Section

3 Stress analysis model

3.1 General

3.2 Stress determination in primary members

3.2.1 Primary

members are major structural members and provide support to decks,

major equipment, etc. and also control the cross-sectional and longitudinal

shape between decks, side shell and bulkheads. The major primary members

are listed in the paragraphs below.

3.2.2 The

following structural items are classed as longitudinal primary members:

- Double bottom girders with attached bottom shell and inner bottom

plating.

- Single bottom girders with attached bottom shell plating.

- Deck girders.

- Longitudinal stringers with attached side shell or longitudinal

bulkhead plating.

- Horizontal diaphragms with attached side shell and inner skin

plating.

3.2.3 The

following structural items are classed as vertical primary members:

- Deep web frames supporting the side shell or bulkheads including

attached plating.

- Double skin web frames including the attached side shell and inner

skin plating.

- Deep vertical bulkhead stiffeners.

3.2.4 The

following structural items are classed as transverse primary members:

- Double bottom floors with bottom shell and inner bottom plating.

- Single bottom floors with bottom shell plating.

- Deep deck or transverse beams with attached deck plating.

- Double skin deck beam with attached upper and lower deck plating.

- Transverse bulkhead stringers with attached bulkhead plating.

3.2.5 Primary

members support the secondary members and can be considered to act

independently of the secondary members. They need to be considered

as a large beam supporting local loads with the global and local membrane

stresses in the attached plating.

3.2.7 The

stresses in primary members are to be derived using the recommended

equations and stiffener end conditions given in Table 3.3.1 Stress determination in primary

members The stress components

used in deriving the primary member stresses are given below.

Table 3.3.1 Stress determination in primary

members

| Stress direction

|

Stress equation

|

Stiffener end

condition

|

Notes

|

| Longitudinal primary members

|

| σx

|

σx = σhg + σxb N/mm2

|

Built in

|

Applicable to the flange and the

attached plating

|

| σy

|

σy = σyg N/mm2 (attached to deck

plating)

σy = σxv N/mm2

(attached to side shell or long bhd plating)

|

N.A.

|

Only applicable to the attached

plating

|

| τxy

|

τxy is to be taken as the shear stress for the attached

plating, see

Vol 1, Pt 7, Ch 3, 3.3 Stress determination in primary/secondary systems or Vol 1, Pt 7, Ch 3, 3.4 Stress determination in grillage systems

|

—

|

Only applicable to the attached

plating

|

| Transverse primary members

|

| σx

|

σx = σyg + σxb N/mm2

|

Built in

|

Applicable to the

flange and the attached plating

|

| σy

|

σy = σhg N/mm2

(attached to deck plating)

σy = σxv

N/mm2

(attached to transverse bulkhead plating

|

N.A.

|

Only

applicable to the attached plating

|

| τxy

|

τxy is to be taken as the shear stress for the

attached plating, see

Vol 1, Pt 7, Ch 3, 3.3 Stress determination in primary/secondary systems or Vol 1, Pt 7, Ch 3, 3.4 Stress determination in grillage systems

|

—

|

Only applicable to

the attached plating

|

| Vertical primary members

|

| σx

|

σx = σxv + σxb N/mm2

|

Built in

|

Applicable to the

flange and the attached plating

|

| σy

|

σy = σhg N/mm2 (attached to

side shell or long bhd plating)

σy =

σyg N/mm2 (attached to transverse bulkhead plating)

|

N.A.

|

Only applicable to

the attached plating

|

| τxy

|

τxy is to be taken as the shear stress for the

attached plating, see

Vol 1, Pt 7, Ch 3, 3.3 Stress determination in primary/secondary systems or Vol 1, Pt 7, Ch 3, 3.4 Stress determination in grillage systems

|

—

|

Only applicable to

the attached plating

|

| Symbols

|

| σx is along the span of the primary member

|

σhg,

σyg and σxv are given in Vol 1, Pt 7, Ch 3, 3.2 Stress determination in primary members 3.2.10

|

| σy is in the normal direction to

the span in the attached plating

|

σxb is given in Vol 1, Pt 7, Ch 3, 3.2 Stress determination in primary members 3.2.12

|

| τxy is only

applicable to the attached plating

|

|

|

|

|

3.2.8 When

it is considered that a different combination of stresses is likely

to produce higher stresses, then this combination should be considered.

