Section

5 Local design loads for decks and bulkheads

5.1 General

5.1.1 This

section gives formulations for design pressure loads for decks, watertight

and deep tank boundaries including decks and bulkheads.

5.1.2 The

loads acting on the deck structures are to reflect the intended purpose

for each deck. If it is envisaged that the role of the ship will be

such that it may be used for emergency evacuation incidents or similar

situations, then the appropriate design loads are to be considered

in the assessment. The maximum permissible deck loading are to be

recorded in the Operations Manual or Stability Information Book.

5.2 Pressure on external decks

5.2.1 The

standard pressure requirements for external decks are given in Vol 1, Pt 5, Ch 3, 3.5 Pressure on exposed and weather decks, Pwd. If the deck is also to be used

for cargo, heavy equipment or similar, then the loads specified in Vol 1, Pt 5, Ch 3, 5.4 Loads for decks designed for cargo or heavy equipment loads, Pcd and Wcd are also to be applied. Consideration

will be given to a reduction in the weather deck pressure loading

if it can be shown that the cargo or equipment stowage makes the weather

deck pressure requirements conservative.

5.3 Pressure on internal decks, P

in

5.3.1 The

pressure acting on internal decks, P

in, not

subject to cargo or heavy equipment loads is to be taken as:

|

P

in

|

= |

5 kN/m2 for accommodation spaces

|

|

P

in

|

= |

7,5 kN/m2 for main evacuation routes

|

|

P

in

|

= |

10 kN/m2 for workshop spaces

|

|

P

in

|

= |

20 kN/m2 for store spaces.

|

5.3.2 Alternatively

the design pressure is to be based on the static loading on the deck

with due allowance for inertial effects as follows:

|

P

in

|

= |

W

in ( 1 + a

z )

kN/m2

|

where the following values of static pressure are

to be assumed

|

W

in

|

= |

3 kN/m2 for accommodation spaces

|

|

W

in

|

= |

6 kN/m2 for workshop spaces

|

|

W

in

|

= |

12 kN/m2 for store spaces

|

a

z is defined in Vol 1, Pt 5, Ch 3, 2.3 Design accelerations 2.3.2.

5.3.3 The

hydrostatic design pressure for decks specified as watertight shall

be taken as that determined by the damage stability analysis and limit

of watertight integrity.

5.3.4 The

static design pressure for internal decks not specified as watertight

may be provided by the designer.

5.4 Loads for decks designed for cargo or heavy equipment loads, P

cd and W

cd

5.4.1 Where

the load applied to the deck can be considered as uniformly distributed,

the cargo deck design pressure, P

cd, is to

be taken as:

|

P

cd

|

= |

W

cd (1 + az) kN/m2

|

5.4.2 Where

the load applied to the deck is not uniformly distributed, the likely

actual forces and force distribution over the deck must be considered.

The forces are to include the following if appropriate:

- gravity

- inertial forces due to ship motion.

- wind loads

- forces imposed by the securing arrangements

- wave impact loads

- icing loads

where

W

ma is

the weight of each mass item on the deck as specified by the designer

in kN

5.5 Loads for deckhouses, bulwarks and superstructures, P

dh

5.5.1 The

design normal pressure, P

dh, for the side,

front and back panels of plating and stiffeners for deckhouses, bulwarks

and superstructures is given by:

where

|

C

1

|

= |

1,25C

2 for exposed deckhouse fronts

and superstructure fronts forward of 0,67L

R

|

| = |

1,15C

2 for exposed

deckhouse fronts and superstructure fronts aft of 0,67L

R

|

| = |

1,15 for exposed machinery casings |

| = |

0,8 for the side and back panels of deckhouses

that are stepped in from the deck edge by 1,0 m or more which are

also above the nominal wave limit height, H

w, see

Vol 1, Pt 5, Ch 3, 3.4 Hydrodynamic wave pressure, Pw 3.4.4

|

| = |

0,5 for non-exposed deckhouse and super structure

fronts, sides and backs which are also above the nominal wave limit

height |

| = |

1,0 elsewhere |

|

P

s

|

= |

is to

be taken at the height of the deck supporting the deckhouse front,

side or back panel under consideration, P

s is

defined in Vol 1, Pt 5, Ch 3, 3.2 Combined hydrostatic and hydrodynamic pressure on the shell plating, Ps

