Section

5 Hull framing

5.1 General

5.1.1 In the

cargo tank region, the scantlings of deck, bottom and side longitudinals,

and of transverse side framing, where fitted, are to be in accordance

with the requirements of this Section.

5.2 Symbols

5.2.1 The

symbols used in this Section are defined as follows:

|

c

1

|

= |

at deck at deck

|

|

|

= |

1,0 at

|

|

|

= |

at base line of ship at base line of ship

intermediate values

of c

1 by interpolation

|

|

c

2

|

= |

at deck at deck

|

|

|

= |

1,0 at

|

|

|

= |

at base line of ship at base line of ship

intermediate values

of c

2 by interpolation

|

|

d

w

|

= |

depth of web, in mm |

|

h

|

= |

distance

of longitudinal below deck at side, in metres. For deck longitudinals, h = 0

|

|

h

o

|

= |

the distance, in metres, from the mid-point of span of the stiffener

to the highest point of tank, excluding hatchway |

|

h

1

|

= |

, but in no case to be taken less than , but in no case to be taken less than  m or (0,01L

1 + 0,7) m, whichever

is the greater, and need not be taken greater than m or (0,01L

1 + 0,7) m, whichever

is the greater, and need not be taken greater than  for bottom longitudinals for bottom longitudinals

|

|

h

2

|

= |

distance, in metres, from mid-point of span of transverse side

frame to deck at side measured at mid-length of tank, but to be taken

not less than 2,5 m |

|

h

3

|

= |

h

0 + Rb

1, but

need not be taken greater than (0,75D + Rb

1) for bottom longitudinals

|

|

l

e

|

= |

effective length, in metres, of longitudinals measured between

span points, but to be taken not less than 1,5 m in double bottom

and 2,5 m elsewhere. For determination of span points, see

Pt 3, Ch 3, 3 Structural idealisation.

|

|

t

f

|

= |

thickness of flange, in mm |

|

t

s

|

= |

thickness of the bilge shell plating, in mm |

|

t

w

|

= |

thickness of web, in mm |

|

D1

|

= |

D, in metres, but is to be taken not less than 10 and need not

be taken greater than 16

|

|

|

= |

where θ is

the roll angle, in degrees |

|

|

= |

and

|

Other symbols are defined in Pt 4, Ch 9, 1.5 General definitions and symbols

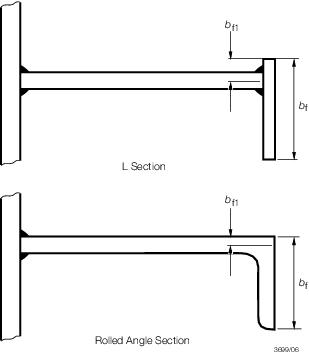

Figure 9.5.1 Definition of b

f and b

f1

5.3 Deck, side and bottom longitudinals

5.3.1 The

modulus of longitudinals within the cargo tank region, except as provided

for in Pt 4, Ch 9, 5.3 Deck, side and bottom longitudinals 5.3.2 and Pt 4, Ch 9, 5.5 Deck longitudinals outside 0,4L amidships is to be not less than the greater

of the following:

-

Z = 0,056s

kh

1

l

e

2

F

1

F

s cm3, or

-

Z = 0,0051s

kh

3

l

e

2

F

2 cm3

where F

1 and F

2 values

are as given in Table 9.5.1 Values of F1 and Table 9.5.2 Values of F2 and F

s is

a fatigue factor to be taken as follows:

|

F

s

|

= |

at 0,6D above the base line at 0,6D above the base line

|

|

|

= |

1,0 at upper deck

at side and at the base line, intermediate values by linear interpolation |

For flat bars and bulb plates  may be taken as 0,5 may be taken as 0,5

The modulus of side longitudinals

need not exceed that of a bottom longitudinal having the same spacing

and configuration.