3.2.9 In general,

a primary member will be subject to the following loads:

- In-plane or axial loading as a consequence hull girder loads,

transverse loading due to side shell pressure loads or vertical support

loads.

- Bending loads due to the member supporting out of plane external

and internal pressures and equipment or cargo loadings.

3.2.10 The

in-plane or axial loading in the primary member attached plating and

flanges is to be taken as the membrane stress derived in accordance

with the following:

-

For longitudinally

effective primary members:

σhg is the longitudinal stress due to hull girder

bending

-

For primary

members in the transverse direction:

σyg is the membrane stress due to a global load

of LT

-

For primary

members in the vertical direction:

σxv is the membrane stress due to a vertical

load of LV

where

|

z

na

|

= |

vertical distance above the neutral axis of the structural member

under consideration, in metres |

|

A

|

= |

is the total area,

in cm2, of the primary member including the full breadth

of attached plating

|

LT and LV are defined in Vol 1, Pt 7, Ch 2, 2.1 Nomenclature 2.1.1.

3.2.12 The

stresses in the flange and attached plating due to bending of the

primary member are to be derived as follows:

|

σxb

|

= |

is

the stress in the plating due to bending of the primary member beam/plate

combination under lateral pressure loading or lateral inertial loads |

|

σxb

|

= |

is

to be taken as the negative value of σsp, i.e. σsp,c, when the primary member axial stress is negative, similarly

the positive value of σsp, i.e. σsp,t,

is to be taken when is the axial stress positive

When

appropriate the σxb value is to be the summation of

stresses as result of inertial pressures and inertial point loads

|

3.2.14 The

total equivalent stress or von Mises stress, σvm, is

to be derived using the following formula:

3.3 Stress determination in primary/secondary systems

3.3.1 The

primary members support the secondary members. The secondary stiffeners

transfer the lateral loads into the primary members.

3.3.2 An example

of a primary/secondary plating and stiffener system is as follows:

a longitudinal spacing of 600 mm and a transverse spacing of 2000

mm with the transverse stiffeners having a section inertia value of

five times the secondary longitudinal stiffeners.

3.3.3 In a

primary/secondary system it is normally sufficient to consider the

secondary stiffeners as acting independently of the primary stiffeners.

Hence the total stress analysis can ignore the effects of bending

of the primary members.

3.3.4 The

total stress analysis can be based on the plating between the primary

transverse members and need only consider plating membrane stresses

and bending stresses in secondary members.

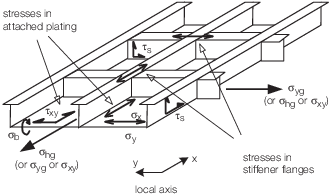

3.3.5 The

stresses in the plating of a primary/secondary plating system are

to be derived using the recommended equations and stiffener end conditions

given in Table 3.3.2 Stress determination in

longitudinal plating of primary/secondary systems, e.g., decks and longitudinal

bulkheads and Table 3.3.3 Stress determination in transverse

plating of primary/secondary systems, e.g., transverse bulkheads The stresses in the flanges

of panel stiffeners are given in Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.6 using

the conditions given in Vol 1, Pt 7, Ch 3, 3.2 Stress determination in primary members 3.2.3 and Vol 1, Pt 7, Ch 3, 3.3 Stress determination in primary/secondary systems 3.3.3 The stresses and nomenclature

