Section

11 Ships for alternate carriage of oil cargo and dry bulk cargo

11.1 Application

11.1.1 The

requirements of this Section apply to ships intended to carry oil

in bulk with a flash point not exceeding 60° (closed-cup test)

or dry bulk cargo alternatively.

11.2 Class notations

11.2.1 Ships

complying with the requirement of this section will be eligible for

one of the following class notations, as applicable.

-

100A1 Oil

or Bulk Carrier, ESP

-

100A1 Oil

or Bulk Carrier strengthened for heavy cargoes, holds ... may be empty,

ESP

-

100A1 Oil

or Bulk Carrier strengthened for heavy cargoes, any hold may be empty,

ESP

-

100A1 Ore

or Oil Carrier, ESP.

11.2.3 The

above notations assume that dry cargoes and oil cargoes will not be

carried simultaneously. However, oil may be retained in slop tanks

when the ship is carrying dry cargo, provided that these tanks comply

with the requirements of the Rules. Gas freeing, inerting, and isolating

by approved arrangements of the remaining tanks and holds before loading

ore or other dry cargoes is the responsibility of the Owner and is

to be in accordance with National and Port Authority requirements.

11.3 Structural configuration and ship arrangement

11.3.1 The

requirements contained in this Section apply to the following ship

types:

-

Oil or bulk carrier

with a basic structural configuration having a single deck hull and

which includes, a double skin side structure, double bottom, hopper

side tanks and topside tanks fitted below the upper deck. A typical

cross-section is indicated in Figure 9.11.1 Structural configuration. However, consideration will be given to other arrangements

on the basis of the requirements of this Section. The requirements

of Pt 4, Ch 7 Bulk Carriers are to be applied.

-

Ore or oil carrier

with a basic structural configuration having a single deck hull and

which includes, a double skin side structure, two longitudinal bulkheads,

and a double bottom throughout the centre hold and wing tanks. A typical

cross-section is indicated in Figure 9.11.1 Structural configuration. The requirements of Pt 4, Ch 11 Ore Carriers are to be applied.

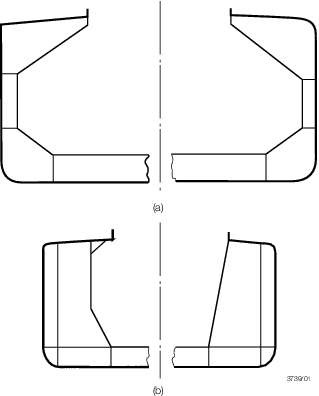

Figure 9.11.1 Structural configuration

11.3.2 Where

oil residues are to be retained on board, slop tanks of sufficient

capacity to meet MARPOL requirements are to be provided and are to

be separated from adjacent spaces by cofferdams which are to be capable

of being flooded, except where the adjacent space is used as a pump-room,

ballast tank, or a fuel oil bunker tank, see also

Pt 4, Ch 9, 1.2 Application and ship arrangement 1.2.2, Pt 5, Ch 15, 1.9 Non-sparking fans for hazardous areas and SOLAS Reg. II-2 Part D - Escape.

11.3.4 Openings

which may be used for cargo operations, for example in the bottom

of topside tanks, are not permitted in bulkheads and decks separating

oil cargo spaces from other spaces not designed and equipped for the

carriage of oil cargoes unless such openings are equipped with alternative

approved means to ensure equivalent integrity.

11.4 Bulkheads in way of dry/oil cargo holds

11.4.2 The

scantlings of vertically corrugated and double plate transverse bulkheads

supported by stools are to be determined in accordance with the requirements

of Pt 4, Ch 9, 7.4 Bulkheads supported by stools 7.4.1, Pt 4, Ch 9, 7.4 Bulkheads supported by stools 7.4.2 and Pt 4, Ch 7, 10.2 Bulkheads supported by stools. In general, the bulkheads

are to have stiffening or corrugations arranged vertically, supported

by top and bottom end stools. Alternative arrangements will, however,

be considered.

11.4.4 The

arrangement of stools and adjacent structure common with dry cargo

holds is to be designed to avoid pockets in which gas could collect.

11.4.5 Where

the form of construction used for transverse bulkheads in wing tanks

is different from that used in centre holds, arrangements are to be

made to ensure continuity of transverse strength through the longitudinal

bulkhead.

11.4.6 Where

partial filling of centre holds with liquid is contemplated, the scantlings

and structural arrangements of the boundary bulkheads are to be capable

of withstanding the loads imposed by the movement of liquid in the

holds. The magnitude of the predicted loadings, together with the

scantling calculations, may require to be submitted.

11.5 Bulkheads in wing tanks of ore or oil carriers

11.6 Cofferdam bulkheads

11.7 Hatchways

11.7.3 Slop

tank hatches and cleaning openings are only permitted on open deck.

Unless these openings are closed with a watertight bolted plate, the

locking arrangements are to be under the control of a responsible

officer.

11.8 Hatch coamings

|