Section

3 Load cases

3.1 General

3.1.1 The

standard load cases, given in Table 2.3.1 Load combinations, are to be considered. The purpose of these load cases

is to ensure that the longitudinal, transverse and shear strength

of the hull structure complies with the acceptance criteria given

in Vol 4, Pt 1, Ch 2, 5 Acceptance criteria.

Table 2.3.1 Load combinations

| Wave direction

|

Load cases

|

Load components (see Note 1)

|

|

|

|

A. M

swh

|

B. M

sws

|

C. M

wh

|

D. M

ws

|

E. M

h

|

F. M

sph

|

G. M

sps

|

H. M

lt

|

I. M

tt

|

J. θmax

|

|

|

(1)

|

1,0

|

|

1,0

|

|

|

0,3

|

|

|

0,2

|

|

| Head

Seas

|

(2)

|

|

1,0

|

|

1,0

|

|

|

0,3

|

|

0,2

|

|

|

|

(3)

|

1,0

|

|

0,1

|

|

|

1,0

|

|

0,2

|

|

|

| Beam

Seas

|

(4)

|

|

1,0

|

|

0,1

|

|

|

1,0

|

0,2

|

|

|

| Oblique Seas

|

(5)

|

(see Note 2)

|

|

|

0,3

|

0,4

|

|

1,0

|

0,3

|

|

|

|

(6)

|

(see Note 2)

|

|

|

1,0

|

0,4

|

|

|

0.2

|

|

|

|

(7)

|

1,0

|

|

|

0,2

|

0,2

|

0,6

|

|

|

1,0

|

|

|

|

(8)

|

|

1,0

|

|

|

|

|

|

|

|

1,0

|

Note

1. For each load case the load components

give the proportion of the Rule moments to be applied. All moments

should be positive.

Note

2. The still water bending moment to be

used is that which results in the highest stress for the load case

under consideration.

|

3.2 Load cases Global model

3.2.1 The

load cases, 18, as described in Table 2.3.1 Load combinations, are to be comprised of the proportion of global load

components as indicated. In each load case, one of the load components

is maximised. The load components may be combined by superposition.

3.3 Load cases Local model

3.3.1 In general,

all load cases specified in Table 2.3.1 Load combinations are to be investigated to identify areas that require

local fine mesh analysis.

3.3.2 The

fine mesh analysis can be carried out by means of separate local finite

element models, in conjunction with the boundary conditions obtained

from the global coarse mesh model. Alternatively, fine mesh zones

may be incorporated into the global coarse mesh model.

3.3.3 Where

appropriate, secondary loads such as pressure loads are to be applied

in conjunction with the boundary displacements obtained from the global

model.

3.4 Component A Still water loads, hog - Component B

Still water loads, sag

3.4.1 The

still water loads are to be applied to the global finite element model

regardless of whether Rule loads are being applied or loads calculated

by direct calculation.

3.4.2 Hog

and sag still water load cases are to be analysed fulfilling the following

criteria:

-

Ship upright and

at or near to the maximum draught.

-

The still water

bending moment cases are to approximate, as far as is possible, the

assigned, or specified, permissible still water bending moment condition

distributions. It may only be necessary to include one loading condition;

if there is not a large variation in the deadweight distribution.

3.4.3 The

following still water loads are to be included:

-

Self weight

as generated from the modelled hull structure, suitably factored to

achieve the specified steel weight, including the position of the

LCG. In this respect, it may be useful to divide the model longitudinally

into a number of material zones, each of which can have a separate

factored value for the steel density.

-

Machinery,

outfit and other equipment all major items to be applied

as point loads or pressure loads at the correct locations. Minor or

unknown items may be included in the steel weight.

-

Buoyancy

loads to be applied as pressure loads , ρgh,

on wetted shell elements, where h is the distance of

the element centroid below the still waterline.

-

Ballast

and fuel oil to be applied as pressure loads on tank

boundaries, based on the actual liquid head and density.

-

Containers

vertical point loads to be applied at each corner of the stack base,

whether above or below deck.

-

Cargo, payload,

passengers or vehicles as point loads, uniformly distributed

loads or pressure loads at the correct locations.

3.5 Component C Vertical wave bending moment, hog - Component

D Vertical wave bending moment, sag

3.5.1 The

vertical wave bending moment load cases are to be applied by using

a static wave balance program. Separate cases are required for the

hog and sag conditions. Each case is comprised of a wave with the

following properties:

-

A wavelength equal

to LBP

-

A wave crest amidships

for the hogging condition and a wave trough amidships for the sagging

condition

-

A sinusoidal wave

profile

-

A wave height

sufficient to induce the Rule hogging or sagging design vertical wave

bending moment (VWBM) amidships, as given in Vol 1, Pt 5, Ch 4, 2.4 Vertical wave bending moment.

3.5.2 The

wave height required to induce the required bending moment will need

to be derived by trial and error using a suitable longitudinal strength

program. The ship is to be balanced on the wave and the resulting

draught, trim and wave parameters are to be used for determination

of external pressure distribution. This wave is to be determined for

both the hog and sag condition.

