Section

4 Design load systems for longitudinally effective components

4.1 Bottom shell structures (BS)

4.1.2 The

design normal pressure, P

BS, for the bottom

shell plating and stiffeners is to be taken as:

where

4.1.3 The

design impulse pressure,  P

BS, for the bottom shell plating

and stiffeners is to be taken as

P

BS, for the bottom shell plating

and stiffeners is to be taken as

P

bi

P

bi

|

= |

kN/m2 (bottom

impact)

|

where

4.1.5 The

design transverse load, LT

BS, due to hydrostatic

and hydrodynamic compressive loading is to be taken as follows:

|

LT

BS

|

= |

–εBS

P

SS

H

d

S

bs kN

|

where

|

H

d

|

= |

half the vertical distance from the keel to the first effective

full breadth deck above the inner bottom, or above the keel, in m.

If no effective full breadth decks exist, then H

d is

to be taken to the strength deck. H

d is illustrated

in Figure 2.4.2 Design parameter Hd for transverse

load

|

|

S

bs

|

= |

length of the bottom shell plating between major transverse

bulkheads, in metres |

|

εBS

|

= |

effectiveness

of the bottom shell plating, i.e. the relative proportion of the load

carried by the bottom shell as opposed to other structure such as

the inner bottom, floors and bulkheads |

| = |

0,5 for full breadth double bottom structures |

| = |

1,0 for single bottom structures or partial

breadth double bottom structures |

P

SS is to be taken at a height H

d/2 above the keel. P

SS is

defined in Vol 1, Pt 7, Ch 2, 3.6 External shell pressures 3.6.1

4.1.6 The

design global shear force, Q

D, may be ignored

for the bottom plating.

4.2 Side shell structures (SS)

4.2.3 The

design impulse pressure,  P

SS, for the side shell plating

and stiffeners is to be taken as follows:

P

SS, for the side shell plating

and stiffeners is to be taken as follows:

-

up to the design

waterline

P

SS =

P

SS =  P

bi kN/m2 (bottom impact)

P

bi kN/m2 (bottom impact)

-

above the design

waterline

P

SS =

P

SS =  P

bf kN/m2 (bow flare

impact)

P

bf kN/m2 (bow flare

impact)

where

P

bi and

P

bi and  P

bf are defined in Vol 1, Pt 7, Ch 2, 2.1 Nomenclature 2.1.2

P

bf are defined in Vol 1, Pt 7, Ch 2, 2.1 Nomenclature 2.1.2

4.2.5 The

design vertical load, LV

SS, supported by the

side shell plating and stiffeners is to be taken as:

|

LV

SS

|

= |

–εSS (S

ss

B

ss

P

CD + L

A +

[F

CD] ) kN

|

where

|

εSS

|

= |

effectiveness

of the side shell plating, i.e. the relative proportion of the load

carried by the side shell as opposed to the bounding major transverse

bulkheads |

| = |

0,5 |

|

L

A

|

= |

appropriate load, in kN, from pillar(s), bulkheads and side

shell structure above the supported deck, assumed zero if there is

none over. L

A may be taken as LV

BP for the supported bulkhead. LV

PB is

given in Vol 1, Pt 7, Ch 2, 5.8 Pillar bulkheads (PB)

|

|

B

ss

|

= |

mean breadth of the supported deck plating, i.e. half the transverse

distance from the side shell to longitudinal bulkheads, or effectively

supported longitudinal girders, in metres |

|

S

ss

|

= |

length of the side shell between major transverse bulkheads,

in metres. |

4.3 Strength deck and internal deck structures (DK)

4.3.1 The

design normal pressure, P

DK, for the deck

plating and stiffeners is to be taken as the greater of the following,

provided that the load component is applicable:

-

P

WD (weather

deck pressure), see

Vol 1, Pt 7, Ch 2, 3.6 External shell pressures 3.6.2

-

(interior deck pressure), see

Vol 1, Pt 7, Ch 2, 5.1 Deck structures (DK) 5.1.3 (interior deck pressure), see

Vol 1, Pt 7, Ch 2, 5.1 Deck structures (DK) 5.1.3

-

P

CD (cargo

deck pressure), see

Vol 1, Pt 7, Ch 2, 5.1 Deck structures (DK) 5.1.2

-

P

tk (deep

tank boundary, where appropriate).

