Section

5 Hydraulic cylinders

5.1 General

5.1.2 For the purposes of certification or classification of lifting

appliances, hydraulic cylinders will be considered for structural adequacy including

the effects of hydraulic pressure. Although they are not considered to be pressure

vessels, they will nevertheless be required to undergo a pressure load test at the

manufacturer’s works. See

Ch 9, 5.9 Testing for testing requirements.

5.1.3 Hydraulic cylinders with special features, such as telescopic types

(including versions with intermediate supports), self-locking types, with trunnion

mounts, with unconventional or no eye plates at one or both ends, etc. shall, as far

as possible, be designed in accordance with the requirements outlined in this

Section. In such cases, design calculations covering those special features will be

required to be submitted.

5.1.4 Where hydraulic cylinders are used in applications covered by specialist

Chapters in this Code, requirements given in those Chapters relating to hydraulic

cylinders shall also be taken into consideration as applicable.

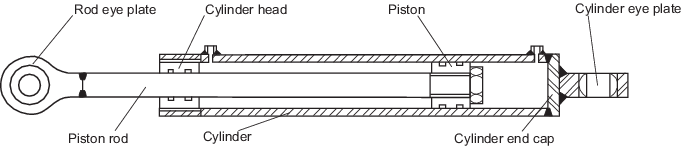

Figure 9.5.1 Hydraulic cylinder

(simplified)

5.2 Definitions

5.2.1 Design pressure

The design pressure, PD is the maximum internal pressure for which

the cylinder has been designed. The design pressure is not to be less than the

highest set pressure of any relief valves in the hydraulic system and/or relief

valves mounted directly on the hydraulic cylinder ports.

5.2.2 Working pressure

The maximum working pressure, Pw, is the maximum

dynamic internal pressure that the cylinder may be subject to in operation which

includes internal pressures generated by external forces e.g. due to the SWL

enhanced by the hoisting factor, accelerations etc., but excludes short duration

pressure peaks (See

Ch 9, 5.3 General design requirements 5.3.6). The

maximum working pressure is not to exceed the design pressure, PD.

5.2.3 Relief valve pressure setting

The relief valve setting is the pressure at which the relief valve is set to

activate.

5.3 General design requirements

5.3.1 Welded cylinder pipes should not generally be used for hydraulic cylinder

applications. Proposals to use welded cylinder pipes will be specially considered

and need to be agreed with LR. The weld procedure including any heat treatment and

non-destructive examination shall be submitted to LR for appraisal.

5.3.2 The cylinder head (or gland) shall have adequate length and capability to guide the

piston rod under load including the self-weight of the hydraulic cylinder. The seals

are to be adequate to prevent hydraulic leakage, and water and dirt entering the

cylinder.

5.3.3 The piston rod shall be suitably finished and coated to ensure adequate sealing

capability and corrosion protection.

5.3.4 The eye plates shall be equipped, where possible, with spherical bearings to prevent

additional end bending moments being introduced. The design shall not allow free

movement of the eye plate between the supporting plates in the direction of the pin.

Alternative arrangements will be specially considered.

5.3.5 The relief valve pressure setting shall not exceed the design pressure.

This setting may be temporarily increased to allow the crane to be proof load

tested, but is to be reset for normal operations. See

Ch 9, 5.9 Testing 5.9.5. To prevent unnecessary

activation of the relief valve, it is desirable that there should be a margin

between the normal pressure at which the hydraulic cylinder operates and the lowest

pressure at which any relief valve is set to lift. The relief valve setting may be

up to 1,25 times the maximum working pressure. Alternative proposals will be

specially considered.

5.3.6 Short duration pressure peaks which exceed the maximum working pressure,

Pw, typical of certain offshore crane applications, need not

be considered in determination of the maximum working pressure providing the

pressure peaks are less than 0,94 x Hydraulic Test Pressure, PT

(see

Ch 9, 5.9 Testing 5.9.1) and less than

or equal to the Design Pressure, PD.

