Section

6 Steel used in repairs

6.1 General

6.1.1 When renewals

are required, Surveyors should ensure that the grade of steel to be

used in the repair is in accordance with, or equivalent to, the grades

listed on the approved plans.

6.1.2 Steel used

for repair of classed ships should be manufactured, tested and certified

in accordance with the requirements of the Rules for Materials.

6.1.3 Limited quantities

of steel complying with the requirements of a national or proprietary

specification may be accepted subject to the following conditions:

-

The material is considered

equivalent to the minimum requirements of the steel grade shown on

the plan.

-

The manufacturer is

approved by LR to supply the grade of steel shown on the plan.

-

The identity stamped

on the material and the material condition clearly conform to the

details shown on the certificate.

-

Representative samples

selected for check mechanical and chemical analysis tests are satisfactory.

-

Copies of the manufacturer’s

test certificate and the results from the check tests are recorded.

6.1.5 When it is

not possible to carry out check tests before the repair is completed,

a sample should be retained for subsequent testing before departure

of the vessel. However, every effort should be made to ensure that

the material is tested before the repair is completed. The repair

is to be considered as incomplete, until such tests have been carried

out and the results confirmed as satisfactory.

6.1.8 Due to the

limited availability of Admiralty long stalk tee bars, alternative

sections may be used. Suitable alternative sections are given in Table 15.6.4 Alternatives to Admiralty long

stalk tee bars. For large scale replacement

IPN beams should be used in preference to fabricated tee bars. Where

alternative sections are used, care is to be taken to ensure a smooth

transition, using a 1 in 4 taper, between different sections. Additional

flat bar pieces of a depth not less than the flange thickness and

extending two times the web depth from the connection, may be necessary

to maintain the continuity of section modulus where the changes in

flange width or thickness between sections is large.

Table 15.6.1 Rolled plate and sections,

material grade equivalence

|

NES Specification

|

Equivalent LR

|

Equivalent international

|

| EN 10025

|

JIS G3106

|

|

-

791 - 43A

-

|

A

-

AH32

|

S235JRG2

S275J0G3

S355 JR

|

SM41B

-

SM50B

|

|

-

791 - 43D

-

|

D

-

DH32

DH36

|

S235J2G3

S275N/M

-

S355N/M

|

SM41C

-

SM50C

SM53C

|

|

791 - B

791 - BX

|

EH32

EH32 (Z Quality)

EH36

|

-

-

S355NL/ML

|

-

-

-

|

Table 15.6.2 Material and welding standard

equivalence

|

Material

|

NES Specification

|

Equivalent LR

|

| Castings

|

849 - A

|

Rules for Materials

Ch 4 Steel Castings

C- Mn (structural)

|

|

|

849 - B to G

|

Rules for Materials Ch 4 Steel Castings

|

| NAB

Castings

|

747 Pt 3

|

Rules for Materials Ch 9, 1 Castings for propellers

Grade 3 Cu3 (propellers/hull fittings)

Rules for Materials Ch 9, 2 Castings for valves, liners and bushes

Aluminium bronze (valves, liners, bushes)

|

Q1N

Plate, forgings,

castings and sections

|

736

|

none

|

| Forgings

|

848 Pt 1

848 Pt 2

|

Rules for Materials Ch 5, 2 Forgings for ship and other structural applications

Rules for Materials Ch 5, 2 Forgings for ship and other structural applications

|

| Welding

|

Hul

Machinery

|

706

DGS 9023

|

Rules for Naval Ships Vol 1, Pt 6, Ch 6 Material and Welding Requirements

Rules for Materials Ch 13 Requirements for Welded Construction

|

| Chain Cable

|

Open link

Stud link

|

176

172 - 1

172 - 2

172 - 3

|

Rules for Materials Ch 10 Equipment for Mooring and Anchoring U2

Rules for Materials Ch 10 Equipment for Mooring and Anchoring U1 forged

Rules for Materials Ch 10 Equipment for Mooring and Anchoring U2 forged

Rules for Materials Ch 10 Equipment for Mooring and Anchoring U3 forged

|

| Anchors

|

174

|

none

|

Table 15.6.3 Admiralty long stalk tee bar

sections

| Type

|

Size

Inches

|

Size

w x d

mm

|

Thickness, mm

|

Wt/m

kg

|

A

cm2

|

Inertia, Ixx

cm4

|

Height of

centroid,

mm

|

Inertia, Iyy

cm4

|

|

t

f

|

t

w1

|

t

w2

|

| 1

|

3”

|

25,4 x 76,2

|

6,4

|

4,4

|

4,4

|

3,64

|

4,64

|

27,89

|

28,2

|

0,83

|

| 2

|

4.5”

|

44,5 x 114,3

|

9,5

|

5,1

|

5,1

|

7,43

|

9,48

|

126,1

|

36,6

|

7,06

|

| 3

|

5”

|

63,5 x 127,0

|

13,4

|

6,9

|

6,4

|

12,62

|

16,13

|

248,5

|

37,6

|

25,80

|

| 4

|

6”

|

76,2 x 152,4

|

14,2

|

7,4

|

6,9

|

16,29

|

20,90

|

468,2

|

44,4

|

46,61

|

| 5

|

7”

|

88,9 x 177,8

|

15,2

|

7,9

|

7,4

|

20,44

|

26,06

|

804,9

|

51,8

|

79,49

|

| 6

|

8”

|

101,6 x 203,2

|

16,3

|

8,4

|

7,9

|

25,01

|

31,93

|

12,89

|

58,4

|

124,9

|

| 7

|

10”

|

127,0 x 254,0

|

18,3

|

9,4

|

8,9

|

35,40

|

45,35

|

28,11

|

69,3

|

273,0

|

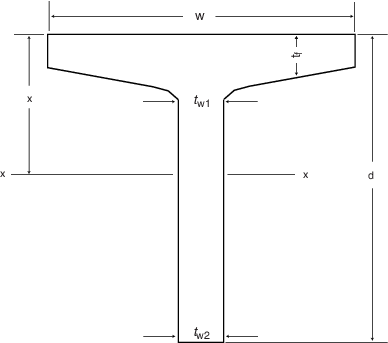

Figure 15.6.1 Standard T bar sections

Table 15.6.4 Alternatives to Admiralty long

stalk tee bars

| Type

|

Size

inches

|

IPN Series

cut

down

Beams

|

IPE Series

cut

down

Beams

|

Fabricated

web,flange

mm

|

| 1

|

3

|

IPN 100

|

IPE 120

|

75 x10

|

| 2

|

4.5

|

IPN 160

|

IPE 240

|

100 x 8,40 x 10

|

| 3

|

5

|

IPN 240

|

IPE 360

|

100 x 8,65 x 15

|

| 4

|

6

|

IPN 260

|

IPE 400

|

130 x 15,75 x 12

|

| 5

|

7

|

IPN 280

|

IPE 450

|

150 x 8,80 x 20

|

| 6

|

8

|

IPN 280

|

IPE 550A

|

180 x 8,100 x 20

|

| 7

|

10

|

IPN 320

|

IPE 600

|

220 x 10,130 x 20

|

|