Section

8 Headers

8.1 Circular section headers

8.2 Rectangular section headers

8.2.1 The

thickness of the flat walls of rectangular section headers is to be

determined at the centre of the sides, at all the lines of holes and

at the corners. The minimum required shall be the greatest thickness

determined by the following formula:

where t, p, c and σ are as defined in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

8.2.2 The

coefficient Y for use in Vol 2, Pt 8, Ch 1, 8.2 Rectangular section headers 8.2.1 is to be determined as follows:

-

at the centre

of the side with internal width, 2m:

where

-

at a line of holes

parallel to the longitudinal axis of the header on the wall of width,

2m:

where

-

to check the effect

of the off-set on a staggered hole arrangement where the holes are

positioned equidistant from the centre line of the wall:

where

-

at the corners:

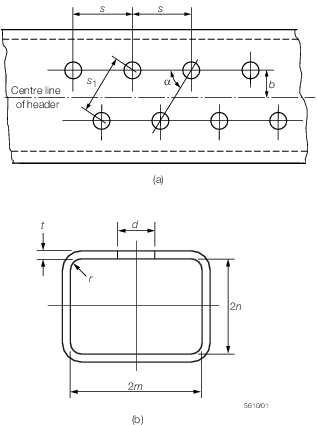

Figure 1.8.1 Rectangular section headers

8.2.3 The

ligament efficiencies, J and J

1,

are to be determined as follows:

-

for a line of

holes parallel to the longitudinal axis of the header:

-

for the diagonals:

-

for a line of

holes parallel to the longitudinal axis of the header:

or

-

for the diagonals:

or

where

|

d

|

= |

diameter

of the hole in the header, in mm |

m, s and s

1,

in mm, are as shown in Figure 1.8.1 Rectangular section headers

8.2.4 In the

case of elliptical holes the value of d to be used in

the equations for J and J

1 is

to be the inside dimension of the hole measured parallel to the longitudinal

axis of the header. For evaluating the two limiting values of d in

the equations for d

1, the value of d is

to be the inside dimension of the hole measured perpendicular to the

longitudinal axis of the header.

8.2.5 The

internal corner radius, r, is to be not less than one

third of the mean of the nominal thicknesses of the two sides, but

in no case to be less than 6,5 mm.

8.3 Toroidal furnace headers

8.3.1 The

minimum thickness of a toroidal header forming the lower end of a

waterwall furnace, and supporting the weight of the boiler and water,

is to be determined by the following formula:

where

t, p, c and σ are as defined in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

|

J

|

= |

ligament

efficiency of tube holes around toroid |

| = |

|

|

S

|

= |

pitch

of tubes around the toroid, in mm |

|

M

|

= |

|

where

|

W

|

= |

imposed

loading on each water wall tube due to the weight of the boiler and

water, in N |

|

d

|

= |

minimum

diameter of the tube hole in the toroid, in mm |

The calculation is to be performed at design pressure

using the allowable stress at saturation temperature, and also at

zero pressure using the allowable stress at 100°C.

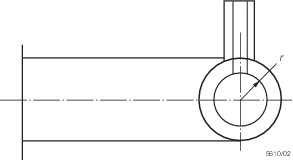

Figure 1.8.2 Toroidal furnace headers

8.4 Header ends

8.4.1 The

shape and thickness of ends forged integrally with the bodies of headers

are to be the subject of special consideration.

8.4.3 Ends

attached by welding are to be designed as follows:

where p, c and σ are as defined in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

|

t

|

= |

minimum

thickness of end plate, in mm |

|

d

i

|

= |

internal diameter of circular header or least width between

walls of rectangular header, in mm |

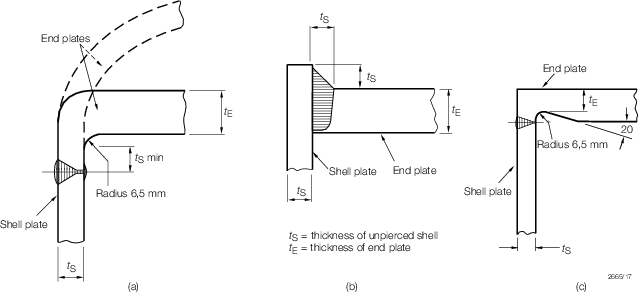

For end plates welded as shown in Figure 1.8.3 Typical methods of attachment of header end closures(a):

|

C

|

= |

0,019

for circular headers |

| = |

0,032 for rectangular headers. |

For end plates welded as shown in Figure 1.8.3 Typical methods of attachment of header end closures(b) and (c):

|

C

|

= |

0,028

for circular headers |

| = |

0,040 for rectangular headers. |

Figure 1.8.3 Typical methods of attachment of header end closures

8.4.4 Where

flat end plates are bolted to flanges attached to the ends of headers,

the flanges and end plates are to be in accordance with recognised

pipe flange standards.

8.4.5 Openings

in flat plates are to be compensated in accordance with Figure 1.2.9 Compensation for welded standpipes or branches in cylindrical shells(a) or (b), with the value

of A

1 the compensation required, calculated

as follows:

where

|

d

o

|

= |

diameter of hole in flat plate, in mm |

|

t

f

|

= |

required thickness of the flat plate in the area under consideration,

in mm, calculated in accordance with Vol 2, Pt 8, Ch 1, 8.4 Header ends 8.4.3 or Vol 2, Pt 8, Ch 1, 9.1 Stayed flat surfaces 9.1.6, as applicable,

without corrosion allowance

|

Limit D = 0,5d

o.

|