Section

1 General

1.1 General

1.1.1 The requirements

of this Chapter are to be complied with in cases where Lloyd’s

Register (LR) is requested to certify the launch and recovery appliances

for the following:

- Lifeboats ‘Survival craft’.

- Life rafts ‘Survival craft’.

- Rescue boats.

- Offshore life saving craft including hyperbaric lifeboats.

- Associated releasing arrangements.

1.1.2 Special consideration

will be given to unconventional launch and recovery life saving systems.

1.1.4 Previous Conventions

are not applicable to new davits except where such davits are replacements

for an existing ship.

1.1.5 Where LR is

required to certify a launch and recovery appliance on behalf of a

National Administration whose requirements differ from those of the

IMO Convention indicated in Ch 3, 1.1 General 1.1.3,

the requirements of the National Administration concerned are to prevail.

1.1.6 This Chapter

is the basis of approval by LR of the following types of davit:

- Roller-trackway.

- Hinged gravity.

- Stored energy.

- Single arm radial.

- Fixed arm cantilever.

- Free fall system.

1.1.7 Davit types

not included above will be specially considered.

1.2 Survival craft davits

1.2.1 For all ships

with the exception of passenger ships, lifeboats are to be boarded

and launched directly from the stowed position and the davits are

to be designed accordingly.

1.2.2 All lifeboats

fitted to passenger ships are to be boarded and launched either directly

from the stowed position or from an embarkation deck, but not both,

and the davits are to be designed accordingly.

1.2.3 The launching

mechanism is to be so arranged that it may be actuated by one person

from a position on the ship’s deck and from a position within

the lifeboat.

1.2.4 When the lowering

of a survival craft is controlled from within the craft by means of

a control wire paid off from an auxiliary drum on the winch, the remote

control mechanism is to be operationally demonstrated throughout the

full launching range of the boat to the Surveyor’s satisfaction.

1.2.5 To launch

a survival craft in either its light or loaded condition, a davit

is not to depend on any means other than gravity or stored energy

generated from a source independent of the ship’s power supplies.

This does not apply to the launching appliance for lowering free-fall

lifeboats by falls.

1.2.6 Where davit

arms are recovered by power, limit switches are to be fitted to ensure

that the power is automatically switched off before the arm reaches

the stops in order to avoid overloading either the fall or the arms,

unless the winch is designed to prevent such overloading.

1.2.7 The trackways

of roller-trackway davit types are to be inclined at an angle of not

less than 35° to the horizontal.

1.2.8 Davits are

to be designed and maintained such that they remain fully effective

under conditions of icing.

1.2.9 The ratios

of the sheave diameter and winch drum diameter to the rope diameter

are to be not less than 12:1 and 16:1 respectively for running wires.

1.2.10 The minimum

thickness of plate and sections used in davit arms and frames is to

be 6 mm.

1.2.11 Davits (including

free-fall ramps) are to be capable of safely launching their fully

equipped survival craft, both with its full complement of persons

and also in the light condition, against the ship’s trim of

10°, either fore or aft, and 20° list in either direction

occurring simultaneously.

1.2.12 Davits fitted

to ships of 20 000 gross registered tons and greater are to be capable

of safely launching a lifeboat with the parent ship making five knots

headway in calm water.

1.2.13 Single arm

radial davits are to be capable of being slewed manually.

1.2.15 A davit’s

launching winch system is to be capable of power recovery of the survival

craft with its crew (i.e. 2 or 3 persons) at a minimum speed of 0,08

m/s to its stowage position with the ship at adverse list and trim

angles of 5° and 2° respectively. In addition, auxiliary manual

means of recovery are also to be provided for this condition, see

Ch 3, 1.8 Davit winches 1.8.5. However, this does not apply to

free-fall lifeboats.

1.2.16 Davits and

their equipment are to be capable of lowering the survival craft in

a controlled manner into the water at speed not less than that obtained

by the following formula for the fully loaded condition, i.e. loaded

with its normal equipment or an equivalent mass and a distributed

mass equivalent to the number of persons it is permitted to accommodate, see

Ch 3, 1.7 Calculation of forces 1.7.6.

where

|

S

|

= |

speed of lowering, in m/s |

|

H

|

= |

height, in metres, from davit head to waterline with the ship in its

lightest sea-going condition. |

1.2.17 The minimum

lowering speed of a life raft in the light condition (i.e. fully equipped

but without persons on board), is to comply with the requirements

of the National Administration concerned. The lowering speed of other

survival craft in the light condition is to be ≥0,7 x S as

calculated in Ch 3, 1.2 Survival craft davits 1.2.16.