5.4 Design criteria

5.4.1 Hydraulic cylinders fitted to lifting appliances are to be designed to

withstand the load combinations as given in the Chapter relevant to the actual

application (see

Ch 4, 2.15 Load combinations and Ch 4, 3.5 Load combinations for Shipboard and

Offshore cranes, Ch 7, 2.5 Load combinations for Lifts). The factored

forces (hoisting and duty factor, as applicable), stowage, test load and any

exceptional conditions resulting from the actual application shall be

considered.

5.4.2 Hydraulic cylinders fitted to life-saving appliances are to be designed to meet the

operational and load test conditions required by SOLAS and the IMO LSA Code as

applicable.

5.4.3 Depending on the design of the hydraulic cylinder the following calculations and

validations are usually required to be carried out as a minimum:

- The eye plates shall be designed for the following conditions,

see

Ch 9, 5.8 Proof of strength and stability 5.8.4:

- local bending, normal and shear-out stress due to pull

forces.

- bearing stress due to pull and push forces.

- The following threaded, bolted and/or welded connections (as

applicable) are to be calculated as per Ch 9, 5.8 Proof of strength and stability 5.8.1,

Ch 4, 2.23 Allowable stress – Joints and connections (as

applicable) and/or Ch 9, 5.8 Proof of strength and stability 5.8.2

respectively:

- connection of cylinder or rod eye plates with the

cylinder’s end cap or piston rod.

- connection of piston with piston rod.

- connection of cylinder head with cylinder tube.

- connection of cylinder end cap with cylinder tube.

- The thickness of the end cap can be calculated as detailed in Ch 9, 5.8 Proof of strength and stability 5.8.2.

- The hoop and longitudinal stress of the hydraulic cylinder wall

shall be calculated as detailed in Ch 9, 5.8 Proof of strength and stability 5.8.5.

- Diametrical expansion of cylinders with large bores possibly affecting the

sealing of the piston is to be considered.

- Bolted connections are to be designed in compliance with Ch 4, 2.23 Allowable stress – Joints and connections. Tapped

holes are to be in compliance with Ch 9, 5.8 Proof of strength and stability 5.8.1.

The thread-engaging length is to be at least 1,5 times the major bolt diameter.

- Axial forces on piston rod.

- External pressure on hollow piston rods shall be taken into consideration as

applicable.

- The pins supporting the eye plates shall be calculated for shear and bending

stresses.

- Trunnion mounts (if fitted) to the cylinder tube.

- Additional calculations for other components of the hydraulic cylinder may be

required depending on the actual design.

5.4.4 For the evaluation of the required design, working and relief valves pressures, it is

not required to take the duty factor into account. For all other design

calculations, the duty factor is required to be taken into consideration.

5.5 Materials

5.5.1 The material requirements (including the Charpy V-notch test

requirements) are to be as per the Chapters applicable to the appliance the

hydraulic cylinder will be used in. For lifting appliances the materials for

hydraulic cylinders are to be selected to meet the requirements detailed in Ch 11 Materials and Fabrication and Ch 4, 2.25 Materials. For life-saving appliances the

materials for hydraulic cylinders are to be selected to meet the requirements of

Ch 11 Materials and Fabrication and Ch 3, 1.11 Materials.

5.5.2 The materials used for hydraulic cylinder applications are to be sufficiently

ductile. Materials that have an elongation of less than 14 per cent shall be

specially considered by LR.

5.5.3 Pressure retaining parts of carbon-manganese steel grades are to be delivered in the

normalised or hot finished condition, whereas alloy grade steels are to be delivered

in the quenched and tempered condition.

5.5.4 The use of stainless steel products in hydraulic cylinder applications is required to

be specially considered by LR.

5.5.5 In cases where hydraulic cylinders are fitted to life-saving appliances, attention is

drawn to materials where the yield strength is very low compared to the ultimate

tensile strength. In such cases, it is particularly important to consider the proof

load test case as a design case in order to prevent actual stresses being in excess

of the yield strength of the material.

