Section

11 Machinery strengthening requirements for navigation in multi-year ice conditions

– Ice Classes PC1, PC2, PC3, PC4, PC5, PC6, PC7 and Icebreaker

11.1 Application

11.1.1 The

contents of this Section apply to main propulsion, steering gear,

emergency and essential auxiliary systems essential for the safety

of the ship and the survivability of the crew and systems and equipment

required by assigned optional classification notations, e.g. navigational

equipment associated with the notations NAV1 or IBS.

11.1.2 For PC6 and PC7, the requirements will be considered with

respect to compliance with the Finnish - Swedish Ice Class Rules.

11.2 Drawings and particulars to be submitted

11.2.1 The

following drawings and particulars to be submitted:

-

Details of the

environmental conditions and the required ice class for the machinery,

if different from ship's ice class.

-

Detailed drawings

of the main propulsion machinery. Description of the main propulsion,

steering, emergency and essential auxiliaries are to include operational

limitations. Information on essential main propulsion load control

functions.

-

Description detailing

how main, emergency and auxiliary systems are located and protected

to prevent problems from freezing, ice and snow and evidence of their

capability to operate in intended environmental conditions.

-

Calculations

and documentation indicating compliance with the requirements of this

Section.

11.3 System design

11.3.1 Systems,

subject to damage by freezing, are to be drainable.

11.3.2 Single

screw vessels classed PC1 to PC5 inclusive are to have means provided

to ensure sufficient vessel operation in the case of propeller damage

including CP mechanism.

11.4 Materials exposed to sea-water

11.4.1 Materials

exposed to sea-water, such as propeller blades, propeller hub and

blade bolts are to have an elongation not less than 15 per cent on

a test piece the length of which is five times the diameter. Charpy

V impact test are to be carried out for other than bronze and austenitic

steel materials. Test pieces taken from the propeller castings are

to be representative of the thickest section of the blade. An average

impact energy value of 20 J taken from three Charpy V tests is to

be obtained at minus 10°C.

11.5 Materials exposed to sea-water temperature

11.5.1 Materials

exposed to sea-water temperature are to be of steel or other approved

ductile material. An average impact energy value of 20 J taken from

three tests is to be obtained at minus 10°C.

11.6 Materials exposed to low air temperature

11.6.1 Materials of essential components exposed to low air temperature shall be

of steel or other approved ductile material. An average impact energy value of 20 J

taken from three Charpy V tests is to be obtained at 10°C below the lowest design

temperature. See also the Rules for the Winterisation of Ships, July 2022 .

11.7 Propeller ice interaction

11.7.1 These

Rules cover open and ducted type propellers situated at the stern

of a vessel having controllable pitch or fixed pitch blades. Ice loads

on bow propellers and pulling type propellers are to receive special

consideration. The given loads are expected, single occurrence, maximum

values for the whole ship's service life for normal operational conditions.

These loads do not cover off-design operational conditions, for example

when a stopped propeller is dragged through ice. These Rules apply

also for azimuthing (geared and podded) thrusters considering loads

due to propeller ice interaction. However, ice loads due to ice impacts

on the body of azimuthing thrusters are not covered by this Section.

11.7.2 The

loads given in Pt 8, Ch 2, 11.7 Propeller ice interaction are total

loads (unless otherwise stated) during ice interaction and are to

be applied separately (unless otherwise stated) and are intended for

component strength calculations only. The different loads given here

are to be applied separately.

11.7.3

F

b is a force bending a propeller blade backwards when the propeller

mills an ice block while rotating ahead. F

f is

a force bending a propeller blade forwards when a propeller interacts

with an ice block while rotating ahead.

11.8 Ice class factors

11.8.1

Table 2.11.1 Propeller ice loads index lists the design ice

thickness and ice strength index to be used for estimation of the

propeller ice loads.