1.2.18 The maximum

lowering speeds for all survival craft in the light condition are

not to exceed 1,0 m/s. Furthermore, the maximum lowering speeds in

the fully loaded condition are not to exceed 1,0 and 1,3 m/s for life

rafts and lifeboats respectively, unless different values are required

by the relevant National Authority.

1.2.19 A free-fall

launching system is required to employ an alternative controlled means

of launching and a means of recovering the lifeboat by falls. Lifeboats

are not to be launched in the free-fall mode where there is a risk

of the presence of ice or insufficient depth of water. A notice to

this effect should be displayed at the operating station.

1.2.20 The davits

are to be arranged so that harmful accelerations are not experienced

by the lifeboat occupants during launching.

1.2.21 Harmful

acceleration is the rate of change of velocity experienced by the

occupants which is in excess of levels calculated in accordance with

the IMO test requirements of Ch 3, 1.1 General 1.1.3,

or other recognised National or International Standards.

1.2.22 Where conditions

are such that the free-fall operating mode is not necessary, a free-fall

lifeboat is to be capable of being safely lowered in a ‘controlled’

manner with the ship inclined at a maximum list of 5° and a maximum

trim of 2°.

1.2.23 The free-fall

launching arrangement is to be a rigid structure with a ramp angle

and length sufficient to ensure that the lifeboat effectively clears

the ship.

1.2.24 Where a

survival craft is designed to float free from its launching appliance,

either by a weak link or by a hydrostatic release unit, the float

free release of the survival craft from the stowed position is to

be automatic.

1.3 Rescue boat davits

1.3.1 This Section

covers davits that are used for launching and recovering lifeboats

which may also be used as rescue boats, as well as davits that are

solely dedicated to launching and recovering rescue boats only.

1.3.2 In addition

to the requirements for survival craft davits in Ch 3, 1.2 Survival craft davits, all rescue boat davits are to meet the following requirements:

-

The davits are to be

capable of launching the rescue boat from the stowed position in not

more than five minutes.

-

The davits and winches

are to be capable of power hoisting the rescue boat, loaded with its

full rescue boat complement and equipment, from the water at a rate

of not less than 0,3 m/s.

1.3.3 For davits

that are solely dedicated to the launching and recovery of rescue

boats, special consideration may be given to recovery arrangements

which are dependent on the ship’s power supply. These davits

may be equipped for single point hoisting.

1.3.4 Special consideration

may be given to the launching mechanism of a dedicated rescue boat

being operable solely from a position on the ship’s deck.

1.4 Offshore life saving systems

1.4.2 The following

additional requirements are applicable to any launch and recovery

system used for handling survival craft (including hyperbaric lifeboats)

and rescue boats, fitted to either fixed or mobile offshore installations.

It should be noted that some National Authorities may have different

requirements.

1.4.3 Davits are

to be capable of launching a fully equipped survival craft with a

full complement of persons against a high or low side list and trim

of the installation of 15° simultaneously. Notwithstanding the

foregoing requirement, davits intended for column-stabilised mobile

drilling units should be capable of operating at the list and trim

resulting from any damaged condition required by the relevant Chapter

of the current IMO Code for the Construction and Equipment of

Mobile Offshore Drilling Units (MODU Code).

1.4.4 All gravity

davits are to be designed for a positive turning-out moment when the

installation is adversely inclined at an angle of 25° high side

list (HSL).

1.4.5 Davits for

rescue boats are to be equipped with suitable shock absorbing or motion

compensating arrangements to facilitate launching and hoisting of

the boat in heavy seas.

1.4.6 Launching

against high side list is not required for rescue boats. Otherwise,

launching should be performed with the aid of gravity or with an arrangement

coupled to the emergency power source.

1.5 Plan approval requirements

1.6 Safety and stress factors

1.6.1 The minimum safety factors (SF) required with respect to the minimum

ultimate tensile stress (σu) of the materials used in the construction of the

primary structural members and the loose gear are given in Table 3.1.1 Minimum safety factors.

