Section

2 Passenger lifts

2.1 General

2.1.1 This Section

applies to electric and hydraulic powered lifts permanently installed

in ships and employing an enclosed car suspended by ropes/chains or

supported by hydraulic cylinders and running between rigid guides

for the transfer of persons, or persons and goods, between the decks.

It is recommended that the rated speed does not exceed 1,0 m/s and

is to be limited to 1,0 m/s for hydraulic lifts and 0,63 m/s for positive

drive lifts. Traction drive lifts designed for a higher rated speed

will be specially considered.

2.1.2 The lift is to comply with the requirements of a recognised National or

International Standard, e.g. EN 81, ISO 8383 and any requirements of the National

Authority of the country of registration and the requirements of this Section.

Deviations from these Standards are to be stated by the manufacturer and require

approval by LR and the Flag State.

2.1.3 The relevant

design criteria, such as rated load, minimum stopping distance, buffer

stroke, type of hoisting drive, type of safety gear and buffer are

to be clearly specified in all lift submissions. For guidance regarding

the submission of relevant plans and information required, see

Ch 1, 3.4 Shiplifts. The certificates for the safety

components are to be submitted for consideration.

2.1.4 The lift is

to be designed such that it can be stowed, either manually or automatically,

in the event of the specified operational conditions being exceeded.

2.1.5 For the operating

conditions, the lift is to be designed with respect to the following

forces:

-

Self-weight of car and

counterweight;

-

Rated load;

-

Dynamic forces due to

lift motion; and

-

Forces due to ship motion

and static inclination.

2.1.6 For the stowed

condition, the lift is to be designed with respect to the following

forces:

-

Self-weight of car and

counterweight; and

-

Forces due to ship motion

and static inclination.

2.1.7 For the safety

device operation or the car striking the buffers, the lift is to be

designed with respect to the following forces:

-

Self-weight of the car

and counterweight;

-

Rated load;

-

Dynamic forces due to

lift motion; and

-

Forces due to static

vessel inclination.

2.1.9 The selected steel grade is to provide adequate assurance against brittle

fracture. The steel is to comply with the Charpy V-notch impact test requirements given

in Ch 11, 1.2 General material requirements 1.2.2.

Alternative proposals in respect of the notch toughness characteristics of the materials

will be considered when the environmental condition of the particular installation is

such that there is a low probability of low temperatures.

2.2 Basic loads

2.2.1 The self-weight

load, L

w, is the load imposed on the hoisting

mechanism by the weight of the permanent components of the lift car

structure and machinery.

2.2.2 The rated

load, L

c, is the load imposed on the lift

car by the passengers and is to be not less than that obtained from Table 7.2.1 Rated load. The load L

c is

to be evenly distributed over those three quarters of the car being

in the most unfavourable position.

Table 7.2.1 Rated load

Rated load,

in

kg

|

Maximum available

car area,

in m2

|

Maximum number

of

passengers

|

| 100

|

0,40

|

1

|

| 180

|

0,50

|

2

|

| 225

|

0,70

|

3

|

| 300

|

0,90

|

4

|

| 375

|

1,10

|

5

|

| 400

|

1,17

|

5

|

| 450

|

1,30

|

6

|

| 525

|

1,45

|

7

|

| 600

|

1,60

|

8

|

| 630

|

1,66

|

8

|

| 675

|

1,75

|

9

|

| 750

|

1,90

|

10

|

| 800

|

2,00

|

10

|

| 825

|

2,05

|

11

|

| 900

|

2,20

|

12

|

Note

1. For intermediate loads, the area is

determined by linear interpolation.

Note

2. The maximum number of persons carried

is given by  , rounded down to the nearest whole number, where

L

c is the rated load. , rounded down to the nearest whole number, where

L

c is the rated load.

Note

3. If the rated load exceeds by more than

15% that indicated in the Table for maximum available car area, the

maximum number of passengers permitted is to correspond to that

area.

