Section

1 General

1.1 Application

1.2 General

1.2.1 The formulae

contained within this Chapter are to be used in conjunction with the

design loadings from Pt 5 Design and Load Criteria to determine

the Rule scantling requirements.

1.3 Direct calculations

1.3.1 Where the

craft is of unusual design, form or proportions, or where the speed

of the craft exceeds 60 knots the scantlings are to be determined

by direct calculation.

1.3.2 The requirements

of this Chapter may be modified where direct calculation procedures

are adopted to analyse the stress distribution in the primary structure.

1.4 Equivalents

1.4.1 Clasifications

Register (hereinafter referred to as 'LR') will consider direct calculations

for the derivation of scantlings as an alternative and equivalent

to those derived by Rule requirements in accordance with Pt 3, Ch 1, 3 Equivalents.

1.5 Symbols and definitions

1.6 Rounding policy for Rule plating thickness

1.6.1 Where plating

thicknesses as determined by the Rules require to be rounded then

this is to be carried out to the nearest full or half millimetre,

with thicknesses 0,75 and 0,25 being rounded up.

1.7 Dimensional tolerance

1.7.1 Dimensional

tolerances for materials are to be in accordance with Ch 8 Aluminium Alloysof the Rules for the Manufacture,

Testing and Certification of Materials (hereinafter referred

to as the Rules for Materials), or an acceptable National or International

Standard.

1.7.2 The under

thickness tolerance acceptable for classification is to be considered

as the lower limit of a range of thickness tolerance which could be

found in the normal production of a conventional rolling mill manufacturing

material, on average, to the nominal thickness.

1.7.4 The minus

tolerance on sections (except for wide flats) is to be in accordance

with a National or International Standard.

1.7.5 The thickness

of plates and strip is to be measured at random locations whose distance

from an edge is to be at least 25 mm. Local surface depressions resulting

from imperfections and ground areas resulting from the elimination

of defects may be disregarded provided that they are in accordance

with the requirements of a National or International Standard.

1.7.6 The responsibility

for maintaining the required tolerances and making the necessary measurements

rests with the manufacturer/Builder. Occasional checking by the Surveyor

does not absolve the manufacturer/Builder from the responsibility.

1.8 Material properties

1.8.1 The basic

grade of aluminium alloy is taken as marine grade 5083-0 with the

following mechanical properties:

|

|

N/mm2

|

| 0,2 per cent proof stress

(minimum)

|

125

|

| Tensile strength

|

260

|

| Modulus of elasticity

|

69 x 103

|

1.8.2 Where other

alloy grades with differing mechanical properties are to be used,

due allowance is given in the determination of the Rule requirement

for plating thickness, section modulus, inertia and cross-sectional

area by use of the following correction factors:

-

Plating thickness

factor =

-

Section modulus and

cross section area factor = k

a

where k

a is as defined in Pt 7, Ch 3, 1.5 Symbols and definitions 1.5.1.

1.9 High strength sheet and plate

1.9.1 Particular

attention is to be given to the welding procedures for the welding

of high strength sheet and plate. The 0,2 per cent yield strength

values in the welded condition will, in general, be significantly

less than in the unwelded condition. These reduced values are to be

used in the determination of the Rule scantlings.

1.10 High strength extrusions

1.10.1 The requirements

of Pt 7, Ch 3, 1.9 High strength sheet and plate are to be complied with.

However, special consideration will be given to the use of un-welded

strength properties for use in the determination of the Rule scantlings

provided that suitable compensation is provided in way of welding

on the face of the stiffener. This compensation can be provided by

butt-straps or other acceptable arrangements, see also

Pt 7, Ch 2, 4.25 Extruded `planking'.

1.10.2 The application

of high strength extrusions is in general limited to superstructures,

deckhouses, decks and bulkheads. Special consideration will be given

to their use in other areas.

1.10.3 Butt

welds and seams are to be carefully positioned clear of areas of high

stress and where practicable are to be orientated parallel to the

direction of the main stresses.

1.11 Effective width of attached plating

1.11.1 The effective

geometric properties of rolled or built sections are to be calculated

directly from the dimensions of the section and associated effective

area of attached plating. Where the web of the section is not normal

to the actual plating, and the angle exceeds 20o, the properties

of the section are to be determined about an axis parallel to the

attached plating.

