Section

2 Longitudinal strength

2.1 General

2.1.1 Longitudinal strength calculations are to be made in accordance with the

requirements given in Pt 3, Ch 4 Longitudinal Strength and the additional notes contained in this Section.

2.1.4 For ships where the side shell or side casings contain large openings or

where the effectiveness of the superstructures in resisting hull girder bending loads is

expected to be reduced by the presence of large numbers of windows or openings, the

combined hull and superstructure response may require to be verified using direct

calculation techniques.

2.1.5 The requirements of Pt 3, Ch 4, 8.3 Loading instrument regarding

loading instruments are not applicable to passenger ferries, roll on-roll off passenger

ferries and passenger vehicle ferries without a ShipRight SDA notation.

2.2 Calculation of hull section modulus

2.2.1 The

calculation of section modulus is to be in accordance with Pt 3, Ch 3, 3.4 Calculation of hull section modulus and the additional

notes in this Section. In general, the effective sectional area of

continuous longitudinal strength members, after deduction of openings,

is to be used for the calculation of midship section modulus. For

ships where the effectiveness of the superstructure is only partial

due to the presence of large or numerous shell openings or discontinuities

in the shell envelope, an equivalent section modulus for the purposes

of this Section may be derived using direct calculations in accordance

with the SDA procedure relevant to the ship type.

2.2.2 Structural

members which contribute to the overall hull girder strength are to

be carefully aligned so as to avoid discontinuities resulting in abrupt

variations of stresses and are to be kept clear of any form of openings

which may affect their structural performances.

2.2.3 In general,

short superstructures, see also

Pt 3, Ch 3, 3.4 Calculation of hull section modulus 3.4.2, or deckhouses

will not be accepted as contributing to the global longitudinal or

transverse strength of the ship. However, where it is proposed to

include substantial continuous stiffening members, special consideration

will be given to their inclusion on submission of the designer's/

Builder's calculations, see also

Pt 4, Ch 2, 2.6 Buckling strength.

2.2.4 Adequate

transition arrangements are to be fitted at the ends of effective

continuous longitudinal strength members in the deck and bottom structures.

2.2.5 Scantlings

of all continuous longitudinal members of the hull girder based on

the minimum section stiffness requirements determined from Pt 4, Ch 4, 5 Lifting appliances, equipment integration and foundations are to be maintained within 0,4L amidships. However, in special cases, based on consideration

of type of ship, hull form and loading conditions, the scantlings

may be gradually reduced towards the ends of the 0,4L part,

bearing in mind the desire not to inhibit the ship's loading and operational

flexibility.

2.2.6 Structural

material which is longitudinally continuous but which is not considered

to be fully effective for longitudinal strength purposes may be specially

considered. The global longitudinal strength assessment must take

into account the presence of such material when it can be considered

effective. The consequences of failure of such structural material

and subsequent redistribution of stresses into or additional loads

imposed on the remaining structure is to be considered.

2.2.7 In particular,

all longitudinally continuous material will be fully effective in

tension whereas this may not be so in compression due to a low buckling

capability. In this case, it may be necessary to derive and apply

different hull girder section moduli to the hogging and sagging bending

moment cases.

2.3 Still water bending moments and shear forces

2.3.1 The

design still water hogging and sagging bending moment distribution

envelope, M

S, is to be taken as the maximum

sagging (negative) and maximum hogging (positive) still water bending

moments, calculated at each position along the ship. The maximum moments

from all loading conditions are to be used to define the still water

bending moment distribution envelope.

2.3.2 It is

normal for ships which have a low deadweight requirement or a uniform

loading rate in association with a low block coefficient to have a

hogging still water bending moment in all conditions of loading. For

these ships, the maximum design sagging still water bending moment

may be taken as the minimum actual hogging bending moment.

2.3.3 The

design still water shear force distribution envelope, Q

S, is to be taken as the maximum positive and negative shear

force values, calculated at each position along the ship. The maximum

shear forces from all loading conditions are to be used to define

the still water shear force distribution envelope.

2.4 Design vertical wave bending moments

2.4.1 The minimum value of vertical wave bending moment, Mw at

any position along the ship may be taken as follows:

where

|

Mwo

|

= |

0,1C1

L2

BWL (Cb + 0,7) kNm |

|

BWL

|

= |

maximum waterline breadth, in metres |

|

|

= |

C1, C2, L and Cb are

given in Pt 3, Ch 4, 5 Hull bending strength

|

|

|

= |

and |

|

f1

|

= |

is given

in Pt 3, Ch 4, 5 Hull bending strength

|

|

f2

|

= |

is the

hogging, f

fH, or sagging, f

fS,

correction factor based on the amount of bow flare, stern flare, length

and effective buoyancy of the aft end of the ship above the waterline

|

|

ffS

|

= |

is the

sagging (negative) moment correction factor and is to be taken as |

|

ffS

|

= |

– 1,10RA

0,3 for values of RA > 1,0 |

|

ffS

|

= |

– 1,10 for values of RA ≤ 1,0 |

|

ffH

|

= |

is the

hogging (positive) moment correction factor and is to be taken as |

|

ffH

|

= |

|

|

RA |

= |

is an area ratio factor, see

Pt 4, Ch 2, 2.4 Design vertical wave bending moments 2.4.2. |

2.4.2 The area ratio factor, RA, for the combined stern and bow

shape is to be derived as follows:

where

|

ABF

|

= |

is the

bow flare area, in m2

|

|

ASF

|

= |

is the

stern flare area, in m2

|

2.4.3 The bow flare area, ABF, is illustrated in Pt 4, Ch 2, 2.4 Design vertical wave bending moments 2.4.3 and may be derived as