Note

4. Recesses and extensions, even of

height less than 1 m, whether protected or not by separating doors,

are only permitted if their area is taken into account in the

calculation of the maximum available car area.

|

2.2.3 Where lifts

are mainly intended to carry goods which are generally accompanied

by persons, the design is to take into account the load to be carried

(including eccentricities) and the weight of any handling device (if

applicable) which may enter the car in addition to the requirements

of Table 7.2.1 Rated load.

2.3 Dynamic forces due to lift motion

2.3.1 The dynamic

forces due to the operation of the lift are to be taken into account

by multiplying the self-weight and rated load by an impact factor,

k, which is to be obtained from Table 7.2.2 Impact factors.

Table 7.2.2 Impact factors

| Impact

|

Impact factor

|

Value

|

| Operation of instantaneous safety

gear or clamping device, neither of the captive roller type

|

k

1

|

5

|

Operation of instantaneous safety

gear; or

Clamping device, both of the captive roller

type; or

Pawl device with energy

accumulation type

buffer; or

Energy

accumulation type buffer

|

3

|

Operation of progressive safety gear;

or

Progressive clamping device; or

Pawl

device with energy dissipation type

buffer; or

Energy dissipation type buffer

|

2

|

| Rupture valve

|

2

|

| Running

|

k

2

|

1,2

|

| Auxiliary parts

|

k

3

|

See Note

|

Note The value is to be determined by the manufacturer

accounting for the actual installation.

|

2.3.2 The rated

speed, minimum stopping distance and buffer stroke are to be obtained

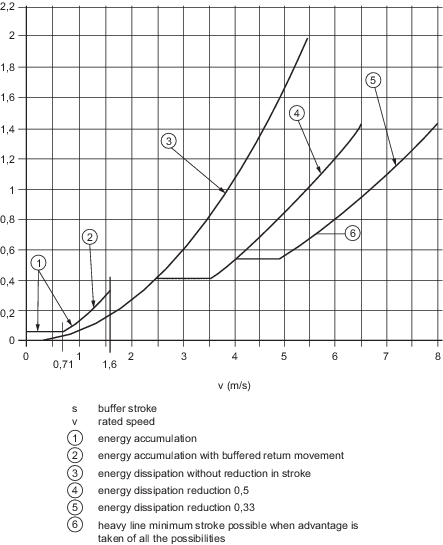

from the lift specification to which the lift is constructed. Figure 7.2.1 Buffer strokes provides typical buffer strokes.

Figure 7.2.1 Buffer strokes

2.4 Static and dynamic forces due to ship motion

2.4.1 Passenger

lifts, their associated machinery and structure are to be designed

to operate at sea with respect to the following conditions:

-

Roll: ±10°,

with 10-second period.

-

Pitch: ±7,5°,

with 7-second period.

2.4.2 In addition

to the operational conditions, the lift, associated machinery and

structure are to be designed to withstand the forces resulting from

consideration of the following conditions when in stowed condition:

-

Roll: ±22,5°,

with 10-second period.

-

Pitch: ±7,5°,

with 7-second period.

-

Heave: Amplitude = 0,0125L with 10-second period.

where

2.4.4 The forces

due to ship motion are to be applied at the centre of the gravity

of the car and counterweight and centre of the gravity of the rated

load of the car in all three directions: neutral to deck (F

N), in transverse (F

T) and longitudinal

direction (F

L), and are to be considered for

all relevant stress proofs.

2.5 Load combinations

2.5.1 The lift and

its associated mechanism and structure are to be considered with respect

to design loads resulting from the following conditions:

-

Case 1:

The lift in the ‘operating condition’ is to be considered

with respect to forces due to ship motion resulting from the conditions

defined in Ch 7, 2.4 Static and dynamic forces due to ship motion 2.4.1 and Ch 7, 2.4 Static and dynamic forces due to ship motion 2.4.3, together with the normal to deck

components of dead load and live load multiplied by the factor, k

2, to be obtained from Ch 7, 2.3 Dynamic forces due to lift motion 2.3.1.

