Section

5 Hatch coamings

5.1 General

5.1.1 The height of coamings above the upper surface of the deck, measured above

sheathing if fitted, for hatchways closed by portable covers secured weathertight by

tarpaulins and battening devices, is to be not less than:

- 600 mm at Position 1,

- 450 mm at Position 2.

5.1.2 Where hatches in locations above Position 2 are included in the consideration of intact

and damage stability or are in critical locations above Position 2, then the height of

hatch coamings is to be specially considered.

5.1.3 The height of coamings of hatchways situated in Positions 1 and 2 closed by

steel covers fitted with gaskets and clamping devices are to be as specified in Pt 3, Ch 11, 5.1 General 5.1.1, but may be reduced, or the coamings may be omitted

entirely, if the safety of the ship is not thereby impaired in any sea condition.

Special attention will be given in such cases to the scantlings of the covers, to their

gasketing and securing arrangements and to the drainage of recesses in the deck. The

agreement of the National Authority concerned will also be required.

5.1.4 The height of coamings may be required to be increased on ships of Type

`B-100' or Type `B-60' where this is shown to be necessary by the floatability

calculations required by the International Convention on Load Lines, 1966.

5.2 Construction

5.2.1 Vertical

cargo hatch coamings 600 mm or more in height are to be stiffened

on their upper edges by a horizontal bulb flat or equivalent which

is to be not less than 180 mm in width for ships where L is

greater than 75 m. Additional support is to be afforded by fitting

brackets or stays from the bulb flat to the deck at intervals of not

more than 3 m. Each bracket or stay is to be aligned with suitable

underdeck stiffeners and is to have a softened nose.

5.2.2 Vertical coamings less than 600 mm in height are to be stiffened at their

upper edge by a substantial rolled or fabricated section. Additional support is to be

arranged as required by Pt 3, Ch 11, 5.2 Construction 5.2.1.

5.2.4 The

scantlings and arrangements of hatch coamings acting as girders will

be specially considered. The coamings are to be arranged with intermediate

continuous horizontal stiffeners supported by the bracket stays.

5.2.5 Sloped

cargo hatch coamings will be specially considered. In general, the

sloped coaming arrangement is to be restricted to the hatch side coamings

with vertical coamings at the ends. The sloped coaming is not to have

a knuckle and the angle to the vertical is not to exceed 30°.

The scantlings are to be in accordance with Pt 3, Ch 11, 5.2 Construction 5.2.1, Pt 3, Ch 11, 5.2 Construction 5.2.2 and Pt 3, Ch 11, 5.3 Strength criteria, except that the end coamings

are to be increased by 20 per cent for a distance of 0,15b from

the side coamings where b is the width of the hatchway

at the deck. Particular care is to be taken where the proposed loadings

exceed those given in Pt 3, Ch 11, 2.3 Load model and Pt 3, Ch 3, 5 Design loading, and where the coamings are not

in alignment with the topside tank vertical strake in bulk carriers.

5.2.6 A radiused

coaming plate at the corner junction of the longitudinal and transverse

cargo hatch coamings is acceptable for ships where L ≤

90 m and the heights of coamings are not in excess of that specified

in Pt 3, Ch 11, 5.1 General 5.1.1. Where L >

90 m the corner junctions are to be rectangular and arranged with

continuation brackets as required by Pt 3, Ch 11, 5.2 Construction 5.2.8.

5.2.7 The

deck plating is to extend inside the coamings and the side coamings

are to be extended in the form of tapered brackets. A recommended

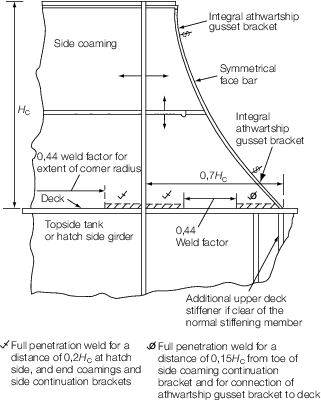

arrangement is shown in Figure 11.5.1 Coaming continuation bracket - Recommended arrangement.

Continuation brackets are also to be arranged athwartships in line

with the hatch end coamings and the under deck transverse. In bulk

carriers the athwartship brackets, in conjunction with the hatch end

beams should be arranged to achieve a satisfactory overlap with the

top side tank transverses. In cases where the hatch end beam is formed

by the transverse bulkhead top stool the horizontal knuckle of the

stool should be arranged well clear of the topside tank knuckle line.

Figure 11.5.1 Coaming continuation bracket - Recommended arrangement

5.2.8 In

bulk carriers where the hatch side coaming does not align with the

topside tank vertical strake the arrangement and scantlings will be

specially considered. In general, suitable underdeck girders and cantilever

brackets are to be arranged taking into consideration the hatch cover

loading. The underdeck girders are to continue beyond the hatch end

for a distance of 2H

c mm. Alternative arrangements

incorporating bulkhead top stool structure or cross-deck structure

will be considered.

5.2.9 Extension

brackets or rails arranged approximately in line with the cargo hatch

side coamings and intended for the stowage of steel covers are not

to be welded to a deckhouse, masthouse or to each other unless they

form part of the longitudinal strength members.

5.2.11 Where

containers are carried on multi-panel hatch covers, the hatch coaming

in way of the loaded panel will be required to be reinforced to resist

the lateral loads imposed on the coaming due to rolling of the ship.

