Section

1 General

1.1 General

1.1.1 This

Chapter applies primarily to the arrangements and scantlings within

the cargo tank region of sea-going tankers having integral cargo tanks,

for the carriage of oil having a flash point not exceeding 60°C

(closed-cup test), in association with the class notation indicated

in Pt 4, Ch 9, 1.3 Class notation and applicable Rules for CSR Double Hull Oil Tankers 1.3.1 or Pt 4, Ch 9, 1.4 Class notation and applicable Rules for non-CSR Double Hull Oil Tankers 1.4.1. Except as indicated in Pt 4, Ch 9, 1.1 General 1.1.2, Pt 4, Ch 9, 1.1 General 1.1.3 and Pt 4, Ch 9, 1.1 General 1.1.4, the

cargo spaces are to be bounded by side and bottom dedicated water

ballast tanks or void spaces constituting a double hull for the ship, see

Table 9.1.1 Cargo tank boundary

requirements.

1.1.5 Where

only oils having flash points exceeding 60ºC are to be carried,

the Rule requirements and class notation will be modified accordingly

the additional class notation ‘F.P. exceeding 60ºC’

will be entered in the Register Book.

1.1.7 The scantlings and arrangements of tankers intended for cargoes other than

oil will be specially considered in relation to the characteristics of the cargo, and

the class notation will be modified accordingly. A full list of such cargoes for a

particular ship, with special requirements as applicable, can be provided by Lloyd’s

Register (hereinafter referred to as ‘LR’) on application. Chemical cargoes listed in

Chapter 18 of the Rules and Regulations for the Construction and Classification of

Ships for the Carriage of Liquid Chemicals in Bulk (hereinafter refered to as the

Rules for Ships of Liquid Chemicals) may be carried in ships for which the arrangements,

scantlings and materials comply with the requirements of that Chapter. Special

consideration will also be given to the carriage of cargoes with a relative density

greater than 1,025, see also

Pt 4, Ch 9, 1.3 Class notation and applicable Rules for CSR Double Hull Oil Tankers and

Pt 4, Ch 9, 1.4 Class notation and applicable Rules for non-CSR Double Hull Oil Tankers.

1.1.8 The Regulations for classification and assignment of the above notations

and other notations, as appropriate to the arrangements, scantlings and service are

provided for in Pt 1, Ch 2, 2 Character of classification and class notations.

Table 9.1.1 Cargo tank boundary

requirements

| Deadweight (DWT) tonnes

|

Minimum

double side width (ds

) metres

|

Minimum

double bottom depth (db

) metres

|

| DWT ≥ 5000

|

ds

= 0,5 +

|

db

=

|

| or

|

or

|

|

ds

= 2,0

|

db

= 2,0

|

| whichever

is the lesser, but not less than 1,0

|

whichever

is the lesser, but not less than 1,0

|

|

|

ds

= 0,4 +

|

db

=

|

| 600 ≤ DWT < 5000

|

or

|

or

|

|

|

ds

= 0,76

|

db

= 0,76

|

|

|

whichever is the greater, see Note 2

|

whichever

is the greater,

|

| DWT < 600

|

ds

= 0

|

db

= 0

|

Note

1. The symbols DWT, ds

and db

are defined in 1.5.

|

Table 9.1.2 Oil cargoes suitable for carriage

in oil tankers, see Note 1

|

Asphalt solutions (see Note 2)

|

Gasoline Blending Stocks

|

| Blending Stocks

|

Alkylates – fuel

|

| Roofers Flux

|

Reformates

|

| Straight Run Residue

|

Polymer – fuel

|

|

|

|

|

Oils

|

Gasolines

|

| Clarified

|

Casinghead (natural)

|

| Crude Oil

|

Automotive

|

| Mixtures containing crude oil

|

Aviation

Straight Run

|

| Diesel Oil

|

Fuel Oil No. 1 (Kerosene)

|

| Fuel Oil No. 4

|

Fuel Oil No. 1-D

|

| Fuel Oil No. 5

|

Fuel Oil No. 2

|

| Fuel Oil No. 6

|

Fuel Oil No. 2-D

|

| Residual Fuel Oil

|

|

| Road Oil

|

Jet Fuels

|

| Transformer Oil

|

JP-1 (Kerosene)