follows:

where

|

AUB

|

= |

is half

the water plane area at a waterline of T

C,U of

the bow region of the hull forward of 0,8L from the AP

|

|

ALB

|

= |

is half

the water plane area at the design draught of the bow region of the

hull forward of 0,8L from the AP

|

|

|

= |

Note the AP is to be taken at the aft end of L

|

|

|

= |

The design draught is to be taken as T, see

Pt 3, Ch 1, 6.1 Principal particulars. |

| = |

|

Alternatively the following formula may be used:

where

|

b0

|

= |

projection of T

C,U waterline outboard of the design draught waterline at the FP, in

metres, see

Pt 4, Ch 2, 2.4 Design vertical wave bending moments 2.4.3

|

|

b1

|

= |

projection of T

C,U waterline outboard

of the design draught waterline at 0,9L from the AP,

in metres

|

|

b2

|

= |

projection of T

C,U waterline outboard

of the design draught waterline at 0,8L from the AP,

in metres

|

|

a

|

= |

projection

of T

C,U waterline forward of the FP, in metres

|

|

TC,U

|

= |

is a

waterline taken C

1/2 m above the design draught

|

|

TC,U

|

= |

|

|

C1

|

= |

is given

in Pt 3, Ch 4 Longitudinal Strength

Table 4.5.1 Wave bending moment factor

|

|

|

= |

For ships with large bow flare angles above the

TC,U waterline the bow flare area may need to be specially

considered. |

Figure 2.2.1 Derivation of bow and stern flare areas

2.4.4 The stern flare area, ASF, is illustrated in Pt 4, Ch 2, 2.4 Design vertical wave bending moments 2.4.3 and is to be derived as

follows:

where

|

AUS

|

= |

is half the water plane area at a waterline of

TC,U the stern region of the hull aft of 0,2L from the

AP |

|

ALS

|

= |

is half the water plane area at a waterline of

TC,L the stern region of the hull aft of 0,2L from the

AP |

|

TC,L

|

= |

is a waterline taken C 1/2 m below the design draught |

|

TC,L

|

= |

|

Where half the water plane area AUS is less than any half

water plane area below the waterline TC,Ufor the longitudinal extents

illustrated in Figure 2.2.1 Derivation of bow and stern flare areas, for example, in the case of ships with tumblehome in the stern region,

the maximum half waterplane area for similar longitudinal extents at any waterline less

than TC,U is to be considered as AUS.

The effects of appendages including bossings are to be ignored in the calculation of

ALS.

Alternately, the impact of stern flare on the design vertical wave bending

moment may be specially considered, see

Pt 4, Ch 2, 2.4 Design vertical wave bending moments 2.4.6.

2.4.6 The sagging correction factor, ffS, in the vertical wave

bending moment formulation in Pt 4, Ch 2, 2.3 Still water bending moments and shear forces 2.3.1 may be derived by direct calculation methods.

Appropriate direct calculation methods include a combination of long-term ship motion

analysis, non linear ship motion analysis and static balance on a wave crest or trough.

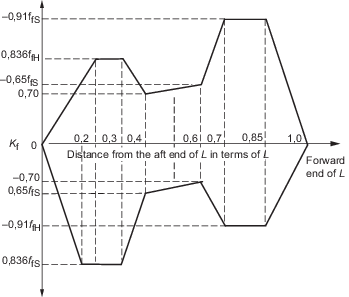

2.5 Design wave shear force

2.5.1 The design vertical wave shear force, Q

w, at any position along the ship is given by:

where

Qwo and K2 are given in Pt 3, Ch 4, 6.3 Design wave shear force

Kf is to be taken as follows, see also

Figure 2.2.2 Shear force factor

Kf

:

-

Positive shear force:

|

Kf

|

= |

0 at aft end of L

|

| = |

+0,836f

fH between 0,2L and 0,3L from aft |

| = |

+0,70 at 0,4L |

| = |

–0,65ffS at 0,6L |

| = |

–0,91ffS between 0,7L and

0,85L from aft |

| = |

0 at forward end of L

|

-

Negative shear force:

|

K

f

|

= |

0 at aft end of L

|

| = |

+0,836ffS between 0,15L and

0,3L from aft |

| = |

+0,65ffS at 0,4L |

| = |

-0,70 at 0,6L |

| = |

–0,91ffH between 0,7L and

0,85L from aft |

| = |

0 at forward end of L

|

Intermediate values of Kf to be obtained by linear

interpolation.

ffS and ffH are defined in Pt 4, Ch 2, 2.4 Design vertical wave bending moments 2.4.1.

Figure 2.2.2 Shear force factor

Kf

2.6 Buckling strength

2.6.4 The

shear buckling requirements of Pt 3, Ch 4, 7.3 Elastic critical buckling stress are to be applied.

Table 2.2.1 Buckling factors of safety,

λ

| Structural item

|

Buckling

factor

of safety, λ

|

| Longitudinally effective plating

|

1,0

|

| Longitudinal stiffeners

when the

buckling failure mode of the attached plating is elasto-plastic,

see Note

|

1,1

|

| Longitudinal stiffeners

when the

buckling failure mode of the attached plating is elastic, see Note

|

1,25

|

Note The buckling mode of failure of the attached plating is

defined as follows:

|

|

|

elastic

|

σE ≤ 0,5 σo

|

|

|

elasto-plastic

|

σE > 0,5 σo

|

where

Note

|

σo

|

= |

specified minimum yield stress, in

N/mm2. |

|

|