Table 3.1.1 Minimum safety factors

| Item

|

SF required on σu

|

| Direct stress

|

Shear stress

|

| Structural components

|

4,5

|

7,8

|

| Loose gear

|

6,0

|

10,3

|

| Release hooks

|

6,0

|

10,3

|

1.6.2 For steel

in which σy/σu ≤0,7, the allowable

compressive stress, σa, in primary structural members

is given by the following expression:

where

|

σcr

|

= |

critical compressive stress |

|

σu

|

= |

minimum ultimate tensile stress, N/mm2

|

|

σy

|

= |

yield stress, N/mm2

|

SF is given in Table 3.1.1 Minimum safety factors.

1.6.3 Steels in which σy/σu > 0,7 will be specially

considered.

1.6.4 The minimum stress factor to be applied for the design test load case for

prototype and production testing is to be taken as 0,85 (see

Ch 4, 2.15 Load combinations 2.15.5.(d) and Table 4.2.6 Stress factor, F

, load case

4). The requirements for prototype testing are defined in Ch 3, 1.12 Testing 1.12.2. The requirements for

production testing are defined in Ch 3, 1.12 Testing 1.12.3. The allowable stresses to

be considered for the prototype and production test load cases are defined in the

applicable Chapters of the Code, i.e.:

- Ch 4, 2.17 Allowable stress – Elastic failure;

- Ch 4, 2.18 Allowable stress – Compression, torsional and bending members;

- Ch 4, 2.19 Crane jibs – Overall stability;

- Ch 4, 2.20 Slenderness ratio;

- Ch 4, 2.21 Allowable stress – Plate buckling failure;

- Ch 4, 2.22 Allowable stress – Buckling failure of thin walled cylinders; and

- Ch 4, 2.23 Allowable stress – Joints and connections

1.7 Calculation of forces

1.7.1 Force diagrams

or calculations are required for the davit arm in its lowest position

subject to both 20° low side list (LSL) (up to 30° for tankers

in the damaged condition) for both the SWL and the weight of the davit

arm. The torsion and lateral bending effects due to the 10° trim

component are also to be considered (20° list component for radial

arm davits).

1.7.2 Calculations

are also required for the davit arm in its stowed position to ensure

that a positive turning out moment exists with the ship at 20°

HSL, see

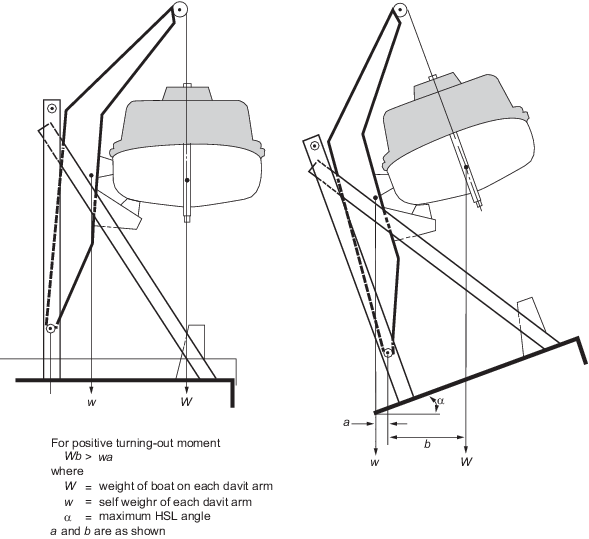

Figure 3.1.1 Davit arm turning-out

moments.

Figure 3.1.1 Davit arm turning-out

moments

1.7.3 The tension

in the boat falls and forces in the davit arms are to be calculated

using the appropriate friction allowance of the blocks and sheaves

for both the following cases:

-

The turning out/lowering

of the fully equipped lifeboat and its total complement of persons,

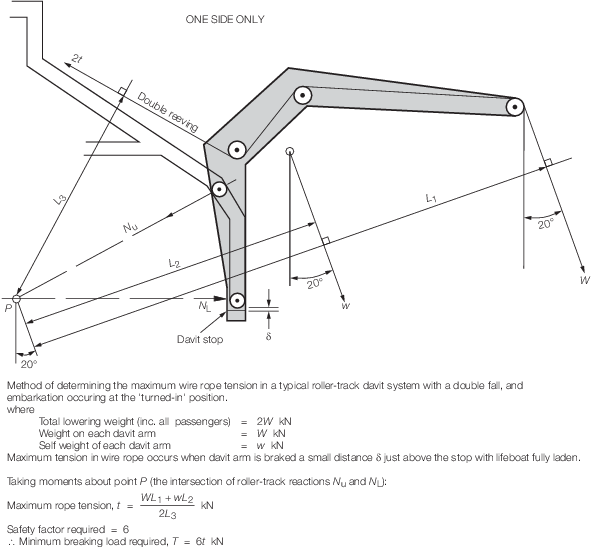

where applicable. For a roller-track system, see

Figure 3.1.2 Roller-track system, maximum wire rope tension.

-

The recovering of the

fully equipped lifeboat and its crew to either the stowed position

or to the embarkation deck.

Figure 3.1.2 Roller-track system, maximum wire rope tension

1.7.5 The resultant

loads on each of the blocks or sheaves in the rig are also to be determined

by appropriate force diagrams or calculation.

1.7.6 For design

purposes, the weight of one person is taken as 82,5 kg, except for

passenger vessels which are to use 75 kg.

1.7.7 Friction in

each sheave and pivot pin is to be taken as 5 per cent. However, sheaves

having roller bearings may be taken as 2 per cent.

1.8 Davit winches

1.8.1 In general,

davit winches are to comply with the requirements of Ch 9 Machinery where applicable.

1.8.2 Winch structural

members are to be designed to have a minimum safety factor of 4,5

in respect of the minimum ultimate tensile stress of the material

when the maximum working load is applied.

1.8.3 Winches with

multiple drums are to be so arranged that all the falls wind on or

off the drums at the same rate when either hoisting or lowering.

1.8.4 Winches are

to be provided with an efficient hand gear arrangement to enable the

survival craft or rescue boat to be recovered manually. The hand gear

handles and wheels are not to be rotated by the moving parts of the

winch when being operated by power. This does not apply to free-fall

lifeboats.

1.8.5 Every davit

winch is to be fitted with brakes capable of stopping the maximum

speed of descent of the survival craft or rescue boat and of holding

it securely when loaded with its full complement of persons and equipment.

1.8.6 Winch brake

pads are to be protected from water and oil, and an efficient means

of preventing them from freezing is to be provided.

1.9 Loose gear

1.9.1 For the purposes

of this Chapter, the loose gear consists of the survival craft or

rescue boat falls together with the blocks, shackles, links, padeyes,

swivels, fastenings or any other fitting attached to the falls.

1.9.3 Bowsing, griping

and tricing tackles are not included in LR’s approval. However,

their adequacy should be operationally demonstrated to the Surveyor’s

satisfaction.

1.9.5 Wire rope

falls are to be galvanised or heavily greased and are to be of a rotation

resistant construction.

1.9.6 The use of

stainless steel wire ropes will be specially considered, but generally

are to be of a higher alloy composition, e.g. Inconel 625, Incoloy

alloy 825, Duplex Ferralium 255. They are to comply with the requirements

of 1.13.6. It is recommended that lower grades of stainless steel

(e.g. SUS 304, SUS 316, etc.) are not used for lifeboat falls as they

are subject to stress corrosion cracking, crevice corrosion and pitting.

1.9.7 The falls

are to be of sufficient length to enable the survival craft or rescue

boat to reach the water with three full turns remaining on the winch

drum with the ship in her lightest sea-going condition and listed

20° in the adverse direction.

1.9.8 The ends of

the falls are to be securely attached to the winch drum.

1.9.9 Wire rope

terminations are to be manufactured and the termination process is

to be in accordance with the requirements of the manufacturer and/or

a National or International Standard. Wire rope grips are not to be

used as the primary load bearing termination. Where used, the number

of grips and their tightening torque is to be strictly in accordance

with the manufacturer’s and/or the National/International Standard

requirements. The tightening torque is to be regularly checked.

1.9.10 Blocks,

shackles, swivels and other fittings are to be designed to have a

minimum safety factor in accordance with Table 3.1.1 Minimum safety factors with respect to the minimum ultimate tensile stress of

the materials when the maximum working load is applied.

1.9.11 Each item

of loose gear is to be proof-tested to 2,2 times its SWL (2,5 times

its SWL for use offshore).

