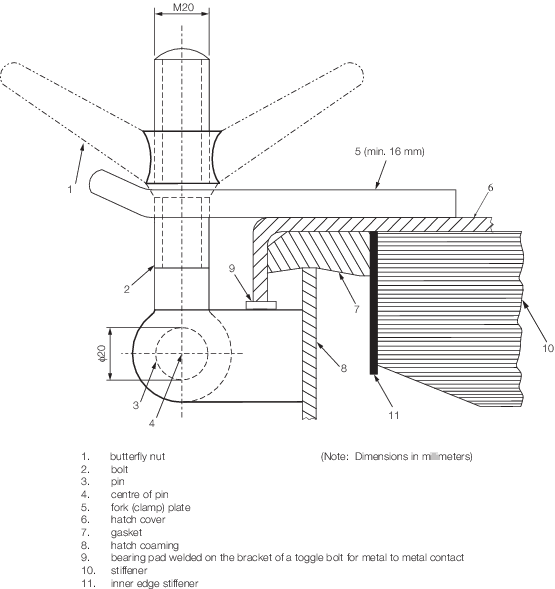

6.6.11 For

a primary securing method using butterfly nuts, the forks (clamps)

are to be of robust design. They are to be designed to minimise the

risk of butterfly nuts being dislodged while in use; by means of curving

the forks upward, a raised surface on the free end, or a similar method.

The plate thickness of unstiffened steel forks is not to be less than

16 mm. An example arrangement is shown in Figure 11.6.3 Example of a primary securing method.

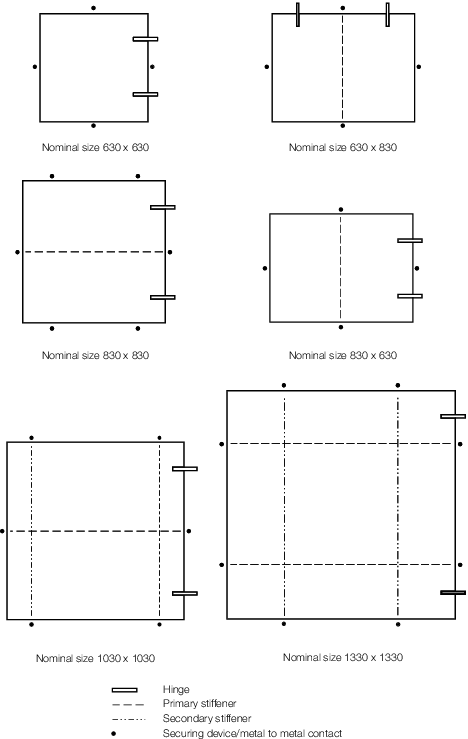

Figure 11.6.2 Arrangement of stiffeners

Figure 11.6.3 Example of a primary securing method

6.6.12 The

hatch cover is to be fitted with a gasket of elastic material. This

is to be designed to allow a metal to metal contact at a designed

compression and to prevent over compression of the gasket by green

sea forces that may cause the securing devices to be loosened or dislodged.

The metal-to-metal contacts are to be arranged close to each securing

device in accordance with Figure 11.6.2 Arrangement of stiffeners,

and of sufficient capacity to withstand the bearing force.

6.6.13 The

primary securing method is to be designed and manufactured such that

the designed compression pressure can be achieved by one person without

the need of any tools.

6.6.14 For

small rectangular steel hatch covers, the plate thickness, stiffener

arrangement and scantlings are to be in accordance with Table 11.6.2 Scantlings for small steel hatch

covers on exposed deck and Figure 11.6.2 Arrangement of stiffeners. Stiffeners, where

fitted, are to be aligned with the metal-to-metal contact points required

in Pt 3, Ch 11, 6.6 Small hatchways on exposed fore decks 6.6.11, see

Figure 11.6.2 Arrangement of stiffeners. Primary stiffeners

are to be continuous. All stiffeners are to be welded to the inner

edge stiffener, see

Figure 11.6.3 Example of a primary securing method.

Table 11.6.2 Scantlings for small steel hatch

covers on exposed deck

| nominal

|

cover

|

primary

|

secondary

|

| size

|

plate

|

stiffeners

|

stiffeners

|

| (mm x mm)

|

thickness

|

Flat bar (mm x mm);

|

|

|

(mm)

|

number

|

| 630 x 630

|

8

|

|

|

| 630 x 830

|

8

|

100 x 8,1

|

|

| 830 x 630

|

8

|

100 x 8,1

|

|

| 830 x 830

|

8

|

100 x 10,1

|

|

| 1030 x 1030

|

8

|

120 x 12,1

|

80 x 8,2

|

| 1330 x 1330

|

8

|

150 x 12,2

|

100 x 10,2

|

6.6.15 For

hatch covers constructed of materials other than steel, the required

scantlings are to provide equivalent strength.

6.6.16 For

small hatch covers of circular or similar shape, the cover plate thickness

and reinforcement are to be of equivalent strength to that of the

small rectangular steel hatch covers described in Pt 3, Ch 11, 2.2 Stiffener arrangement 2.2.1.

6.6.17 For

hatch covers located on the deck forward of the fore-most cargo hatch,

the hinges are to be fitted such that the predominant direction of

green sea will cause the cover to close. The hinges are normally to

be located on the fore edge.

6.6.18 On

small hatches located between the main hatches, for example between

Numbers 1 and 2, the hinges are to be placed on the fore edge or outboard

edge, whichever is practicable for protection from green water in

beam sea and bow quartering conditions.

6.6.19 Hatches,

excluding emergency escape hatches, are to be fitted with an independent

secondary securing device, e.g. by means of a sliding bolt, a hasp

or a backing bar of slack fit, which is capable of keeping the hatch

cover in place, even in the event that the primary securing device

became loosened or dislodged. It is to be fitted on the side opposite

to the hatch cover hinges.

6.6.20 Small

hatches, including escape hatches, are to be situated clear of cargo

containment areas, particularly in the case of offshore supply ships.

6.6.21 Where

portable plates are required in decks for unshipping machinery, or

for other similar reasons, they may be accepted provided they are

of equivalent strength to the unpierced deck and are secured by gaskets

and closely spaced bolts at a pitch not exceeding five diameters.

|