3.5.3 The

pressure values to be applied should not include the pressure component

or buoyancy loads due to the still water condition.

3.6 Component E Horizontal wave bending moment

3.6.1 The

Rule horizontal bending moment distribution, as described in Figure 2.3.1 Horizontal wave moment distribution, is to be modelled by

applying longitudinal force pairs at each transverse bulkhead position

in the plane of the side shell. These loads are to be distributed

longitudinally along the depth of the side hull structure or of the

centre hull structure at the forward and aft ends where the side hull

structure has terminated. When integrated along the ship length, the

incremental moment couples are to generate the Rule horizontal wave

bending moment distribution specified in Vol 1, Pt 5, Ch 4, 2.6 Horizontal bending moment.

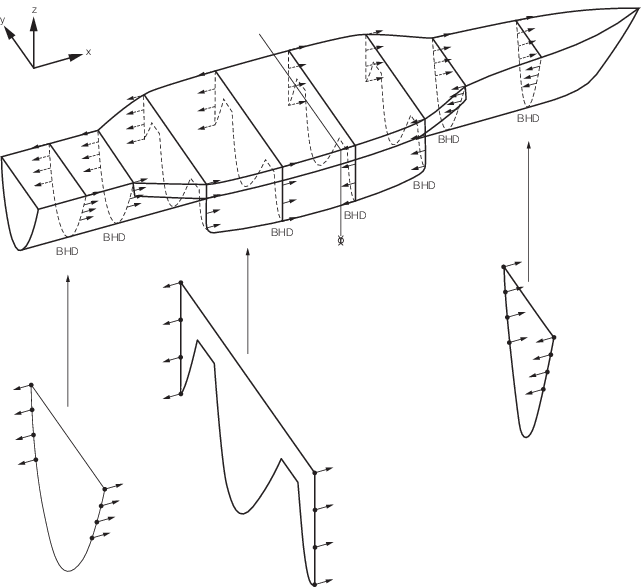

Figure 2.3.1 Horizontal wave moment distribution

3.7 Component F Splitting moment, hog - Component G

Splitting moment sag

3.7.1 The

splitting moment occurs when the waves force the side hulls away from

(sag) or towards (hog) the centre hull, resulting in stresses in the

cross-deck structure.

3.7.2 The

splitting moment may be achieved by applying simplified line loads,

in the directions depicted in Figure 2.3.2 Splitting moment, hog for hog and Figure 2.3.3 Splitting moment, sag for

sag, at the following locations:

-

A line load is

to be applied vertically on the length of the keel of each of the

side hulls.

-

A line load is

also to be applied transversely, near the keel in way of supporting

structure, along the length of the outboard side of both side hulls.

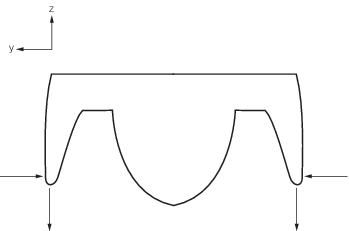

Figure 2.3.2 Splitting moment, hog

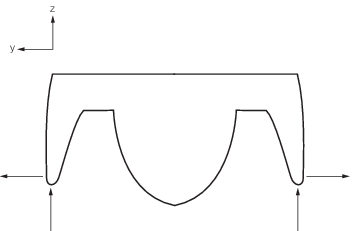

Figure 2.3.3 Splitting moment, sag

3.7.3 The

magnitude of the distributed loads should be determined so that the

resulting splitting moment distribution along the cross-deck is equal

to that specified in Vol 1, Pt 5, Ch 4, 3.1 Splitting moment.

3.7.4 Alternatively,

uniformly distributed loads may be applied to the side hulls in order

to achieve the Rule splitting moment distribution. In the sag case,

these loads would act on the inside of the side hulls and in the case

of the hog would act on the outside of the side hulls. The loads would

consist of a hydrostatic head, as well as a dynamic component sufficient

to generate the Rule splitting moment value.

3.8 Component H Longitudinal torsional moment

3.8.2 The

moment is to be applied as a distributed force couple on all nodes

in the 'vertical' portion of the bulkhead where it intercepts the

side shell.

3.8.3 The

torsional moment, T, required at each bulkhead position

can be calculated from:

where

|

M

Tf

|

= |

is the Rule torsional moment value midway between the bulkhead

under consideration and the next bulkhead forward |

|

M

Ta

|

= |

is the Rule torsional moment value mid-way between the bulkhead

under consideration and the next bulkhead aft. |

3.8.4 Other

proposed methods of modelling the Rule hydrodynamic torque distribution

will be specially considered.

3.9 Component I Transverse torsional moment

3.10 Component J Maximum roll

3.10.1 A

static roll angle of 30° is to be applied to the model. The draft

and trim are to be adjusted in order to balance the hydrostatic loads

and the displacement. Still water loads are to be included in this

load case. All loads subject to gravity are to be resolved into their

correct components given the heeled position of the ship.

|