This is represented by the following expression:

k

2 (F

N,Lw + F

N,Lc) + F

T,Lw + F

T,Lc + F

L,Lw + F

L,Lc

where

|

F

N,Lw

|

= |

normal to deck force resulting from selfweight L

w

|

|

F

N,Lc

|

= |

normal to deck force resulting from rated load L

c

|

|

F

T,Lw

|

= |

transverse force due to roll resulting from L

w

|

|

F

T,Lc

|

= |

transverse force due to roll resulting from L

c

|

|

F

L,Lw

|

= |

longitudinal force due to pitch resulting from L

w

|

|

F

L,Lc

|

= |

longitudinal force due to pitch resulting from L

c

|

-

Case 2:

The lift in the ‘stowed condition’ (self-weight only)

is to be considered with respect to the forces resulting from the

accelerations due to the ship's motion as defined in Ch 7, 2.4 Static and dynamic forces due to ship motion 2.4.2 and Ch 7, 2.4 Static and dynamic forces due to ship motion 2.4.3.

This is represented by the following expression:

F

N,Lw + F

T,Lw + F

L,Lw

-

Case 3:

The lift in the exceptional condition, e.g. buffer stroke, safety

device operation or rupture valve operation, is to be considered with

respect to the forces resulting from the inclinations due to ship

motions, as defined in Ch 7, 2.4 Static and dynamic forces due to ship motion 2.4.1, together

with the normal to deck components of dead load and live load multiplied

by the factor k

1 which is to be obtained from Ch 7, 2.3 Dynamic forces due to lift motion 2.3.1. This is represented by the following

expression:

k

1 (F

stat,N,Lw+ F

stat,N,Lc) + F

stat,T,Lw + F

stat,T,Lc + F

stat,L,Lw + F

stat,L,Lc

where

|

F

stat,N,Lw

|

= |

normal to deck force resulting from static component of self-weight L

w

|

|

F

stat,N,Lc

|

= |

normal to deck force resulting from static component of the

rated load L

c

|

|

F

stat,T,Lw

|

= |

transverse force resulting from the static component of roll

angle resulting from L

w

|

|

F

stat,T,Lc

|

= |

transverse force resulting from the static component of roll

angle resulting from L

c

|

|

F

stat,L,Lw

|

= |

longitudinal force resulting from the static component of the

pitch angle due to L

w

|

|

F

stat,L,Lc

|

= |

longitudinal force resulting from the static component of the

pitch angle due to L

c.

|

2.6 Allowable stresses

2.6.1 The allowable

stress, σa, is to be taken as the failure stress of

the component concerned multiplied by a stress factor, F,

which depends on the load case considered. The allowable stress is

given by the general expression:

where

|

σa

|

= |

allowable stress |

|

F

|

= |

stress factor |

|

σ |

= |

failure stress. |

2.6.2 The stress

factor, F, for steels in which σy/σu ≤0,85 is given in Table 7.2.3 Stress factor, F

where

|

σy

|

= |

yield

stress of material |

|

σu

|

= |

ultimate

tensile stress of the material. |

Table 7.2.3 Stress factor, F

| Load case

|

Stress factor, F

|

| Case 1

|

0,60

|

| Case 2

|

0,75

|

| Case 3

|

0,85

|

2.6.3 For steel

with σy/σu > 0,85, the allowable stress

is to be derived from the following expression:

|

σa

|

= |

0,459F (σu+ σy) |

|

τa

|

= |

0,266F (σu + σy) |

where

|

τa

|

= |

allowable shear stress. |

2.6.4 Steels with

σy/σu > 0,94 are, generally, not acceptable

and need to be specially considered.

2.6.5 The failure

stress for the elastic modes of failure are given in Table 7.2.4 Failure stress.