Table 2.11.1 Propeller ice loads index

|

Ice Class

|

H

ice

, in metres

|

S

ice

|

S

qice

|

|

PC1

|

4,0

|

1,2

|

1,15

|

|

PC2

|

3,5

|

1,1

|

1,15

|

|

PC3

|

3,0

|

1,1

|

1,15

|

|

PC4

|

2,5

|

1,1

|

1,15

|

|

PC5

|

2,0

|

1,1

|

1,15

|

|

PC6

|

1,75

|

1,0

|

1,00

|

|

PC7

|

1,5

|

1,0

|

1,00

|

| where

|

|

H

ice

|

= |

ice thickness for machinery strength design |

|

|

S

ice

|

= |

ice strength index for blade ice force |

|

|

S

qice

|

= |

ice strength index for blade ice torque |

|

11.9 Design ice loads for open propeller

11.9.1 The

maximum backward blade force, F

b, is to be

taken as:

when D < D

limit

|

F

b

|

= |

kN kN |

when D ≥ D

limit

|

F

b

|

= |

kN kN |

where

|

D

limit

|

= |

0,85 (H

ice)1,4

|

|

n

|

= |

the

nominal rotational speed in rev/sec (at MCR free running condition)

for CP-propeller and 85 per cent of the nominal rotational speed (at

MCR free running condition) for a FP-propeller (regardless of driving

engine type). |

11.9.2

F

b is to be applied as a uniform pressure distribution to an

area on the back (suction) side of the blade for the following load

cases:

-

Load case 1:

from 0,6R to the tip and from the blade leading edge

to a value of 0,2 chord length

-

Load case 2:

a load equal to 50 per cent of the F

b is to

be applied on the propeller tip area outside of 0,9R

-

Load case 5:

for reversible propellers, a load equal to 60 per cent of the F

b is to be applied from 0,6R to the tip and from

the blade trailing edge to a value of 0,2 chord length.

See load cases 1, 2, and 5 in Table 2.11.4 Load cases for open

propeller.

11.9.3 The

maximum forward blade force, F

f, is to be

taken as:

when D < D

limit

|

F

f

|

= |

kN kN

|

when D ≥ D

limit

|

F

f

|

= |

kN kN

|

where

|

D

limit

|

= |

m m

|

|

d

|

= |

propeller

hub diameter, in metres |

|

D

|

= |

propeller

diameter, in metres |

|

EAR

|

= |

expanded

blade area ratio |

|

Z

|

= |

number

of propeller blades. |

11.9.4

F

f is to be applied as a uniform pressure distribution to an

area on the face (pressure) side of the blade for the following load

cases:

-

Load case 3:

from 0,6R to the tip and from the blade leading edge

to a value of 0,2 chord length.

-

Load case 4:

a load equal to 50 per cent of F

f is to be

applied on the propeller tip area outside of 0,9R.

-

Load case 5:

for reversible propellers a load equal to 60 per cent of F

f is to be applied from 0,6R to the tip and from

the blade trailing edge to a value of 0,2 chord length.

See load cases 3, 4, and 5 in Table 2.11.4 Load cases for open

propeller.

11.9.5 The

blade spindle torque, Q

smax, around the spindle

axis of the blade fitting is to be calculated both for the load cases

described in Pt 8, Ch 2, 11.9 Design ice loads for open propeller 11.9.1 and Pt 8, Ch 2, 11.9 Design ice loads for open propeller 11.9.3 for F

h and F

f. If these spindle torque values are less than

the default value given below, the default minimum value is to be

used:

where

|

C

0,7

|

= |

length of the blade chord at 0,7R radius, in m

|

|

F

|

= |

F

h or F

f whichever has the greater absolute

value.

|

11.9.6 The

maximum propeller ice torque applied to the propeller is to be taken

as:

when D < D

limit

|

Q

max

|

= |

kNm kNm |

when D ≥ D

limit

|

Q

max

|

= |

kNm kNm |

where

|

S

qice

|

= |

ice strength index for blade ice torque |

|

P

0,7

|

= |

propeller pitch at 0,7R, in m

|

|

|

= |

for CP propellers, P

0,7 is to correspond

to MCR in bollard condition. If not known, P

0,7 is

to be taken as 0,7P

0,7n

|

|

P

0,7n

|

= |

propeller pitch at MCR free running condition |

|

t

0,7

|

= |

maximum thickness at 0,7R

|

|

n

|

= |

the rotational propeller speed, in rev/sec, at bollard condition.

If not known, n is to be taken as follows: for CP propellers and FP

propellers driven by turbine or electric motor = n

n

|

|

for FP propellers driven by engine |

= |

0,85n

n

|

|

n

n

|

= |

the nominal rotational speed at MCR, free running condition. |

11.9.7 The

maximum propeller ice thrust applied to the shaft is to be taken as:

11.10 Design ice loads for ducted propellers

11.10.1 The

maximum backward blade force, F

b is to be

taken as:

when D < D

limit

|

F

b

|

= |

|

when D ≥ D

limit

|

F

b

|

= |

|

where

11.10.2

F

b is to be applied as a uniform pressure distribution

to an area on the back side for the following load cases:

-

Load case 1:

on the back of the blade from 0,6R to the tip and from

the blade leading edge to a value of 0,2 chord length

-

Load case 5:

for reversible rotation propellers a load equal to 60 per cent of F

b is applied on the blade face from 0,6R to

the tip and from the blade trailing edge to a value of 0,2 chord length.