|

| Lubricating Oils and Blending

Stocks

|

JP-3

JP-4

|

| Mineral Oil

|

JP-5 (Kerosene, Heavy)

|

| Motor Oil

|

Turbo Fuel

|

| Penetrating Oil

|

Kerosene

|

| Spindle Oil

|

Mineral Spirit

|

| Turbine Oil

|

|

|

|

Naphtha (see Note 3)

|

|

Distillates

|

Solvent

|

| Straight Run

|

Petroleum

|

| Flashed Feed Stocks

|

Heartcut Distillate Oil

|

|

|

|

|

Gas Oil

|

|

| Cracked

|

|

Note

1. This list of oils is taken from

Appendix 1 to Annex 1 of the MARPOL Convention. Special consideration

will be given to the carriage of oil cargoes not included in the above

list.

Note

2. Asphalt solutions, see Chapter

18 of the Rules for Ships for Liquid Chemicals.

Note

3. For naphtha coal tar and naphthalene

molten, see Chapter 17 of the Rules for Ships for Liquid

Chemicals.

|

1.2 Application and ship arrangement

1.2.2 The

applicable Rules for double hull tankers with length, L,

greater than or equal to 150 m of unusual hull form or structural

arrangements will be specially considered.

1.2.4 Any

dry tanks, or tanks intended for water ballast and thus empty in the

loaded condition, are to be so arranged that they cannot be used for

any other purpose.

1.2.5 Cofferdams

are to be provided at the forward and after ends of the oil cargo

spaces; cofferdams are to be at least 760 mm in length and are to

cover the whole area of the end bulkheads of the cargo spaces.

1.2.7 Where

the lower portion of the pump-room is recessed into the machinery

space, the height of the recess is not, in general, to exceed one-third

of the moulded depth above the keel, see also

Pt 5, Ch 15, 1 General requirements.

1.2.9 A cofferdam

is also to be arranged between a cargo oil tank and accommodation

spaces, and between cargo oil tanks and spaces containing electrical

equipment, other than spaces where the only items of electrical equipment

are lighting fittings complying with Pt 6, Ch 2, 14 Electrical equipment for use in explosive gas atmospheres or in the presence of combustible dusts. Where a corner to corner situation occurs, protection

may be formed by a diagonal plate across the corner. The scantlings

and testing arrangements are to comply with Rule requirements for

cofferdam bulkheads, and arrangements are to be made to enable the

space to be filled with water ballast to assist in gas freeing, see

also

Pt 5, Ch 15, 3 Cargo handling system. Suitable

corrosion protection, drainage and gas-freeing arrangements are to

be provided to such spaces.

1.2.10 Passages

or tunnels passing through, or adjacent to, a cargo oil tank and not

separated from it by a cofferdam, are to be provided with mechanical

ventilation, and any access is to be from the open deck.

1.2.11 Arrangements

are to be provided to enable double bottom and vertical wing tanks

to be filled with water ballast to assist in gas freeing these tanks, see

Pt 5, Ch 15, 3 Cargo handling system.

1.2.12 Fittings

within cargo tanks and pump-rooms are to be securely fastened to the

structure.

1.2.13 Accommodation,

control and service spaces are to be located clear of the cargo tank

region such that a single failure of deck or bulkhead will not allow

cargo fumes into these spaces. Navigation positions, where fitted

above the cargo tank region, are to be separated from the cargo tank

deck by means of an open space with a height of at least 2,0 m.

1.2.15 Alternative

arrangements which are proposed as being equivalent to the Rules will

receive individual consideration, taking into account any relevant

National Authority requirements.

1.2.16 Reference

should also be made to the relevant Regulations of the International

Convention for the Safety of Life at Sea, 1974 and applicable

amendments.

1.2.18 Where DWT ≥ 5000 tonnes, double bottom tanks as required by Pt 4, Ch 9, 1.2 Application and ship arrangement 1.2.17 may be dispensed with, provided

the following requirements are complied with:

-

The cargo height, hc

, in contact with the bottom shell plating is

to be not greater than:

where the symbols are defined in Pt 4, Ch 9, 1.6 Information required for CSR Double Hull Oil Tankers.