Thrust blocks are to be fitted on the coaming rest bar to prevent

the covers from moving. Where one-piece hatch covers are fitted with

locating devices, the coamings are to be reinforced in way of the

locators.

5.2.12 Cut

outs in the top of hatch coamings are to be avoided. Where these are

necessary for the securing devices they are to be circular or elliptical

in shape. Also any local reinforcements should be given a tapered

transition in the longitudinal direction with a taper the rate of

which should not exceed 1 in 3. Cut-outs and drain holes are to be

avoided in the hatch side coaming continuation brackets. Where these

are necessary the size, shape and position will be specially considered.

5.2.13 Material

for hatch coamings is to be steel, according to the requirements for

ship’s hull. Alternative materials will be subject to special

consideration.

5.2.14 Secondary

stiffeners of hatch coamings are to be continuous over the breadth

and length of hatch coamings.

5.2.15 Longitudinal

hatch coamings with a length exceeding 0,1L m are to

be provided with tapered brackets or equivalent transitions and a

corresponding substructure at both ends. At the end of the brackets

they are to be connected to the deck by full penetration welds of

minimum 300 mm in length.

5.2.16 Hatch

coamings and supporting structures are to be adequately stiffened

to accommodate the loading from hatch covers, in longitudinal, transverse

and vertical directions. Structures under deck are to be checked against

the load transmitted by coaming stays.

5.2.17 On

ships carrying cargo on deck, such as timber, coal or coke, coaming

stays are to be spaced not more than 1,5 m apart.

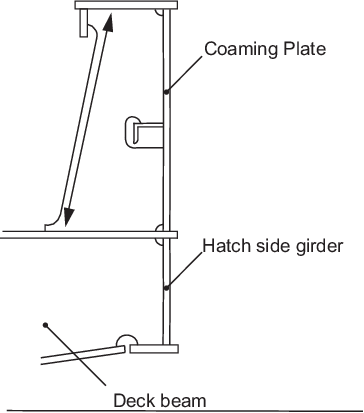

5.2.18 Coaming plates are to extend to the lower edge of the deck beams; they or

hatch side girders are to be fitted that extend to the lower edge of the deck beams.

Extended coaming plates and hatch side girders are to be flanged or fitted with face

bars or half-round bars. Figure 11.5.2 Example of hatch side

girder and Figure 11.5.3 Example of coaming stays give examples.

Figure 11.5.2 Example of hatch side

girder

5.3 Strength criteria

5.3.1 The

strength requirements in this Section are applicable to hatch coamings

of stiffened plate construction.

5.3.2 The

local net plate thickness of weather deck hatch coamings is not to

be less than the larger of the following values:

|

|

= |

where |

|

s

|

= |

stiffener

spacing, in mm |

|

L

1

|

= |

L need not be taken greater than 300 metres

|

|

pA

|

= |

pressure, in kN/m2, as defined in Pt 3, Ch 11, 2.3 Load model 2.3.3

|

|

|

= |

Longitudinal strength aspects are to be observed. |

5.3.3 Secondary

stiffeners of coamings must be continuous at the coaming stays. For

stiffeners with both ends constrained, the elastic net section modulus Z in cm3 and net shear area A

S in

cm2, calculated on the basis of net thickness, are not

to be less than:

|

|

= |

where |

|

l |

= |

secondary

stiffener span, in metres, to be taken as the spacing of coaming stays |

|

s

|

= |

stiffener

spacing in mm |

|

pA

|

= |

pressure, in kN/m2, as defined in Pt 3, Ch 11, 2.3 Load model 2.3.3.

|

5.3.4 For

sniped stiffeners at coaming corners, section modulus and shear area

at the fixed support are to be increased by 35 per cent. The gross

thickness of the coaming plate at the sniped stiffener end is not

to be less than:

5.3.6 At the connection with deck, the net

section modulus Z, in cm3, and the gross thickness

tw, in mm, of the coaming stays designed as beams with flange

(examples 1 and 2 are shown in Figure 11.5.3 Example of coaming stays) are to be taken not less

than:

and

where

|

e

|

= |

spacing of coaming stays, in metres |

|

hs |

= |

height of coaming stays, in metres |

|

hw |

= |

web height of coaming stay at its lower end, in metres |

|

tc |

= |

corrosion addition, in mm, according to Table 11.1.2 Corrosion addition t

c

|

|

p

A

|

= |

pressure, in kN/m2, as defined in Pt 3, Ch 11, 2.3 Load model 2.3.3. |

|

σo |

= |

minimum yield stress, in N/mm2. |

5.3.8 Coaming

stays are to be supported by appropriate substructures. Face-plates

may be included in the calculation only if an appropriate substructure

is provided and welding ensures an adequate joint.

5.3.9 Webs

of coaming stays are to be connected to the deck by fillet welds on

both sides with a throat thickness of a = 0,44t

w.

5.3.11 Hatch

coamings which are part of the longitudinal hull structure are to

be designed according to the requirements for longitudinal strength

in Pt 3, Ch 4 Longitudinal Strength.

5.3.12 For

structural members welded to coamings and for cut-outs in the top

of coamings, sufficient fatigue strength is to be verified.

5.4 Rest bars in hatchways

5.4.1 Rest

bars are to provide at least 65 mm bearing surface and are to be aligned

if required to suit the slope of the hatches.

5.5 Loading in excess of Rule requirements

|