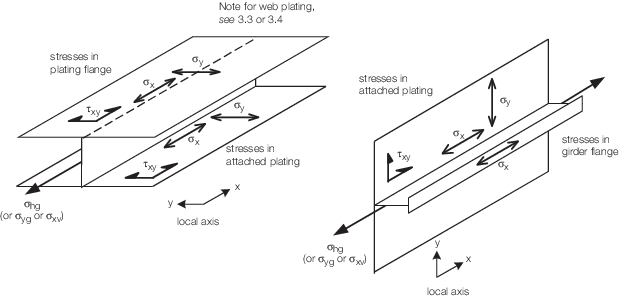

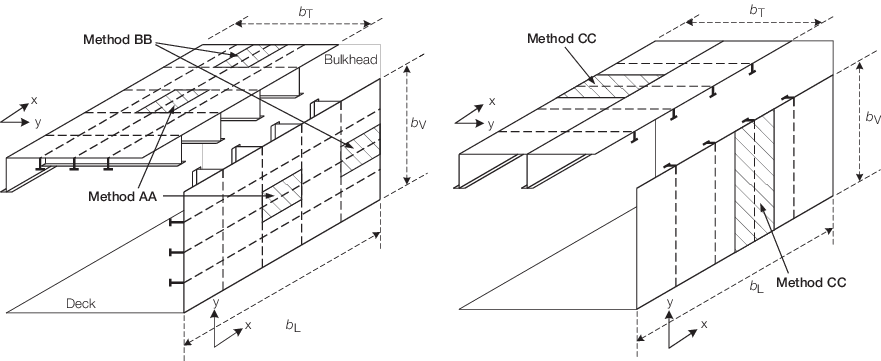

are shown in Figure 3.3.1 Definition of stresses in a primary/secondary stiffened panel

Table 3.3.2 Stress determination in

longitudinal plating of primary/secondary systems, e.g., decks and longitudinal

bulkheads

| Stress direction

|

Stress equation

|

Stiffener end condition

|

| Plating

|

Stiffener flange

|

|

Method AA Longitudinal secondary stiffeners

|

| σx

|

Equation A

σx = σxg + σxb

N/mm2

|

σsx,

see

Vol 1, Pt 7, Ch 3, 3.11 Derivation of total stresses in stiffener flanges

|

Built in

|

| σy

|

Equation D

σy = σyg N/mm2

|

N.A.

|

N.A.

|

| τxy

|

Equation E

|

δs,

see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.4

τs, see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.5

|

|

|

Method BB Longitudinal secondary stiffeners adjacent to bulkhead

|

| σx

|

Equation A

σx = σxg + σxb

N/mm2

|

|

Edge end built in.

Other end free to deflect,no rotation, see Note 2

|

| σy

|

Equation D

σy = σyg N/mm2

|

N.A.

|

N.A.

|

| τxy

|

Equation E

|

δs,

see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.4

τs, see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.5

|

|

|

Method CC Transverse secondary stiffeners

|

| σx

|

Equation B

σx = σxg N/mm2

|

N.A.

|

N.A.

|

| σy

|

Equation C

σy = σyg +

σybN/mm2

|

σsx, see

Vol 1, Pt 7, Ch 3, 3.11 Derivation of total stresses in stiffener flanges

|

Built

in

|

| τxy

|

Equation E

|

δs, see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.4

τs, see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.5

|

|

Note

2. Alternatively the deflection from the

transverse member over its full span, excluding the support from

longitudinal stiffeners, may be applied.

|

|

Table 3.3.3 Stress determination in transverse

plating of primary/secondary systems, e.g., transverse bulkheads

| Stress direction

|

Stress equation

|

Stiffener end condition

|

| Plating

|

Stiffener flange

|

|

Method DD Vertical secondary stiffeners

|

| σx

|

Equation H

σx = σxg + σxb

N/mm2

|

σsx,

see

Vol 1, Pt 7, Ch 3, 3.11 Derivation of total stresses in stiffener flanges

|

N.A.

|

| σy

|

Equation G

σy = σyg N/mm2

|

N.A.

|

Built in

|

| τxy

|

Equation J

|

δs,

see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.4

τs, see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.5

|

|

|

Method EE Horizontal secondary stiffeners

|

| σx

|

Equation I

σx = σxv N/mm2

|

N.A.

|

N.A.

|

| σy

|

Equation F

σy = σyg + σyb

N/mm2

|

σsx,

see

Vol 1, Pt 7, Ch 3, 3.11 Derivation of total stresses in stiffener flanges

|

Built in

|

| τxy

|

Equation J

|

δs,

see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.4

τs, see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.5

|

|

|

|

|

Figure 3.3.1 Definition of stresses in a primary/secondary stiffened panel

3.3.6 When

it is considered that a different combination of stresses is likely

to produce higher stresses, then this combination should be considered.

