Section

2 Materials for hull construction at low temperatures – Winterisation

H

2.1 Hull construction materials

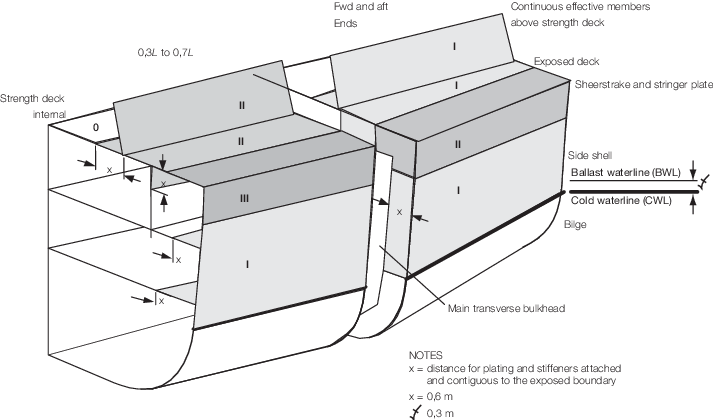

2.1.4 In addition to the requirements of Table 1.2.1 Material classes and

grades and Figure 1.2.1 Distribution of material classes for cold weather, miscellaneous attachments are to comply with

Table 1.2.5 Material classes and

grades.

Table 1.2.1 Material classes and

grades

| Structural member category

|

Material

class

|

| Within 0,4L amidships

|

Outside 0,4L amidships

|

SECONDARY:

- Deck plating exposed to weather, in general

- Side plating above CWL, see Note 5

- Transverse bulkheads above CWL, see Notes 5 and

6

|

I

|

I

|

PRIMARY:

- Strength deck plating

- Continuous longitudinal members above strength deck,

excluding longitudinal hatch coamings

- Longitudinal bulkhead above CWL, see Notes 5 and

6

- Top wing tank bulkhead above CWL, see Notes 5 and

6

|

II

|

I

|

SPECIAL:

- Sheerstrake at strength deck, see Note 1

- Stringer plate in strength deck, see Note 1

- Deck strake at longitudinal bulkhead, see Note 2

- Continuous longitudinal hatch coamings, see Note

3

|

III

|

II

|

Note

1. Not to be less than Grade E/EH within

0,4L amidships in ships with length exceeding 250 m.

Note

2. In ships with breadth exceeding 70 m

at least three deck strakes are to be Class III.

Note

3. Not to be less than Grade D/DH.

Note

4. Within 0,4L amidships, single

strakes which are required to be of Class III or of Grade E/EH or FH

are to have breadths not less than 800 + 5L, but need not be

greater than 1800 mm.

Note 6. Applicable to

plating attached to hull envelope plating exposed to cold air. At least

one strake is to be considered in the same way as exposed plating and the

strake width is to be at least 600 mm. If thermal stress calculations are

performed then the extent of plate requiring consideration is to be

adjusted accordingly.

|

Table 1.2.2 Materials for Class I

| Thickness,

mm

|

External design air temperature

|

| −24°C to −28°C

|

–29°C to –38°C

|

–39°C to –48°C

|

–49°C to –58°C

|

–59°C to –68°C

|

| MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

| t ≤ 10

|

A

|

AH

|

A

|

AH

|

B

|

AH

|

D

|

DH

|

D

|

DH

|

| 10 <

t ≤ 15

|

A

|

AH

|

B

|

AH

|

D

|

DH

|

D

|

DH

|

D

|

DH

|

| 15

< t ≤ 20

|

A

|

AH

|

B

|

AH

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

| 20 <

t ≤ 25

|

B

|

AH

|

D

|

DH

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

| 25

< t ≤ 30

|

B

|

AH

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

| 30

< t ≤ 35

|

D

|

DH

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

| 35

< t ≤ 45

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

| 45

< t ≤ 50

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

n/a

|

FH

|

|

Note 2. MS and HT are defined as Mild Steel and High Tensile Steel

respectively.

|

Table 1.2.3 Materials for Class II

| Thickness, mm

|

External design air temperature

|

| −24°C to −28°C

|

−29°C to −38°C

|

−39°C to −48°C

|

−49°C to −58°C

|

−59°C to −68°C

|

| MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

| t ≤

10

|

A

|

AH

|

B

|

AH

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

| 10 < t ≤

20

|

B

|

AH

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

| 20 < t ≤

30

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

| 30 < t ≤

40

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

n/a

|

FH

|

| 40 < t ≤

45

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

n/a

|

FH

|

n/a

|

n/a

|

| 45 < t ≤

50

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

n/a

|

FH

|

n/a

|

n/a

|

|

Note 2. MS and HT are defined as Mild Steel and High Tensile Steel

respectively.