1.11.3 The effective

width of attached plating to secondary members b

e is

to be taken as  but not greater than s. σa is

not to be taken as greater than 169 N/mm2 for aluminum

alloy. E, s and σa are as

defined in Pt 7, Ch 3, 1.5 Symbols and definitions 1.5.1. but not greater than s. σa is

not to be taken as greater than 169 N/mm2 for aluminum

alloy. E, s and σa are as

defined in Pt 7, Ch 3, 1.5 Symbols and definitions 1.5.1.

1.11.5 Where

primary stiffening members support areas of plating of the extruded

plank type, or the floating frame system is used, the effect of the

plating attached to the secondary stiffening members is to be ignored

when calculating the actual section modulus and inertia of the primary

stiffening members, i.e. the full section modulus and inertia are

to be provided by the primary stiffening member only, see also

Pt 7, Ch 2, 4.26 Aluminium/steel transition joints.

1.12 Other materials

1.12.1 Special

consideration will be given to the use of materials other than aluminium

alloy. Details of the type of material, the specification to which

it was manufactured and its mechanical properties are to be submitted

for appraisal.

1.13 Fibre reinforced plastic (FRP)

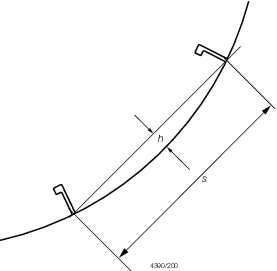

1.14 Convex curvature correction

1.14.1 The thickness

of plating as determined by the Rules may be reduced where significant

curvature exists between the supporting members. In such cases a plate

curvature correction factor may be applied:

|

γ |

= |

plate curvature

factor |

|

|

= |

1 - h/s, and is not to be taken as less than 0,7

|

|

h

|

= |

the

distance, in mm, measured perpendicularly from the chord length s (i.e.

spacing) to the highest point of the curved plating arc between the

two supports.

|

See

Figure 3.1.1 Convex curvature.

Figure 3.1.1 Convex curvature

1.15 Aspect ratio correction

1.15.1 The thickness

of plating as determined by the Rules may be reduced when the panel

aspect ratio is taken into consideration. In such cases a panel aspect

ratio correction factor may be applied:

|

β |

= |

aspect ratio

correction factor |

|

|

= |

A

R(1

- 0,25A

R) for A

R ≤

2

|

where

|

A

R

|

= |

panel aspect ratio |

|

|

= |

panel length/panel

breadth. |

1.16 Plating general

1.16.1 The requirements

for the thickness of plating, t

p, is, in general,

to be in accordance with the following:

s, γ, β, p, σa are

as defined in Pt 7, Ch 3, 1.5 Symbols and definitions 1.5.1.

1.17 Stiffening general

1.17.1 The requirements

for section modulus, inertia and web area of stiffening members are

in general to be in accordance with the following:

-

Section modulus:

p, s,  e and σa are as defined in Pt 7, Ch 3, 1.5 Symbols and definitions.

e and σa are as defined in Pt 7, Ch 3, 1.5 Symbols and definitions.

-

Inertia:

p, s,  e, and E are as defined in Pt 7, Ch 3, 1.5 Symbols and definitions 1.5.1.

e, and E are as defined in Pt 7, Ch 3, 1.5 Symbols and definitions 1.5.1.

-

Web area:

p, s,  e, and τa are as defined in Pt 7, Ch 3, 1.5 Symbols and definitions 1.5.1.

e, and τa are as defined in Pt 7, Ch 3, 1.5 Symbols and definitions 1.5.1.

1.18 Geometric properties and proportions of stiffener sections

1.18.1 From

structural stability and local buckling considerations, the proportions

of stiffening members are, in general, to be in accordance with Table 3.1.2 Stiffener proportions.

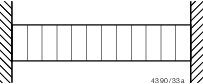

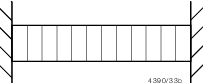

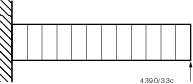

1.19 Determination of span point

1.19.1 The effective

length of span,  e, of a stiffening member is generally less

than the overall length,

e, of a stiffening member is generally less

than the overall length,  , by an amount which depends on the design of the end connections.