3.4 Stress determination in grillage systems

3.4.1 A grillage

system of plating and stiffeners is one where the bending stiffness

of the orthogonal stiffeners are similar in magnitude and the orthogonal

stiffeners work together to support the applied loads. The grillage

system is in turn supported by primary structural items such as deep

girders, deep transverse beams or bulkheads.

3.4.2 An example

of a grillage system is as follows: plating supported by a longitudinal

spacing of 600 mm and a transverse spacing of 1500 mm with the transverse

stiffeners having an section inertia value of 1,5 times the longitudinal

stiffeners.

3.4.3 Normally

it is necessary to use direct calculations to evaluate the stresses

within a grillage plating system. However, it may be sufficient to

consider the stiffeners perpendicular to an edge of the grillage panel

as acting independently of the grillage system. See

Table 3.3.4 Stress determination in

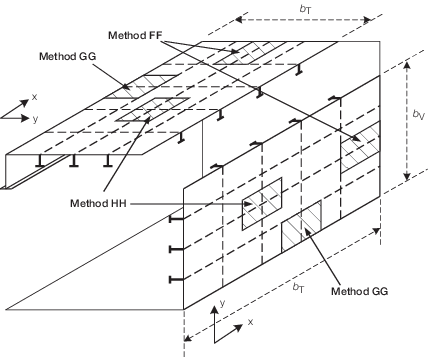

longitudinal plating of grillage systems, e.g., decks and longitudinal

bulkheads and Methods FF and GG

in the attached figure, also Methods II and JJ in Table 3.3.5 Stress determination in transverse

plating of grillage systems, e.g., transverse bulkheads..

Table 3.3.4 Stress determination in

longitudinal plating of grillage systems, e.g., decks and longitudinal

bulkheads

| Stress direction

|

Stress equation

|

Stiffener end condition

|

| Plating

|

Stiffener flange

|

|

Method FF At the fore and aft edges of a grillage panel

|

| σx

|

Equation A

σx = σxg + σxb

N/mm2

|

σsx,

see

Vol 1, Pt 7, Ch 3, 3.1 General 3.1.1

|

Edge end built

in. Other end free to deflect, no rotation, see Note 2

|

| σy

|

Equation D

σy = σyg N/mm2

|

N.A.

|

N.A.

|

| τxy

|

Equation E

|

δs,

see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.4

τs, see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.5

|

|

|

Method GG At the port and starboard edges of a grillage panel

|

| σx

|

Equation B

σx = σxg N/mm2

|

N.A.

|

N.A.

|

| σy

|

Equation C

σy = σyg + σyb

N/mm2

|

σsx,

see

Vol 1, Pt 7, Ch 3, 3.11 Derivation of total stresses in stiffener flanges

|

Edge end built in.

Other end free to deflect, no rotation, see Note 3

|

| τxy

|

Equation E

|

δs,

see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.4

τs, see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.5

|

|

|

Method HH At the centre of a grillage panel

|

| σx

|

Equation A

σx = σxg + σxb

N/mm2

|

σsx,

see

Vol 1, Pt 7, Ch 3, 3.11 Derivation of total stresses in stiffener flanges

|

Built in

|

| σy

|

Equation C

σy = σyg +

σybN/mm2

|

σsx,

see

Vol 1, Pt 7, Ch 3, 3.11 Derivation of total stresses in stiffener flanges

|

Built in

|

| τxy

|

Equation E

|

δs,

see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.4

τs, see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.5

|

|

Note

2. Alternatively the deflection from the

longitudinal member over its full span, excluding the support from

transverse stiffeners, may be applied.