4.3.3 The

design load matrix, [F

DK], in kN for the deck

plating and stiffeners is to be taken as the combination of the following,

as appropriate:

These loads are to be applied in addition to the

design pressures above.

4.3.4 Normally,

the design impulse pressure,  P

DK, for the deck plating and stiffeners

may be ignored. However, the design impulse pressure will need to

be considered for decks designed to withstand helicopter or aircraft

landing operations, cargo handling at sea or similar.

P

DK, for the deck plating and stiffeners

may be ignored. However, the design impulse pressure will need to

be considered for decks designed to withstand helicopter or aircraft

landing operations, cargo handling at sea or similar.

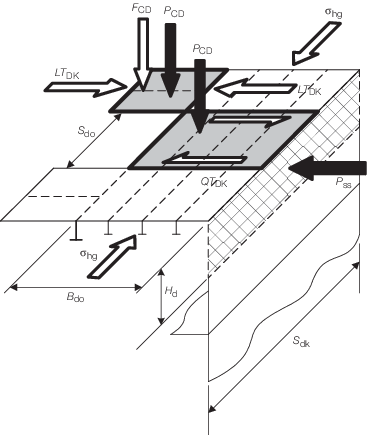

4.3.6 The

design transverse load, LT

DK, due to hydrostatic

and hydrodynamic compressive loading is to be taken as follows, see

also

Vol 1, Pt 7, Ch 2, 4.3 Strength deck and internal deck structures (DK) 4.3.8:

|

LT

DK

|

= |

–εDK

P

SS

H

d

S

dk kN

|

where

|

H

d

|

= |

half the vertical distance from the first full breadth deck

below the deck under consideration to the first full breadth deck

above this deck, or to the strength deck if there are no decks above,

in metres |

|

εDK

|

= |

effectiveness

of the deck, i.e. the relative proportion of the load carried by the

deck as opposed to other structure such as bulkheads |

| = |

0,8 |

P

SS is to be taken at the

mid height of the H

d depth, P

SS is defined in Vol 1, Pt 7, Ch 2, 3.6 External shell pressures 3.6.1

H

d is illustrated in Figure 2.4.2 Design parameter Hd for transverse

load

Figure 2.4.4 Design loads for the deck structure

4.3.8 If the

deck is not continuous across the full breadth, due to the presence

of large openings, then LT

DK may be taken

as zero over the opening breadth. In this case it may be necessary

to consider the local shear force in the deck plating due to hydrostatic

and hydrodynamic loading on the longitudinal span of the deck. This

shear force acts in the transverse direction and is to be taken as:

|

QT

DK

|

= |

P

SS

H

d

S

do/2 kN

|

where

|

S

do

|

= |

length of the deck plating between major transverse bulkheads

or the length of the deck opening, whichever is lesser, in metres |

P

SS and H

d are

defined in Vol 1, Pt 7, Ch 2, 4.3 Strength deck and internal deck structures (DK) 4.3.6

The

shear area of the deck plate supporting this shear load is to be based

on the breadth of the deck edge strip, B

do.

4.4 Inner bottom structures (IB)

4.4.1 For

all loading conditions, the design normal pressure,  , for the inner bottom plating and stiffeners is to be

taken as the greater of: , for the inner bottom plating and stiffeners is to be

taken as the greater of:

-

(interior deck pressure), see

Vol 1, Pt 7, Ch 2, 5.1 Deck structures (DK) 5.1.3 (interior deck pressure), see

Vol 1, Pt 7, Ch 2, 5.1 Deck structures (DK) 5.1.3

-

P

CD (cargo

deck pressure), see

Vol 1, Pt 7, Ch 2, 5.1 Deck structures (DK) 5.1.2

-

P

tk (deep

tank pressure, where appropriate).

4.4.2 For

loading conditions which represent damaged situations, the design

normal pressure, , for the inner bottom plating and stiffeners is to be

taken as the greater of the following. If this is greater than Vol 1, Pt 7, Ch 2, 4.4 Inner bottom structures (IB) 4.4.1: , for the inner bottom plating and stiffeners is to be

taken as the greater of the following. If this is greater than Vol 1, Pt 7, Ch 2, 4.4 Inner bottom structures (IB) 4.4.1:

-

P

da (damage

head).

-

P

SS (pressure

on shell plating, where appropriate).

4.4.4 The

design impulse pressure for the inner bottom plating and stiffeners

may be ignored.