Table 9.5.1 Values of F

1

| Item

|

F

1

|

Deck longitudinals and side longitudinals

above

|

|

Side longitudinal and bottom

longitudinals

below

|

|

NOTE

Minimum F

1 = 0,12

|

Table 9.5.2 Values of F

2

| Item

|

F

2

|

Deck longitudinals and side

longitudinals

above

|

|

Side longitudinal and bottom

longitudinals

below

|

|

NOTE

Minimum F

2 = 0,73

|

5.3.4 Where

the spacing of transverses exceeds 5,5 m, the scantlings of side and

bottom longitudinals in way of bulkheads and primary members, including

end connections, are to be verified by direct calculation.

5.3.5 The

side and bottom longitudinal scantlings derived from Pt 4, Ch 9, 5.3 Deck, side and bottom longitudinals 5.3.1 and Pt 4, Ch 9, 5.3 Deck, side and bottom longitudinals 5.3.2, using the midship thickness

of plating, are to extend throughout the cargo tanks. Where the shell

plating is inclined at an angle to the horizontal longitudinal axis

of greater than 10°, the span of the longitudinals is to be measured

along the member. Where the shell plating is inclined at an angle

to the vertical axis of greater than 10°, the spacing of longitudinals

is to be measured along the chord between members. Where the angle

of attachment of side longitudinals clear of amidships varies by 20°

or more from a line normal to the plane of the shell, the properties

of the section are to be determined about an axis parallel to the

attached plating. Angles of slope greater than 40° are to be avoided.

5.3.6 Fabricated

longitudinals having the face plate welded to the underside of the

web, leaving the edge of the web exposed, are not recommended for

shell, inner hull or longitudinal bulkhead longitudinals. Where it

is proposed to fit such sections, a symmetrical arrangement of connection

to transverse members is to be incorporated. This can be achieved

by fitting backing brackets on the opposite side of the transverse

web or bulkhead. The primary member web stiffener and backing bracket

are to be lapped to the longitudinal. Recommended examples of such

backing structure can be seen in the ShipRight FDA Procedure,

Structural Detail Design Guide (SDDG).

5.3.7 Where

partial filling of the tanks is also contemplated the deck longitudinals

are to comply with the requirements of Pt 4, Ch 9, 6.1 General 6.1.2.

5.3.8 Stiffeners

and brackets on vertical webs in wing ballast tanks, where fitted

on one side and connected to higher tensile steel longitudinals between

the base line and 0,8D above the base line, are to have

their heels well radiused to reduce stress concentrations. Where a

symmetrical arrangement is fitted, i.e. bracket or stiffening on both

sides, and they are connected to higher tensile steel longitudinals,

the toes of the stiffeners or brackets are to be well radiused. Alternative

arrangements will be considered if supported by appropriate fatigue

life assessment calculations.

5.3.9 Where

higher tensile steel side longitudinals pass through transverse bulkheads

in the cargo area, well radiused brackets of the same material are

to be fitted on both the fore and after side of the connection between

the upper turn of bilge and 0,8D above the base line.

Particular attention should be given to ensuring the alignment of

these brackets. Alternative arrangements will be considered if supported

by appropriate fatigue life assessment calculations.

Table 9.5.3 Determination of b

1

| Item

No.

|

Structural arrangement

|

Location

|

Value

of b

1, metres

|

| 1

|

|

(a) Bottom longitudinals

|

The greater horizontal distance from ship side to

the longitudinal

|

|

|

Where wing and double bottom ballast

tanks port and starboard are interconnected

|

(b) Side longitudinals

|

Breadth of ship

|

|

|

|

(c) Deck longitudinals

|

(i) In way of cargo tanks and inboard

ballast tanks, the greater horizontal distance from tank corner at top of

tank to longitudinal, either side

|

|

|

|

|

(ii) In way of wing ballast tanks, the

greater horizontal distance from ship side to longitudinal, either

side

|

| 2

|

Where wing ballast tanks port and

starboard are separate

|

(a) Bottom

longitudinals

|

The

horizontal distance from ship side to longitudinal

|

| (b) Side longitudinals

|

Width of wing ballast tank

|

5.4 Bilge longitudinals and brackets

5.4.1 The

scantlings of bilge longitudinals are to be graduated between those

required for the bottom and lowest side longitudinals.