-

Where a mid-deck

dividing the cargo oil tanks into upper and lower spaces is arranged,

it is to be located at a height of not less than the lesser of  or 6 m, but or 6 m, but

not more than 0,6D, above the base line.

-

Below a level

1,5db

above the base line, the cargo tank

boundary line may be vertical down to the bottom shell plating as

shown in Figure 9.1.3 Cargo tank boundary lines for oil tankers having mid-deck

arrangement (See

Pt 4, Ch 9, 1.2 Application and ship arrangement 1.2.18

)

.

1.2.21 Where

DWT ≥ 5000 tonnes, the cargo pump-room shall be provided with a

double bottom such that at any cross-section the depth of each double

bottom tank or space shall be such that the distance d

c, as defined in 1.5, is not

less than the lesser of  and 2 m and 2 m

dc is in no case to be

less than 1 m.

In the case of cargo pump-rooms whose bottom

plate is located above the base line by at least the minimum height

required, there will be no need for a double bottom construction in

way of the cargo pump-room.

1.2.22 Notwithstanding

the requirements of Pt 4, Ch 9, 1.2 Application and ship arrangement 1.2.21,

above, where the flooding of the cargo pump-room would not render

the ballast or cargo pumping system inoperative, a double bottom need

not be fitted.

| Number of longitudinal bulkheads inside cargo tanks

|

One

(on centreline)

|

Two

|

Three

(one on centreline)

|

Where no

longitudinal bulkhead is arranged or where longitudinal bulkheads are

perforated across breadth of cargo tanks

|

| Length of wing cargo tank

|

|

0,2LL

|

0,2LL

|

|

| Length

of centre tank

|

bi

≥ 0,2B

|

—

|

0,2LL

|

0,2LL

port and starboard

|

or

|

|

|

bi

≥ 0,2B

|

—

|

|

port and starboard

|

0,2LL

whichever is the lesser

|

|

|

1.3 Class notation and applicable Rules for CSR Double Hull Oil Tankers

1.4 Class notation and applicable Rules for non-CSR Double Hull Oil

Tankers

1.4.3 At the

Owner's request, the notation MARPOL 20.1.3 may be appended

to the notation100A1 Double Hull Oil Tanker for vessels

not meeting the minimum double side width (ds

)

requirements of Table 9.1.1 Cargo tank boundary

requirements but

which comply with MARPOL Annex I, Regulation 20.1.3.

1.4.4 At the

Owners request, the notation MARPOL 21.1.2 may be appended

to the notation 100A1 Double Hull Oil Tanker for vessels

of less than 5000 tonnes deadweight which have a double hull in accordance

with MARPOL Annex I, Regulation 21.1.2.

1.4.11 The

structural configurations may include one or more of the arrangements

shown in Table 9.1.3 Structural arrangement. These

provisions do not preclude the fitting of additional bulkheads or

the perforation of longitudinal bulkheads.

1.4.12 The

bottom shell, inner bottom and deck are generally to be framed longitudinally

in the cargo tank region where the ship length, L, exceeds

75 m. However, consideration will be given to alternative proposals

for ships of special design.

1.4.13 The

side shell, inner hull bulkheads and longitudinal bulkheads are generally

to be longitudinally framed where the ship length, L,

exceeds 150 m, but alternative proposals, taking account of resistance

to buckling, will be considered.

1.4.14 Where

the side shell is longitudinally framed, the inner hull bulkheads

are to be similarly constructed.

1.4.15 Provided

the ship length, L, does not exceed 200 m the longitudinal

bulkheads may be horizontally corrugated. Vertically corrugated centreline

bulkheads may also be considered on the basis of direct calculations.

1.4.17 Alternative

arrangements, which are proposed as being equivalent to the Rules,

will receive individual consideration. Particular attention is to

be paid to deflection of members and to the ability of the structure

to resist buckling. Where necessary, additional calculations will

be required.

1.4.19 The

scantlings of structural items may be determined by direct calculation.