4.4.6 The

design transverse load,  , due to hydrostatic and hydrodynamic compressive loading

is to be taken as follows: , due to hydrostatic and hydrodynamic compressive loading

is to be taken as follows:

|

= |

–ε P

SS

H

d

S

ib kN

P

SS

H

d

S

ib kN

|

where

|

H

d

|

= |

half the vertical distance from the keel to the first full breadth

deck above the inner bottom, in metres |

ε

|

= |

effectiveness of the inner

bottom, i.e. the relative proportion of the load carried by the inner

bottom as opposed to other structure such as the bottom shell, floors

and bulkheads |

| = |

0,5 normally |

P

SS is to be taken at a height

of H

d/2 above the keel, P

SS is defined in Vol 1, Pt 7, Ch 2, 3.6 External shell pressures

H

d is illustrated in Figure 2.4.2 Design parameter Hd for transverse

load

4.4.7 The

design global shear force, Q

D, may be ignored

for the inner bottom plating.

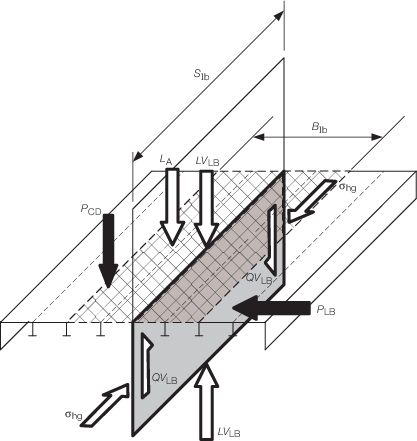

4.5 Longitudinal bulkhead structures (LB)

4.5.2 The

design normal pressure for longitudinal bulkhead plating with vertical

stiffeners is to be considered separately for the plating and the

vertical stiffeners. The design normal pressure for the plating, P

LB, is to be taken as P

BHP as given

in Vol 1, Pt 7, Ch 2, 5.2 Transverse watertight and deep tank bulkheads (BH) 5.2.1. The design normal

pressure for the stiffener, P

LBS, is to be

taken as P

BHS as given in Vol 1, Pt 7, Ch 2, 5.2 Transverse watertight and deep tank bulkheads (BH) 5.2.1

4.5.3 The

design impulse pressure,  P

LB, for the longitudinal bulkhead

plating and stiffeners may be ignored, unless these members are likely

to be subjected to significant sloshing loads or similar.

P

LB, for the longitudinal bulkhead

plating and stiffeners may be ignored, unless these members are likely

to be subjected to significant sloshing loads or similar.

4.5.7 If the

longitudinal bulkhead is not continuous over the full depth of the

ship then it will be necessary to consider the local shear force in

the longitudinal bulkhead plating as the vertical load must be transferred

into the supporting structure, such as transverse bulkheads. This

shear force acts in the vertical direction and is to be taken as:

The shear area of the longitudinal bulkhead plate

supporting this shear load is to be based on the depth of the longitudinal

bulkhead between decks.

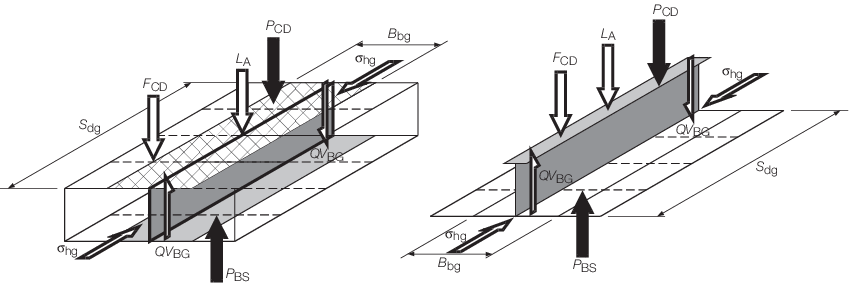

4.6 Bottom longitudinal girders (BG)

4.6.2 The

design normal pressure, P

BG, for girder web

plating is to be taken as the greater of:

-

P

tk kN/m2 (Deep Tank, if applicable), see

Vol 1, Pt 7, Ch 2, 5.1 Deck structures (DK) 5.1.4

-

P

da kN/m2 (WT subdivision, only if applicable and for loading

conditions which represent damaged situations), see

Vol 1, Pt 7, Ch 2, 5.1 Deck structures (DK) 5.1.4

-

5,0 (minimum value

for no direct loading).

