Section

2 Rule structural concepts

2.1 Definition of requirements

2.2 Definition of fore end region

2.2.1 The

fore end region structure is considered to include structure forward

of the midship 0,4L region.

2.3 Definition of aft end region

2.3.1 The

aft end region structure is considered to include all structure aft

of the midship 0,4L region.

2.4 Symbols

2.4.1 The

symbols used in this Section are defined as follows:

|

z

D,

z

B

|

= |

vertical distance, in metres, from the hull

transverse neutral axis to the moulded deck line at side and to the

top of keel respectively |

|

z

ht

|

= |

vertical extent of higher tensile steel. |

2.5 Taper requirements for hull envelope

2.5.1 The

thickness of the shell envelope and strength deck plating, and the

modulus and sectional area of strength deck longitudinals are to taper

gradually from the midship region to the fore and aft ends. For the

requirements, see

Table 3.2.1 Taper requirements for hull

envelope.

2.5.2 Outside

the line of openings where higher tensile steel is used amidships

and mild steel at the ends, the equivalent mild steel midship thickness

for plating, equivalent mild steel midship deck longitudinal area

and equivalent mild steel midship total deck area, for taper purposes

are to be determined as follows:

-

Equivalent mild

steel value

-

If the higher

tensile steel plating is based on minimum thickness requirements,

then:

Equivalent mild steel midship plating thickness determined from Pt 4, Ch 1 General Cargo Ships and Pt 4, Ch 9 Double Hull Oil Tankers.

2.5.3 The

transition from higher tensile steel to mild steel is to be as shown

in Figure 3.2.2 Transition of steel grades for the forward

region. The transition in the aft region is to be similar to the forward

region.

2.5.4 Where

the higher tensile steel longitudinals extend beyond the point of

transition from higher tensile to mild steel plating, the modulus

of the composite section is not to be taken less than the required

mild steel value at the deck plate flange, and k times

the mild steel value at the higher tensile flange.

2.6 Vertical extent of higher tensile steel

2.6.1 Higher

tensile steel may be used for both deck and bottom structures or deck

structure only. Where fitted, it is to be used for the whole of the

longitudinal continuous material for the following vertical distances:

-

from the line

of deck at side

-

from the top of

keel

In the above formulŠ F

D and F

B are to be taken not less than k

L.

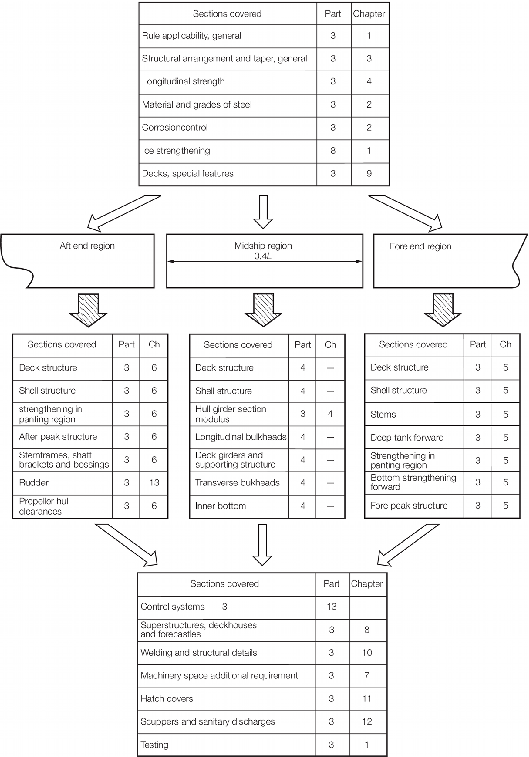

Figure 3.2.1 Rule Scantlings - Schematic layout of requirements

Table 3.2.1 Taper requirements for hull

envelope

| Item

|

Location

|

Requirement

|

| Plating

|

| (1)

|

Shell

envelope plating,

see Notes 1 and 2

|

Fore and aft ends

|

The

thickness, in mm, is to be the greater of the following:(a)

(see Note 3) (see Note 3)

|

|

|

(b)

|

| (2)

|

Strength deck plating,

see Notes 1 and

2

|

Fore and

aft ends

|

The thickness, in mm, is

to be the greater of the following:

(a)

(see Note 3) (see Note 3)

|

|

|

(b)

|

| Longitudinals outside 0,4L amidships

|

| (3)

|

Strength

deck,

see Notes 1 and 2

|

Fore and aft

ends

|

MODULUSThe

section modulus in association with deck plating, in cm3, is to

be the greater of the following:

(a)

(see Note 3)

(see Note 3)

|

| (b)

As determined by Table 5.2.3 Strength/weather deck

longitudinals forward, Table 6.2.3 Strength/weather deck

longitudinals aft, and Pt 4, Ch 9 Double Hull Oil Tankers, as appropriate

|

| SECTIONAL

AREA

The deck longitudinals may be gradually tapered outside

the 0,4L midships region in association with the deck plating on

the basis of area.

|

|

The sectional area of one longitudinal without plating, in

cm2, is to be not less than the following:

(see Note 3) (see Note 3)

|

| Strength deck area

|

| (4)

|

Deck area

taper,

see Notes 1 and 2

|

Fore and aft

decks

|

The total area of

longitudinals and deck plating outside line of openings at midship region

should have a linear taper from 0,2L from midships to 0,075L

from F.P. or A.P. such that the area at 0,075L and 0,15L from

the F.P. or A.P. is not less than 30 and 50 per cent respectively of the

total midships area, see Note 3.

|

| Symbols

|

|

L, k, s, T as defined in Pt 3, Ch 5, 1.4 Symbols and definitions 1.4.1

|

|

d

|

= |

distance, in m, from 0,2L forward or aft of

amidships to the mid-length of the building block, strake, or

longitudinal under consideration |

|

|

|

|

s

1

|

= |

s, but is to be taken not less than s

b

|

|

|

t

c

|

= |

actual thickness of deck or shell plating within the

0,4L midships region |

|

|

t

e1

|

= |

basic shell end thickness for taper and is (6,5 +

0,033L) f2)  at 0,075L from the A.P. or F.P. at 0,075L from the A.P. or F.P. |

|

|

t

e2

|

= |

basic strength deck end thickness for taper and is

(5,5 + 0,02L)  at 0,075L from the A.P. or F.P. at 0,075L from the A.P. or F.P. |

|

|

t

t

|

= |

taper thickness for strength deck and shell

plating |

|

|

Z

c

|

= |

section modulus of deck longitudinal in association

with deck plating, in cm3, within the 0,4L

midships region |

|

|

Z

e

|

= |

section modulus of deck longitudinal in association

with deck plating, in cm3, at 0,075L from the

ends |

|

|

Z

t

|

= |

taper section modulus of deck longitudinal in

association with deck plating, in cm3

|

|

|

A

c

|

= |

cross-sectional area of one longitudinal without

attached plating, in cm2, within the 0,4L

midships region |

|

|

A

e

|

= |

cross-sectional area of one longitudinal without

attached plating, in cm2, at 0,075L from the ends |

|

|

A

t

|

= |

taper cross-sectional area of one longitudinal

without attached plating, in cm2

|

|

|

f

2

|

= |

factor to be taken as:

but need not be taken greater

than 1. L/T is not to be taken greater than 25. but need not be taken greater

than 1. L/T is not to be taken greater than 25.

|

|

|

|

Note

2. The taper requirement does not apply

to container ships or open type ships, see

Pt 3, Ch 4, 2.3 Open type ships, where the requirements of Pt 4, Ch 8, 3.2 Longitudinal strength are applicable, nor to fast cargo

ships where the requirements of Pt 4, Ch 1, 3 Longitudinal strength are applicable. See

also

Pt 3, Ch 4, 5 Hull bending strength for hull section modulus

requirement away from the midship area.

|

|

|

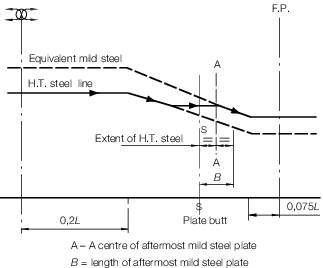

Figure 3.2.2 Transition of steel grades

2.7 Grouped stiffeners

2.7.1 Where

stiffeners are arranged in groups of the same scantling, the section

modulus requirement of each group is to be based on the greater of

the following:

-

the mean value

of the section modulus required for individual stiffeners within the

group,

-

90 per cent of

the maximum section modulus required for individual stiffeners within

the group.

2.8 Rounding policy for plate thickness

2.8.1 Where plating thicknesses as determined by the Rules are required to be rounded, then

this should be carried out to the nearest half millimetre, with thicknesses 0,75 mm

and 0,25 mm being rounded up.

For example,

- for 10,75 ≤ t < 11,25 mm, the Rule required

thickness is 11,0 mm;

- for 11,25 ≤ t < 11,75 mm, the Rule required

thickness is 11,5 mm.

|