1.9.12 In addition,

loose gear is to be prototype tested to 6 times its SWL to demonstrate

its structural adequacy against failure.

1.10 Release hooks

1.10.1 Release

hooks may be of the type fixed to the wire fall. These are generally

used for single point suspension or of the type permanently attached

to the craft being launched.

1.10.2 Release

hooks for davit launched life rafts and dedicated inflatable/semi-rigid

rescue boats are to comply with the following requirements:

-

Only one type of release

hook, or other release mechanism, is to be fitted to similar survival

craft or rescue boats on board a ship.

-

Each release hook and

its mechanism is to be designed to have a minimum safety factor in

accordance with Table 3.1.1 Minimum safety factors, with

respect to the minimum ultimate tensile stress of the materials used

when the maximum safe working load of the hook is applied.

-

The release mechanism

is to be capable of releasing the craft in either the ‘off-load’

condition, i.e. when it is waterborne or when there is no load on

the hooks, or, in the ‘on-load’ condition (however, this

capability is to be adequately protected against accidental or inadvertent

use).

-

Release hooks are to

be designed and maintained such that they remain fully effective under

conditions of icing.

-

A prototype release

hook and its mechanism is to be proof loaded to 6 times its SWL, holding

this load for at least 5 minutes. After removal of the load, the release

mechanism is to be dismantled and examined for damage.

-

A prototype release

hook and its mechanism is to be proof-load tested by subjecting it

to a steadily increasing load until failure occurs. This breaking

load is to be recorded.

-

Additionally, each

release hook and its mechanism is to be ‘dynamically’

tested by lowering a proof-load of 1,1 times its SWL and abruptly

applying the brakes when the lowering speed has been reached.

1.10.3 Release

hooks for lifeboats, combined liferaft/rescue boats and rigid rescue

boats are to comply with the requirements of Ch 3, 1.10 Release hooks 1.10.2 and, in addition, a mechanism is to be fitted to each

lifeboat or rescue boat to ensure that each hook is released simultaneously.

The effectiveness of this is to be demonstrated to the Surveyor’s

satisfaction.

1.11 Materials

1.11.3 Where a ship is intended for service in more severe environments (e.g. ice

breakers in polar waters) the Charpy V-notch impact test requirements will be specially

considered based on the minimum service temperature specified.

1.11.5 Steel or

spheroidal graphite iron materials may be accepted for cast components.

Grey cast iron is not a suitable material and may only be accepted

for components after special consideration of the proposed application.

1.12 Testing

1.12.2 Prototype

testing of survival craft (excluding free-fall) and rescue boat davits

and winches is to comply with the following requirements:

-

The davit with the

arm in the outboard position is to be statically tested to 2,2 times

the SWL. This test load is to be applied 10° either side of the

vertical in the fore and aft direction, first with 0° list and

then with both 20° HSL and 20° LSL conditions simulated.

-

The davit is to be

dynamically tested to 1,1 times the maximum load appropriate to the

part of the operating cycle concerned, over the full operating range

with the ship at 0° list. This test is to be repeated with a 20°

HSL and 10° trim condition simulated e.g. for a lifeboat/rescue

boat davit fitted to a passenger ship where embarkation occurs with

the davit arm in the turned-out position, the tests are to be conducted

with the loads indicated in Table 3.1.2 Prototype: Dynamic test

factors.

-

The dynamic tests in Ch 3, 1.12 Testing 1.12.2.(b) are to be repeated with a test

load equal to the weight of the fully equipped lightest craft, without

persons, through at least one complete operating cycle in order to

demonstrate satisfactory functioning of the davit under light conditions.

-

For davits intended

for installation on oil tankers, chemical tankers or gas carriers,

all the foregoing tests are to be carried out at the final list angle

(LSL only) where this is found to exceed 20°.

-

A ‘static’

test load of 1,5 times safe working moment (SWM) is to be held on

the winch brakes with the maximum number of turns of rope on the winch

drum. This is to be demonstrated through at least one revolution of

the winch drum.

-

A ‘dynamic’

load test of 1,1 times SWL is to be lowered at maximum speed for at

least three metres and stopped by abruptly applying the winch brakes.

This test load should not drop more than one metre after the brake

is applied and is to be repeated several times to achieve a cumulative

lowering distance of at least 150 m.