5.5.6 For hydraulic cylinder components subjected to tensile loads (e.g. cylinder end caps

on pull cylinders) consideration is to be given to the application of Z-grade

material. For the evaluation whether Z-grade materials are to be used in the design

the methods and criteria of a recognised National or International Standard can be

applied.

5.6 Safety features

5.6.1 Hydraulic cylinders are to be equipped with pilot-operated non-return

valves at both the inlet and outlet manifolds to ensure that the cylinders remain in

position in the event of a hydraulic failure (e.g. hose/tube rupture). The required

pilot-operated non-return valves are to be fitted directly to the cylinder ports.

The cylinder ports shall either be an integral part of the cylinder wall or shall be

connected by means of full penetration welds. Proposals to use valve types other

than pilot-operated non-return valves will be specially considered.

5.6.2 The hydraulic system shall be equipped with relief valves to protect the

system against overpressure in the hydraulic circuit originating from the lifting

appliance itself or the hydraulic system/pump.

5.7 Allowable stresses

5.7.2 For hydraulic cylinders subject to push loading a second order buckling analysis is

to be carried out unless it can be demonstrated that a simplified analysis would

give conservative results.

5.7.4 In second order buckling calculations, the hydraulic cylinder shall be idealised

taking into account the relevant cross-sections (piston rod and cylinder) and shall

be calculated by means of the principles of the 2nd order theory. The calculation

shall include all relevant, but at least, the following influences:

- Dead weight and angle of the hydraulic cylinder;

- at least a sinusoidal pre-deformation of L/300 along the various possible

hydraulic cylinder lengths (other types and values of pre-deformations maybe

required and will be specially considered);

- any hoisting factor and material stress factor to be used to enhance the

external load used in the calculation;

- the bending stresses (due to 2nd order theory) of the cylinder

shall be superimposed with the hoop and radial stress due to internal

pressure (reference is made to Ch 9, 5.8 Proof of strength and stability 5.8.5);

- as this is a 2nd order analysis, all safety (stress factor, hoisting factor,

etc.) need to be placed on the load side.

5.7.5 Alternative proposals to demonstrate adequate safety against column buckling will be

specially considered.

5.8 Proof of strength and stability

5.8.1 Threaded connections (as opposed to bolted connections) shall be calculated as

follows:

where

|

τTh |

= |

shear stress in thread, in MPa |

|

F |

= |

axial force applied to the threaded connection, in N |

|

d3 |

= |

root diameter of the threaded connection, in mm |

|

l |

= |

length of the threaded connection, in mm |

|

τa |

= |

allowable shear stress, in MPa |

The hydraulic cylinder tube thickness at the threaded section is to be

not less than the required thickness for internal pressure measured at the bottom of

the internal thread. Alternatively, detailed calculations for the threaded

connection as per a recognised National or International Standard (e.g. EN 14359)

may be performed and submitted for consideration.

5.8.3 The hydraulic cylinder end cap may be calculated using the formula below:

where

|

σec |

= |

bending stress in the end cap due to internal pressure, in MPa |

|

p |

= |

internal pressure acting on the end cap, in MPa |

|

do |

= |

outer diameter of the cylinder, in mm |

|

di |

= |

inner diameter of the cylinder, in mm |

|

υ |

= |

Poisson's ratio |

|

t |

= |

wall thickness of the end cap, in mm |

|

σa |

= |

allowable bending stress as per Ch 9, 5.7 Allowable stresses , in MPa |

The above method outlines a simplified approach which does not take into account

possible reinforcements of eye plate connected to the end cap. If the end cap is

reinforced and the above stress proof fails, alternative means of analysis may be

applied.

5.8.4 The eye plates of the hydraulic cylinders may be calculated using the methods of a

recognised National or International Standard.