The span points, between which the value of , by an amount which depends on the design of the end connections.

The span points, between which the value of  e is measured, are to be determined as follows:

e is measured, are to be determined as follows:

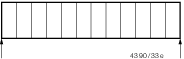

-

For rolled or built-up

secondary stiffening members:

The span point is to be taken at the point where the depth of

the end bracket, measured from the face of the secondary stiffening

member, is equal to the depth of the member, see

Figure 3.1.2 Span points. Where there is no end bracket,

the span point is to be measured between primary member webs.

-

For primary support

members:

The span point is to be taken at a point distant, b

e from the end of the member, where

where b

e, b

b, d

w and d

B are as shown in Figure 3.1.2 Span points.

1.19.2 Where

the stiffener member is inclined to a vertical or horizontal axis

and the inclination exceeds 10o, the span is to be measured

along the member.

Table 3.1.1 Section modulus, inertia and web

area coefficients

Load

Model

|

Position

|

Position

|

Web area

coefficient

|

Section modulus

coefficient

|

Inertia

coefficient

|

Application

|

| 1

|

2

|

3

|

ΦA

|

ΦZ

|

ΦI

|

| (a)

|

|

1

2

3

|

1/2

-

1/2

|

1/12

1/24

1/12

|

-

1/384

-

|

Primary

and other members where the end fixity is considered encastre

|

| (b)

|

|

1

2

3

|

1/2

-

1/2

|

1/10

1/10

1/10

|

-

1/288

-

|

Local,

secondary and other members where the end fixity is considered to be

partial

|

| (c)

|

|

1

2

3

|

5/8

-

3/8

|

1/8

9/128

-

|

-

1/185

-

|

Various

|

| (d)

|

|

1

2

3

|

1

-

-

|

1/2

-

-

|

-

-

1/8

|

Various

|

| (e)

|

|

1

2

3

|

1/2

-

1/2

|

-

1/8

-

|

-

5/384

-

|

Hatch

covers, glazing and other members where the ends are simply

supported

|

Table 3.1.2 Stiffener proportions

| Type of

stiffener

|

Requirement

|

| (1) Flat bar

|

Minimum web thickness:

|

| (2) Rolled or built sections

|

(a) Minimum web

thickness:

|

|

|

(b) Maximum unsupported face plate (or

flange) width:

|

| Symbols

|

|

t

w = web thickness of stiffener with unstiffened webs, in mm

d

w = web depth of stiffener, in mm

b

f = face plate (or flange) unsupported width, in mm

t

f = face plate (or flange) thickness, in mm

|

1.19.3 Where

the stiffening member is curved then the span is to be taken as the

effective chord length between span points.

1.19.4 Where

there is a pronounced turn of bilge, chine or the structure is significantly

pitched, the span may be measured as in Figure 3.1.2 Span points.

1.19.5 It is

assumed that the ends of stiffening members are substantially fixed

against rotation and displacement. If the arrangement of supporting

structure is such that this condition is not achieved, consideration

will be given to the effective span to be used for the stiffener.

1.20 Secondary member end connections

1.20.2 Where

bracketed end connections are fitted in accordance with these requirements,

they may be taken into account in determining the effective span of

the member.

1.21 Scantlings of end brackets

1.21.1 Where

a longitudinal strength member is cut at a primary support and the

continuity of strength is provided by brackets, the scantlings of

the end brackets are to be such that their section modulus and effective

cross-sectional area are not less than those of the member. Care is

to be taken to ensure correct alignment of the brackets on each side

of the primary member.

1.21.2 In other

cases the scantlings of the bracket are to be based on the modulus

as follows:

-

Bracket connecting

stiffener to primary member - modulus of the stiffener.

-

Bracket at the head

of a main transverse frame where frame terminates - modulus of the

frame.

-

Brackets connecting

lower deck beams or longitudinals to the main frame in the forward

0,5L

R - modulus of the frame.

-

Elsewhere - the

lesser modulus of the members being connected by the bracket.