Note

3. Alternatively the deflection from the

transverse member over its full span, excluding the support from

longitudinal stiffeners, may be applied.

|

|

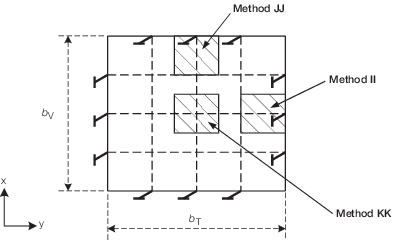

Table 3.3.5 Stress determination in transverse

plating of grillage systems, e.g., transverse bulkheads.

| Stress direction

|

Stress equation

|

Stiffener end condition

|

| Plating

|

Stiffener flange

|

|

Method II Horizontal stiffeners at the port and starboard edges of a

grillage panel

|

| σx

|

Equation I

σx = σxv N/mm2

|

N.A.

|

Edge end Built

in.

Other end free to deflect, no rotation, see Note

2

|

| σy

|

Equation F

σy = σyg + σyb

N/mm2

|

σsx,

see

Vol 1, Pt 7, Ch 3, 3.11 Derivation of total stresses in stiffener flanges

|

N.A.

|

| τxy

|

Equation J

|

δs,

see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.4

τs, see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.5

|

—

|

|

Method JJ Vertical stiffeners at the top and bottom edges of a

grillage panel

|

| σx

|

Equation H

σx = σxv + σxb

N/mm2

|

σsx,

see

Vol 1, Pt 7, Ch 3, 3.11 Derivation of total stresses in stiffener flanges

|

N.A.

|

| σy

|

Equation G

σy = σyg N/mm2

|

N.A.

|

Edge end built in.

Other end free to deflect, no rotation, see Note 3

|

| τxy

|

Equation J

|

δs,

see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.4

τs

see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.5

|

—

|

|

Method KK At the centre of a grillage panel

|

| σx

|

Equation H

σx = σxv + σxb

N/mm2

|

σsx,

see

Vol 1, Pt 7, Ch 3, 3.11 Derivation of total stresses in stiffener flanges

|

Built in

|

| σy

|

Equation F

σy = σyg + σyf +

σyb N/mm2

|

σsx,

see

Vol 1, Pt 7, Ch 3, 3.11 Derivation of total stresses in stiffener flanges

|

Built in

|

| τxy

|

Equation J

|

δs,

see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.4

τs, see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.5

|

—

|

Note

2. Alternatively the deflection of the

vertical member over its full span, excluding the support from

horizontal stiffeners, may be applied instead of the free to deflect

condition.

Note

3. Alternatively the deflection from the

horizontal member over its full span, excluding the support from

vertical stiffeners, may be applied instead of the free to deflect

condition.

|

|

3.4.4 The

bending stresses in the edge stiffeners may be evaluated on the basis

of encastre at the edge of the grillage panel and no rotation and

free to deflect at the intersection with the first orthogonal stiffener.

3.4.5 In this

case, the total stress analysis is to be based on the membrane stress

in the plating of the grillage panel and consider the bending stresses

in the middle stiffener perpendicular to the edge of the panel.

3.4.6 It will

be necessary to derive the total stress at the edge of the panel for

each stiffener direction.

3.4.7 The

total stress in the centre of the grillage panel should also be checked.

In this case it is necessary to consider the stresses in the plate

due to bending of the stiffener in each direction as well as the plating

stresses due to membrane loads.

3.4.8 The

stresses in the plating of a grillage plating system are to be derived

using the recommended equations and stiffener end conditions given

in Table 3.3.4 Stress determination in

longitudinal plating of grillage systems, e.g., decks and longitudinal

bulkheads and Vol 1, Pt 7, Ch 3, 3.3 Stress determination in primary/secondary systems 3.3.5 The stresses in the flanges

of the panel stiffener are given by Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.6, using the conditions given in Table 3.3.4 Stress determination in