See load cases 1 and 5 in Table 2.11.5 Load cases for ducted

propeller.

11.10.3 The

maximum forward blade force, F

f, is to be

taken as:

when D ≤ D

limit

|

F

f

|

= |

kN kN

|

when D > D

limit

|

F

f

|

= |

kN kN

|

where

|

D

limit

|

= |

m. m.

|

11.10.4

F

f is to be applied as a uniform pressure distribution

to an area on the face (pressure) side for the following load cases:

-

Load case 3:

on the blade face from 0,6R to the tip and from the blade

leading edge to a value of 0,5 chord length.

-

Load case 5:

a load equal to 60 per cent F

f is to be applied

from 0,6R to the tip and from the blade leading edge

to a value of 0,2 chord length.

See load cases 3 and 5 in Table 2.11.5 Load cases for ducted

propeller.

11.10.5 The

maximum propeller ice torque, Q

max, applied

to the propeller is to be taken as:

when D ≤ D

limit

|

Q

max

|

= |

kNm kNm |

when D > D

limit

|

Q

max

|

= |

kNm kNm |

where

|

D

limit

|

= |

1,8H

ice in metres

|

|

n

|

= |

the

rotational propeller speed, in rps, at bollard condition. If not known, n is to be taken as follows: for CP propellers and FP propellers

driven by turbine or electric motor = n

n

|

|

for FP propellers driven by engine |

= |

0,85n

n

|

|

n

n

|

= |

the nominal rotational speed at MCR at free running condition |

|

P

0,7

|

= |

for CP propellers, propeller pitch, P

0,7 is

to correspond to MCR in bollard condition. If not known, P

0,7 is to be taken as 0,7P

0,7n

|

|

P

0,7n

|

= |

propeller pitch at MCR free running condition. |

11.10.6 The

spindle torque for CP-mechanism design, Q

smax,

around the spindle axis of the blade fitting is to be calculated for

the load case described in Pt 8, Ch 2, 11.7 Propeller ice interaction.

If these spindle torque values are less than the default value given

below, the default value is to be used:

where

|

C

0,7

|

= |

the length of the blade section at 0,7R

|

|

F

|

= |

F

b or F

f whichever has the greater absolute

value.

|

11.10.7 The

maximum propeller ice thrust (applied to the shaft at the location

of the propeller) is to be taken as:

11.11 Design loads on propulsion line – Torque

11.11.1 The

propeller ice torque excitation for shaft line dynamic analysis is

to be described by a sequence of blade impacts which are of half sine

shape and occur at the blade. The torque due to a single blade ice

impact as a function of the propeller rotation angle is to be taken

as:

|

Q(φ) |

= |

|

where

Table 2.11.2 Torque load factors

| Torque excitation

|

Propeller-ice interaction

|

C

q

|

αi.

|

| Case 1

|

Single ice

block

|

0,50

|

45

|

| Case 2

|

Single ice

block

|

0,75

|

90

|

| Case 3

|

Single ice

block

|

1,00

|

135

|

| Case 4

|

Two ice blocks

with 45 degree phase in rotation angle

|

0,50

|

45

|

11.11.2 The

total ice torque is obtained by summing the torque of single blades

taking into account the phase shift 360°/Z. The number

of propeller revolutions during a milling sequence is to be obtained

with the formula:

where

Figure 2.11.1 The shape of the propeller ice torque excitation for 45,

90, 135 degrees single blade impact sequences and 45 degrees double

blade impact sequence (two ice pieces) on a four bladed propeller

11.11.3 The milling torque sequence duration is not valid for pulling bow

propellers, which are subject to special consideration. The response torque at any shaft

component is to be analysed considering excitation torque Q(φ) at the propeller,

actual engine torque, Qe, and mass elastic system. Where

Qe is the actual maximum engine torque at considered speed.

11.11.4 The design torque, Qr, of the shaft component is to be

determined by means of torsional vibration analysis of the propulsion line. Calculations

are to be carried out for all excitation cases given above and the response is to be

applied on top of the mean hydrodynamic torque in bollard condition at considered

propeller rotational speed.