Table 7.2.4 Failure stress

| Mode of failure

|

Symbol

|

Failure stress

|

| Tension

|

σt

|

1,0σy

|

| Compression

|

σc

|

1,0σy

|

| Shear

|

τ

|

0,58σy

|

| Bearing

|

σbr

|

1,0σy

|

2.6.6 For components

subjected to combined stresses, the following allowable stress criteria

are to be used:

-

σxx ≤

σa

-

σyy ≤

σa

-

τo ≤

τa

-

where

|

σxx

|

= |

applied stress in x direction |

|

σyy

|

= |

applied stress in y direction |

|

τo

|

= |

applied shear stress. |

2.6.7 The allowable

bearing stress for rotatable and fitted pin connections are to be

taken as σa.br = 0,8σy for Case 1 and

Case 2 and σa.br = 1,0σy for Case 3.

The allowable bearing stress for rotatable pin connections with dynamics

or loose fit will be specially considered. Ball and roller bearings

are to be in accordance with a recognised National or International

Standard. The allowable bearing stress for other surface-tosurface

contact (pressures) is to be taken as in Ch 7, 2.6 Allowable stresses in

combination with Table 7.2.4 Failure stress

2.6.8 In the case

where the structural analysis is carried out by means of detailed

finite element models, higher allowable stresses can be applied as

follows:

-

σxx.FE ≤

1,1σa

-

σyy.FE ≤

1,1σa

-

τo.FE ≤

1,1τa

-

σe.FE ≤

1,12 σa

where

|

σ1.FE

|

= |

first principal stress |

|

σ2.FE

|

= |

second principal stress |

|

σe.FE

|

= |

equivalent stress |

Higher allowable stresses, as defined above, can only be applied

if the actual stresses are localised. In the case where the actual

stresses can also be calculated by means of analytical methods, these

higher allowable stresses are not applicable and Ch 7, 2.6 Allowable stresses 2.6.1 are to be applied.

2.7 Deflection criteria

2.7.1 The deflection

of the car structural members is not to exceed l/600 mm.

2.7.2 The maximum

permissible deflections for guide rails are as follows:

-

5,0 mm for guide rails

on which safety gears are operating.

-

10,0 mm for guide rails

without safety gears operating.

2.7.3 The car walls

or doors in their closed position are to be able to resist without

permanent deformation or elastic deformation greater than 15 mm a

force of 300 N evenly distributed over a circular or square area of

500 mm2, applied parallel to the deck from the inside towards

the outside of the car. The doors are to be capable of operating normally

after being subjected to this load.

2.7.4 The car roof

is to withstand, without permanent deformation, a force of 2000 N

representing two persons applied at any position, normal to deck and

distributed over an area of 200 x 200 mm2.

2.8 Guides

2.8.1 At least two

steel guide rails are to be installed for each car and each counterweight

or balance weight. The surface finish of the guide rails is to be

sufficiently smooth to allow free running of the car and each counterweight.

2.8.2 The guide

rails, their joints and attachments are to be designed to resist forces

resulting from the load combinations as in Ch 7, 2.5 Load combinations.

2.9 Safety gear

2.9.1 The car and

counterweight are to be provided with a safety gear capable of operating

only in a downward direction by gripping the guide rails. It is to

be capable of stopping the fully laden car or counterweight at the

tripping speed of the overspeed governor, even if the suspension device

breaks. The car safety gear is to be tripped by an overspeed governor,

but the counterweight safety gear may be tripped by failure of the

suspension gear or by a safety rope, in case the rated speed does

not exceed 1,0 m/s.

2.9.2 The car safety

gear shall be:

-

Of the progressive type

if the rated speed of the life exceeds 1,0 m/s.

and may be:

-

Of the instantaneous

type with buffered effect if the rated speed is not in excess of 1,0

m/s.

-

Of the instantaneous

type if the rated speed does not exceed 0,63 m/s.

For hydraulic lifts, safety devices such as restrictors and

rupture valves shall be provided.