-

A ‘recovery’

test is to be performed if the winch is to be used with a rescue boat

to demonstrate that the fully loaded rescue boat can be recovered

at a rate not less than 0,3 m/sec. It should be demonstrated that

the winch hand recovery gear can recover a maximum load equivalent

to a fully loaded boat.

-

After completion of

the tests, the winch should be stripped for inspection.

Table 3.1.2 Prototype: Dynamic test

factors

| Boat position

|

Lifeboat

|

Rescue boat

|

| From

|

To

|

| Stowed

|

Embarkation

|

1,1 × P

1

|

1,1 × P

1

|

| Embarkation

|

Sea level

|

1,1 × P

2

|

1,1 × P

1

|

| Sea level

|

Embarkation

|

1,1 × P

1

|

1,1 × P

2

|

| Embarkation

|

Stowed

|

1,1 × P

1

|

1,1 × P

1

|

| Symbols

|

|

P

1

|

= |

weight of the lifeboat or rescue boat (as

appropriate) with full equipment and weight of operating crew |

|

P

2

|

= |

weight of the lifeboat or rescue boat with full

equipment and weight of crew and weight of passengers (i.e.

SWL) |

|

1.12.3 Production

testing of survival craft (excluding free-fall) and rescue boat davits

and winches is to comply with the following requirements:

-

A ‘static’

load test of 2,2 times SWL is to be held by the davit in its fully

outboard position at 0° list (2,5 times SWL for use offshore).

-

A ‘static’

load test of 1,5 times SWL is to be held on the winch brakes.

-

Each block and shackle

supplied with the davit is to be tested to 2,2 times their individual

SWL (2,5 times SWL for use offshore). When they are not supplied with

a manufacturer’s certificate, tests are to be witnessed and

LR’s certificate issued.

-

All fall ropes should

be supplied with a manufacturer’s certificate of test indicating

the breaking strength of the rope, which is to be not less than 6

times the maximum tension.

1.12.4 On board

(installation) testing of survival craft (excluding free-fall) and

rescue boat davits and winches is to comply with the following requirements:

-

A ’dynamic’

lowering test of 1,1 times SWL is to be carried out with the davit

in the outboard position. When the maximum lowering speed is reached,

the brakes are to be abruptly applied to demonstrate the adequacy

of both the attachment to the supporting structure in way of the winch

and to the davits. For ships with inboard embarkation, the test is

to be conducted from this position.

-

A ’dynamic’

lowering test is to be performed with the lifeboat or rescue boat

in the fully loaded condition to demonstrate that its entry into the

water is not less than the figure calculated from the expression in Ch 3, 1.2 Survival craft davits 1.2.16 and is within the limit detailed

in Ch 3, 1.2 Survival craft davits 1.2.18.

-

The above test is to

be repeated with the lifeboat or rescue boat in the ’light’

condition (i.e. equipped but without personnel) to ensure that the

frictional resistance of the winch, fall, blocks, etc. can be overcome.

In this condition, the minimum entry speed of the boat is to comply

with the requirements of Ch 3, 1.2 Survival craft davits 1.2.17.

-

For a life raft in

the ‘light’ condition, it is generally only necessary

to demonstrate that it has sufficient weight to overcome the friction

in the davit reeving system.

-

It is to be demonstrated

to the Surveyor’s satisfaction that the davits and winches are

able to recover and return the survival craft to its stowage position,

with satisfactory operation of limit switches, and be properly secured.

Additionally, it is to be demonstrated that the survival craft can

be recovered and returned to its stowage position using the emergency

hand gear.

-

For rescue boat launching

appliances, it is to be demonstrated that the rescue boat, with weight

equal to its rescue complement, can be recovered using the davit winch

at a rate not less than 0,3 m/s.

-

It is to be demonstrated

to the Surveyor’s satisfaction that the remote control release

mechanism inside the survival craft operates correctly.

1.12.5 Prototype

testing of free-fall launching ramps and associated controlled launch

auxiliary davits is to be carried out as follows:

-

The ramp structure

is to be tested in applying a static load of 2,2 times SWL in positions

along the ramp which gives maximum stress in the ramp structure with

simulated shipboard 20° HSL and LSL and 10° fore and aft trim.