1.21.5 The lengths, a and b of the arms are to be measured from the

plating to the toe of the bracket and are to be such that:

-

a + b ≥ 2,0 b

b

-

a ≥

0,8 b

b

-

b ≥

0,8 b

b

where a and b are the actual lengths

of the two arms of the bracket, in mm, measured from the plating to

the toe of the bracket.

b

b

|

= |

|

|

Z |

= |

the section modulus

of the secondary member, in cm3

|

In no case is  b to be taken as less than twice the web depth

of the stiffener on which the bracket scantlings are to be based.

b to be taken as less than twice the web depth

of the stiffener on which the bracket scantlings are to be based.

1.21.6 The free

edge of the bracket is to be stiffened where any of the following

apply:

-

The section modulus, Z, exceeds 500 cm3.

-

The length of free

edge exceeds 40 times the bracket thickness.

-

The bracket is fitted

at the lower end of main transverse side framing.

1.21.7 Where

a face flat is fitted, its breadth, b

f, is

to be not less than:

but not less than 40 mm

1.21.8 Where

the edge is stiffened by a welded face flat, the cross-sectional area

of the face flat is to be not less than:

-

0,017 k

a

b

f

T

B cm2 for

offset edge stiffening.

-

0,014 k

a

b

f

T

B cm2 for

symmetrically placed stiffening.

|

b

f

|

= |

breadth of face flat, in mm |

|

T

B

|

= |

the thickness of the bracket, in mm |

1.21.9 Where

the stiffening member is lapped onto the bracket, the length of overlap

is to be adequate to provide for the required area of welding. In

general, the length of overlap is not to be less than  , or the depth of stiffener, whichever is the greater. , or the depth of stiffener, whichever is the greater.

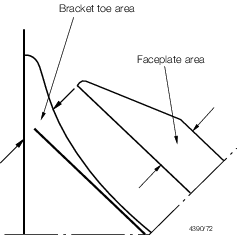

Figure 3.1.3 Stiffener end brackets

1.21.10 Where

the free edge of the bracket is hollowed out, it is to be stiffened

or increased in size to ensure that the modulus of the bracket through

the throat is not less than that of the required straight edged bracket.

1.21.11 The

arrangement of the connection between the stiffener and the bracket

is to be such that at no point in the connection is the actual modulus

reduced to less than that of the stiffener with associated plating.

1.21.12 The

design of end connections and their supporting structure is to be

such as to provide adequate resistance to rotation and displacement

of the joint.

1.22 Primary member end connections

1.22.1 The requirements

for section modulus and inertia (if applicable) of primary members

are given in the appropriate Chapter. The scantling requirements for

primary member end connections in dry spaces and in tanks of all craft

types are generally to comply with the requirements of Pt 7, Ch 3, 1.21 Scantlings of end brackets, taking Z as the section

modulus of the primary member.

1.22.2 Primary

members are to be so arranged as to ensure effective continuity of

strength, and abrupt changes of depth or section are to be avoided.

Where members abut on both sides of a bulkhead, or on other members,

arrangements are to be made to ensure that they are in alignment.

Primary members in tanks are to form a continuous line of support

and wherever possible, a complete ring system.

1.22.3 The members

are to have adequate lateral stability and web stiffening and the

structure is to be arranged to minimise hard spots and other sources

of stress concentration. Openings are to have well rounded corners

and smooth edges and are to be located having regard to the stress

distribution and buckling strength of the panel.

1.22.4 Primary

members are to be provided with adequate end fixity by end brackets

or equivalent structure. The design of end connections and their supporting

structure is to be such as to provide adequate resistance to rotation

and displacement of the joint and effective distribution of the load

from the member.

1.22.5 Where

the primary member is supported by structure which provides only a

low degree of restraint against rotation, the member is generally

to be extended beyond the point of support and thereafter tapered

and/or scarfed into the adjacent structure over a distance generally

not less than two frame spaces.

1.22.6 Where

primary members are subject to concentrated loads, particularly if

these are out of line with the member web, additional strengthening

may be required.

1.22.7 The thickness

of the bracket is to be not less than that of the primary member web.

The free edge of the bracket is to be stiffened.

1.22.8 Where

a deck girder or transverse is connected to a vertical member on the

shell or bulkhead, the scantlings of the latter may be required to

be increased to provide adequate stiffness to resist rotation of the

joint.