|

|

C

2

|

= |

1,2 for panels below the nominal wave limit height |

| = |

1,0 elsewhere |

|

|

= |

Typical values of C

1 are shown in Figure 3.5.1 Illustration of the C1 coefficients for deckhouse

and superstructure pressures

|

|

|

= |

Where there is more than one deckhouse, the front of the most

forward deckhouse will normally be considered exposed, whereas the

back of this deckhouse will be non-exposed. Normally, the front of

the deckhouse aft of this one will also be considered non-exposed. |

Figure 3.5.1 Illustration of the C1 coefficients for deckhouse

and superstructure pressures

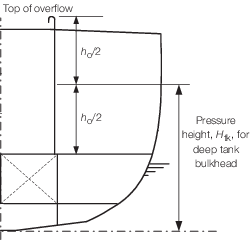

5.6 Pressure height for deep tank bulkheads and boundaries, H

tk

5.6.1 The

design lateral pressure height for tank and deep tank bulkheads and

boundaries, H

tk, is to be taken as

|

H

tk

|

= |

the distance, in m, from the baseline to half the distance from

the top of the tank to the top of the overflow. For determination

of the maximum head, the top of the overflow is to be taken as not

less than 1,8 m above the crown of the tank, see

Figure 3.5.2 Pressure height for deep tank bulkheads

|

Figure 3.5.2 Pressure height for deep tank bulkheads

5.6.2 For

tanks which are connected to a filling tank system, H

tk may be taken as the distance, in m, from the baseline to the

highest point of the overflow pipe from the filling tank into the

overflow tank. Consideration may need to be given to the pressure

height for situations where any of the valves in the filling system

may be closed. The transfer pump must feed only into the filling tank

and must not be linked directly to the tanks.

5.6.3 In a

filling tank system, suitable measures are to be provided such that

the maximum design level in the system cannot be exceeded. Automatic

shutdown measures are to ensure a fail safe arrangement to avoid overfilling

the filling tank or the overflow tank. The overflow pipe is to be

of sufficient size to ensure that the filling trunk is not overfilled.

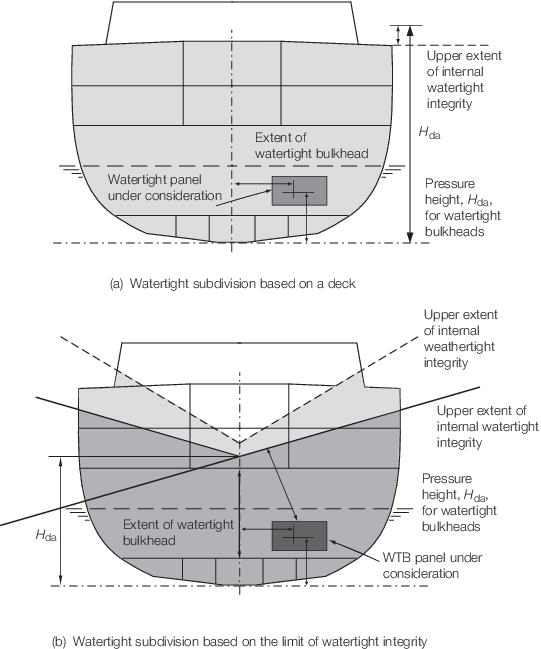

5.7 Pressure height for watertight bulkheads

and boundaries, Hda

5.7.1 The design lateral pressure height for watertight bulkheads and boundaries,

Hda, is to be taken as

-

for a watertight bulkhead design philosophy based on a SOLAS type

approach, i.e. to the top of a watertight bulkhead deck or freeboard deck,

see

Vol 1, Pt 3, Ch 2, 1.3 Watertight and weathertight integrity 1.3.8 and illustrated in Figure 2.1.1 .