2.9.3 The counterweight

safety gear is to be of the instantaneous type if the rated speed

is not in excess of 1,0 m/s and is to be of the instantaneous type

with buffered effect in the case of rated speeds in excess of 1,0

m/s.

2.9.4 The jaws of

safety devices are not to be used as guide shoes.

2.10 Overspeed governors

2.10.1 Tripping

of the overspeed governors for the car safety gear is to occur at

a speed of at least 115 per cent of the rated speed and less than

the following:

-

0,8 m/s for instantaneous

safety gears except for the captive roller type;

-

1,0 m/s for safety

gears of the captive roller type;

-

1,5 m/s for instantaneous

safety gear with buffered effect and for progressive safety gear used

for rated speeds not exceeding 1,0 m/s; or

-

1,25v + 0,25/v for

progressive safety gear for rated speeds exceeding 1,0 m/s,

where

2.10.2 The tripping

speed of an overspeed governor for a counterweight safety gear is

to be higher than that for the car safety gear but is not to exceed

it by more than 10 per cent.

2.10.3 The force

exerted by the overspeed governor when tripped is to be not less than

the greater of:

-

300 N; or

-

twice the force necessary

to engage the safety gear.

2.10.4 The breaking

load of the overspeed governor operating rope is to have a safety

factor of 8:1 with respect to the force required to operate the safety

gear. The rope is to be not less than 6,0 mm diameter and the ratio

of the bottom of the sheave groove diameter to rope diameter is to

be not less than 30:1.

2.11 Buffers

2.11.1 The car

and counterweight are to be provided with buffers at their bottom

limit of travel. When the car is resting on its fully compressed buffers,

the free distance between the pit floor and the lower extension of

the car floor is to be at least 0,5 m.

2.11.2 Energy accumulation

type buffers are only to be used if the rated speed of the lift does

not exceed 1,0 m/s. Energy accumulation type buffers with buffered

return movement are to be used only if the rated speed of the lift

does not exceed 1,6 m/s. Energy dissipation type buffers can be used

at any rated speed of the lift.

2.11.3 Where energy accumulation type buffers with linear characteristics are used,

the total possible stroke of the buffers are to be at least equal to twice the gravity

stopping distance corresponding to 115 per cent of the rated speed, i.e.:

|

S

|

= |

0,135V

2, but not less than 0,065 m |

where

|

S

|

= |

stroke, in metres |

|

V

|

= |

rated speed, in metres/second. |

Buffers are to be designed for the above stroke, under a static load between 2,5 and 4,0

times the self-weight of the car plus its rated load or the self-weight of the

counterweight.

2.11.4 Where non-linear

energy accumulation type buffers are used, the deceleration due to

the buffers acting on a freefalling car (with the rated load in it

and 115 per cent of the rated speed) is not to exceed 1,0g on

average. The maximum deceleration is not to exceed 2,5g and

the return speed of the car is not to exceed 1 m/s.

2.11.5 No permanent

deformation after buffer contact is permitted.

2.12 Hoisting arrangements

2.12.1 Each lift

is to have at least one engine of its own. The hoisting arrangements

may consist of:

-

Traction drive using

sheaves and ropes; or

-

Positive drive, consisting

of:

-

Drum and rope without

counterweight; or

-

Sprocket and chain.

-

Hydraulic cylinders,

which are either directly or indirectly acting.

2.12.2 The ratio

of the pitch diameter of sheaves, pulleys or drums and the rope diameter

of the suspension rope is to be at least 39:1. Where drum drive is

used, the drum is to be grooved and the fleet angle of the rope in

relation to the groove is not to be greater than 4° either side

of the groove axis.

2.12.3 Not more

than one layer of rope is to be wound on the drum and when the car

rests on its fully compressed buffers, one and a half turns of rope

are to remain in the grooves.

2.12.4 The safety

factor of the means of suspension, defined as the ratio of minimum

breaking load of the rope/chain to the maximum load on the rope/chain

when the car is at its lowest level and subjected to its rated load,

is to be not less than:

-

12:1 in the case of

traction drive with three ropes or more.