1.22.9 Where

a member is continued over a point of support, such as a pillar or

pillar bulkhead stiffener, the design of the end connection is to

be such as to ensure the effective distribution of the load into the

support. Proposals to fit brackets of reduced scantlings, or alternative

arrangements, will be considered.

1.22.10 Connections

between primary members forming a ring system are to minimise stress

concentrations at the junctions. Integral brackets are generally to

be radiused or well rounded at their toes. The arm length of the bracket,

measured from the face of the member, is to be not less than the depth

of the smaller member forming the connection.

1.23 Tank boundary penetrations

1.23.1 Where

structural members pass through the boundary of a tank, and leakage

into the adjacent space could be hazardous or undesirable, full penetration

welding is to be adopted for the members for at least 150 mm on each

side of the boundary. Alternatively a small scallop of suitable shape

may be cut in the member close to the boundary outside the compartment,

and carefully welded all round.

1.24 Web stability

1.24.1 Primary members are to be supported by tripping brackets. The tripping

brackets supporting asymmetrical sections are to be spaced no more than two secondary

frames apart. The tripping brackets supporting symmetrical sections are to be spaced no

more than four secondary frames apart.

1.24.2 Tripping

brackets are in general required to be fitted at the toes of end brackets

and in way of heavy or concentrated loads such as the heels of pillars. See also LR's Guidance Notes for Structural Details.

1.25 Openings in the web

1.25.1 Where

openings are cut in the web, the depth of opening is not to exceed

50 per cent of the web depth, and the opening is to be so located

that the edges are not less than 25 per cent of the web depth from

the face plate. The length of opening is not to exceed the web depth

or 60 per cent of the secondary member spacing, whichever is the greater,

and the ends of the openings are to be equidistant from the corners

of cut-outs for secondary members. Where larger openings are proposed,

the arrangements and compensation required will be specially considered.

1.25.2 Openings

are to have smooth edges and well rounded corners.

1.26 Continuity and alignment

1.26.1 The arrangement

of material is to be such as will ensure structural continuity. Abrupt

changes of shape or section, sharp corners and points of stress concentration

are to be avoided.

1.26.2 Where

members abut on both sides of a bulkhead or similar structure, care

is to be taken to ensure good alignment.

1.26.3 Pillars

and pillar bulkheads are to be fitted in the same vertical line wherever

possible, and elsewhere arrangements are to be made to transmit the

out of line forces satisfactorily. The load at head and heel of pillars

is to be effectively distributed and arrangements are to be made to

ensure the adequacy and lateral stability of the supporting members.

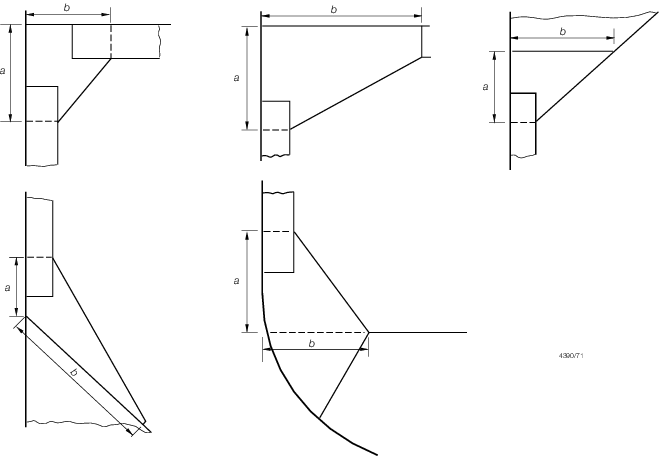

1.26.4 Continuity

is to be maintained where primary members intersect and where the

members are of the same depth, a suitable gusset plate is to be fitted, see

Figure 3.1.4 Primary member intersection.

Figure 3.1.4 Primary member intersection

1.26.5 End connections

of structural members are to provide adequate end fixity and effective

distribution of the load into the supporting structure.

1.26.6 The toes

of brackets, etc. are not to land on unstiffened panels of plating.

Special care is to be taken to avoid notch effects at the toes of

brackets, by making the toe concave or otherwise tapering it off, see

also LR's Guidance Notes for Structural Details.

