Section

1 Introduction

1.1 General

1.1.1 This

Chapter contains information regarding the derivation of local design

loads that are to be used for the assessment of scantlings to local

loads as specified in Vol 1, Pt 6, Ch 2 Design Tools

1.1.2 The

formulae for ship motion loads given in this Chapter are suitable

for all ships that operate in the displacement mode. Ship motion loads

for ships that operate in the fully planing mode will need to be specially

considered.

1.2 Environmental conditions

1.2.1 The

environmental conditions for the determination of the local loads

are to be based on the normal environmental design criteria specified

in Vol 1, Pt 5, Ch 2, 2.3 Wave environment unless otherwise

stated.

1.2.2 The

wave height factor for local loads, f

Hs, is

dependent on the service area notation and is to be taken as follows:

|

f

Hs

|

= |

1,0 for SA1 service area notation, i.e. unrestricted sea-going

service |

otherwise

|

f

Hs

|

= |

|

| = |

|

f

Hs is not to be taken as less than

0,5

H

dw is given in Vol 1, Pt 5, Ch 2, 2.3 Wave environment 2.3.3.

1.2.4 The

local design loads for assessment of the residual strength notation, RSA, or for special loading conditions where the ship will

not experience severe weather or severe sea states may be adjusted

for the appropriate environmental conditions. A reduced wave height

factor, f

Hs, may be applied, see

Vol 1, Pt 5, Ch 3, 5.10 Design loads for RSA notation assessmentand Vol 1, Pt 5, Ch 3, 5.10 Design loads for RSA notation assessment 5.10.3.

1.3 Symbols and definitions

1.3.1 The symbols and definitions applicable to this Chapter are defined below or

in the appropriate sub-Section. LWL, B, BWL,

D, T and Cb are defined in Vol 1, Pt 3, Ch 1, 5.2 Principal particulars.

|

V

cr

|

= |

two thirds the cruising speed, in knots |

|

V

sp

|

= |

is to

be taken as the greater of the cruising speed or two thirds the sprint

speed, in knots. For ships where it is not required to maintain high

speeds in severe weather then the value of V

sp may

be specially considered

|

|

T

|

= |

mean draught at midships, in metres, to the design draught waterline

measured from the moulded baseline |

|

Tx

|

= |

local draught, in metres, measured from the underside of the keel to

the design draught waterline at the longitudinal position under consideration,

see

Figure 3.1.2 Definition of symbols. For the calculation of bottom impact

pressures, Tx (TFB) is to be taken as the

minimal draught for all operational loading conditions measured from the underside

of the keel to the operational waterline at the longitudinal position under

consideration, see

Vol 1, Pt 5, Ch 3, 4.2 Bottom impact pressure, IPbi 4.2.1. |

|

xwl

|

= |

longitudinal distance, in metres, measured forwards from the

aft end of the L

WL to the position or centre

of gravity of the item being considered

|

|

y

|

= |

transverse

distance, in metres, from the centreline to the centre of gravity

of the item being considered. y is positive to port and

negative to starboard

|

|

z

|

= |

vertical

distance, in metres, from the base line to the position or centre

of gravity of the item being considered. z is positive

above the baseline

Normally the following definitions

are to be applied:

For a longitudinally framed plate

panel, z is to be taken at the panel centre

For

a transversely framed plate panel, z is to be taken at

two thirds of the panel height

For short stiffener members: z is to be taken at the stiffener mid position

For

long stiffener members: z is generally to be taken at

the stiffener mid position, but may need to be specially considered,

especially when there is a significant pressure variation along its

length

|

|

∆ |

= |

moulded

displacement of the ship, in tonnes |

1.3.2

Froude

Number F

n.

The Froude number is a nondimensional

parameter which is the primary constituent part of the wave making

resistance and which dictates the maximum displacement speed. It is

defined as:

|

F

n

|

= |

|

where

|

g

|

= |

is the acceleration

due to gravity and is taken to be 9,81 m/s2

|

|

V

m

|

= |

is the

appropriate ship speed in m/s. |

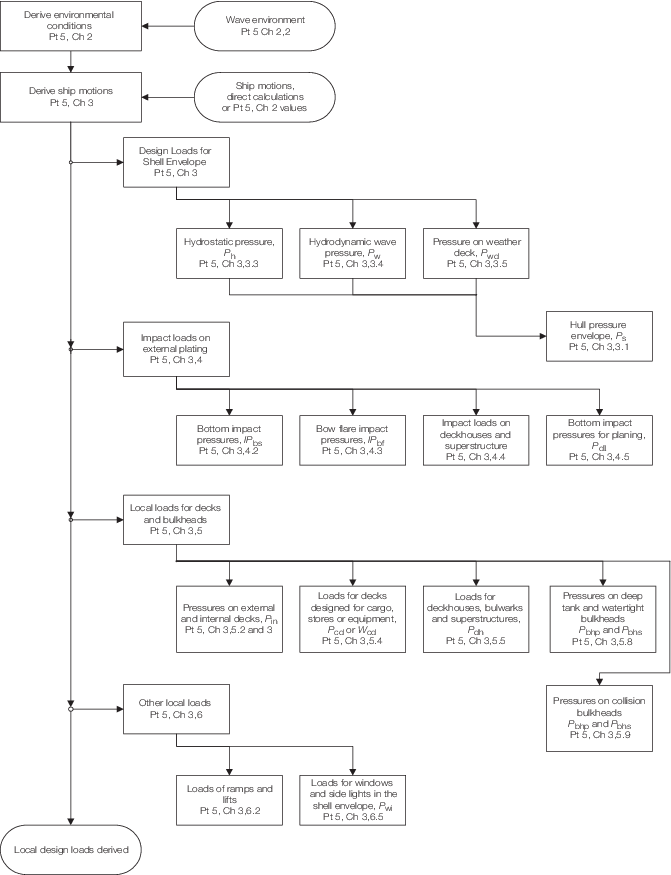

Figure 3.1.1 Overview of derivation of local design loads

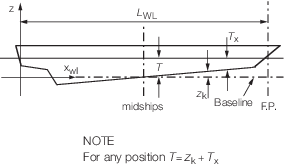

Figure 3.1.2 Definition of symbols

1.3.3

Design loading condition. The design loading condition is to be taken as the

draught condition with tanks and consumables, etc. in the departure state, see

also

Vol 1, Pt 5, Ch 4, 2.1 General 2.1.3. Where there is a significant

variation in loading conditions or operating modes, then it may be necessary to consider

additional loading conditions which represent the extremes of service requirements. For

example:

- a ship which can operate in displacement and non-displacement

modes;

- a ship which is required to operate at a temporary draught deeper than

the design draught for off-loading payload.

- a ship which is required to be involved in humanitarian emergency

evacuation incidents or similar situations where short term overloading

may be necessary.

1.3.4

LCG. The

LCG is the longitudinal centre of gravity of the ship measured in

metres from the aft end of the L

WL for the

design loading condition.

1.3.5

Displacement

mode. Displacement mode means the regime, whether at rest or

in motion, where the weight of the ship is fully or predominantly

supported by hydrostatic forces. Typically this applies to craft with

a Taylor Quotient, Γ, less than 3. However, some craft are designed

to plane with Γ less than 3 and these should be considered as

operating in the non-displacement mode.

1.3.6

Fully

planing mode or Non-displacement mode. Non-displacement mode

means the normal operational regime of a ship when non-hydrostatic

forces substantially or predominantly support the weight of the ship.

Typically this applies to craft with a Taylor Quotient, Γ, greater

than 3. However, some craft are designed not to plane with Γ greater

than 3 and these should be considered as operating in the displacement

mode unless they are classified as a high speed craft.

1.3.7 Taylor

Quotient Γ. The Taylor Quotient is defined as:

1.3.8

Support

girth G

S

. The support girth is the

girth distance at the LCG, in metres, and is to be calculated as follows:

- For craft with chines, it is to be taken as the distance around

the shell plate between the girth chine locations, see

Figure 3.1.3 Definition of girth chine location, B

C, B

WL and G

S when chine is

below deepest load waterline

. Girth chine location

is to be taken as the lowest chine above which the shell plate has

an angle to the horizontal greater than 50°.

- For craft where the design waterline intercepts the shell plate

below the bilge tangential point or the girth chine location, the

support girth is to be taken as the distance around the shell plate

up to the design waterline, see Fig. Figure 3.1.4 Definition of girth chine location, B

C, B

WL and G

S when chine is

above deepest load waterline

.

- For craft with round bilges, it is to be taken as the distance

around the shell plate between the bilge tangential points of the

hull. The bilge tangential point is defined as the tangential point

of the bilge with an oblique line sloped at 50° to the horizontal

at the LCG, see

Figure 3.1.5 Definition of bilge tangential point, B

C, B

WL and G

S

.

- For multi-hull craft, it is to be taken as the summation of girths

for each individual hull between the inner and outer bilge tangential

points or chines, as appropriate.

The definition aims to define the canoe body. Narrow keels and

skegs can be ignored.

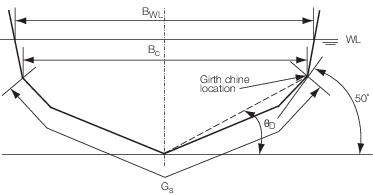

Figure 3.1.3 Definition of girth chine location, B

C, B

WL and G

S when chine is

below deepest load waterline

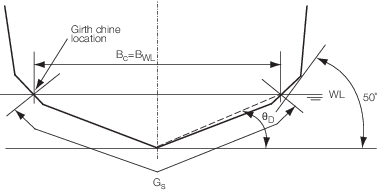

Figure 3.1.4 Definition of girth chine location, B

C, B

WL and G

S when chine is

above deepest load waterline

Figure 3.1.5 Definition of bilge tangential point, B

C, B

WL and G

S

|