-

16:1 in the case of

traction drive with two ropes.

-

12:1 in the case of

drum drive or indirect hydraulic lifts.

-

10:1 in the case of

suspension chains.

2.12.5 A device

is to be fitted at one end of the hoisting arrangement to equalise

the tension in the ropes or chains. In the case of a two rope/chain

suspension, a device is to be fitted which stops the lift in the case

of abnormal relative extension of one rope/chain. Positive drive lifts

are to have a slack rope/chain detection device. If more than one

hydraulic cylinder is provided, they are to be hydraulically connected

to ensure pressure and compression force equilibrium in the hydraulic

cylinder.

2.12.6 Where compensating

ropes are used, the ratio between the pitch sheave groove diameter

and diameter of the rope is to be not less than 30:1.

2.12.7 For traction

sheaves, pulleys and sprockets, protection is to be provided to avoid:

-

Bodily injury.

-

The ropes/chains leaving

the pulleys/sprockets, if slack.

-

The introduction of

objects between ropes/chains and pulleys/sprockets.

2.12.8 The junction

between the rope and the rope termination is to be able to resist

at least 80 per cent of the minimum breaking load of the rope.

2.12.9 The lift

is to be provided with a braking system which operates automatically

in the event of loss of the mains power supply or in the event of

the loss of the supply to control circuits. Furthermore, it is to

be equipped with an emergency operation device either working manually

or with means of emergency electrical operation.

2.13 Lift trunk and motor room

2.13.1 In sections

of the ship where the lift trunk is required to contribute against

the spread of fire, the lift trunk and machinery spaces are to be

completely enclosed, suitably ventilated and constructed to give fire

protection in compliance with the requirements of SOLAS 1974, as amended.

2.13.2 Clearances

around the car are also to be guarded or arranged to preclude the

possibility of personnel falling between the car and trunk. In addition,

when the counterweight rests on its fully compressed buffer, the free

distance above the roof of the car is to be at least 0,75 m.

2.13.3 Only pipes

and cables belonging to the lift may be installed in the trunk. Travelling

cables are to be protected by an internally smooth metal trough which

is to be provided with a slot having rounded edges to allow free passage

of the cables leaving the lift car and be of sufficient width to allow

passage of the free hanging loop of the travelling cable.

2.13.4 Where two

or more lifts are fitted into one trunk, each car and its associated

counterweight is to be separated by means of sheet steel over the

full height of the trunk.

2.13.5 The lift

trunk is not to be part of the ship's ventilation ducting but is to

be ventilated by an independent system.

2.13.6 The trunk

entrances are to be located to prevent the ingress of water or cargo

into the trunk. The deck areas at entrances are to be non-slip and

of approved material which will not readily ignite.

2.13.7 Where the

lift is for the crew, the headroom of the trunk (the space above the

car roof when the car is in its highest position) is to incorporate

an escape hatch which opens outwards of at least 0,24 m2 with

a side length not less than 350 mm.

2.13.8 The floor

of the pit is to be able to support the car buffer considering four

times the static load being imposed by the mass of the fully laden

car without permanent deformation. In addition, if accessible spaces

do exist below the car, the counterweight or the balancing weight,

the base of the pit is to be designed for an imposed load of at least

5 kN/m2.

2.14 Lift car and counterweight

2.14.1 The car

is to be constructed of steel or equivalent non-flammable material,

have a non-slip floor and be provided with at least one handrail where

access for persons is clearly available. A load plate is to be prominently

displayed specifying the safe working load in persons and kilograms.

2.14.2 The car

entrances are to be provided with doors of an imperforate type fitted

with devices to prevent untimely opening and slamming. The clearance

between the car and car door is to be not more than 6,0 mm.