4.6.3 The

design impulse pressure,  P

BG, for the bottom girder web

plating may be ignored, unless these members are subjected to sloshing

loads or similar.

P

BG, for the bottom girder web

plating may be ignored, unless these members are subjected to sloshing

loads or similar.

4.6.5 The

design vertical load, LV

BG, acting on the

web plating of bottom girders is to be based on the supported loads.

Typically these include downwards local inertial pressures, P

CD, inertial forces, [F

CD], and pillar

bulkhead loads above, L

A, all acting on the

plating of the inner bottom or the bottom girder flange and the upwards

buoyancy loads on the bottom shell plating, P

BS.

The design vertical load is to be taken as:

|

LV

BG

|

= |

–εBG (B

bg

S

bg (P

CD – P

BS )

+ [F

CD] + L

A) kN

|

where

|

ε

BG

|

= |

effectiveness of the bottom girders, i.e. the relative proportion

of the load carried by the bottom girders as opposed to other structure

such as the transverse floors |

| = |

0,5 |

|

B

bg

|

= |

mean spacing of longitudinal girders or other primary longitudinal

structure, in metres, see Note 2

|

|

S

bg

|

= |

span or length of the longitudinal girder between transverse

bulkheads, in metres |

P

BS is defined in Vol 1, Pt 7, Ch 2, 4.1 Bottom shell structures (BS) 4.1.2

P

CD is defined in Vol 1, Pt 7, Ch 2, 5.1 Deck structures (DK) 5.1.2

Note

1. For single bottom girders P

CD is

likely to be zero. In this situation B

bg =

span or length of the longitudinal girder between transverse bulkheads. P

CD should be taken as the distributed machinery

load, if it is not included in [F

CD].

Note

2. Where the girder is part of a longitudinally

stiffened bottom structure with closely spaced floors, the mean spacing B

bg may be taken as the spacing of the longitudinal

stiffeners. For grillage or transversely stiffened systems then the

spacing is to be taken as stated.

Figure 2.4.6 Loads to be applied to longitudinal bulkhead plating

Figure 2.4.7 Loads to be applied to bottom girders

4.6.6 The

design shear force for the bottom girder web plating is to include

local and global components.

-

The design global

shear force is to be taken as Q

D, as defined

in Vol 1, Pt 7, Ch 2, 3.3 Design global loads – Intact conditions or Vol 1, Pt 7, Ch 2, 3.4 Design global loads – Damaged conditions or Residual Strength Assessment (RSA) conditions. If the girder depth is reasonably

small then Q

D may be ignored.

-

The local shear

force component, QVBG, is due to the difference

between the buoyancy and the inertial forces. It acts in the vertical

direction and is to be taken as:

|

QVBG

|

= |

εBG (B

bg

S

bg (P

CD – P

BS) + [F

CD] + L A)/2 |

where

|

B

bg

|

= |

mean spacing of longitudinal girders or other primary longitudinal

structure, in metres, see Note 2.

|

4.6.7 The

design bending load for bottom girder primary member is to be taken

as:

εBG (B

bg

S

bg (P

CD – P

BS )

+ [F

CD] + L

A) kN

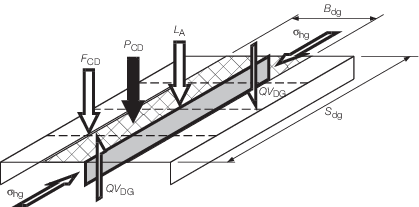

4.7 Deck girders (DG)

4.7.1 The

design normal pressure, P

DG, for deck girder

web plating may be ignored.

4.7.2 The

design impulse pressure,  P

DG, for deck girder web plating

may be ignored, unless these members are subjected to sloshing loads

or similar.

P

DG, for deck girder web plating

may be ignored, unless these members are subjected to sloshing loads

or similar.

4.7.4 The

design vertical load for deck girder webs may be ignored.

4.7.5 The

design shear force for the deck girder web plating is to include local

and global components.

-

The design global

shear force is to be taken as Q

D, as defined

in Vol 1, Pt 7, Ch 2, 3.3 Design global loads – Intact conditions or Vol 1, Pt 7, Ch 2, 3.4 Design global loads – Damaged conditions or Residual Strength Assessment (RSA) conditions. If the girder depth is reasonably

small then Q

D may be ignored.