1.26.7 Particular

attention is to be paid to the design of the end bracket toes in order

to minimise stress concentrations. Sniped face plates which are welded

onto the edge of primary member brackets are to be carried well around

the radiused part of the bracket toe and are to incorporate a taper

not exceeding one in three. Where sniped face plates are welded adjacent

to the edge of primary member brackets, adequate cross sectional area

is to be provided through the bracket toe at the end of the snipe.

In general, this area measured perpendicular to the face plate, is

to be not less than 60 per cent of the full cross-sectional area of

the face plate, see

Figure 3.1.5 Bracket toe construction.

Figure 3.1.5 Bracket toe construction

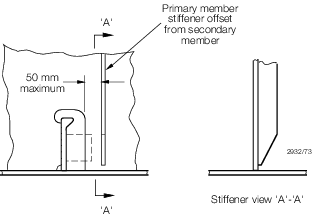

1.27 Arrangement with offset stiffener

1.27.1 Where

the stiffeners of the double bottom floors and transverse bulkheads

are unconnected to the secondary members and offset from them, see

Figure 3.1.6 Arrangement with offset stiffener, the collar arrangement

for the secondary members are to satisfy the requirements of Pt 7, Ch 3, 1.28 Arrangements at intersection of continuous secondary and primary members. In addition, the fillet welds

attaching the lugs to the secondary members are to be based on a weld

factor of 0,44 for the throat thickness. To facilitate access for

welding the offset stiffeners are to be located 50 mm from the slot

edge furthest from the web of the secondary member. The ends of the

offset stiffeners are to be suitably tapered and softened.

Figure 3.1.6 Arrangement with offset stiffener

1.27.2 Alternative

arrangements will be considered on the basis of their ability to transmit

load with equivalent effectiveness. Details of the calculations made

and testing procedures are to be submitted.

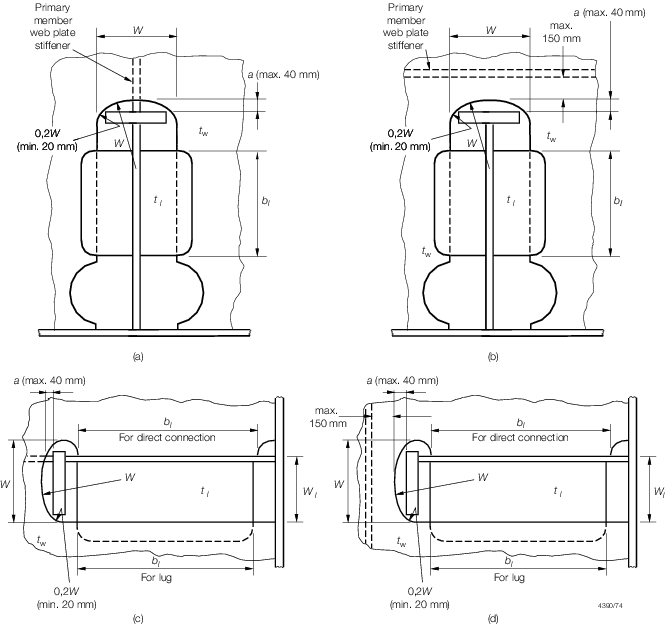

1.28 Arrangements at intersection of continuous secondary and primary

members

1.28.1 Cut-outs

for the passage of secondary members through the webs of primary members,

and the related collaring arrangements, are to be designed to minimise

stress concentrations around the perimeter of the opening and in the

attached hull envelope or bulkhead plating. The critical shear buckling

stress of the panel in which the cut-out is made is to be investigated.

Cut-outs for longitudinals will be required to have double lugs in

areas of high stress.

1.28.2 The cross-sectional areas of connections are to be determined from the load transmitted

through each component in association with its appropriate permissible stress.

1.28.4 Total load, P, transmitted to the primary member from the secondary member is to

be derived by:

where

|

s |

= |

secondary stiffener spacing, mm |

|

S |

= |

primary stiffener spacing, m |

|

p |

= |

design plating pressure, kN/m2 |

|

P |

= |

total load, kN |

1.28.5 The arrangement of lug/collar/direct connection to the primary web

stiffener determines the load apportioned to each component. The effect on each

component of the intersection is to be assessed, as appropriate, for shear and direct

stress. Where the web stiffener is not connected to the secondary member, the load,

P, is transmitted through the lug/collar/direct connection.