Hda =

the vertical distance, in m, from baseline to a line 0,91 m above the top of the

watertight bulkhead at side, see

Figure 3.5.3 Pressure height for watertight bulkheads.

-

for a watertight bulkhead design philosophy based on a standard which

requires a damaged stability draught and heel envelope approach, e.g. the red risk

line approach, see

Vol 1, Pt 3, Ch 2, 1.3 Watertight and weathertight integrity 1.3.9 and illustrated in Figure 2.1.2 .

Hda

= the distance, in m, from baseline to the damaged stability draught envelope at

the centreline, see

Figure 3.5.3 Pressure height for watertight bulkheads.

Note: The effect of lesser angles of heel in the damage situation may lead

to an increase in the effective pressure height, especially in way of the forward end of

the ship where it may be necessary to consider Hda based on a zero

heel angle.

Figure 3.5.3 Pressure height for watertight bulkheads

5.8 Design pressures for watertight and deep tank bulkheads and boundaries

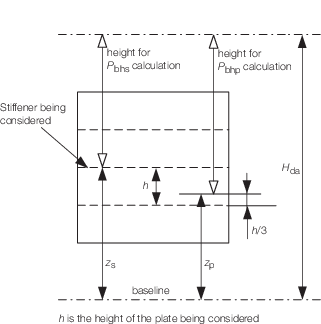

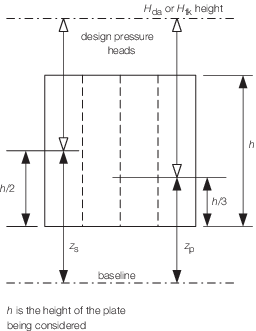

5.8.1 The

design normal pressure for bulkhead plating with stiffeners is to

be considered separately for the plating and the stiffeners. The design

normal pressure for the plating, P

bhp, is

to be taken as follows:

Deep Tank

ρg (H

tk – z

p) kN/m2

WT sub-division

based on the head normal to the line of watertight integrity

maximum of

10((H

da – z

p) cosθ +y

p sin

θ) kN/m2

10(H

da – z

p) kN/m2

where

|

ρ

|

= |

density

of fluid, in tonnes/m3, and is not to be taken as less

than 1,025

|

|

z

p

|

= |

distance above the baseline of a point one-third of the height,

above the lower edge, of the plate strake under consideration, z

p is illustrated in Figure 3.5.4

Z, distance above baseline for pressure head

for plating with horizontal stiffeners

for

horizontally stiffened plating and Figure 3.5.5

Z, distance above baseline for pressure head

for plating head for plating with vertical stiffeners

for vertically stiffened plating

|

|

y

p

|

= |

distance from the centreline of the mid-breadth of the plate

strake under consideration, y

p, is always

to be taken as positive

|

|

θ |

= |

the stipulated

damaged stability heel angle, see also

Vol 1, Pt 3, Ch 2, 1.3 Watertight and weathertight integrity For a SOLAS type approach, θ

is normally to be taken as 0,0.

|

Figure 3.5.4

Z, distance above baseline for pressure head

for plating with horizontal stiffeners

Figure 3.5.5

Z, distance above baseline for pressure head

for plating head for plating with vertical stiffeners

5.8.2 The

design normal pressure for the stiffener, P

bhs,

is to be taken as follows:

Deep Tank

ρg (H

tk - z

s) kN/m2 (Deep Tank)

WT sub-division

maximum of:

10((H

da - z

s) cos θ + y

s sin θ)

kN/m2

10(H

da - z

s) kN/m2

where

or

|

y

s

|

= |

distance from the centreline of the mid span of the stiffener

under consideration, y

s is always to be taken

as positive

|

|

ρ

|

= |

density

of fluid, in tonnes/m3, and is not to be taken as less

than 1,025.

|

5.8.3 The

appropriate design criteria are to be applied to the bulkhead plating

and stiffeners, see

Vol 1, Pt 6, Ch 5 Structural Design Factors It is not permissible to use watertight criteria for

a deep tank design head.