11.12 Design loads on propulsion line – Maximum response thrust

11.12.1 The

maximum thrust along the propeller shaft line is to be calculated

with the formulae below. The factors 2,2 and 1,5 take into account

the dynamic magnification due to axial vibration. Alternatively, the

propeller thrust magnification factor may be calculated by dynamic

analysis.

Maximum shaft thrust forwards

Maximum shaft thrust backwards

where

|

T

f

|

= |

maximum forward propeller ice thrust, in kN. |

Table 2.11.3 Propeller thrust factor

| Propeller type

|

T

n

|

| CP propellers

(open)

|

1,25T

|

| CP propellers

(ducted)

|

1,10T

|

| FP propellers

driven by turbine or electric motor

|

T

|

| FP propellers driven

by engine (open)

|

0,85T

|

| FP propellers

driven by engine (ducted)

|

0,75T

|

| Symbols

|

|

T

|

= |

nominal propeller thrust at MCR at free running open

water conditions |

|

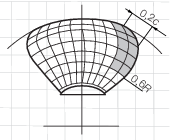

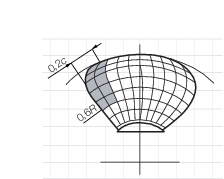

Table 2.11.4 Load cases for open

propeller

| Load case

|

Force

|

Loaded area

|

Right handed propeller blade seen

from back

|

| Load case 1

|

F

b

|

Uniform pressure

applied on the back of the blade (suction side) to an area from 0,6R

to the tip and from the leading edge to 0,2 times the chord length.

|

|

| Load case 2

|

50% of F

b

|

Uniform pressure applied on the back of the blade

(suction side) on the propeller tip area outside of 0,9R radius.

|

|

| Load case 3

|

F

f

|

Uniform pressure applied on the blade face

(pressure side) to an area from 0,6R to the tip and from the leading

edge to 0,2 times the chord length.

|

|

| Load case 4

|

50% of F

f

|

Uniform pressure applied on propeller face

(pressure side) on the propeller tip area outside of 0,9R radius.

|

|

| Load case 5

|

60% of F

f or F

b whichever is the greater

|

Uniform pressure applied on propeller face

(pressure side) to an area from 0,6R to the tip and from the trailing

edge to 0,2 times the chord length.

|

|

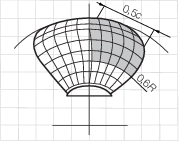

Table 2.11.5 Load cases for ducted

propeller

|

Load case

|

Force

|

Loaded area

|

Right handed propeller blade seen from back

|

| Load case 1

|

F

b

|

Uniform pressure applied on the back of the

blade (suction side) to an area from 0,6R to the tip and from the

leading edge to 0,2 times the chord length

|

|

| Load case 3

|

F

f

|

Uniform pressure applied on the blade face

(pressure side) to an area from 0,6R to the tip and from the leading

edge to 0,5 times the chord length

|

|

| Load case 5

|

60% of F

f or F

b

|

Uniform pressure applied on propeller face

(pressure side) to an area from 0,6R to the tip and from the trailing

edge to 0,2 times the chord length

|

|

11.13 Design loads on propulsion line – Blade failure load for

both open and nozzle propellers

11.13.1 The

force is acting at 0,8R in the weakest direction of the

blade and at a spindle arm of 2/3 of the distance of axis of blade

rotation of leading and trailing edge whichever is the greatest. The

blade failure load is to be taken as:

|

F

ex

|

= |

|

where

|

σ0,2 and σu

|

= |

representative values for the blade material |

|

c, t and r

|

= |

the actual chord length, thickness and radius of the cylindrical

root section of the blade at the weakest section outside root fillet

and typically will be at the termination of the fillet into the blade

profile. |

11.14 Design – Design principle

11.14.1 The

strength of the propulsion line is to be designed:

-

for maximum

loads in Pt 8, Ch 2, 11.7 Propeller ice interaction;

-

such that the

plastic bending of a propeller blade will not cause damage in other

propulsion line components;

-

with sufficient

fatigue strength.

11.15 Design – Azimuthing main propulsors

11.15.1 In

addition to the above requirements, special consideration will be

given to the loading cases which are extraordinary for propulsion

units when compared with conventional propellers. Estimation of the

loading cases must reflect the operational realities of the ship and

the thrusters. In this respect, for example, the loads caused by impacts

of ice blocks on the propeller hub of a pulling propeller are to be

considered. Also, loads due to thrusters operating in an oblique angle

to the flow are to be considered. The steering mechanism, the fitting

of the unit and the body of the thruster is to be designed to withstand

the loss of a blade without damage. The plastic bending of a blade

is to be considered in the propeller blade position, which causes

the maximum load on the studied component.