5.8.5 The hoop, longitudinal and radial stresses in the hydraulic cylinder wall can be

calculated using the formulae below:

- Hoop stress, in MPa

where

|

σH |

= |

cylinder hoop stress, in MPa |

|

p |

= |

internal pressure, in MPa |

|

do |

= |

external cylinder diameter, in mm |

|

di |

= |

internal cylinder diameter, in mm |

|

x |

= |

actual diameter of the hydraulic cylinder wall stresses

are required to be evaluated, in mm |

|

σa |

= |

allowable stress as per Ch 9, 5.7 Allowable stresses ,

in MPa |

- Longitudinal (axial) stress, in MPa

where

|

σL |

= |

cylinder longitudinal (axial) stress, in MPa |

- Radial stress, in MPa

where

|

σR |

= |

Radial stress, in MPa |

5.8.6 Equivalent stress

The equivalent stress shall be calculated taking into account the following

stresses:

- Cylinder tube:

- Hoop stress (due to internal pressure).

- Radial stress (due to internal pressure).

- Axial stress (due to external force and/or internal pressure).

- Bending stress (due to 2nd order bending, see

Ch 9, 5.7 Allowable stresses 5.7.4).

- Piston rod:

- Hoop stress (due to external pressure in case of a hollow piston).

- Radial stress (due to external pressure in case of a hollow

piston).

- Axial stress (due to external force).

- Bending stress (due to 2nd order bending, see

Ch 9, 5.7 Allowable stresses 5.7.4).

5.8.7 Where appropriate, fatigue calculations are to be carried out in accordance with a

recognised National or International Standard using load cycles and a load spectrum

agreed between the manufacturer and the Owner.

5.8.9 Cases where the piston is in contact with the end cap or the cylinder head shall be

taken into consideration for the design of the hydraulic cylinder. This is of

particular importance for cases where the push or pull forces for the contact

situation are above those which can be generated by design internal pressures.

5.9 Testing

5.9.1 The hydraulic cylinder is to be hydraulically tested with the maximum of

the following defined test pressures pT:

- pT = 1,5 pW

- pT = 1,3 pD

where

|

pT |

= |

hydraulic test pressure, in MPa |

|

pW |

= |

maximum working pressure, in MPa |

|

pD |

= |

maximum design pressure, MPa |

5.9.2 The minimum hydraulic test pressure for life-saving appliances shall be the pressure

in the hydraulic cylinder required for the prototype test of 2,2 times the SWL

amplified by an additional safety factor of 1,06. Hydraulic test pressures for

life-saving appliances used in offshore applications are often dependant on national

administrations’ requirements and will be specially considered.

5.9.3 The hydraulic cylinders are also to be tested as part of the proof load testing of

the lifting or life-saving appliances.

5.9.4 The designer shall ensure that the hydraulic cylinder design is able to

withstand the hydraulic test pressure as defined in Ch 9, 5.9 Testing 5.9.1 and the proof load testing of the

lifting or life-saving appliance. The proof loads for lifting appliances are defined

in Ch 12, 1.5 Derricks and derrick cranes.

The proof loads for life-saving appliances are defined in Ch 3, 1.12 Testing. The actual

stresses due to the applied test pressure and due to proof load testing of the

hydraulic cylinders shall not exceed the allowable stresses stated in the relevant

chapters applicable to the appliance being considered (see

Ch 4, 2.17 Allowable stress – Elastic failure for the test

loadcase (case 4) for both lifting and life-saving appliances, Ch 6, 5.2 Load combinations for

Ro-Ro access equipment, etc.).

5.9.5 After proof load testing of the lifting or life-saving appliance, the pressure relief

valve is to be reset by the manufacturer to the appropriate operational setting to

ensure the appliance cannot be overloaded.

5.10 Handling of personnel

5.10.1 Luffing, folding and telescoping motion shall be realised by two independent

hydraulic cylinders where each cylinder is able to hold the SWL for handling of

personnel. Alternative arrangements using one hydraulic cylinder will be specially

considered.

|