2.14.3 Power operated

doors are to be of the centre opening balanced type and manual doors

of the two-panel centre opening type or concertina or telescopic type

opening from one side only. Alternative arrangements which are considered

to be of equivalent safety will be accepted. The effort needed to

prevent the door from closing is not to exceed 150 N. Manual single

sliding entrances of the concertina or telescopic type are to be fitted

with devices to prevent slamming.

2.14.4 The car

and counterweight are to be guided over their full travel, including

overtravel and an independent guidance medium to limit car movement

in the event of primary guidance failure.

2.14.5 Counterweights

are to be constructed of steel or equivalent material and filler weights

are to be securely clamped in position within steel frames. Concrete

filler weights are not permitted. A suitable device is to be fitted

to stop and support the counterweight in the event of rope failure.

2.14.6 Traction

drive lifts are to incorporate a device to stop and support the car

if:

-

When a start is initiated,

the lift machine does not rotate.

-

The car or counterweight

is stopped in a downwards movement by an obstruction which causes

the ropes to slip on the driving pulley.

2.14.7 The device

is to function in a time not greater than the lesser of the following

values:

-

45 seconds.

-

Time for the car to

travel the full travel distance plus 10 seconds, with a minimum of

20 seconds if the full travel time is less than 10 seconds.

2.14.8 The device

is not to affect either the inspection or electrical recall operation.

2.14.9 The lift

is to be fitted with a device to prevent the lift operating in the

event of overload in the car. The overload is defined as rated load

plus 10 per cent with a minimum of rated load plus 75 kg.

2.15 Landing doors

2.15.1 Steel doors

are to be fitted at all entrance stations. When closed, the doors

are to provide fire resistance at least as effective as the trunk

to which they are fitted.

2.15.2 Power operated

doors are to be of the centre opening balanced type and manual doors

of the two-panel centre opening type or concertina or telescopic type

opening from one side only. Alternative arrangements which are considered

to be of equivalent safety will be accepted. The effort needed to

prevent the door from closing is not to exceed 150 N. Manual single

sliding entrances of the concertina or telescopic type are to be fitted

with devices to prevent slamming.

2.15.3 The doors,

including their locks, are to have mechanical strength such that in

the locked position they are to be able to resist, without permanent

deformation or elastic deformation greater than 15 mm, a force of

300 N. The force is to be evenly distributed over an area of 500 mm2 applied at right angles to the panel at any point on either

face. The doors are to be capable of operating normally after being

subjected to this load.

2.15.4 When the

distance between consecutive landing doors exceeds 11 m, intermediate

emergency doors are to be provided.

2.15.5 The horizontal

distance between the sill of the car and the sill of the landing doors

is not to exceed 35 mm.

2.16 Emergency means of escape

2.16.1 To enable

crew to escape independently, the trunk is to be fitted with a ladder

over its entire length leading to the escape hatch in the headroom.

2.16.2 For lifts

intended solely for passengers, a suitable ladder is to be provided

to give access to the lift car roof from a landing door. Another is

to be provided to give access into the car from the emergency opening

in the car roof. These ladders are to be kept in a watchkeeping room

or another room accessible to competent persons.

2.16.3 A trap door in the roof of the lift car with suitable access to it from the

inside is to be provided with an opening of at least 0,24 m2, having a side

length not less than 350 mm. Where the lift is solely for passengers, the trap door is

to be fitted with a mechanical lock which can only be operated from the outside. Where

the lift is solely for crew, the trap door is to be fitted with a mechanical lock which

can be operated from inside and outside the car. Alternative emergency evacuation

arrangements, procedures or methods instead of a trap door will be specially

considered.

2.16.4 For crew

lifts, an escape hatch is to be provided in the headroom of the trunk.

Opening the hatch from the outside is only to be possible by means

of a special key which is to be kept in a box immediately by the hatch.

2.16.5 Notices

in English, other languages and pictographs as necessary, describing

the escape routine, are to be fixed in the following locations:

-

Inside the car.

-

On the car roof.

-

Inside the trunk, adjacent

to every exit.

|