11.15.2 Azimuth

thrusters are also to be designed for estimated loads due to thruster

body/ice interaction as in Pt 8, Ch 2, 10.26 Appendages.

11.16 Blade design – Maximum blade stresses

11.16.1 Blade

stresses are to be calculated using the backward and forward loads

given in sub-Sections Pt 8, Ch 2, 11.9 Design ice loads for open propeller and Pt 8, Ch 2, 11.10 Design ice loads for ducted propellers. The stresses are to be calculated

with recognised and well documented FE-analysis or another acceptable

alternative method. The stresses on the blade are not to exceed the

allowable stresses, σall, for the blade material given

below. The calculated blade stress for the maximum ice load is to

comply with the following:

|

σcalc < σall

|

= |

|

where

|

σref

|

= |

reference

stress, defined as: |

|

|

= |

0,6 σ0,2 +

0,4σu whichever is less

|

|

σu and σ0,2

|

= |

representative values for the blade material. |

11.17 Blade design – Blade edge thickness

11.17.1 The

blade edge thicknesses, t

ed, and tip thickness t

tip, are to be greater than t

edge given

by the following formula:

where

|

x

|

= |

distance

from the blade edge measured along the cylindrical sections from the

edge and is to be 2,5 per cent of chord length, however not to be

taken greater than 45 mm. |

|

|

= |

In the tip area

(above 0,975R radius) x is to be taken as 2,5 per cent

of 0,975R section length and is to be measured perpendicularly

to the edge, however not to be taken greater than 45 mm.

|

|

|

= |

16 MPa for leading

edge and tip thickness |

11.17.2 The

requirement for edge thickness is to be applied for leading edge and

in case of reversible rotation open propellers also for the trailing

edge. Tip thickness refers to the maximum measured thickness in the

tip area above 0,975R radius. The edge thickness in the

area between the position of maximum tip thickness and edge thickness

at 0,975 radius has to be interpolated between edge and tip thickness

value and smoothly distributed.

11.18 Prime movers

11.18.1 The

main engine is to be capable of being started and running the propeller

with the CP in full pitch.

11.18.2 Provisions

are to be made for heating arrangements to ensure ready starting of

the cold emergency power units at an ambient temperature applicable

to the Polar class of the ship.

11.18.3 Emergency

power units are to be equipped with starting devices with a stored

energy capability of at least three consecutive starts at the design

temperature in Pt 8, Ch 2, 11.18 Prime movers 11.18.2.

The source of stored energy is to be protected to preclude critical

depletion by the automatic starting system, unless a second independent

means of starting is provided. A second source of energy is to be

provided for an additional three starts within 30 min., unless manual

starting can be demonstrated to be effective.

11.19 Machinery fastening loading accelerations

11.19.1 Essential

equipment and main propulsion machinery supports are to be suitable

for the accelerations as indicated in the following. Accelerations

are to be considered acting independently.

11.19.2 The

maximum longitudinal impact acceleration, al, at any point

along the hull girder is to be taken as:

|

a

l

|

= |

m/s2 m/s2

|

where

|

H

|

= |

distance

from the waterline to the point being considered, in metres |

|

L

|

= |

length

between perpendiculars, in metres |

|

φ |

= |

maximum friction

angle between steel and ice, normally taken as 10, in degrees |

|

γ |

= |

bow stem

angle at waterline, in degrees |

11.19.3 The

combined vertical impact acceleration, a

v,

at any point along the hull girder, is to be taken as:

|

a

v

|

= |

m/s2 m/s2

|

where

|

|

= |

1,3 at the AP for

vessels conducting icebreaking astern |

- intermediate values are to be determined by linear interpolation.

11.19.4 The

combined transverse impact acceleration, at, at any point

along hull girder, is to be taken as:

|

a

t

|

= |

m/s2 m/s2

|

where

|

|

= |

1,5 at the AP for

vessels conducting icebreaking astern |

- intermediate values are to be determined by linear interpolation

11.20 Auxiliary systems

11.20.1 Machinery

is to be protected from the harmful effects of ingestion or accumulation

of ice or snow. Where continuous operation is necessary, means are

to be provided to purge the system of accumulated ice or snow.

11.20.2 Means

are to be provided to prevent damage due to freezing, to tanks containing

liquids.