-

The auxiliary davit

arm is to be statically tested on the ramp and in its outboard position

to 2,2 times SWL, with simulated shipboard 20° HSL and LSL and

10° fore and aft trim.

-

Additionally, the auxiliary

davit arm is to be dynamically tested on the ramp to 1,1 times the

maximum load appropriate to the part of the operating cycle concerned,

over the full operating range with the ship at 0° list.

-

The tests indicated

in Ch 3, 1.12 Testing 1.12.2.(c), Ch 3, 1.12 Testing 1.12.2.(d), Ch 3, 1.12 Testing 1.12.2.(e), Ch 3, 1.12 Testing 1.12.2.(f) and Ch 3, 1.12 Testing 1.12.2.(h) are

also to be conducted for free-fall systems.

-

The pressure parts

of the hydraulically operated lifting system are to be hydrostatically

tested to 1,5 times design pressure.

-

If the ramp is an adjustable

type, it is to be demonstrated that it may be satisfactorily adjusted

with the free-fall lifeboat loaded to 1,2 times its fully laden weight.

1.12.6 Production

and installation testing of a free-fall system is to be carried out

in accordance with Ch 3, 1.12 Testing 1.12.3 and Ch 3, 1.12 Testing 1.12.4 except as follows:

-

During a free-fall

launch of the lifeboat, the water entry speed is to be such that no

harmful forces are experienced by the lifeboat occupants.

-

Each new free-fall

lifeboat is to be loaded to 1,1 times its fully laden weight and launched

by free fall with the ship on an even keel and in its lightest sea-going

condition.

-

During the ‘controlled’

mode of launching, the free-fall lifeboat is to be loaded to 1,1 times

SWL and released by the operation of the launching controls on deck.

When the lifeboat has reached its maximum lowering speed of not greater

than 1,3 m/s, the brake is to be applied abruptly in order to demonstrate

the attachment and adequacy of the support structure in way of the

davit and winch.

-

It is to be demonstrated

that the lifeboat may be recovered to its stowage position and can

be safely and properly secured.

1.12.7 Periodical

re-testing in accordance with the installation testing described in Ch 3, 1.12 Testing 1.12.4 and Ch 3, 1.12 Testing 1.12.6 is to be carried out every five years. Attention is drawn

to the applicable requirements in the IMO Life Saving Appliance (LSA)

Code, as amended.

1.12.8 After any

repair affecting the strength of the davit or winch, the appliance

is to be subject to the ‘dynamic’ loaded lowering test

described in Ch 3, 1.12 Testing 1.12.4.

1.13 Inspection and maintenance

1.13.1 Every survival

craft or rescue boat davit is to be visually inspected once a week

by the crew to ensure they are at all times ready for immediate use.

1.13.2 It is recommended

that rescue boats, including lifeboats which double as rescue boats,

are to be launched using their davits at least once every month. In

all cases, this recommendation is to be complied with at least once

every three months for both lifeboats and rescue boats. For lifeboats

installed on offshore platforms, this recommendation is to be complied

with at least once every two months.

1.13.3 Every davit

and winch is to be constructed so as to reduce routine maintenance

to a minimum. Those parts requiring regular maintenance are to be

readily accessible and easily maintained by the ship’s crew.

Where possible, the use of maintenance free sealed bearings is to

be adopted.

1.13.4 All parts

subject to wear should be examined with respect to the manufacturer’s

recommendations and repaired or replaced as necessary.

1.13.5 All davits

and winches are to be adequately protected against corrosion and are

to be constructed so as to prevent incendive friction or impact sparking

during launching.

1.13.6 Davit falls

are to be inspected periodically and must be renewed every five years

or sooner should their condition deteriorate.

1.13.7 A record

of maintenance, repair and test should be kept for each davit.

1.14 Certification and documentation

1.14.1 The minimum

requirements for the issue of LR certification for life-saving launch

and recovery appliances are as indicated in Ch 1, 1.2 Certification 1.2.5.

1.14.3 When LR

is authorised by Governments or National Administrations to issue,

on their behalf, statutory Safety Equipment Certificates on LR classed

ships, all tests are required to be witnessed by LR.

1.14.4 Life-saving

launch and recovery appliances are an integral aspect of a ship’s

list of safety equipment which is to satisfy LR’s requirements

prior to the issue of Safety Equipment Certification and Record of

Safety Equipment (Report S.E.1).

|