1.28.6 The breadth of cut-outs is to be as small as practicable, with the top edge

suitably radiused. Cut-outs are to have smooth edges, and the corner radii are to be as

large as practicable. Where the web depth is greater than 100 mm the corner radii are to

be a minimum of 20 per cent of the breadth of the cut-out or 20 mm, whichever is the

greater, and for large cut-outs greater than 250 mm deep, the web plate connection to

the hull envelope, or bulkhead, should end in a smooth tapered `soft toe'. Recommended

shapes of cut-out are shown in Figure 3.1.7 Cut-outs and connections, but consideration will be given to other shapes

on the basis of maintaining equivalent strength and minimising stress concentration,

see also LR's Guidance Notes for Structural Details.

1.28.7 Consideration

is to be given to the provision of adequate drainage and unimpeded

flow of air and water when designing the cut-outs and connection details.

Figure 3.1.7 Cut-outs and connections

1.28.8 Asymmetrical

secondary members are to be connected on the heel side to the primary

member web plate. Additional connection by lugs on the opposite side

may be required.

1.28.9 Symmetrical

secondary members are to be connected by lugs on one or both sides,

as necessary.

1.28.10 Where

the primary member stiffener is connected to the secondary member

it is to be aligned with the web of the secondary member, except where

the face plate of the latter is offset and abutted to the web, in

which case the stiffener connection is to be lapped.

1.28.11 Fabricated

longitudinals having the face plate welded to the underside of the

web, leaving the edge of the web exposed, are not recommended for

side shell and longitudinal bulkhead longitudinals. Where it is proposed

to fit such sections, a symmetrical arrangement of connection to transverse

members is to be incorporated. This can be achieved by fitting backing

structure on the opposite side of the transverse web or bulkhead.

1.28.12 Where

a bracket is fitted to the primary member web plate in addition to

a connected stiffener it is to be arranged on the opposite side to,

and in alignment with the stiffener. The arm length of the bracket

is to be not less than the depth of the stiffener, and its cross-sectional

area through the throat of the bracket is to be included in the calculation

of the area of the primary web stiffener in way of the connection.

1.28.13 Alternative

arrangements will be considered on the basis of their ability to transmit

load with equivalent effectiveness. Details of the calculations made

and testing procedures are to be submitted.

1.29 Openings

1.29.1 Manholes,

lightening holes and other cut-outs are to be avoided in way of concentrated

loads and areas of high shear. In particular, manholes and similar

openings are not to be cut in vertical or horizontal diaphragm plates

in narrow cofferdams or in floors and double bottom girders close

to their span ends, or below the heels of pillars, unless the stresses

in the plating and the panel buckling characteristics have been calculated

and found satisfactory.

1.29.2 Manholes,

lightening holes and other openings are to be suitably framed and

stiffened where necessary.

1.29.3 Air and

drain holes, notches and scallops are to be kept at least 200 mm clear

of the toes of end brackets and other areas of high stress. Openings

are to be well rounded with smooth edges. Closely spaced scallops

are not permitted. Widely spaced air or drain holes may be accepted,

provided that they are of elliptical shape, or equivalent, to minimise

stress concentration and are, in general, cut clear of the weld connection.