11.20.3 Vent

pipes, intake and discharge pipes and associated systems are to be

designed to prevent blockage due to freezing or ice and snow accumulation.

11.21 Sea inlets and cooling water systems

11.21.1 Cooling

water systems for machinery that are essential for the propulsion

and safety of the vessel, including sea chest inlets, are to be designed

for the environmental conditions applicable to the ice class.

11.21.2 At

least two sea chests are to be arranged as ice boxes for classes PC1 to PC5 inclusive. The calculated volume for each

of the ice boxes is to be at least 1 m3 for every 750 kW

of the total installed power. For PC6 and PC7,

there is to be at least one ice box located preferably near centreline.

11.21.3 Ice

boxes are to be designed for an effective separation of ice and venting

of air.

11.21.4 Sea

inlet valves are to be secured directly to the ice boxes. The valves

are to be a full bore type.

11.21.5 Ice

boxes and sea bays are to have vent pipes and are to have shut off

valves connected directly to the shell.

11.21.6 Means

are to be provided to prevent freezing of sea bays, ice boxes, ship

side valves and fittings above the load waterline.

11.21.7 Efficient

means are to be provided to re-circulate cooling seawater to the ice

box. The total sectional area of the circulating pipes is not to be

less than the area of the cooling water discharge pipe.

11.21.8 Detachable

gratings or manholes are to be provided for ice boxes. Manholes are

to be located above the deepest load line. Access is to be provided

to the ice box from above.

11.21.9 Openings

in ship sides for ice boxes are to be fitted with gratings, or holes

or slots in shell plates. The net area through these openings is to

be not less than 5 times the area of the inlet pipe. The diameter

of holes and width of slot in shell plating is to be not less than

20 mm. Gratings of the ice boxes are to be provided with a means of

clearing. Clearing pipes are to be provided with screw-down type non-return

valves.

11.22 Ballast tanks

11.23 Ventilation system

11.23.1 The

air intakes for machinery and accommodation ventilation are to be

located on both sides of the ship.

11.23.2 Accommodation

and ventilation air intakes are to be provided with means of heating.

11.23.3 The

temperature of the inlet air provided to machinery from the air intakes

is to be suitable for the safe operation of the machinery.

11.24 Steering arrangements

11.24.1 The steering gear for ships assigned the notation Icebreaker

should be designed such that the rudder is centred automatically, immediately

before the ship goes astern.

11.24.2 The effective holding torque of the rudder actuator, at safety valve set

pressure, is obtained by multiplying the open water torque requirements

(QR) at open water design speed (maximum 18 knots) determined

from Pt 3, Ch 13, 2 Rudders, by the factor obtained from

Table 2.11.6 Steering gear holding torque factor.

Table 2.11.6 Steering gear holding torque factor

| Ice

Class

|

PC1

|

PC2

|

PC3

|

PC4

|

PC5

|

PC6

|

PC7

|

| Holding

torque factor

|

5

|

5

|

3

|

3

|

3

|

2

|

1,5

|

11.24.3 The rudder actuator is to be protected by torque relief arrangements,

assuming the turning speeds obtained from Table 2.11.7 Rudder turning speed for relief valve discharge capacity without undue pressure rise.

Table 2.11.7 Rudder turning speed for relief valve discharge capacity

| Ice

Class

|

PC1,

PC2

|

PC3, PC4,

PC5

|

PC6,

PC7

|

| Rudder

turning speed (degrees/second)

|

8

|

6

|

4

|

11.24.4 For icebreakers, additional fast acting torque relief arrangements

(acting at 15 per cent higher pressure than the set pressure of safety valves in

Pt 8, Ch 2, 11.24 Steering arrangements 11.24.2) are to provide effective protection of the rudder actuator in case

the rudder is pushed rapidly hard over against the stops assuming the turning speeds

obtained from Table 2.11.8 Rudder turning speed for fast acting relief valve discharge capacity. The arrangement is to be

such that steering capacity is readily regained. Fast acting torque relief

arrangements are recommended for ships without the Icebreaker notation.

Table 2.11.8 Rudder turning speed for fast acting relief valve discharge capacity

| Ice

Class

|

PC1,

PC2

|

PC3, PC4,

PC5

|

PC6,

PC7

|

| Rudder

turning speed (degrees/second)

|

40

|

20

|

10

|

11.25 Alternative design

11.25.1 As

an alternative a comprehensive design study may be submitted and may

be requested to be validated by an agreed test programme.

|