longitudinal plating of grillage systems, e.g., decks and longitudinal

bulkheads and Table 3.3.5 Stress determination in transverse

plating of grillage systems, e.g., transverse bulkheads.. The

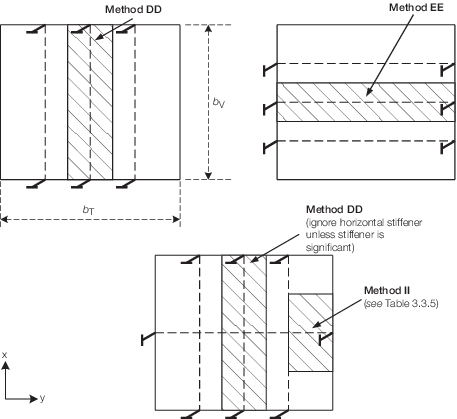

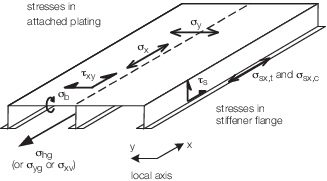

stresses are illustrated in Figure 3.3.2 Definition of stresses in a grillage stiffened panel

Figure 3.3.2 Definition of stresses in a grillage stiffened panel

3.4.9 When

it is considered that a different combination of stresses is likely

to produce higher stresses, then this combination should be considered.

3.5 Derivation of the combined longitudinal stress on panels subjected

to hull girder bending

3.5.2

Equation

A is used for grillage systems or plating systems with the

secondary stiffeners orientated in the longitudinal direction. For

these systems, the stress in the plating/stiffener combination due

to local bending needs to be considered in addition to the membrane

stresses due to hull girder bending. The stress components in Equation

A are given below.

3.5.3

Equation

B is used for plating systems with the secondary stiffeners

orientated in the transverse (or vertical) direction. For these systems

only the longitudinal stress due to hull girder bending needs to be

considered.

3.5.4 The

longitudinal stress components associated with Equations A and B are

given below:

|

σxg

|

= |

is

the longitudinal membrane stress due to hull girder bending |

|

σxb

|

= |

is

the stress in the plating due to bending of the longitudinal stiffener/plate

combination under lateral pressure loading or lateral inertial loads

Normally σxb is to be taken as the negative

value of σsp, i.e. σsp,c, when the hull

girder bending stress σxg is negative, similarly the

positive value of σsp, i.e. σsp,t, is

to be taken when σxg is positive, see

Figure 3.2.2 Bending stresses in stiffener beam However, there may be

cases where it is necessary to consider the opposite situation

When

appropriate, the σxb value is to be the summation of

stresses as result of inertial pressures and inertial point loads

|

|

z

na

|

= |

vertical distance above the neutral axis of the structural member

under consideration, in metres |

3.6 Derivation of the combined transverse stress acting on panels

subjected to hull girder bending

3.6.2

Equation

C is used for grillage systems or plating systems with the

secondary stiffeners orientated in the transverse direction. For these

systems, the stress in the plating/stiffener combination due to local

bending needs to be considered in addition to membrane stresses due

to global transverse loading. The stress components in Equation C

are given below.

3.6.3

Equation

D is used for plating systems with the secondary stiffeners

orientated in the longitudinal direction. For these systems, only

membrane stress due to global transverse loading needs to be considered.

3.6.4 The

transverse stress components associated with equations C and D are

given below:

|

σyg

|

= |

is

the membrane stress due to global transverse loading |

|

σyb

|

= |

is

the stress in the plating due to bending of the longitudinal stiffener/plate

combination under lateral pressure loading or lateral inertial loads

Normally, σyb is to be taken as the negative

value of σsp, i.e. σsp,c, when the global

transverse stress σyg is negative, similarly the positive

value of σsp, i.e. σsp,t, is to be taken

when σyg is positive, see

Figure 3.3.2 Definition of stresses in a grillage stiffened panel. However, there may be

cases where it is necessary to consider the opposite situation.

When appropriate, the σyb value is to be the

summation of stresses as result of inertial pressures and inertial

point loads

|

|

t

p

|

= |

thickness of plating, in mm |

|

b

L

|

= |

breadth of plating, in metres, over which the load LT applies.

Normally, this is the distance between decks or the height of the

plating panel.

|

3.7 Derivation of the total shear stress

3.7.1

Equation

E is used to derive the total shear stress in the plating for

all plating systems.