1.30 Fittings and attachments, general

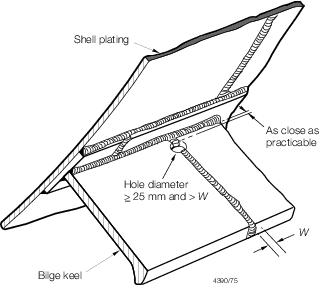

1.31 Bilge keels and ground bars

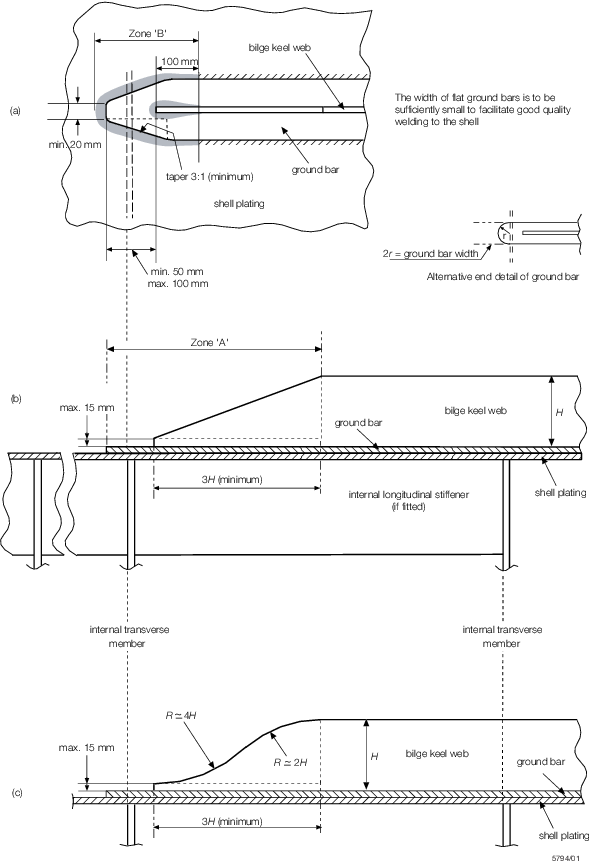

1.31.1 It is

recommended that bilge keels are not to be fitted in the forward 0,3L

R region on ships intended to navigate in ice conditions.

1.31.2 Bilge

keels are to be attached to a continuous ground bar as shown in Figure 3.1.8 Bilge keel construction. Butt welds in shell plating,

ground bar and bilge keels are to be staggered.

Figure 3.1.8 Bilge keel construction

1.31.3 The thickness

of the ground bar is to be not less than the thickness of the bottom

shell or 8 mm, whichever is the greater, but need not be taken as

greater than 15 mm.

1.31.4 The material

class, grade and quality of the ground bar are to be similar to those

of the adjacent shell plating.

1.31.5 The ground

bar is to be connected to the shell with a continuous fillet weld

and the bilge keel to the ground bar with a light continuous fillet

weld.

1.31.6 Direct

connection between ground bar butt welds and shell plating, and between

bilge keel butt welds and ground bar is to be avoided.

1.31.7 The end

details of bilge keels and intermittent bilge keels, where adopted,

are to be as shown in Figure 3.1.9 Bilge keel end design.

Figure 3.1.9 Bilge keel end design

1.31.10 An

internal transverse support is to be positioned as close as possible

to halfway between the end of the bilge keel web and the end of the

ground bar, see

Figure 3.1.9 Bilge keel end design(b).

1.31.12 For

craft over 65 m in length, L

R, holes are to

be drilled in the bilge keel butt welds. The size and position of

these holes are to be as illustrated in Figure 3.1.8 Bilge keel construction. Where the butt weld has been subject to non-destructive

examination the stop hole may be omitted.

1.31.14 Within

zone 'B' (see

Figure 3.1.9 Bilge keel end design(a)),

welds at the ends of the ground bar and the bilge plating, and at

the ends of the bilge keel web and ground bar, are to have weld factors

of 0,44 and 0,34 respectively. These welds are to be ground and to

blend smoothly with the base materials.

1.31.15 A plan

of the bilge keels is to be submitted for approval of material grades,

welded connections and detail design.

1.32 Other fittings and attachments

1.32.1 Gutterway

bars at the upper deck are to be so arranged that the effect of main

hull stresses on them is minimised.

1.32.2 Minor

attachments, such as pipe clips, staging lugs and supports, are generally

to be kept clear of toes of end brackets, corners of openings and

similar areas of high stress. Where connected to asymmetrical stiffeners,

the attachments may be in line with the web providing the fillet weld

leg length is clear of the offset face plate or flange edge. Where

this cannot be achieved the attachments are to be connected to the

web, and in the case of flanged stiffeners they are to be kept at

least 25 mm clear of the flange edge. On symmetrical stiffeners, they

may be connected to the web or to the centreline of the face plate

in line with the web.

1.32.3 Where

necessary in the construction of the craft, lifting lugs may be welded

to the hull plating but they are not to be slotted through. Where

they are subsequently removed, this is to be carried out by mechanical

cutting close to the plate surface, and the remaining material and

welding ground off. After removal the area is to be carefully examined

to ensure freedom from cracks or other defects in the plate surface.

|