-

The local shear

force component, QVDG, is due to the difference

between the buoyancy and the inertial forces. It acts in the vertical

direction and is to be taken as:

|

QV

DG

|

= |

εBG (B

dg

S

dg

P

CD + [F

CD]

+ L

A)/2 kN

|

where

|

εBG

|

= |

effectiveness

of the deck girders, i.e. the relative proportion of the load carried

by the deck girders as opposed to other structure such as the deck

beams |

| = |

0,5 |

|

S

dg

|

= |

span or length of the longitudinal girder between transverse

bulkheads, in metres |

|

L

A

|

= |

load, in kN, from pillar(s) above, assumed zero if there is

none over |

Figure 2.4.8 Loads to be applied to deck girders

4.7.7 The

design bending load for the deck girder primary member is to be taken

as:

εBG (B

dg

S

dg

P

CD + [F

CD]

+ L

A) kN.

4.8 Longitudinal stringers (ST)

4.8.1 This

sub-Section covers stringers supporting side shell plating, horizontal

girders on longitudinal bulkheads and also covers horizontal diaphragms

fitted between a double skin. The design loads are illustrated in Figure 2.4.9 Design loads for longitudinal stringers

4.8.2 The

design normal pressure, P

ST, for the web plating

of stringer may be ignored unless the stringer forms part of a tank

boundary or watertight subdivision, i.e. a watertight horizontal diaphragm.

In this case the design pressure is to be taken as the greater of

-

P

tk kN/m2 (Deep Tank, if applicable), see

Vol 1, Pt 7, Ch 2, 5.1 Deck structures (DK) 5.1.4

-

P

da kN/m2 (WT subdivision, only if applicable and for loading conditions

which represent damaged situations), see

Vol 1, Pt 7, Ch 2, 5.1 Deck structures (DK) 5.1.4.

-

5,0 (minimum value

for no direct loading).

4.8.3 The

design impulse pressure,  P

ST, for the web plating of stringer

may be ignored, unless these members are subjected to sloshing loads

or similar.

P

ST, for the web plating of stringer

may be ignored, unless these members are subjected to sloshing loads

or similar.

4.8.5 The

design transverse load, LT

ST, acting on the

web plating of horizontal diaphragms is to be based on the pressure

loads acting on the plating of the inner skin or longitudinal bulkhead P

LB (outwards) and the side shell P

SS (inwards). The design transverse load, LT

ST,

is to be taken as the lesser of:

-

–εST

B

st

S

st

P

SS kN

-

–εST

B

st

S

st

P

LB kN

where

|

εST

|

= |

effectiveness

of the horizontal diaphragms, i.e. the relative proportion of the

load carried by the horizontal diaphragms as opposed to other structure

such as the transverse web or normal frames |

| = |

0,5 |

|

H

st

|

= |

mean spacing, in metres, of stringers (or horizontal girders)

and other primary horizontal structure, i.e. decks or similar |

P

SS is to be taken as the

side shell pressure at the height of the stringer, see

Vol 1, Pt 7, Ch 2, 3.6 External shell pressures 3.6.1. P

SS is

to be ignored for horizontal girders attached to longitudinal bulkheads.

P

LB is to be taken as the longitudinal

bulkhead normal pressure at the height of the horizontal girder, see

Vol 1, Pt 7, Ch 2, 4.5 Longitudinal bulkhead structures (LB) 4.5.1 This is only

required for longitudinal bulkheads that form part of a deep tank

or watertight boundary.

Note Where the horizontal diaphragm is part of a longitudinally

stiffened structure with regular transverse webs, the mean spacing H

st may be based on the longitudinal spacing. For

grillage or transversely stiffened systems then the spacing is to

be taken as originally stated.

4.8.6 The

design transverse load, LT

ST, for stringers

and horizontal girders may be ignored.

4.8.7 The

design shear force, QT

ST, in the stringer

web due to hydrostatic, hydrodynamic or tank loading acts in the transverse

direction is to be taken as the greater of:

-

εST

H

st

S

st

P

SS/2

-

εST

H

st

S

st

P

LB/2

where

|

H

st

|

= |

mean spacing, in metres, of stringers (or horizontal girders)

and other primary horizontal structure, i.e. decks or similar. |

4.8.8 The

design bending load for the deck girder primary member is to be taken

as:

-

εST

H

st

S

st (P

SS – P

LB)

where

|

H

st

|

= |

mean spacing, in metres, of stringers (or horizontal girders)

and other primary horizontal structure, i.e. decks or similar. |

|