5.4.2 Where

bilge longitudinals are omitted, the spacing of transverses or equivalent

bilge brackets must not exceed:

Where no intermediate brackets are fitted between

transverses, the spacing between the two outermost bottom longitudinals

and between the two lowest side longitudinals is not to exceed one-third

of the bilge radius or 40 times the local shell thickness, whichever

is the greater.

5.5 Deck longitudinals outside 0,4L amidships

5.5.1 Within

the cargo tank region, deck longitudinals may be gradually tapered

outside 0,4L amidships in association with the deck plating,

on the basis of area and modulus. For the requirements, see

Pt 3, Ch 3, 2.5 Taper requirements for hull envelope and Table 3.2.1 Taper requirements for hull

envelope, see also

Pt 4, Ch 9, 5.3 Deck, side and bottom longitudinals 5.3.5.

5.5.2 The

midship spacing of longitudinals is, in general, to be maintained

throughout the cargo tank region. The plating thickness and longitudinal

depth and thickness are not to be increased at any point in the direction

of the taper of area towards the ends of the ship, other than as may

be required for compensation for openings. Changes of longitudinal

section are, in general, to be avoided.

5.5.4 Where

the spacing of transverses in cargo tanks is not constant and variations

in longitudinal scantlings are contemplated to suit differing spans,

individual consideration will be given to the taper arrangements.

5.6 Stability of longitudinals

5.6.1 The

lateral and torsional stability of longitudinals together with web

and flange buckling criteria are to be verified in accordance with Pt 3, Ch 4, 7 Hull buckling strength.

5.6.2 In addition,

the following requirements are to be satisfied:

-

Flat bar longitudinal

-

when continuous

at bulkheads

-

when non-continuous

at bulkheads

-

Built sections

-

-

15 for asymmetric sections 15 for asymmetric sections

-

30 for symmetric sections. 30 for symmetric sections.

5.7 Connections of longitudinals

5.7.1 Connections

of longitudinals to bulkheads are to provide adequate fixity and continuity

of longitudinal strength. See also the ShipRight

FDA Procedure, Structural Detail Design Guide (SDDG), for recommended

design details in critical areas.

5.7.2 Where

the length of the ship exceeds 150 m, the longitudinals within 0,1D of the bottom and deck are to be continuous through the transverse

bulkheads. Higher tensile steel longitudinals are to be continuous

irrespective of ship length. Alternative arrangements will be individually

considered.

5.8 Openings in longitudinals

5.8.1 In general,

closely spaced scallops are not permitted in longitudinals within

the range of cargo tanks except in way of ballast pipe suctions, reinforcement

in these areas will be specially considered.

5.8.2 Small

air and drain holes, cut-outs at erection butts and similar widely

spaced openings are, in general, to be not less than 200 mm clear

of the toes of end brackets, intersections with primary supporting

members and other areas of high stress. All openings are to be well

rounded with smooth edges.

5.8.3 Drain

holes in higher tensile steel longitudinals attached to higher tensile

steel plating are to be elliptical in shape or of equivalent design

to minimise stress concentrations. The opening is generally to be

located clear of the welded connection to the plating, but where a

flush opening is essential for drainage the weld connection is to

end in a soft toe.

5.8.4 Small

circular air holes may be arranged in higher tensile steel deck longitudinals.

5.8.5 Isolated

openings spaced greater than 1 metre apart need not be taken into

account in calculating the section modulus of the longitudinal, provided

that the depth does not exceed 10 per cent of the web depth, or 75

mm, whichever is the greater, but in no case more than 25 per cent

of the depth of the longitudinal.

5.9 Transverse side frames

5.9.2 The section modulus of transverse side frames is to be not less than:

Z = 0,01025ksh

2

l

e

2 cm3, where side webs are fitted;

or

Z = 0,012ksh

2

l

e

2 cm3, where side webs are not fitted.

5.9.5 The inertia of transverse side frames is to be not less than:

In the forward 0,15L:  = 3,5le

Z cm4 = 3,5le

Z cm4

Elsewhere:  = 3,2le

Z cm4. = 3,2le

Z cm4.

|