5.8.4 The

design impulse pressure,  bh, for the bulkhead plating and stiffeners

may be ignored, unless these members are likely to be subjected to

significant sloshing loads or similar. In this case it will be necessary

to determine the sloshing loads using a suitable direct calculation

procedure.

bh, for the bulkhead plating and stiffeners

may be ignored, unless these members are likely to be subjected to

significant sloshing loads or similar. In this case it will be necessary

to determine the sloshing loads using a suitable direct calculation

procedure.

5.9 Design pressures for collision bulkheads

5.9.1 The

design lateral pressure height for collision bulkheads, H

cb, is to be taken as:

|

H

cb

|

= |

the vertical distance, in m, from the baseline to 0,91 m above

the uppermost point of the collision bulkhead. |

5.9.2 The

design normal pressure for the collision bulkhead plating, P

bhp, is to be taken as:

|

P

bhp

|

= |

10 (H

cb – z

p)

kN/m2

|

where

|

z

p

|

= |

distance above baseline of a point one third of the height,

above the lower edge, of the plate strake under consideration. |

5.9.3 The

design normal pressure for bulkhead stiffeners, P

bhs,

is to be taken as:

|

P

bhs

|

= |

10 (H

cb – z

s)

kN/m2

|

5.9.5 If there

is a design requirement for the ship to be able to remain operational

after an incident which results in the collision bulkhead becoming

the primary watertight boundary to the sea, then it will be necessary

to design the collision bulkhead using the pressures for the shell

envelope, P

s, given in Vol 1, Pt 5, Ch 3, 3 Loads on shell envelope and the shell envelope design

criteria. It will also be necessary to consider the effects of wave

impact pressures, see

Vol 1, Pt 5, Ch 3, 4.3 Bow flare and wave impact pressures, IPbf,

using the design speed requirement after damage.

5.10 Design loads for RSA notation assessment

5.10.1 The

capability of transverse bulkheads, longitudinal bulkheads, watertight

decks and other structure to withstand any additional loads as a consequence

of damage, e.g. sloshing loads on watertight bulkheads, may need to

be specially considered. Pressure heads consistent with draughts and

heel angles determined from the damage stability analyses are to be

used for local scantling assessment.

5.10.2 Where

watertight boundaries for damage control purposes are specified in

the subdivision and stability standard, the nominated bounding decks

are to be assigned as watertight see

Vol 1, Pt 6, Ch 3, 10 Deck structures. The pressure heads used

in the assessment of damage control decks are to be the greater of

that determined from the Rules or that specified by the Owner.

5.10.3 The local design loads for structures subjected to additional loading as a

consequence of structural damage are to be taken as specified in this Chapter except

that the wave height factor, fHs, may be reduced, to account for the

lesser environmental requirements, as follows:

|

fHs

|

= |

may be

reduced by a factor of 1,85 |

5.10.4 Where

local strength issues need to be considered, the following local loads

are to be applied in the evaluation contained in Vol 1, Pt 6, Ch 4, 4.1 Application:

- Hydrostatic load due to flooding, taking account of the increase in

local draught.

- Wave and inertial loads in the damaged condition, derived using

the reduction factor given in Vol 1, Pt 5, Ch 3, 5.10 Design loads for RSA notation assessment 5.10.3.

- Local loads on watertight divisions as a consequence of flooding. For

the evaluation of local loads on watertight divisions, the standard design pressure,

Hda (see

Vol 1, Pt 5, Ch 3, 5.7 Pressure height for watertight bulkheads and boundaries, Hda)

may be applied. Alternatively the external hydrostatic and wave pressure load,

Ps, may be applied using the reduction factor given in Vol 1, Pt 5, Ch 3, 5.10 Design loads for RSA notation assessment 5.10.3.

- Wave impact loads need not be considered unless a significant

operational requirement is necessary following damage.

5.11 Design pressure for magazine decks and bulkheads

5.11.1 For

magazine structure which is assessed in accordance with Pt 4, Ch 1,6.4

the quasi-static design pressure is to be taken as follows:

|

P

mag

|

= |

|

where

|

W

e

|

= |

weapon equivalent weight of TNT, in kg |

|

V

|

= |

free

compartment volume, in m3.

|

|