1.5 General definitions and symbols

1.5.1 The

following symbols and definitions are applicable to this chapter unless

otherwise stated:

L, LL, B, D, T

as defined in Pt 3, Ch 1, 6 Definitions.

|

d

c

|

= |

the height between the ship's base line and the bottom of the

cargo pump-room, in metres |

|

DWT

|

= |

deadweight,

in tonnes, at the summer load waterline |

|

b

|

= |

the

width of plating supported by the primary or secondary member, in

metres or mm respectively |

|

h

|

= |

the

load height applied to the item under consideration, in metres |

|

le

|

= |

effective length, in metres, of the primary or secondary member,

measured between effective span points. For determination of span

points, see

Pt 3, Ch 3, 3 Structural idealisation

|

|

s

|

= |

spacing

of secondary members, in mm |

|

t

|

= |

thickness

of plating, in mm |

|

= |

the moment

of inertia, in cm4, of a primary or secondary member, in

association with an effective width of attached plating determined

in accordance with Pt 3, Ch 3, 3 Structural idealisation

|

|

L1

|

= |

length of ship, in metres, but need not be taken greater than

190 m |

|

Pv

|

= |

pressure/vacuum relief valve positive setting, in bar |

|

Tm

|

= |

minimum operating moulded draught of the ship at amidships under

any expected cargo loading condition, in metres |

|

Z

|

= |

the

section modulus, in cm3, of the primary or secondary member,

in association with an effective width of attached plating determined

in accordance with Pt 3, Ch 3, 3 Structural idealisation

|

|

ρ

|

= |

maximum

cargo density, in t/m3.

|

1.5.4 The

expression ‘primary member’ as used in this Chapter is

defined as a girder, floor, transverse, vertical web, stringer, cross-tie

or buttress. ‘Secondary members’ are supporting members

other than primary members.

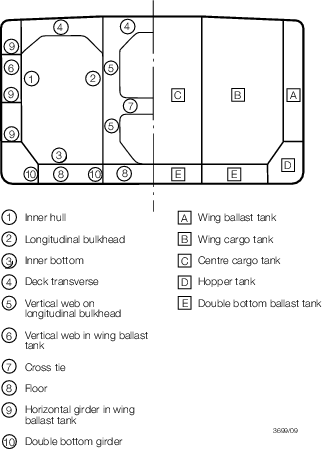

Figure 9.1.4 Structural and spatial terminology

1.6 Information required for CSR Double Hull Oil Tankers

1.6.1 Plans and supporting documents/calculations are to be submitted for approval

in accordance with the requirements of the CSR.

1.6.3 A Ship Construction File (SCF) is to be provided on board of the ship

containing information to facilitate inspection/survey, repair and maintenance. As a

minimum it is to include documentation and plans in accordance with the requirements of

the CSR.

1.6.6 In all cases, as required by the CSR, Pt 1, Ch 13 Ship in Operation -

Renewal Criteria, the mid-ship section plan to be supplied on board the ship is

to include the minimum required hull girder sectional properties. Sectional properties

are to be provided for transverse sections within the cargo length, i.e. each cargo

hold, and are to include:

- sectional properties as defined in CSR, Pt 1, Ch 5, 1 Strength

Characteristics of Hull Girder Transverse Sections;

- the defined section modulus at Deck and at Bottom calculated with

the gross offered thickness;

- the sectional area of the defined Deck and Bottom Zones calculated

with the gross offered thickness; and

- the sectional area of the defined Neutral Axis Zone calculated with

the gross offered thickness minus 0,5 tc.

1.7 Information required for Non-CSR Double Hull Oil Tankers

1.7.1 In addition

to the plans required by Pt 3, Ch 1, 5 Information required,

plans showing the connections for all longitudinals and other framing

members and arrangements at intersections of transverse and longitudinal

framing are also to be submitted.

1.7.2 Any

dry tanks, or tanks for water ballast only, are to be indicated on

the principal structural and arrangement plans.

1.7.4 A docking

plan is to be submitted for consideration of strength requirements

in association with the intended docking condition.

1.7.5 A plan

showing the location of all openings in the deck is to be submitted.

Where it is intended to provide holes in the deck for staging wires,

these holes are also to be shown. Full particulars of the proposed

closing arrangements for all deck openings are to be submitted.

|