3.7.2 The

shear stress components associated with Equation E are given below:

|

|Q| |

= |

denotes the absolute value of

parameter Q

|

hg

hg

|

= |

|

|

Q

D

|

= |

is global hull girder shear force, in kN. This will be zero

for all transverse plating systems |

A

z,  hg and δi are given in Vol 1, Pt 6, Ch 4, 2.3 Shear strength 2.3.6

hg and δi are given in Vol 1, Pt 6, Ch 4, 2.3 Shear strength 2.3.6

NOTE

All shear force loads are to be

assumed positive.

3.8 Derivation of the combined transverse stress acting on transversely

orientated panels

3.8.2

Equation

F is used for grillage systems or plating systems with the

secondary stiffeners orientated in the transverse direction.

3.8.3

Equation

G is used for plating systems with the secondary stiffeners

orientated in the vertical direction.

3.9 Derivation of the combined vertical stress acting on transversely

orientated panels

3.9.2

Equation

H is used for grillage systems or plating systems with the

transverse secondary stiffeners orientated in the vertical direction.

3.9.3

Equation

I is used for plating systems with the secondary stiffeners

orientated in the transverse direction.

3.9.4 The

vertical stress components associated with Equations H and I are given

below:

|

σxv

|

= |

is

the membrane stress due to vertical loading |

|

|

= |

N/mm2 N/mm2

|

|

σxb

|

= |

is

the stress in the plating due to bending of the longitudinal stiffener/plate

combination under lateral pressure loading or lateral inertial loads

Normally σxb is to be taken as the negative

value of σsp, i.e. σsp,c, when the vertical

stress σxv is negative, similarly the positive value

of σsp, i.e. σsp,t, is to be taken when

σxv is positive, see

Vol 1, Pt 7, Ch 3, 3.2 Stress determination in primary members 3.2.2. However, there may be cases

where it is necessary to consider the opposite situation

When

appropriate, the σxb value is to be the summation of

stresses as result of inertial pressures and inertial point loads

|

where

|

t

p

|

= |

thickness of plating, in mm |

|

b

T

|

= |

breadth of plating, in metres, over which the load LV applies.

Normally, this is the distance between the side shell(s) or longitudinal

bulkheads but it is to be reduced for the presence of large openings.

|

3.10 Derivation of the total shear stress on transversely orientated

panels

3.10.1

Equation

J is used to derive the total shear stress in any plating system

which is not subjected to global hull girder shear force.

3.10.2 The

shear stress components associated with Equation J are given below:

NOTE

All shear force loads are to be

assumed positive.

3.11 Derivation of total stresses in stiffener flanges

3.11.1 The

total compressive and tensile stresses in stiffener flanges, σsx, are given by the following:

|

σsx,c

|

= |

σax + σsf,c N/mm2 (compressive)

|

|

σ

sx,t

|

= |

σax + σsf,t N/mm2 (tensile)

|

where

|

σax

|

= |

is the axial stress

in the stiffener at the combined stiffener plate neutral axis, this

is normally to be taken as the membrane stress in the plating, i.e.

σxg, σyg or σxv depending

on the orientation of the stiffener, see

Vol 1, Pt 7, Ch 3, 3.5 Derivation of the combined longitudinal stress on panels subjected to hull girder bending 3.5.4, Vol 1, Pt 7, Ch 3, 3.6 Derivation of the combined transverse stress acting on panels subjected to hull girder bending

3.6.4 or Vol 1, Pt 7, Ch 3, 3.9 Derivation of the combined vertical stress acting on transversely orientated panels 3.9.4

|

|

σsf,t, σsf,c

|

= |

are the tensile and compressive bending stresses the stiffener

flange, see

Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.3 and Vol 1, Pt 7, Ch 3, 2.3 Stresses in secondary and primary member stiffeners 2.3.6, using the appropriate boundary

conditions given in Vol 1, Pt 7, Ch 3, 3 Stress analysis model

|

3.11.2 These

formulae may be applied to grillage and primary/secondary stiffened

plating systems. The stresses in a stiffener beam subjected to more

than one load may be derived by adding the stresses from each load

component.

3.12 Derivation of total equivalent stress

3.12.1 The

total equivalent stress or von Mises stress, σvm, is

to be derived using the following formula:

|