|

Table 1.2.4 Materials for Class III

| Thickness, mm

|

External design air temperature

|

| −24°C to −28°C

|

−29°C to −38°C

|

−39°C to −48°C

|

−49°C to −58°C

|

−59°C to −68°C

|

| MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

| t ≤

10

|

B

|

AH

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

| 10 < t ≤

20

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

| 20 < t ≤

25

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

E

|

FH

|

n/a

|

FH

|

| 25 < t ≤

30

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

n/a

|

FH

|

| 30 < t ≤

35

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

n/a

|

FH

|

n/a

|

n/a

|

| 35 < t ≤

40

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

n/a

|

FH

|

n/a

|

n/a

|

| 40 < t ≤

50

|

E

|

EH

|

n/a

|

FH

|

n/a

|

FH

|

n/a

|

n/a

|

n/a

|

n/a

|

|

Note 2. MS and HT are defined as Mild Steel and High Tensile Steel

respectively.

|

Figure 1.2.1 Distribution of material classes for cold weather

Table 1.2.5 Material classes and

grades

| Structural member

|

External design air temperature for structural member °C

|

Material class

|

| Exposed structures of length greater than

0,09L and subjected to hull girder stress

|

t

|

Constructed of the same material class to that of

the material to which they are attached, however need not be greater than

class II

|

| Hatch coamings, hatch covers, crane pedestals

and windlass seats

|

t + 5

|

Constructed of the same material class to that

of the material to which they are attached, or class II, whichever is the

greater

|

| Forecastle deck

|

t + 10

|

Class II

|

| External bulkheads of

accommodation block

|

t + 20

|

Class II

|

| Forecastle side shell plating

|

| Plating and stiffeners attached and contiguous to

the exposed boundary plating distance 'x', see

Figure 1.2.1 Distribution of material classes for cold weather and Note 2

|

t + 10

|

Class I, but need not be taken greater than D or

DH

|

| Other exposed structures of length

less than 0,09L, e.g. bulwarks, breakwaters, unlagged gas turbine

intake structures, side screens, etc.

|

Need not be taken lower than –33

|

Class I

|

| Stern frames, rudders,

rudder horns, shaft brackets and stem (including the strake of shell plating

to which the item is attached)

|

Fully

immersed

|

t + 20

|

Class II

|

| Periodically

immersed or exposed

|

t

|

Note

1. For built-up stiffeners within the

distance ‘x’, the web and flange are considered to be a single

stiffening member and both members are to comply with the material

requirements. For bulb stiffeners and stiffeners with the flange

outside the distance ‘x’, the web only may be required to comply with

the material requirements.

|

2.1.5 Steel plate materials for stern frames, rudders, rudder horns, shaft brackets, and stem

(including the strake of shell plating to which the item is attached) and internal

members attached to these items are to be in accordance with Table 1.2.2 Materials for Class I, Table 1.2.3 Materials for Class II and

Table 1.2.4 Materials for Class III, using the appropriate

temperature in Table 1.2.5 Material classes and

grades. The steel casting and

forging materials for the rudders, rudder stocks, rudder horns, shaft brackets, stern

frames and stem are to be in accordance with Table 1.2.2 Materials for Class I, Table 1.2.3 Materials for Class II and Table 1.2.4 Materials for Class III, using the appropriate

temperature in Table 1.2.6 Steel casting and forging materials for rudder, rudder horn, rudder stock, shaft

bracket, stern.

2.1.7 Welding consumables are to be suitable for the applicable steel grades,

see

Ch 11 Approval of Welding Consumables of the Rules for the Manufacture, Testing and Certification of Materials, July 2022.

Table 1.2.6 Steel casting and forging materials for rudder, rudder horn, rudder stock, shaft

bracket, stern

| Item

|

Condition

|

External design air temperature for

item,°C

|

Steel grade (see Notes 1,2

and 3)

|

| Casting

|

Forging

|

| Rudder horn & Shaft brackets

|

Fully immersed

|

t + 20

|

Special Grade

|

Structural

|

| Periodically immersed or exposed

|

t

|

Ferritic Grade or Ni steel

|

Ferritic

|

| Rudder & Rudder stock

|

Fully immersed

|

t + 20

|

Normal Grade

|

Structural

|

| Periodically immersed or exposed

|

t

|

Ferritic Grade or Ni steel

|

Ferritic

|

| Stern frame

|

Fully immersed

|

t + 20

|

Special Grade

|

Structural

|

| Periodically immersed or exposed

|

t

|

Ferritic Grade

|

Ferritic

|

| Stem, (including the strake of shell plating to which the

item is attached)

|

Fully immersed

|

t + 20

|

Normal Grade

|

Structural

|

| Periodically immersed or exposed

|

t

|

Ferritic Grade or Ni steel

|

Ferritic

|

|

|

|